Cross-linking low-smoke halogen-free and flame-retardant POE and preparation method thereof

An elastomer and flame retardant technology, which is applied in the field of cross-linked low-smoke halogen-free flame-retardant POE elastomer and its preparation, can solve the problems of long production process and large energy waste of cross-linked flame-retardant POE elastomer, and achieves The effect of shortening the crosslinking time, saving energy and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

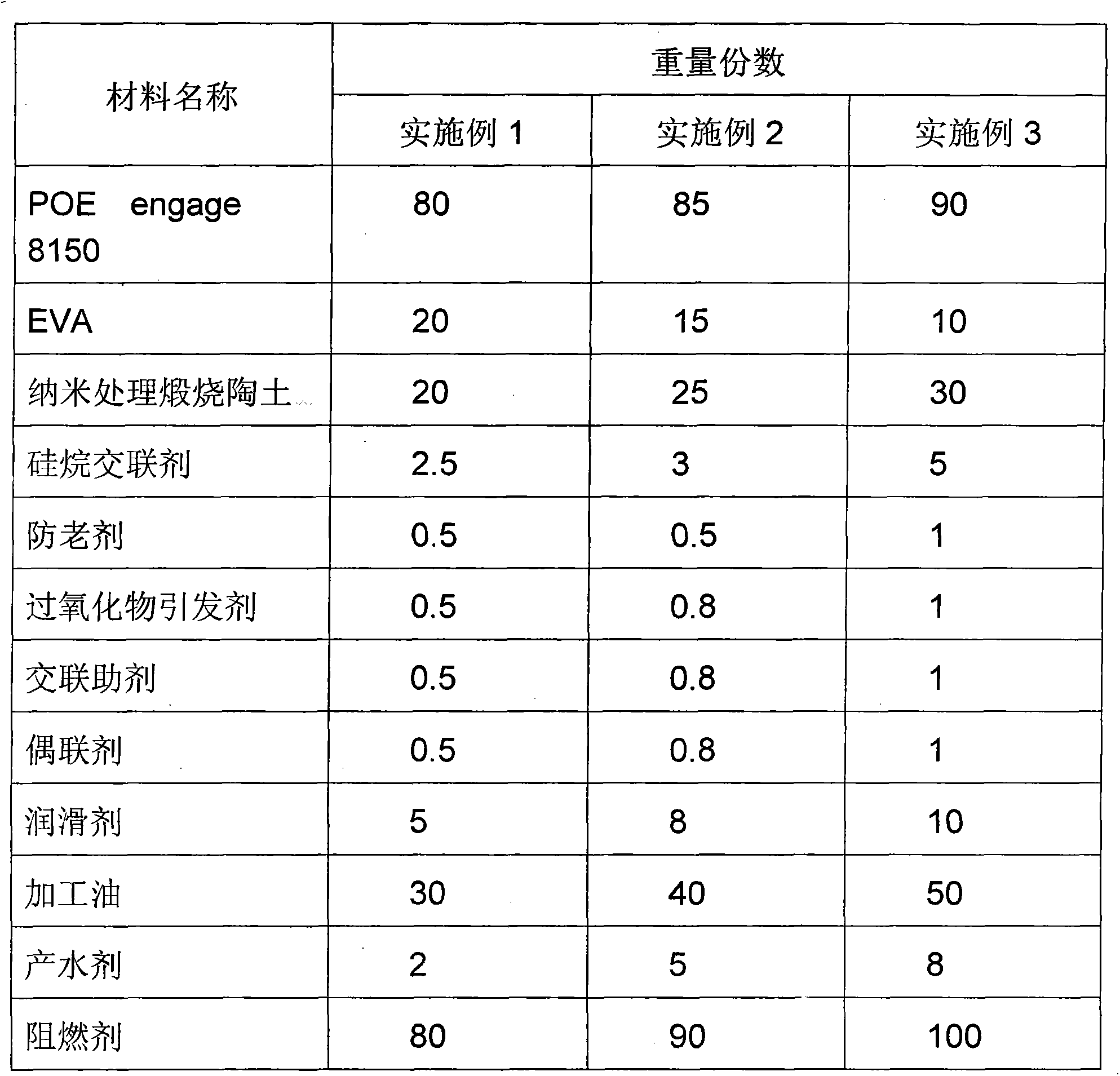

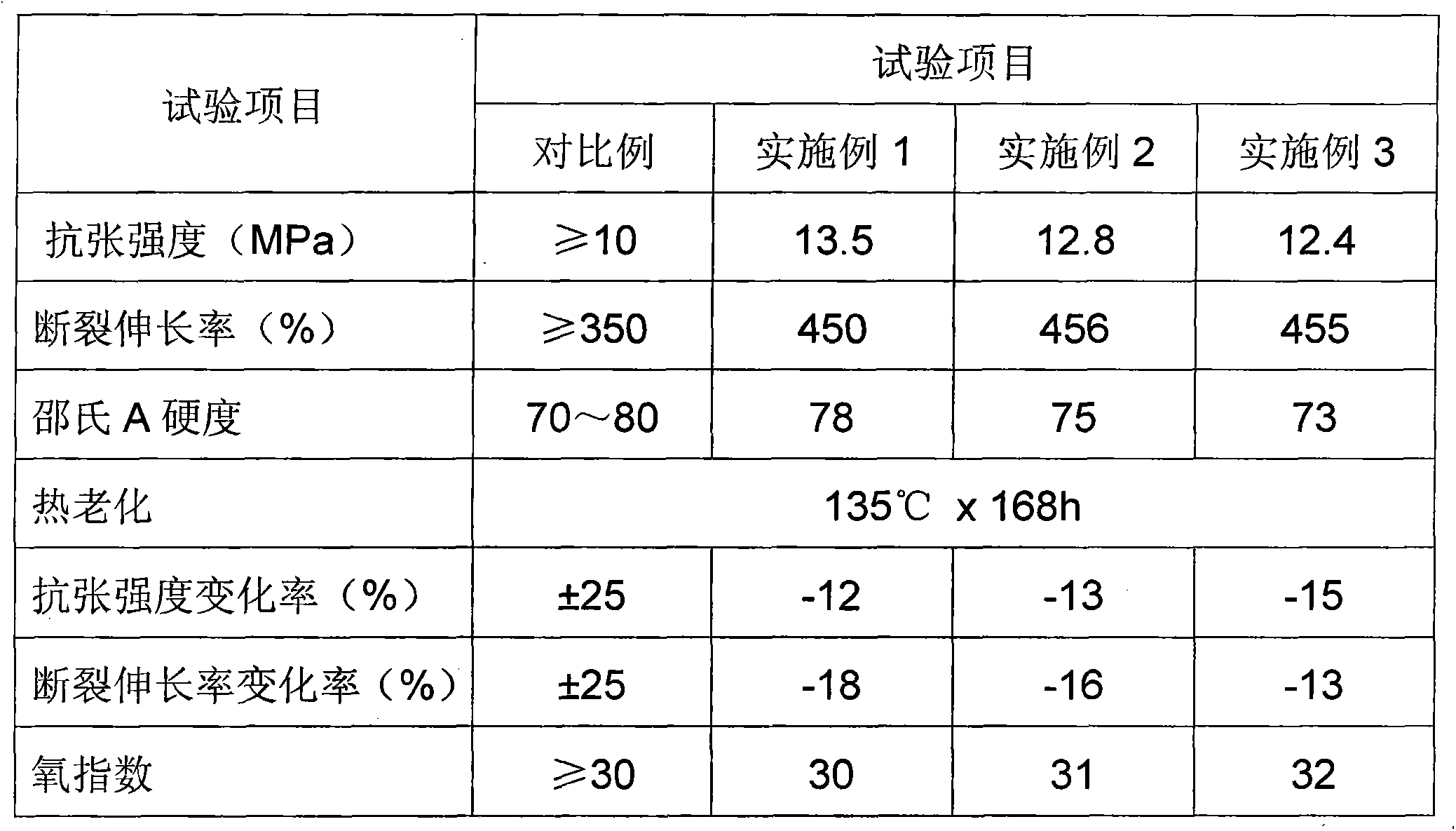

[0020] Specific examples of the present invention 1-3 cross-linked flame retardant POE elastomer components are as follows:

[0021]

[0022] The one-step preparation method of the present invention is as follows:

[0023] After mixing the silane crosslinking agent, peroxide initiator and crosslinking aid, put them into the high-speed kneader at one time with POE and EVA, 120°C for 20 minutes, and banbury at 95-100°C for 5 minutes Add nano-treated calcined clay, then add lubricant and processing oil, etc., continue banburying for 3 minutes, then add coupling agent, and banbury for 2 minutes before unloading. Thin pass the rubber material after banburying on the mill for three times at 18 o'clock, then make five triangular bags, pass it five times, then roll the strips or cool and granulate; or pass the rubber material after banburying through a single Extrusion and granulation by screw extruder or double-stage extruder, the temperature of each zone is: feed zone 120°C, 125°C,

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap