Packaging bag and application thereof

A packaging bag and body technology, applied in the field of plastic packaging, can solve the problems of raw material storage and transportation that cannot meet the requirements of ventilation, foreign substances entering the bag, and content pollution, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solutions of the present invention will be further described below through specific examples.

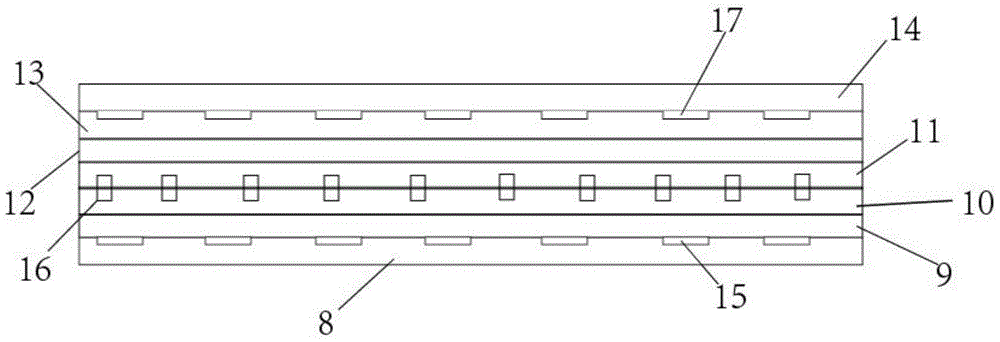

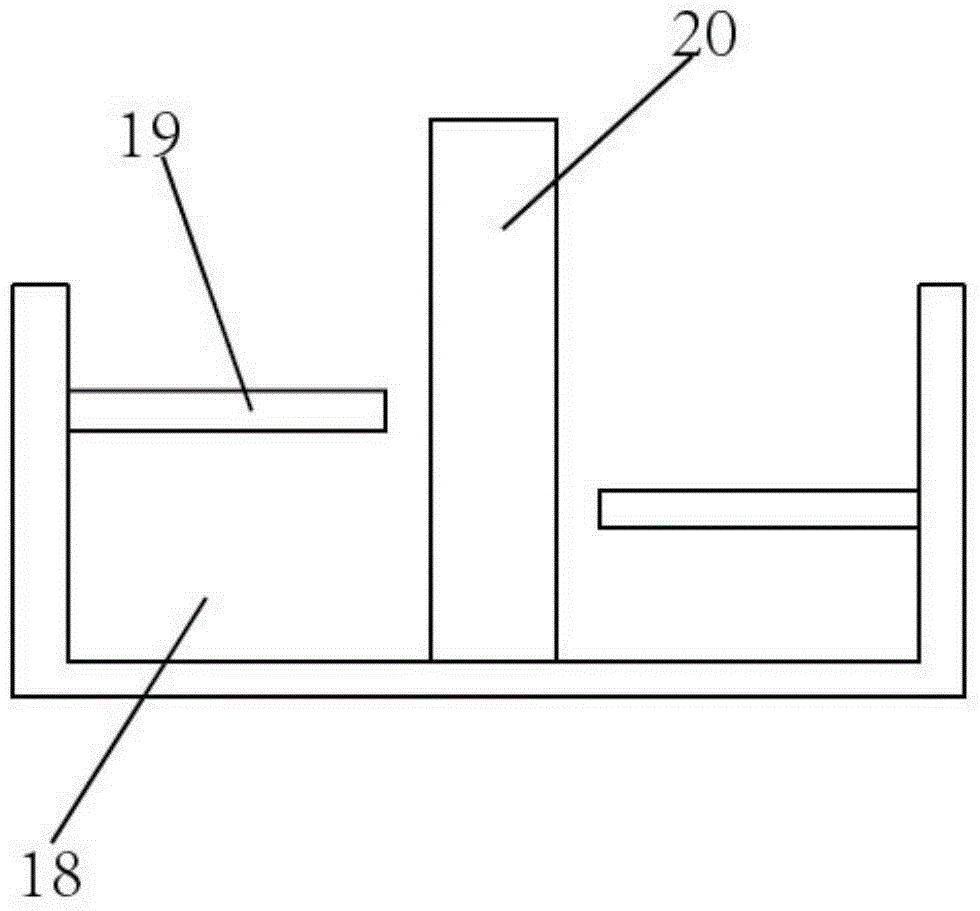

[0019] like Figure 1 to Figure 4 As shown, among them, 1 is the opening of the packaging bag, 2 is the body of the packaging bag, 3 is the tear line slider, 4 is the tear line, 5 is the inner folding line, 6 is the sealing adhesive strip, 7 is the outer layer, 8 10 is the first polyethylene layer, 11 is polyamide, 12 is the elastic layer, 13 is the antibacterial layer, 14 is the second polyethylene layer, 15 is the waterproof reinforcement groove, 16 is the reinforcement Components, 17 is an antibacterial reinforcement groove, 18 is a groove, 19 is a transverse reinforcement, 20 is a longitudinal reinforcement, 21 is a longitudinal component, 22 is a first transverse component, and 23 is a second transverse component.

[0020] The packaging bag includes a plastic film layer, an outer layer, a tearing wire puller, a packaging bag opening and a packaging bag body.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap