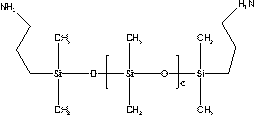

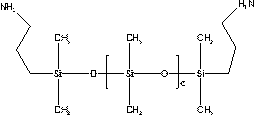

Synthesis of end amino silicone oil modified stryenemaleic anhydride copolymer

A styrene maleic acid and amino-terminated technology, applied in the field of polymer materials, can solve the problems of limited application range, high hardness, poor toughness and processing performance, and achieve the effect of broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

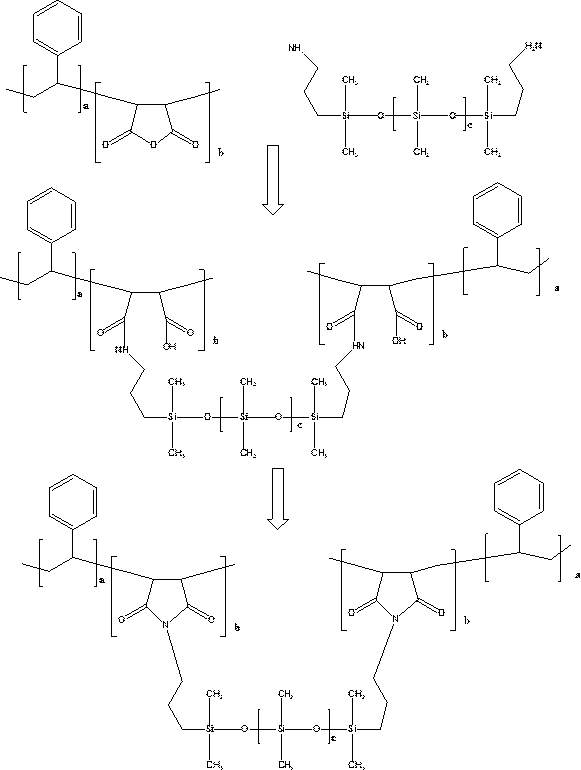

Method used

Image

Examples

Embodiment 1

[0020] In a four-necked flask equipped with a thermometer, stirrer, water separator and reflux device, add 100 parts of SMA (the molar ratio of styrene and maleic anhydride in the copolymer is 5:1), 100 parts of toluene, and open nitrogen. Stir and raise the temperature to 60°C. When the materials are completely dissolved, add 1.1 parts of 10%wt acetic acid aqueous solution, keep for 0.5h, and use a constant flow pump to add 20 parts of 50% amino-terminated silicone oil toluene solution (amino-terminated silicone oil c=30). Set the dripping time for 0.5h. After the dripping is completed, heat up to 80°C, keep it for 3h, continue to heat up to 120°C, reflux for 5h, cut off the low boiling point in the system with a water trap, and dry after the reaction is complete. Get the target product.

Embodiment 2

[0022] In a four-necked flask equipped with a thermometer, agitator, water separator and reflux device, add 100 parts of SMA (the molar ratio of styrene and maleic anhydride in the copolymer is 3:1) and 100 parts of toluene. Stir and heat up to 60℃. When the materials are completely dissolved, add 1.1 parts of 10%wt acetic acid aqueous solution, keep for 0.5h, and use constant flow pump to add 20 parts of 50%wt amino-terminated silicone oil toluene solution (amino-terminated silicone oil c=30) , Set the dripping time to 0.5h. After the dripping is completed, heat up to 80°C, keep it for 3h, continue to heat up to 120°C, reflux for 5h, cut off the low boiling point in the system with a water trap, and dry after the reaction is complete. The target product is obtained.

Embodiment 3

[0024] In a four-necked flask equipped with a thermometer, agitator, water separator and reflux device, add 100 parts of SMA (the molar ratio of styrene and maleic anhydride in the copolymer is 3:1) and 100 parts of toluene. Stir and raise the temperature to 60℃. When the materials are completely dissolved, add 1.1 parts of 10%wt acetic acid aqueous solution, keep for 0.5h, and use constant flow pump to add 30 parts of 50% amino-terminated silicone oil in toluene solution (amino-terminated silicone oil c=30) , Set the dripping time 0.5h. After the dripping is completed, the temperature is raised to 80°C, kept for 3 hours, and the temperature is continued to 120°C, refluxed for 5 hours, the low boiling point in the system is cut off with a water separator, and after the reaction is completed, it is dried to obtain the target product.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap