Resistance detection device for wire winding machine

A technology of resistance detection and wire winding machine, which is applied in measurement devices, measurement of resistance/reactance/impedance, measurement of electrical variables, etc., can solve the problems of troublesome detection and low production efficiency, and achieve the effect of convenient detection and high detection efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

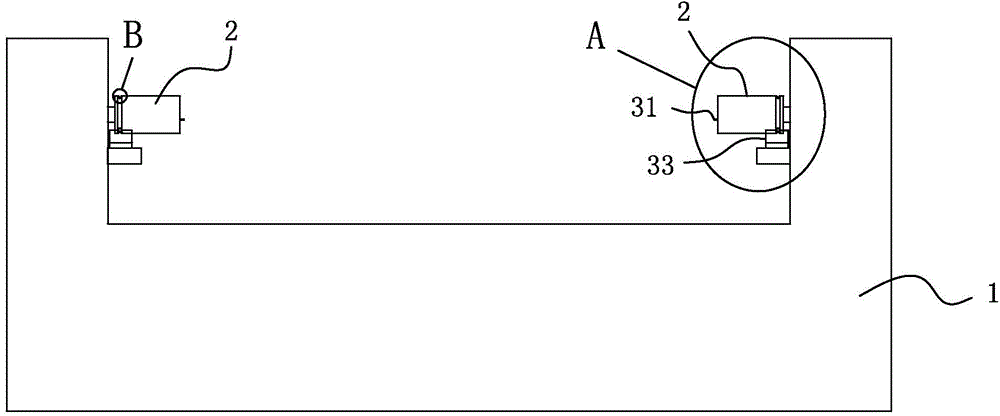

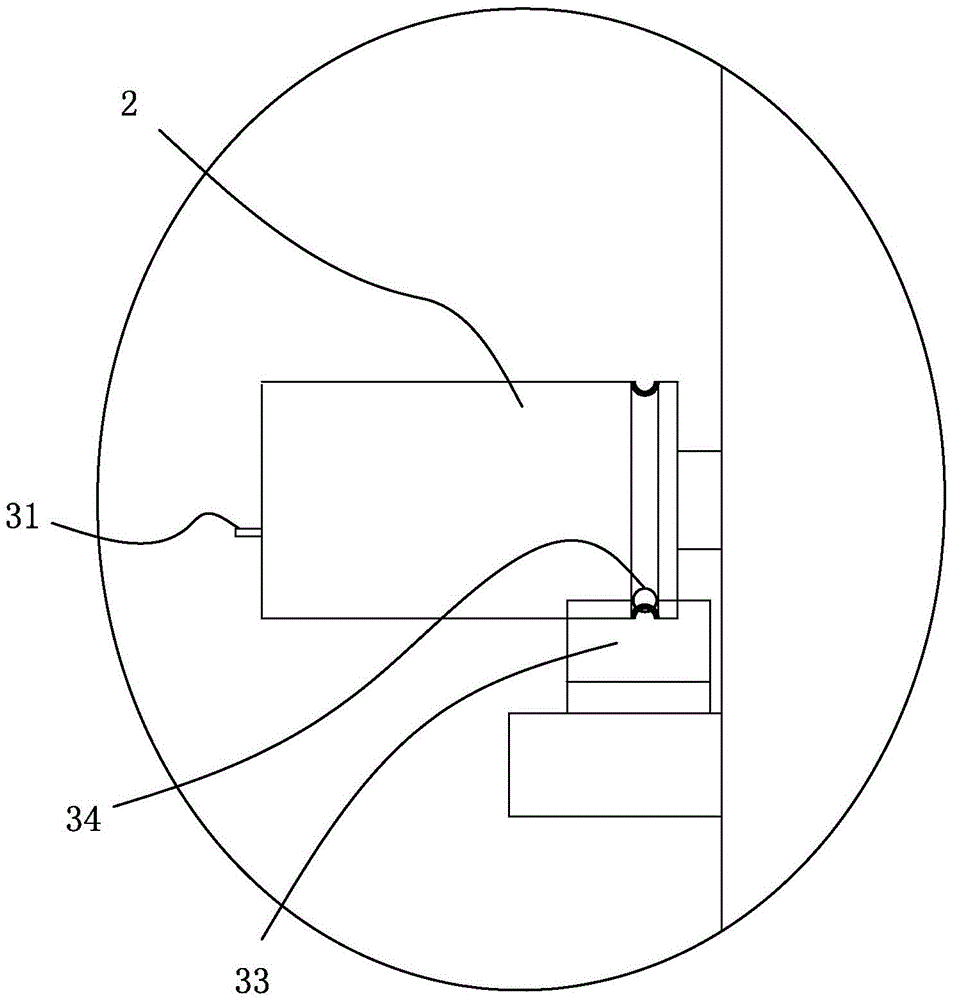

[0018] refer to Figure 1 to Figure 5 , the resistance detection device of a kind of wire winding machine of the present invention, comprises the rotatable rotating collet 2 that is used for clamping the wire wrapping board that is located at both ends of frame 1, and described rotary collet 2 is provided with and rotary collet 2 Insulate and extend the conductive tongue 31 of the rotary chuck 2, and the circular groove 21 surrounding the rotation center of the rotary chuck 2, the circular groove 21 is surrounded by a conductor 32 insulated from the rotary chuck 2, the conductor 32 Electrically connected with the conductive tongue 31, the two ends of the frame 1 are respectively provided with an insulating frame 33 below the rotary chuck 2, and the insulating frame 33 is provided with all conductors 32 on the same side of the frame to form an electrical connection. Outlet 34. In this structure, since the conductor 32 surrounds the annular groove 21 , the contact between the cond

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap