Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

49results about "Lifting devices" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

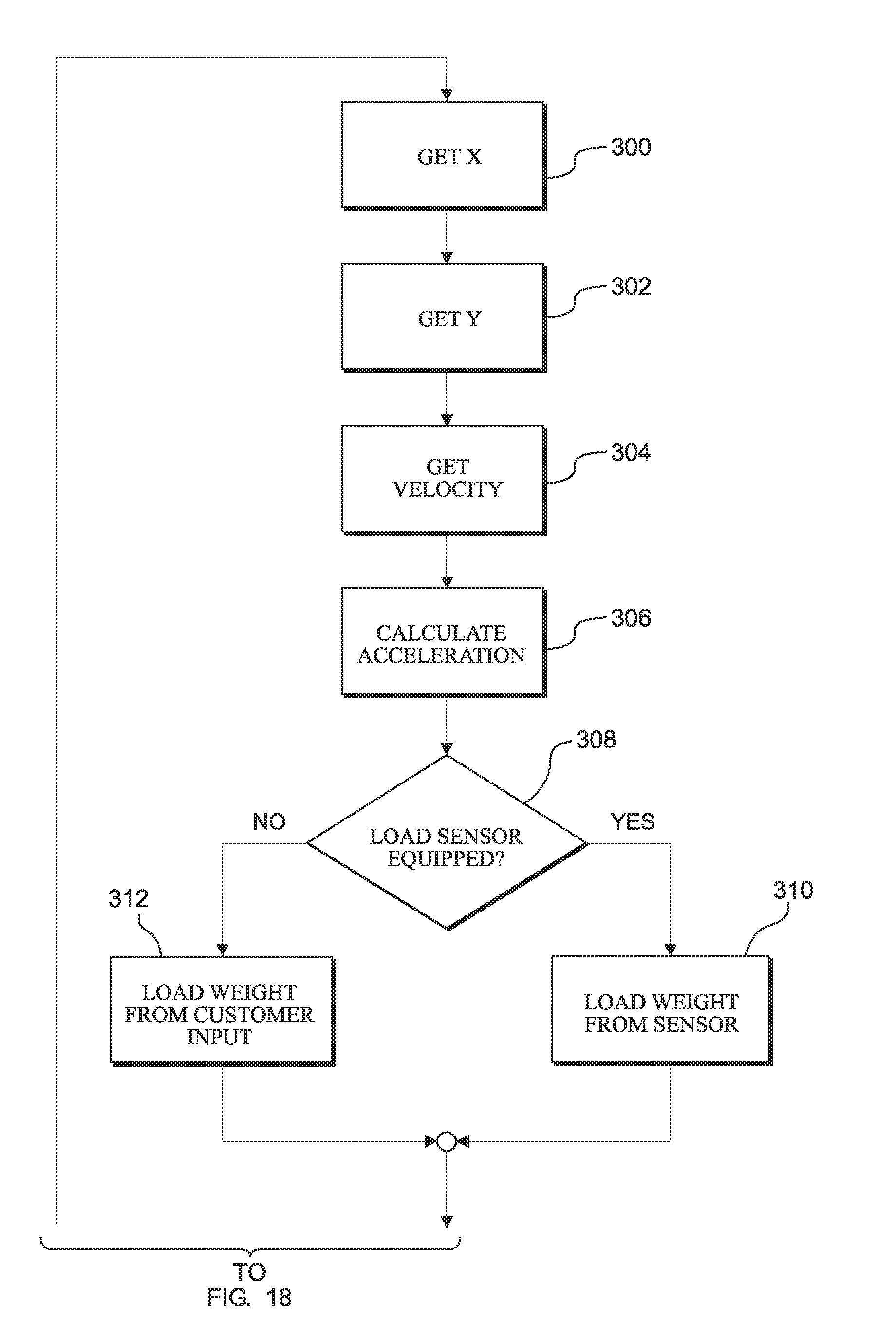

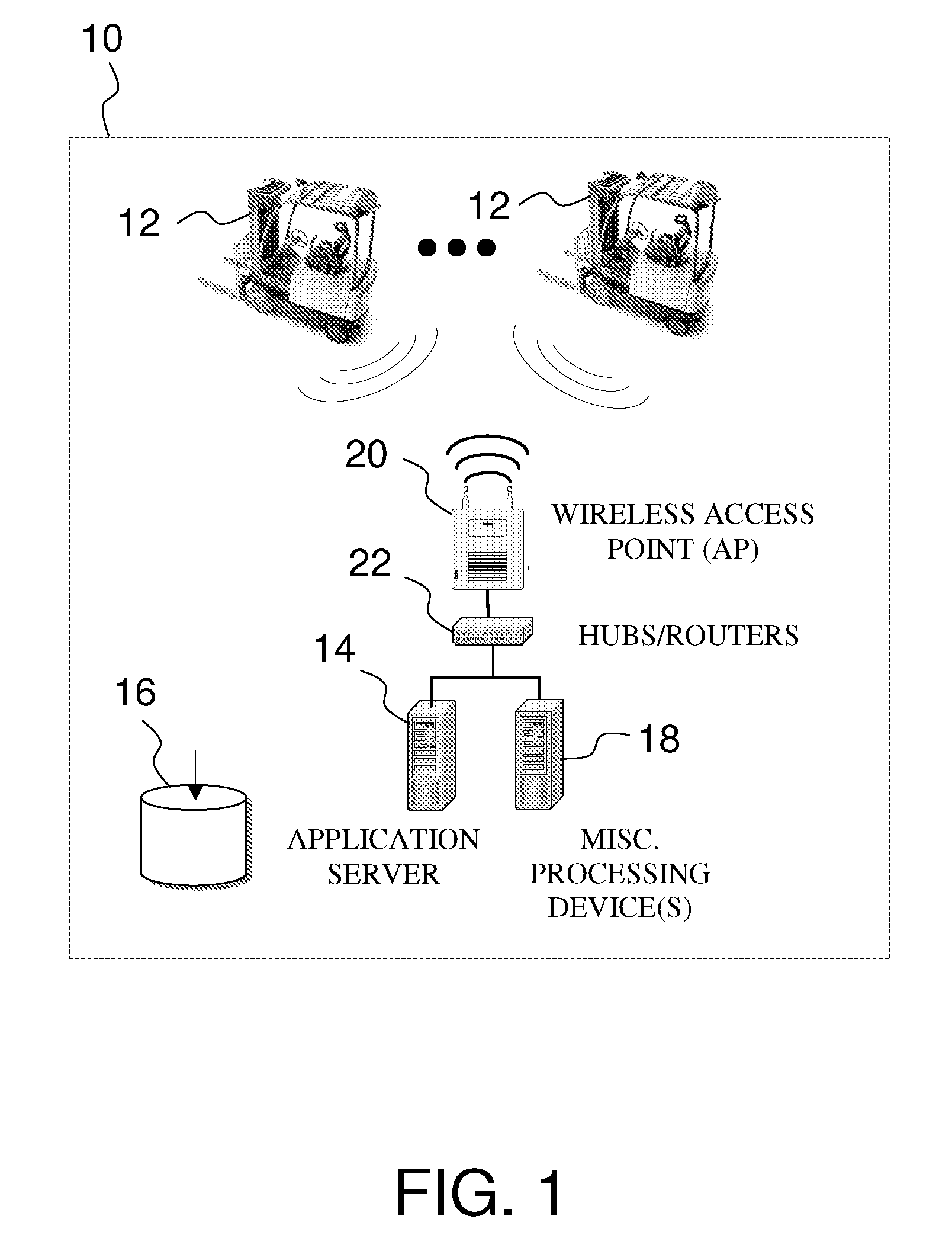

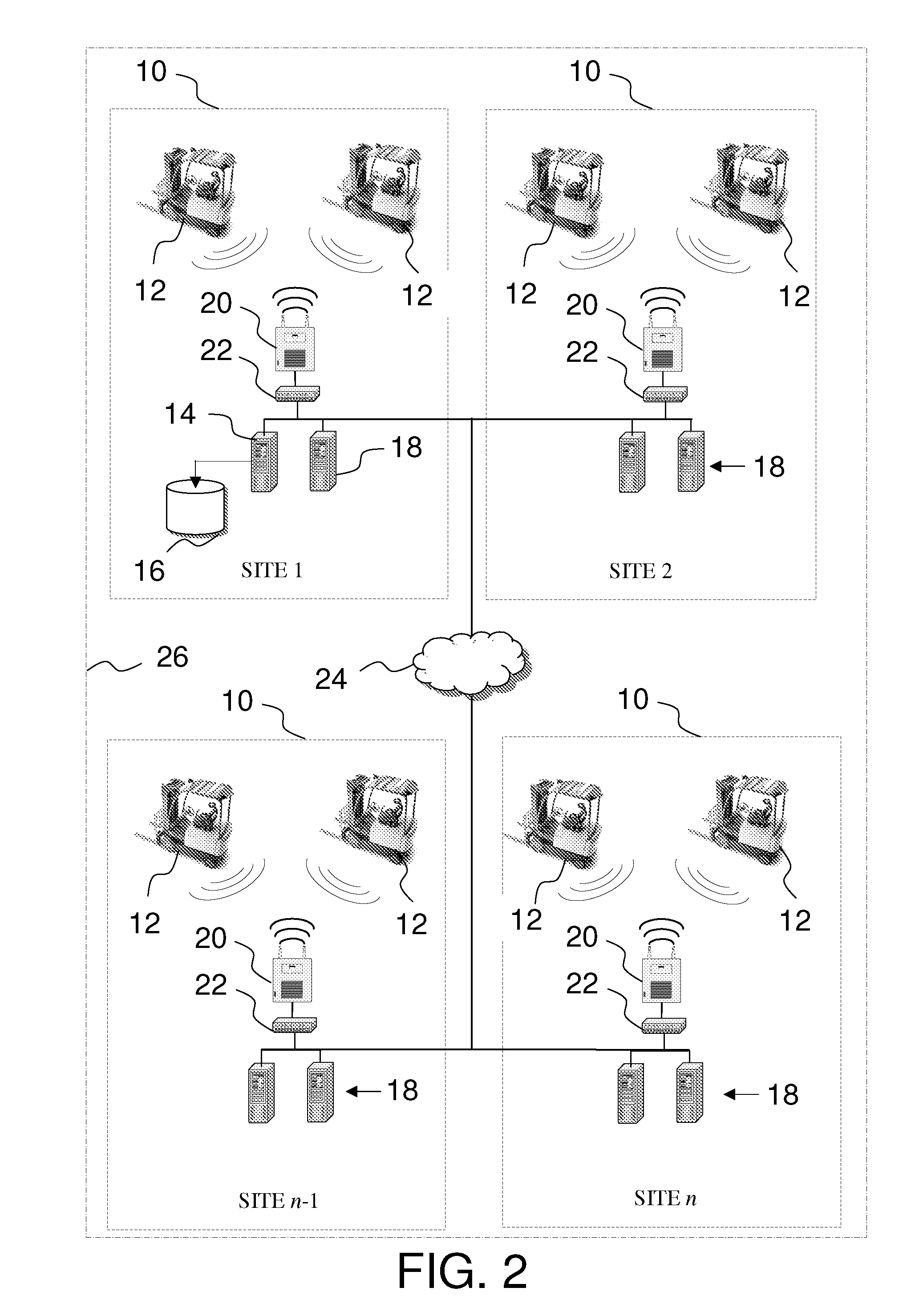

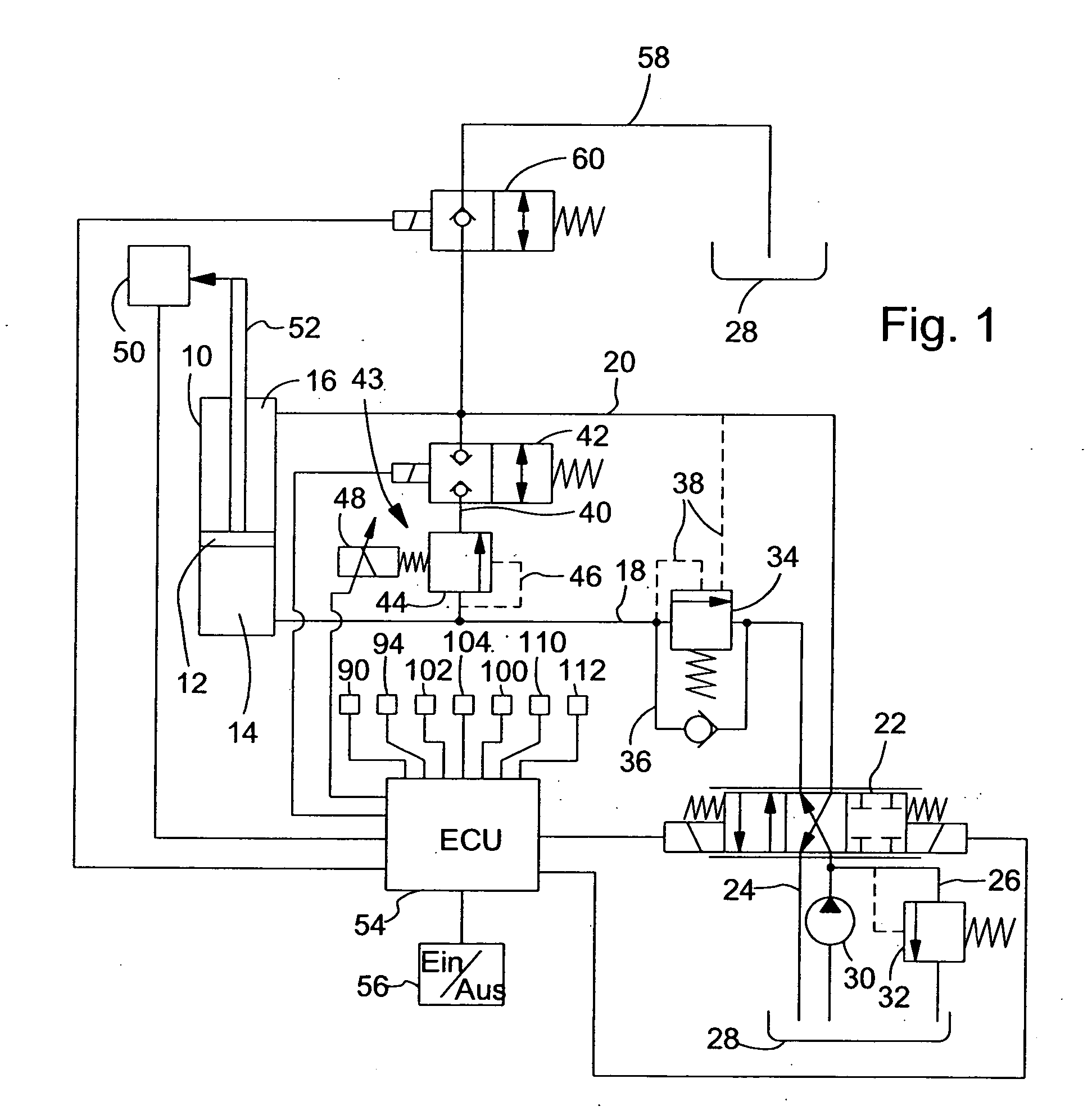

Impact sensing usable with fleet management system

ActiveUS20100039247A1Registering/indicating working of vehiclesPedestrian/occupant safety arrangementFleet managementMomentum

Owner:CROWN EQUIP CORP

Ratchet Platform

A height adjustable platform and method include a ratchet platform. In an embodiment, the ratchet platform is height adjustable and includes a platform upper assembly having a platform and a ratchet. The ratchet includes a platform riser tube and a ratchet rail secured to the platform riser tube. The ratchet platform further includes a platform lower assembly having a support column and a platform base. The support column is secured to the platform base. An end of the ratchet is proximate the platform and an opposing end of the ratchet is disposed within an interior of the support column. The platform base is adapted to be secured within a vehicle. The ratchet platform also includes a platform upper assembly actuator having a pedal sub assembly and an upper linkage. The upper linkage is attached to the pedal sub assembly. Actuation of the pedal sub assembly actuates the upper linkage. In addition, actuation of the upper linkage actuates the ratchet to adjust the height of the ratchet platform.

Owner:BLACK MOUNTAIN INDS

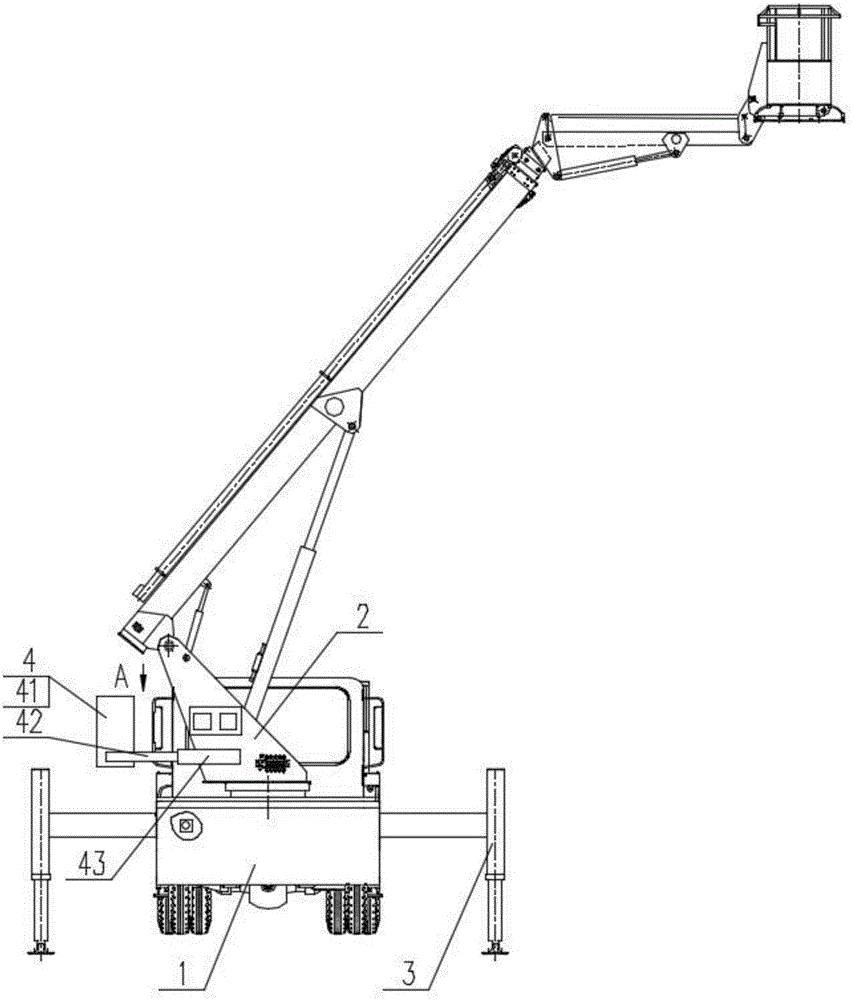

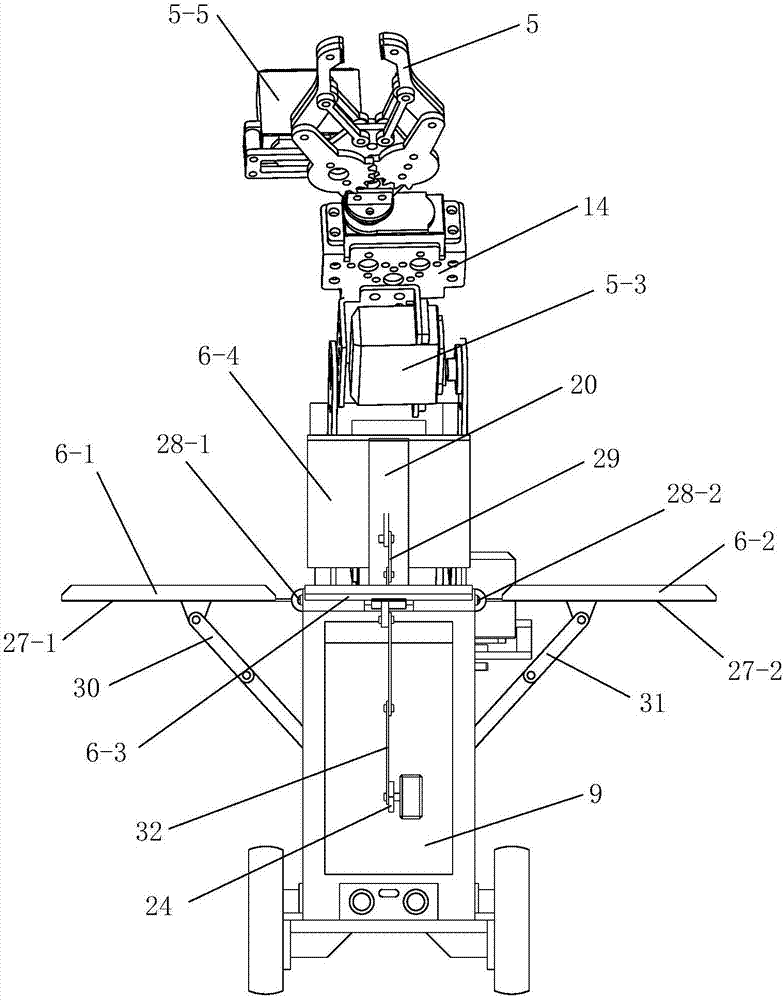

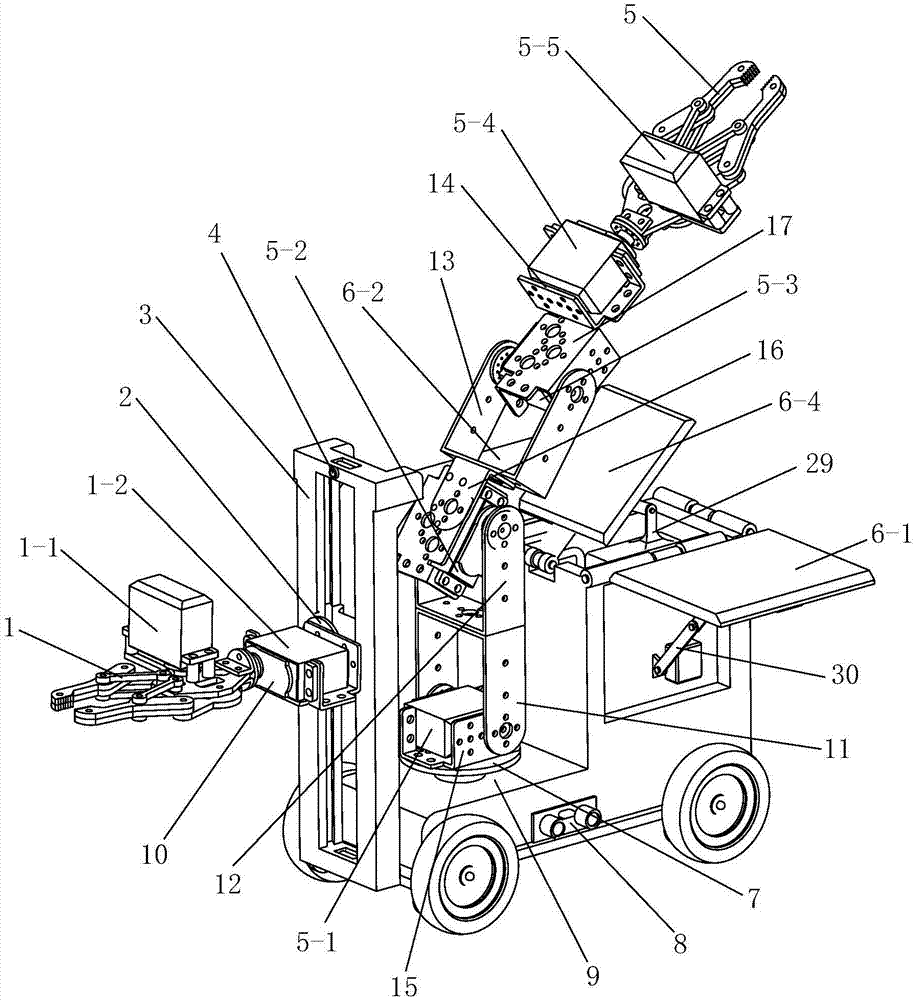

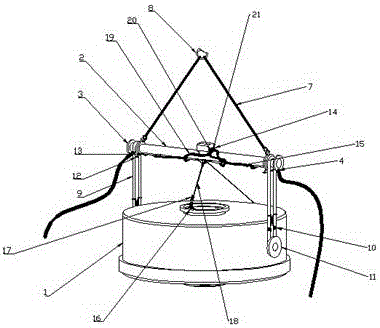

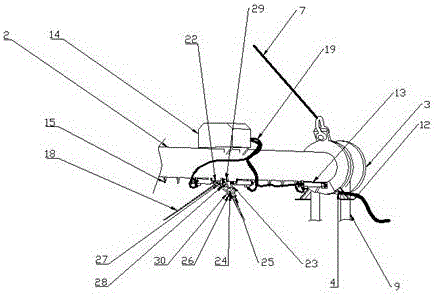

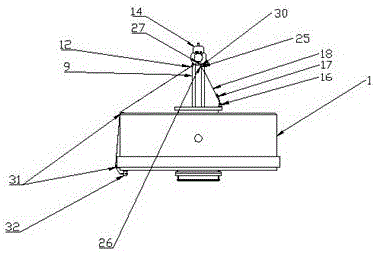

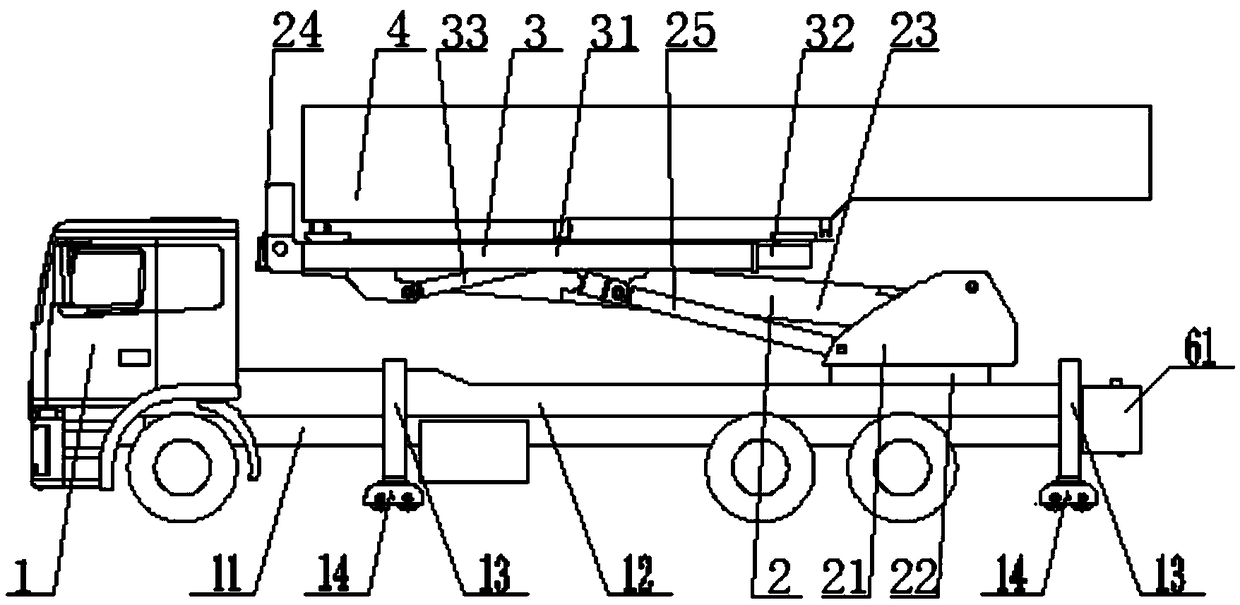

Aerial work vehicle with self-stabilizing system and self-stabilizing control method thereof

Owner:XUZHOU HANDLER SPECIAL VEHICLE

Vehicle body lifter

ActiveCN105417451AEffectively control the ascentEffective altitude controlLifting devicesEngineeringAutomotive engineering

Owner:HUAQIANG FANGTE WUHU CULTURE TECH CO LTD

Aerial work platform vehicle

InactiveCN107601383AAccurately reflectImprove securityLifting devicesSpecial purpose weighing apparatusAerial work platformIndustrial engineering

Owner:XCMG CONSTR MACHINERY

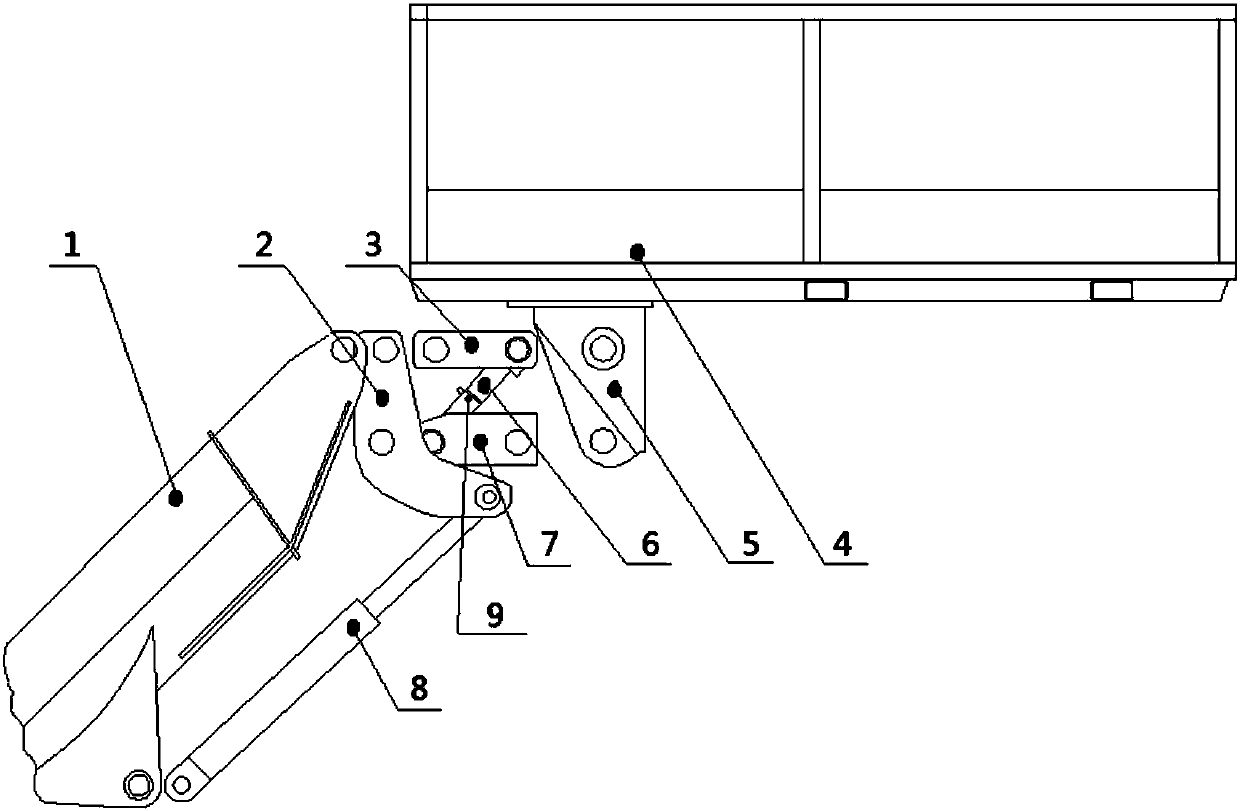

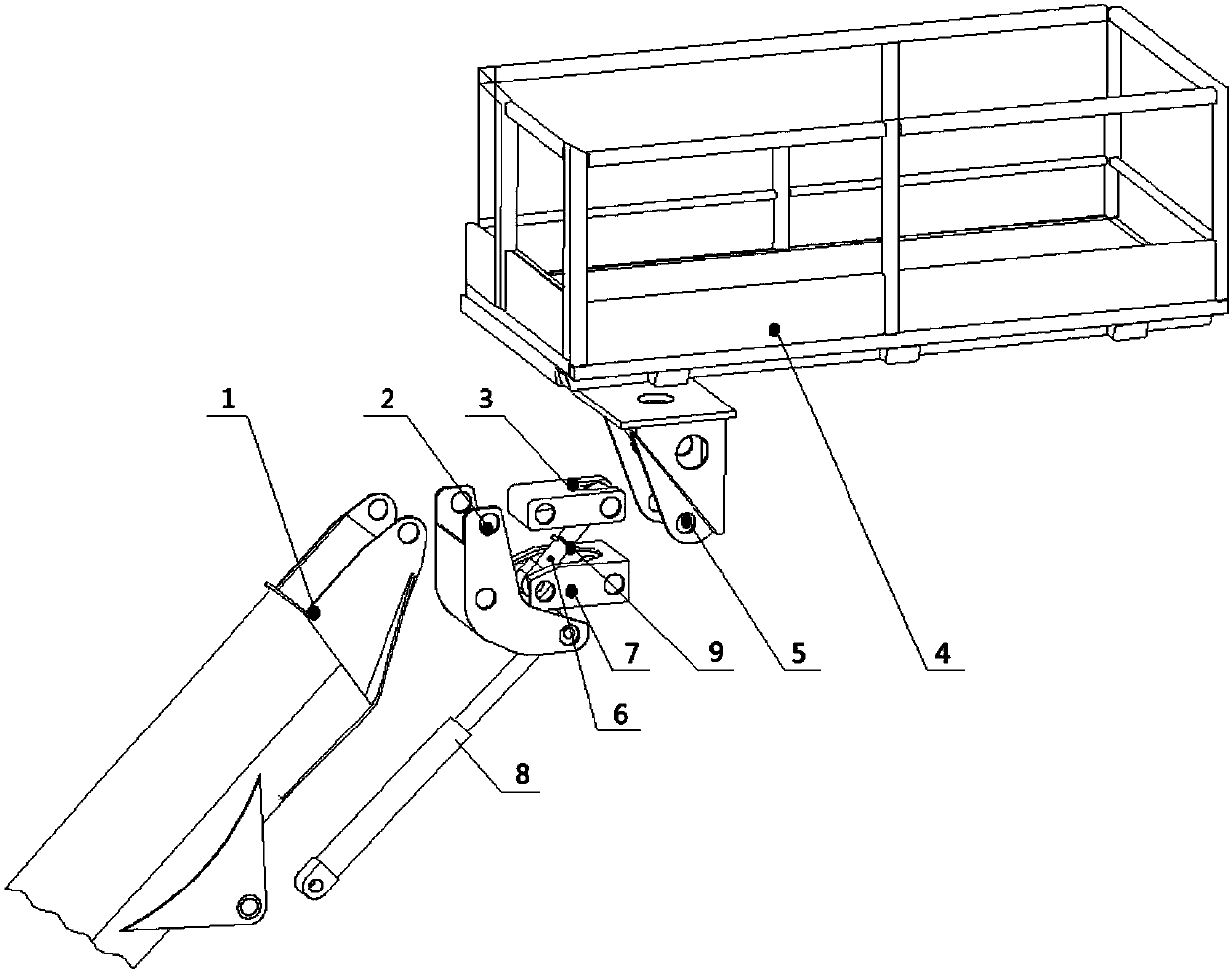

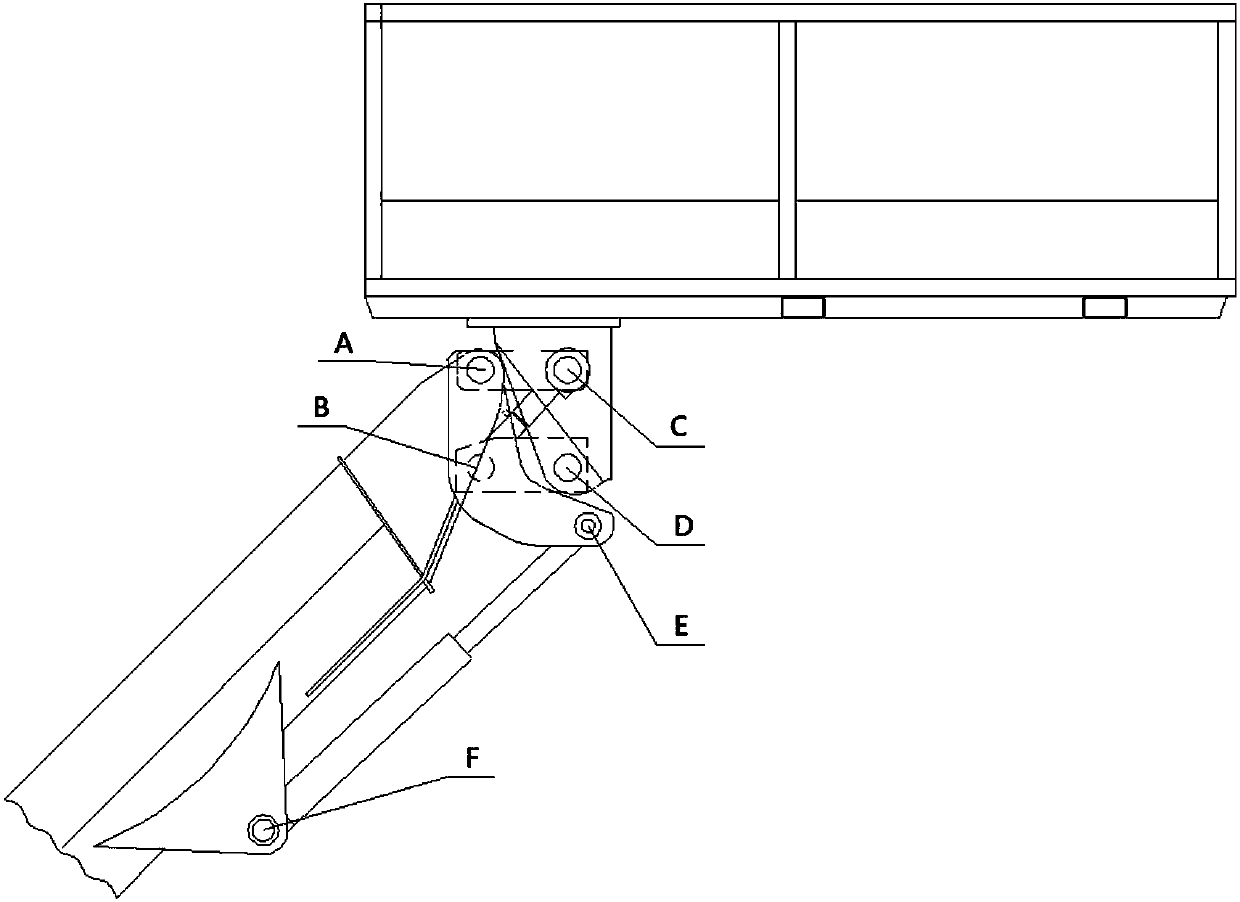

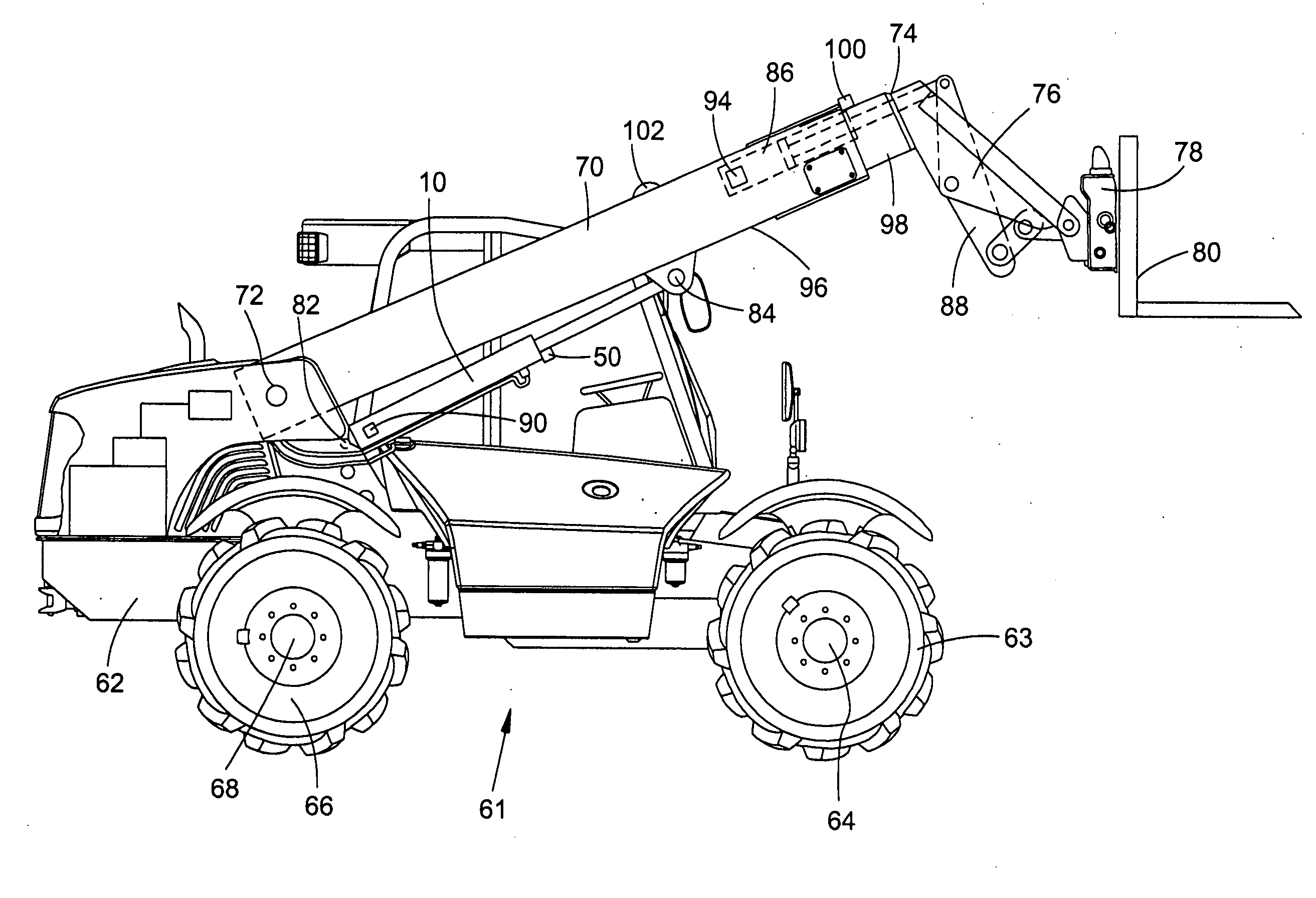

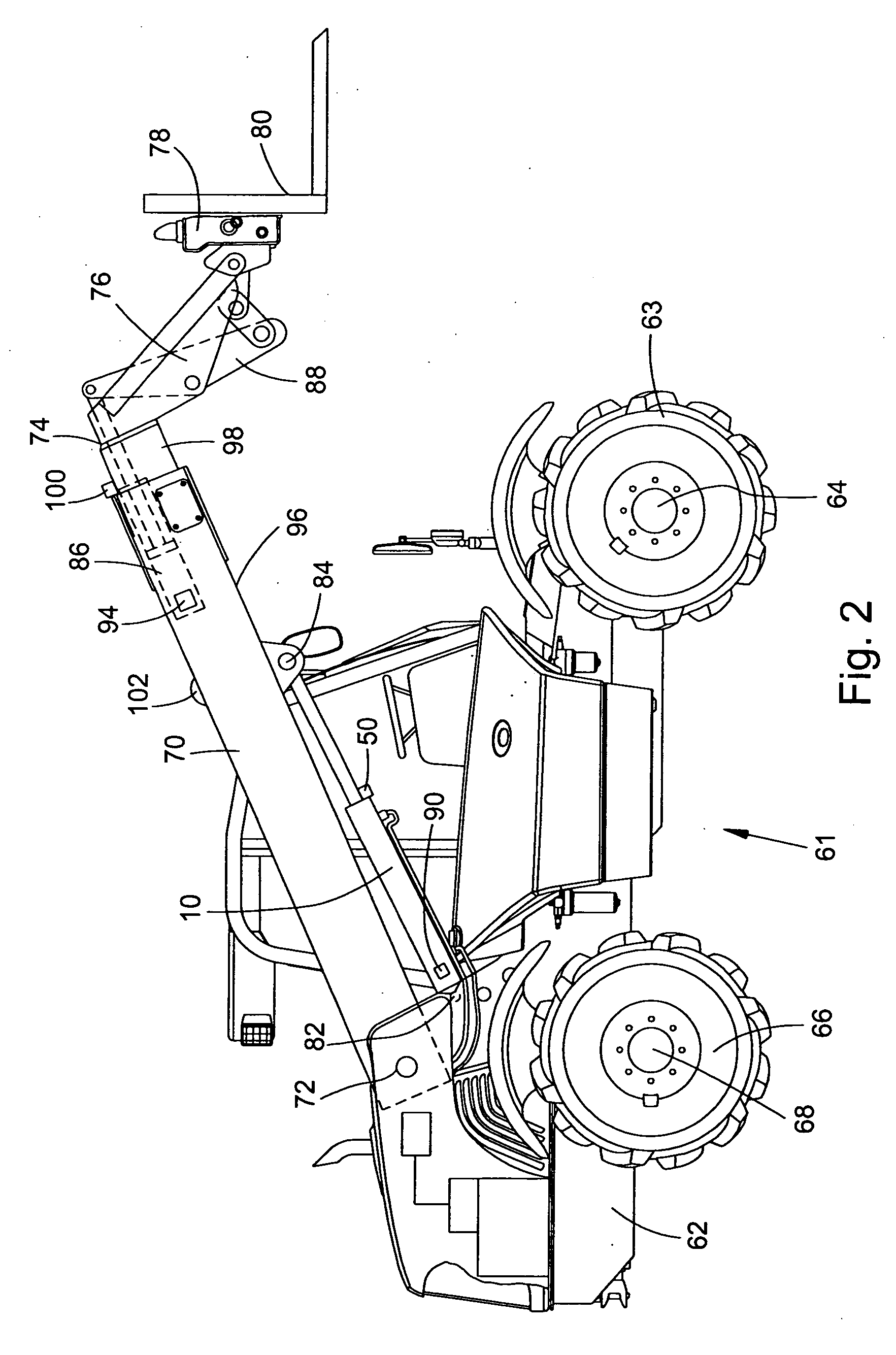

Loading implement

InactiveUS20070059146A1Increased operating comfortAdjustable positionSoil-shifting machines/dredgersLifting devicesEngineeringFuel tank

Owner:DEERE & CO

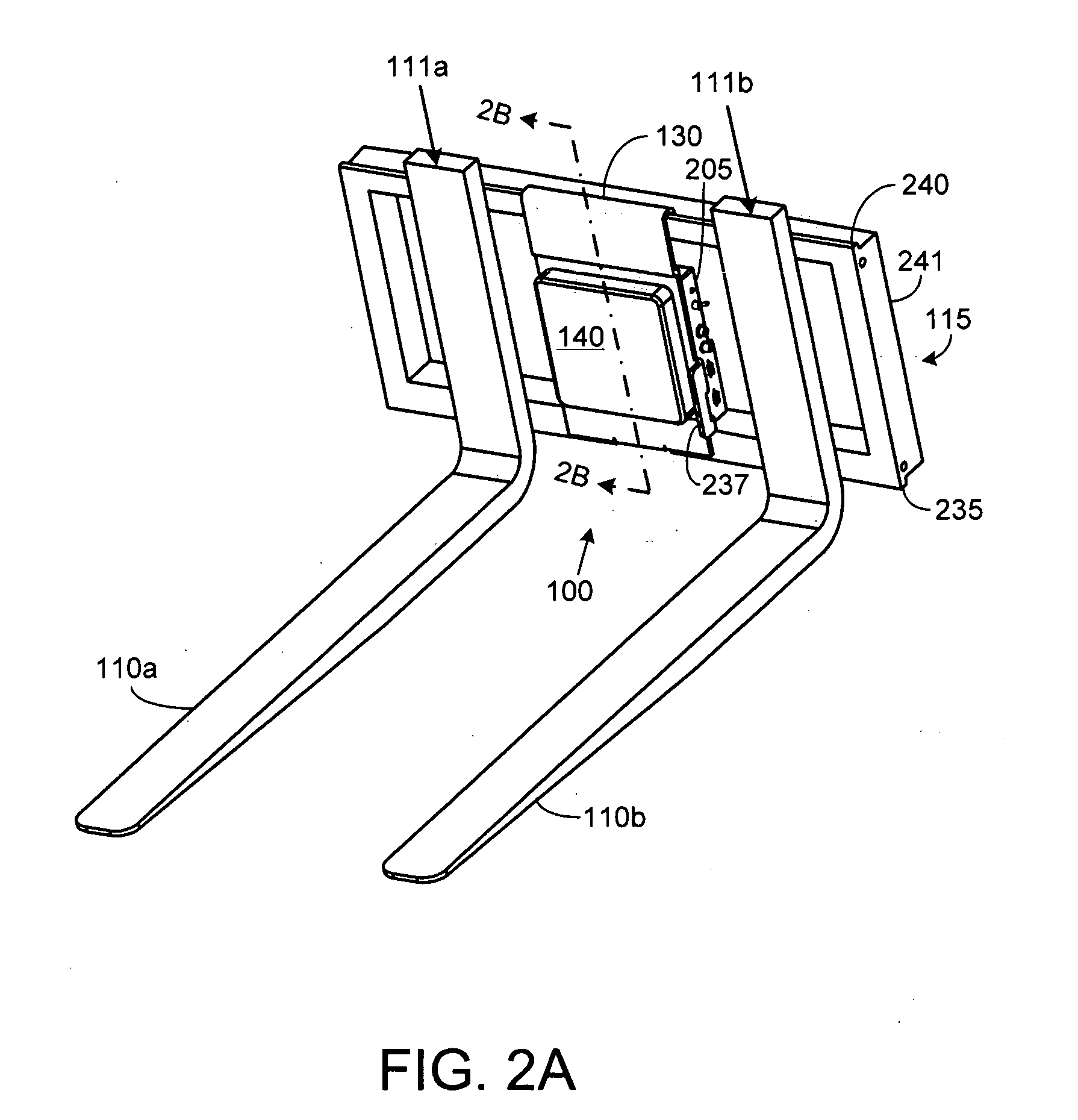

Removable mount for mounting an electronic system component on a forklift

ActiveUS20070096922A1Lifting devicesBurglar alarm by hand-portable articles removalFastenerEngineering

Owner:EMS TECHNOLOGIES

Bagged barium sulfate convenient transfer device in workshop

Owner:GUANGXI LIANZHUANG SCI & TECH CO LTD

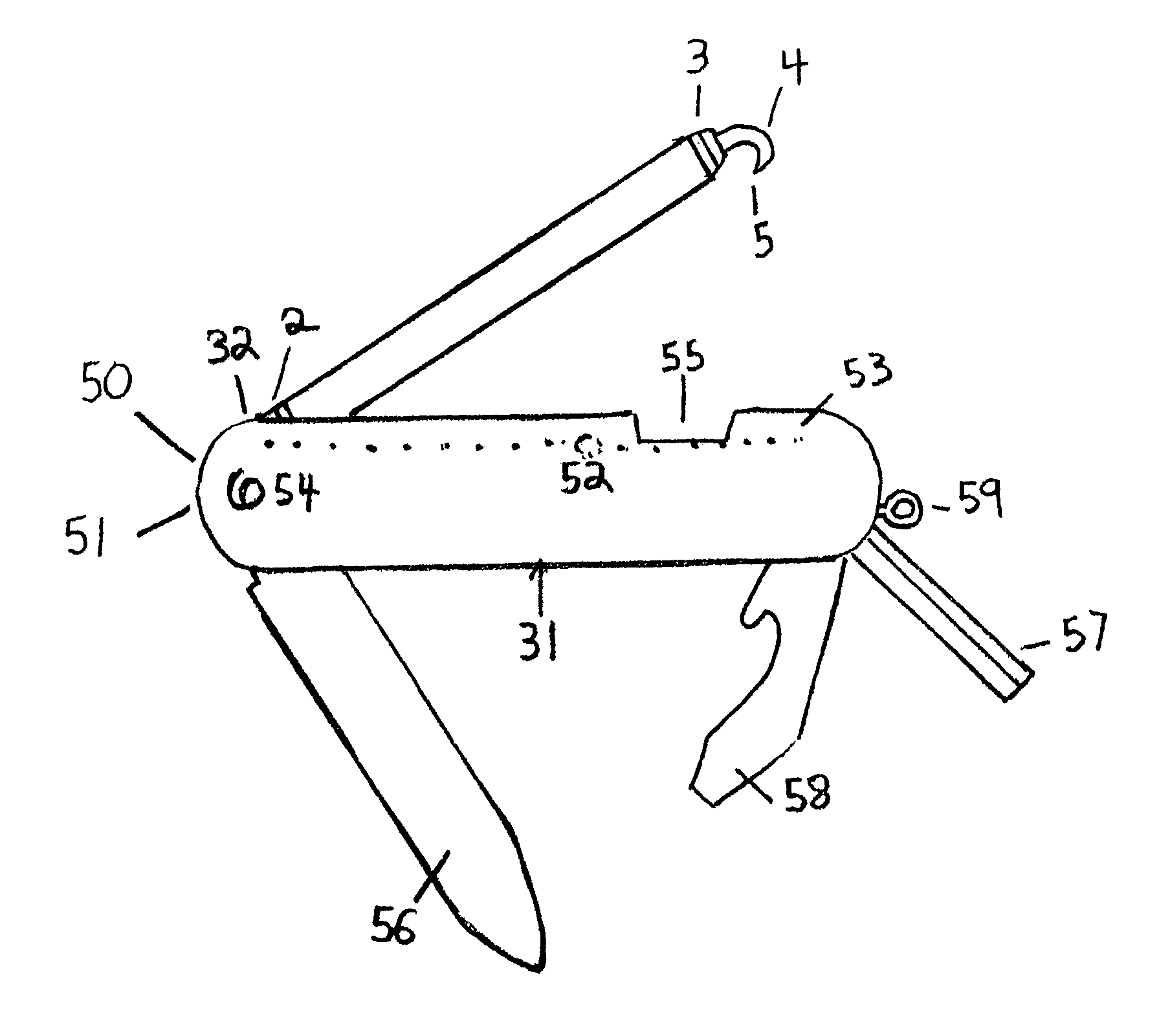

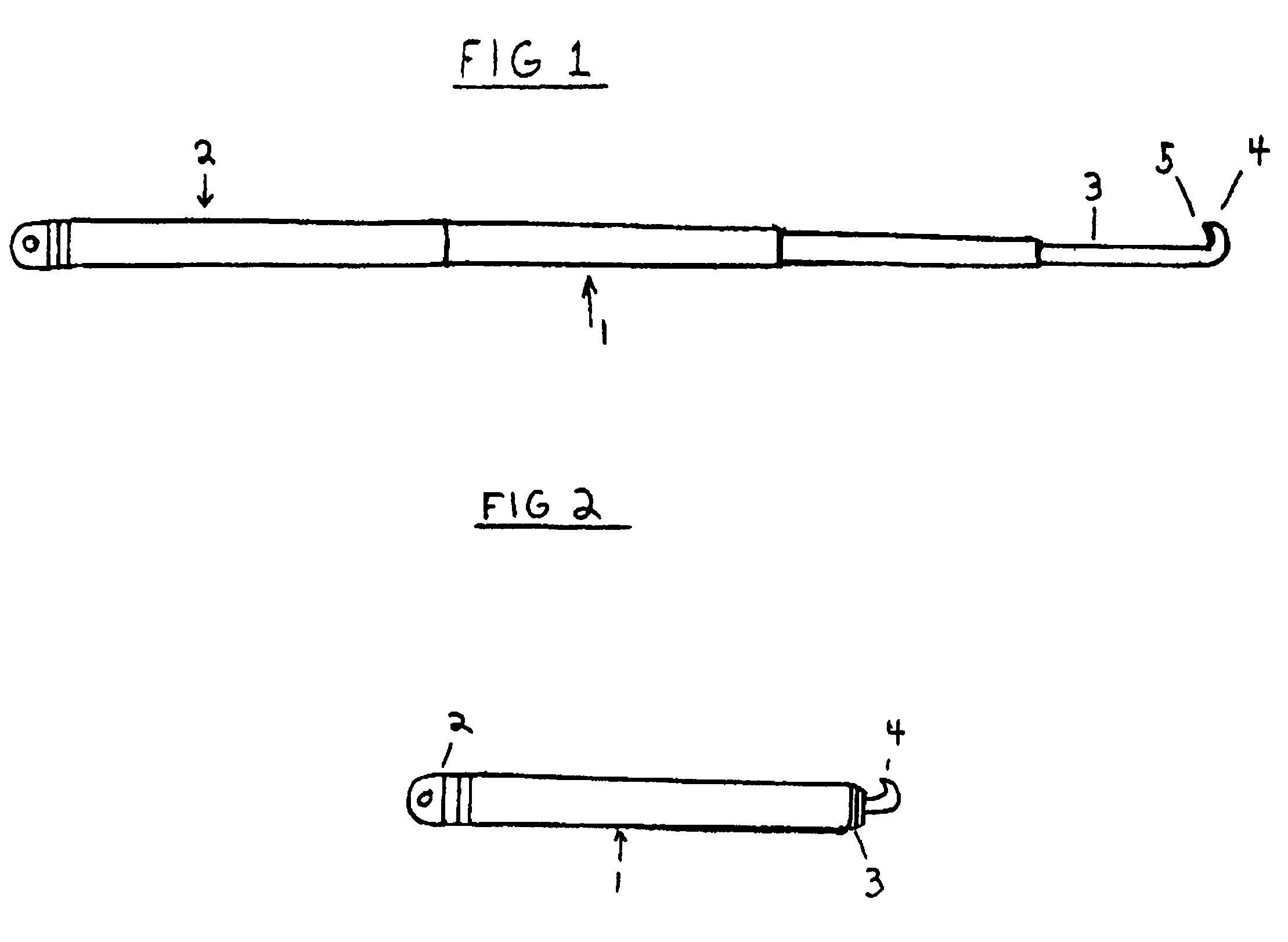

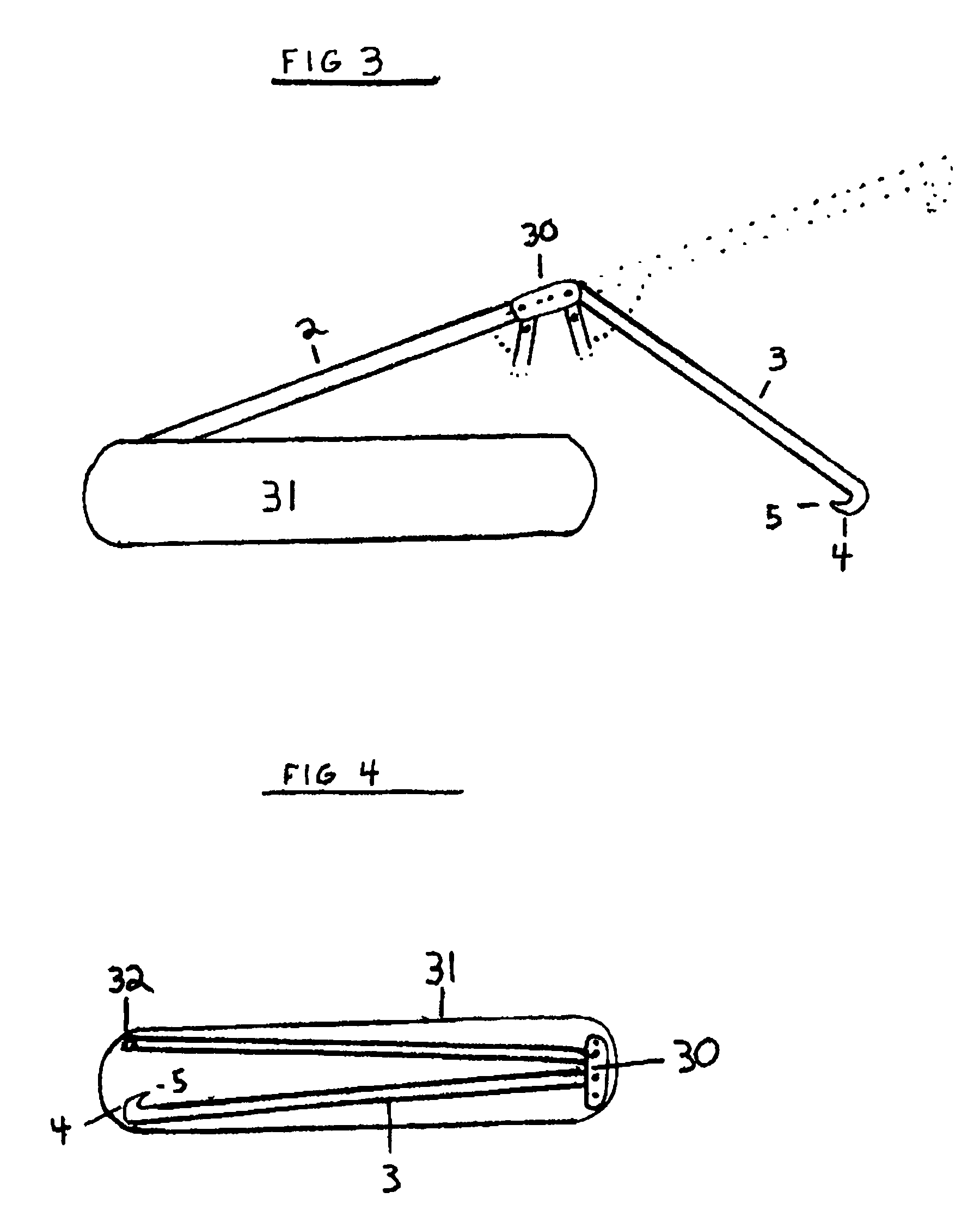

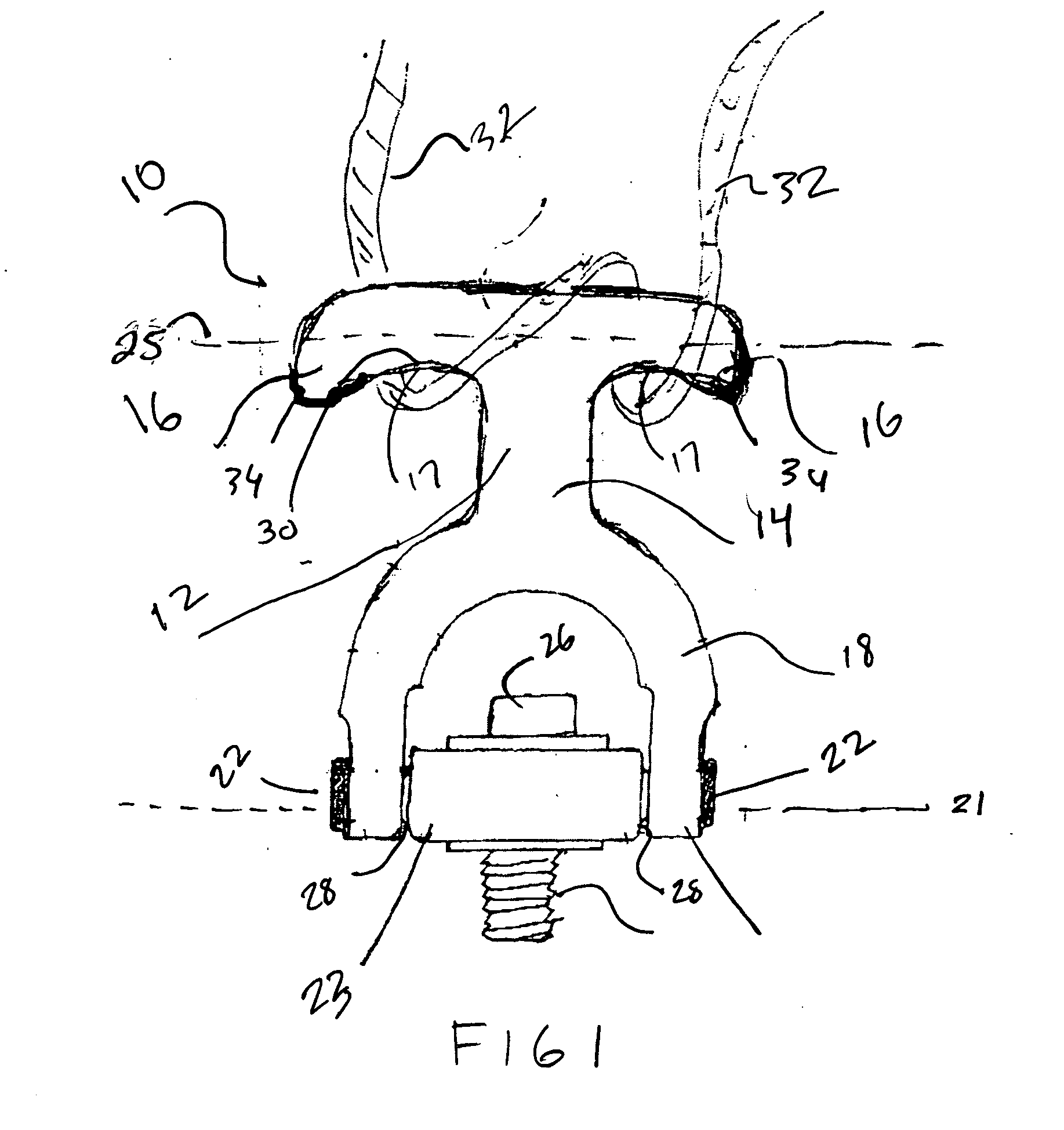

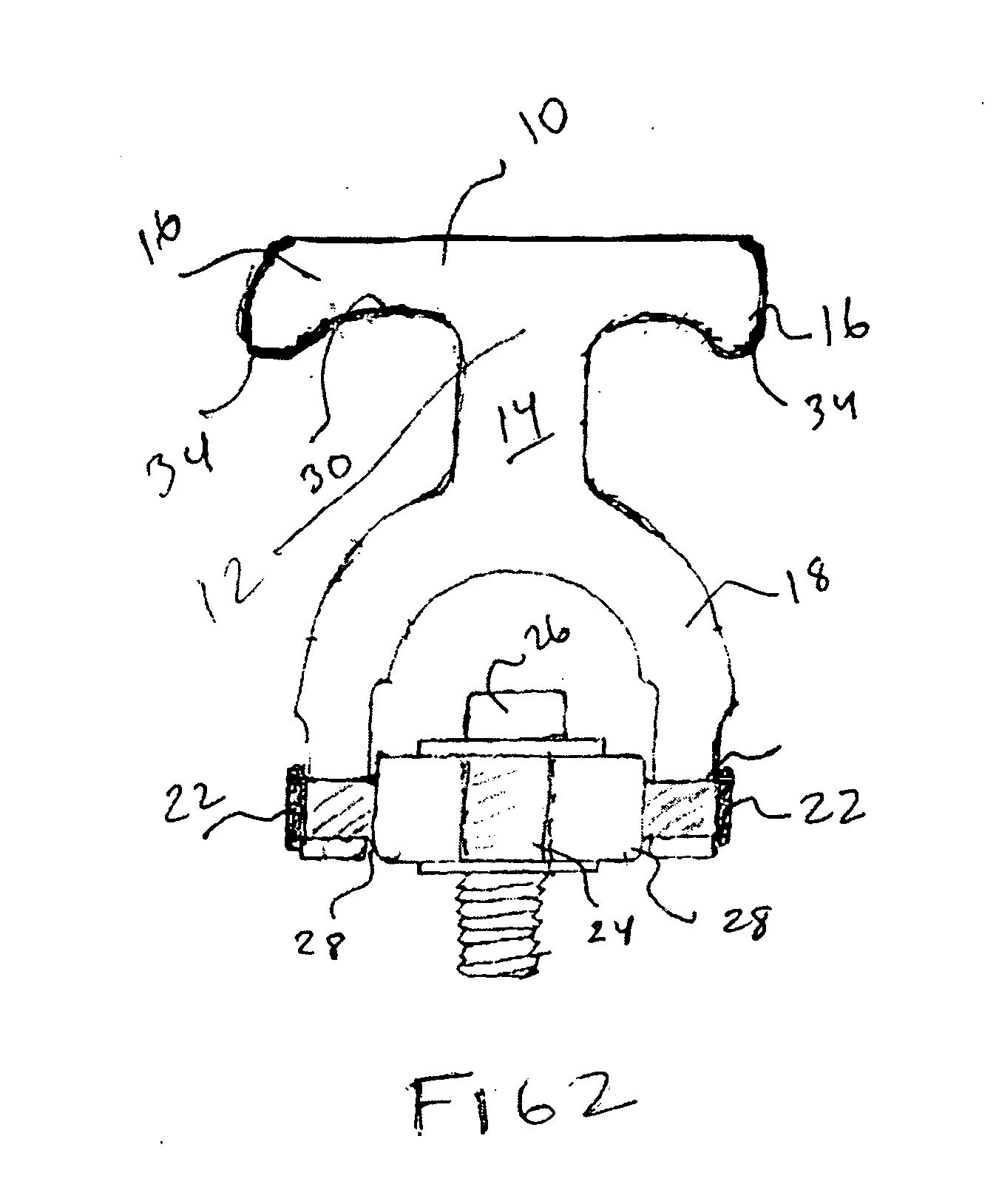

Climbing and rappelling accessory and method

InactiveUS7725969B1Speeding creationEasy to carryMountaineeringLifting devicesIndustrial engineering

Owner:OSTEYEE IAN ANDREW

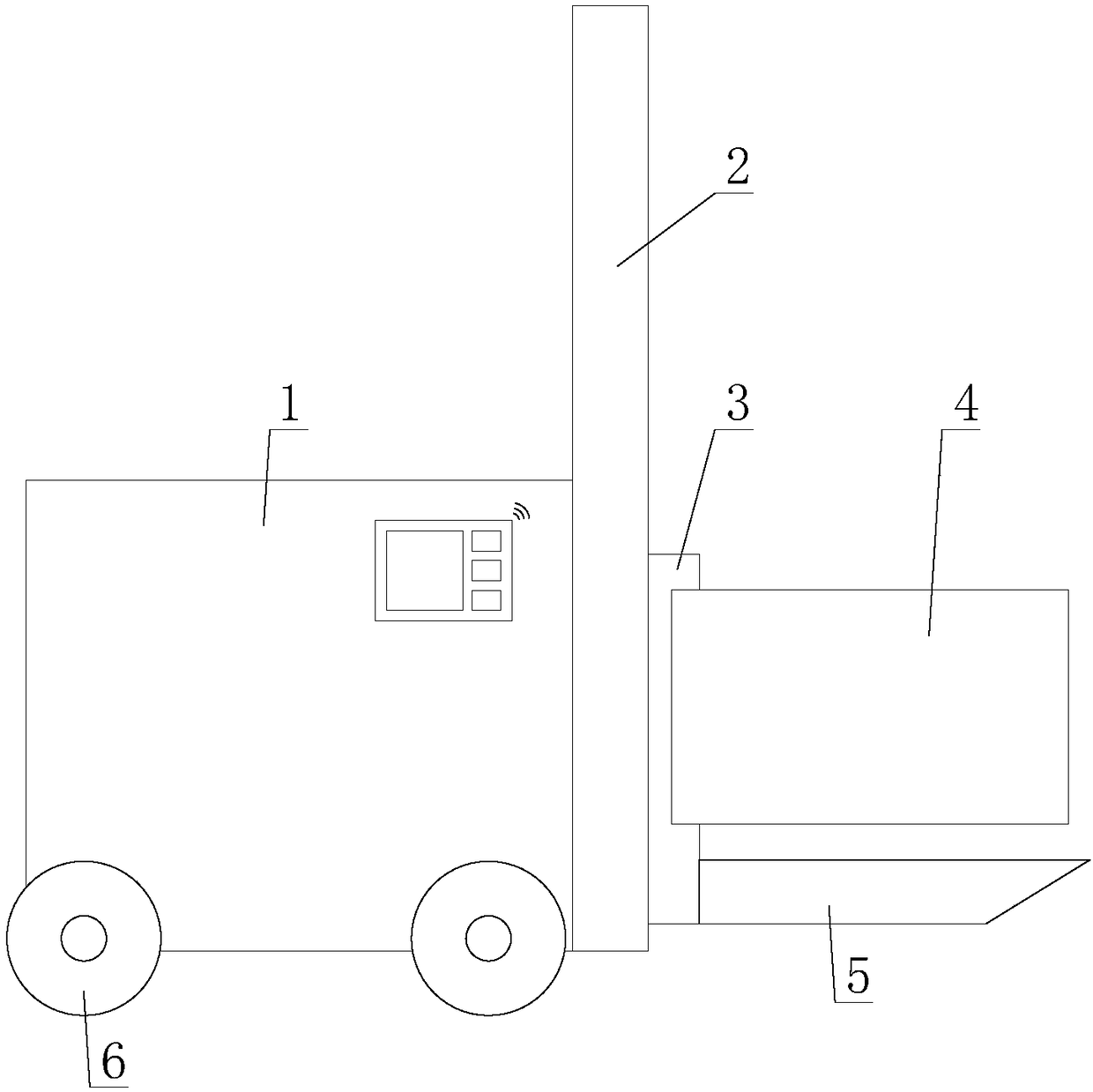

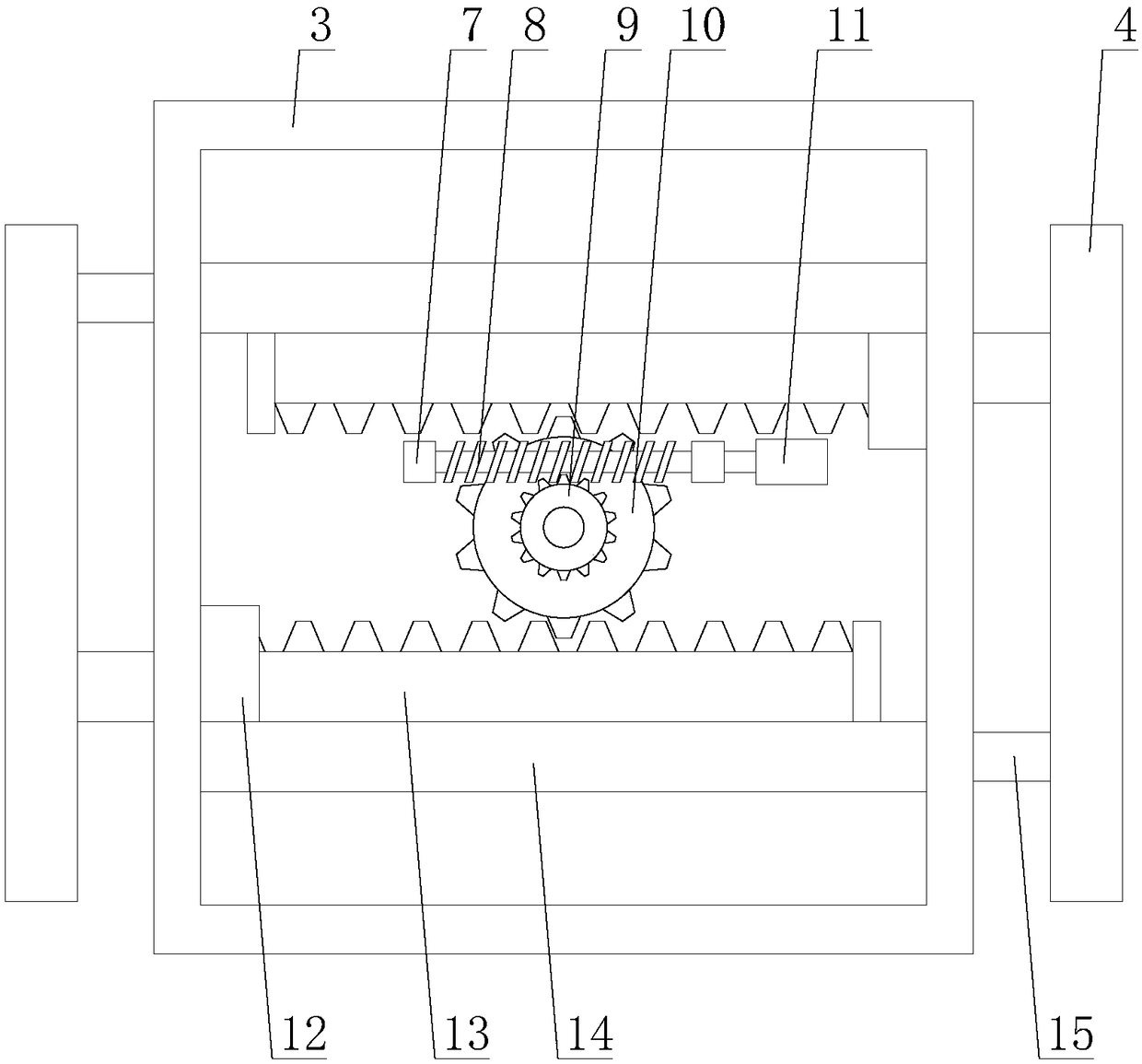

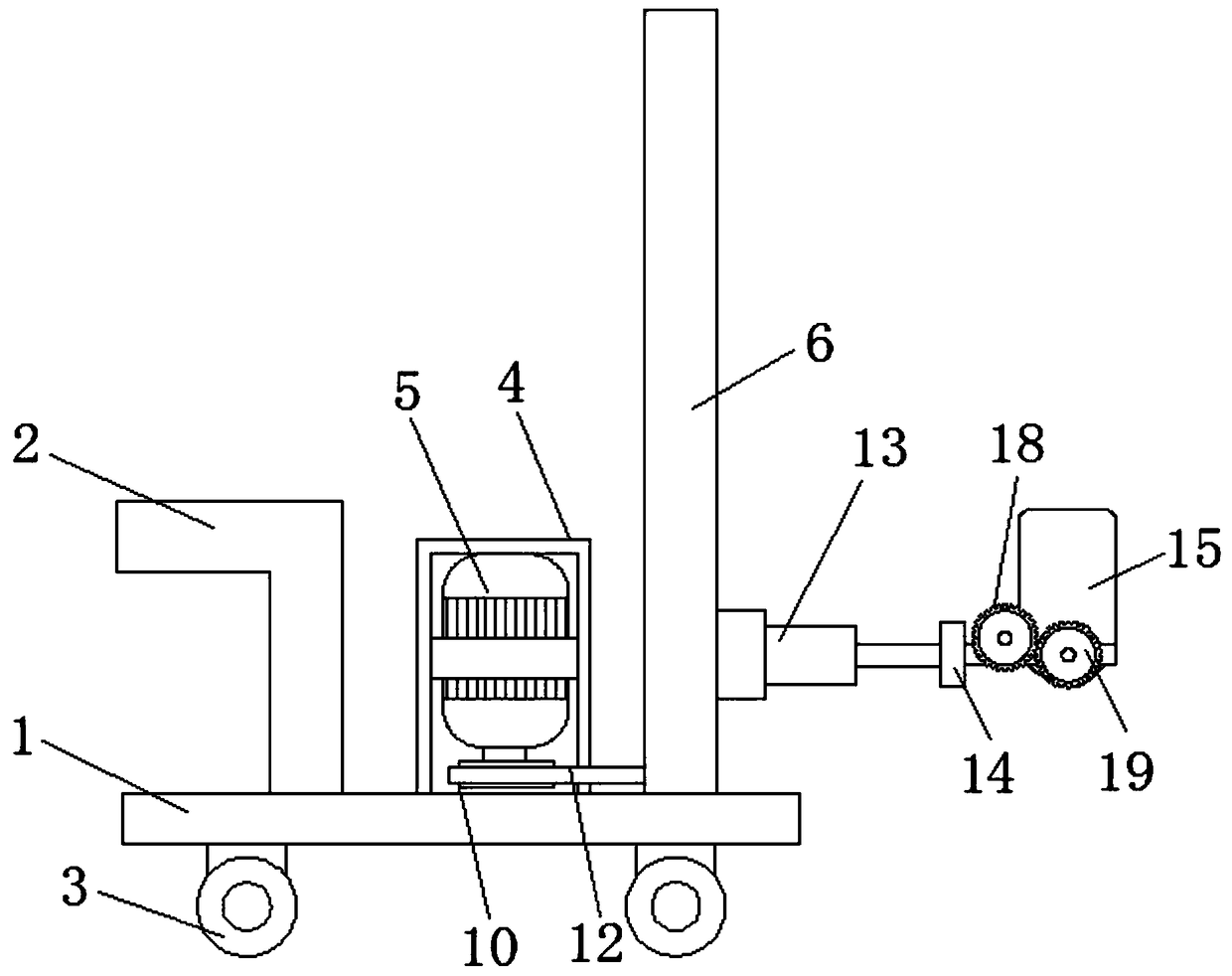

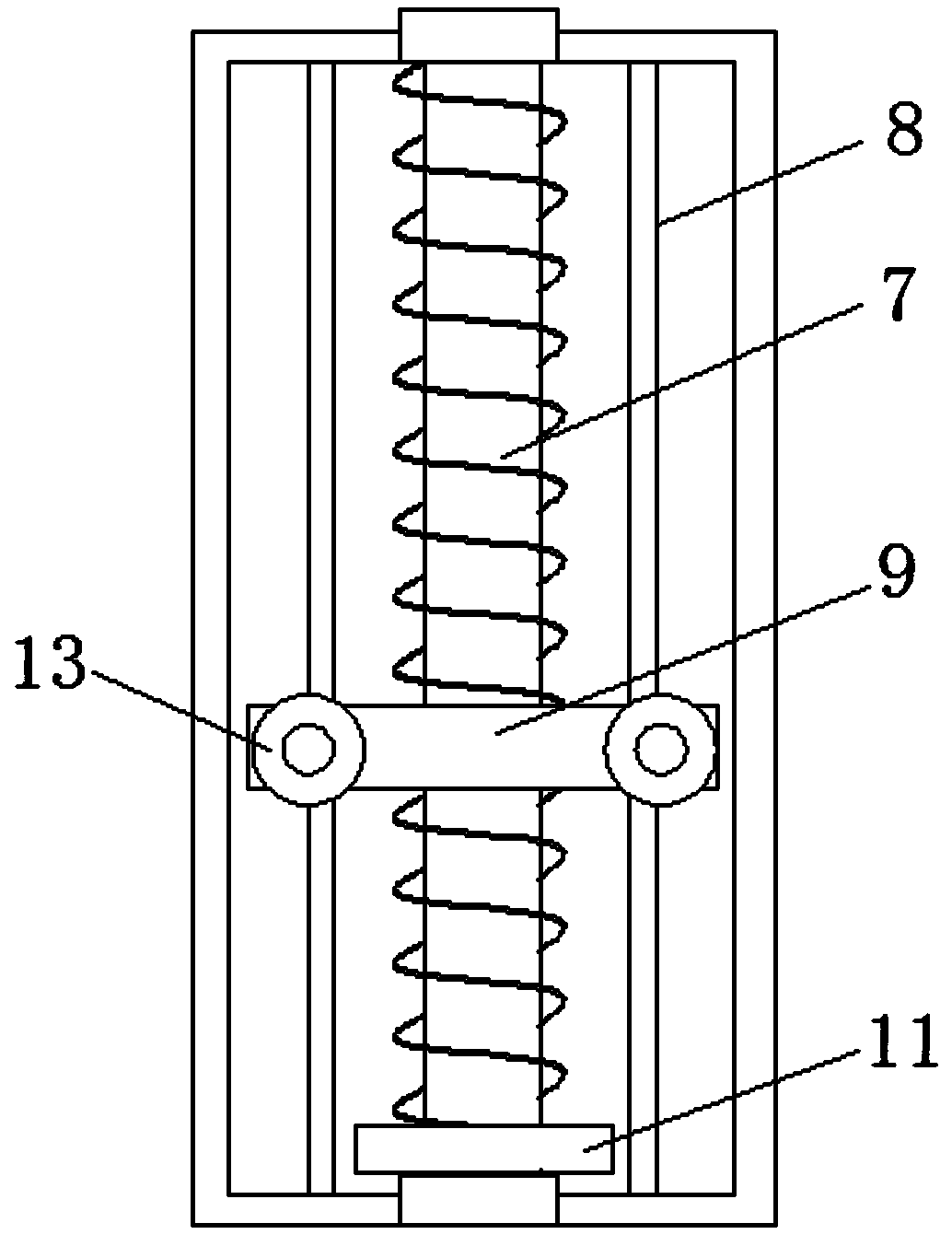

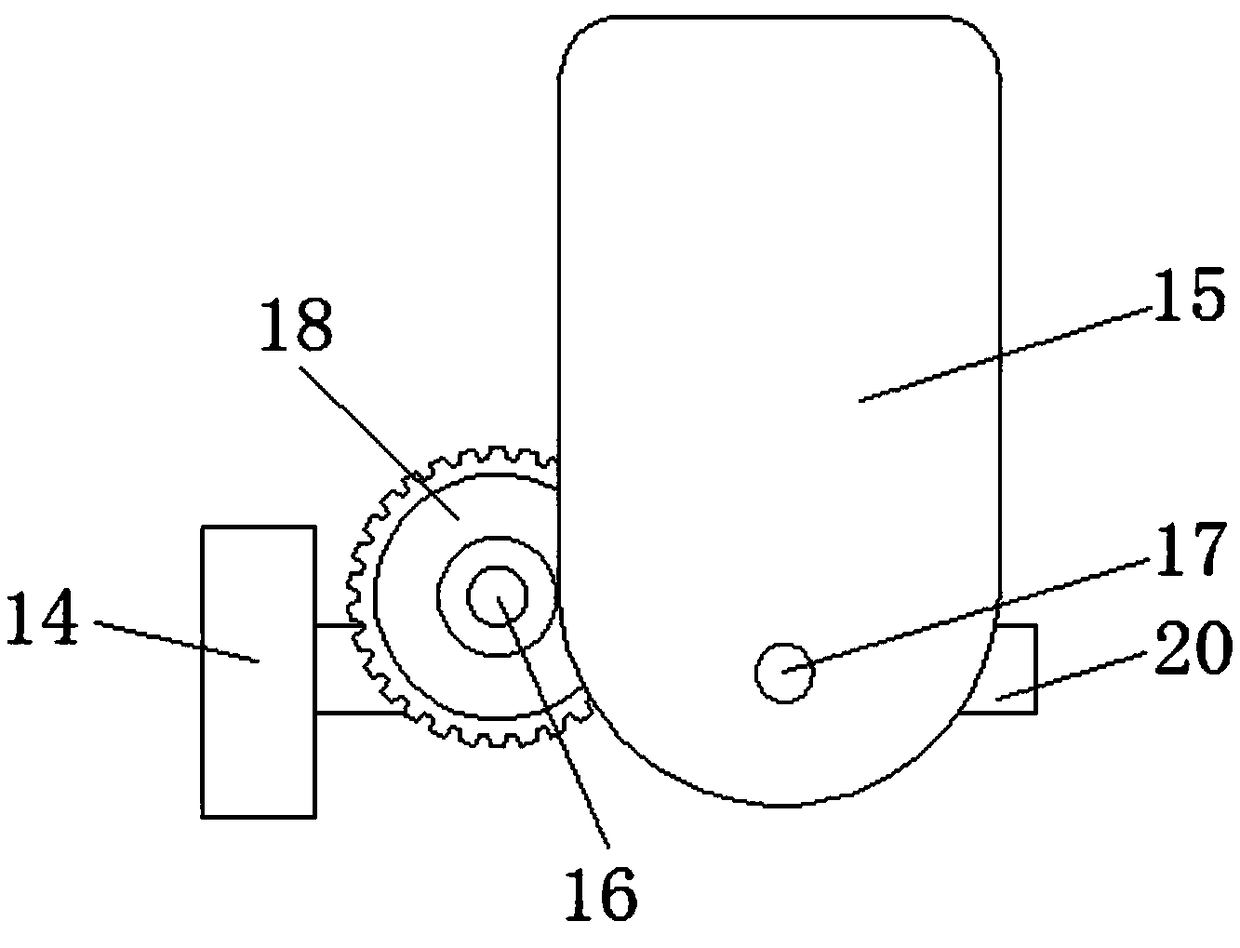

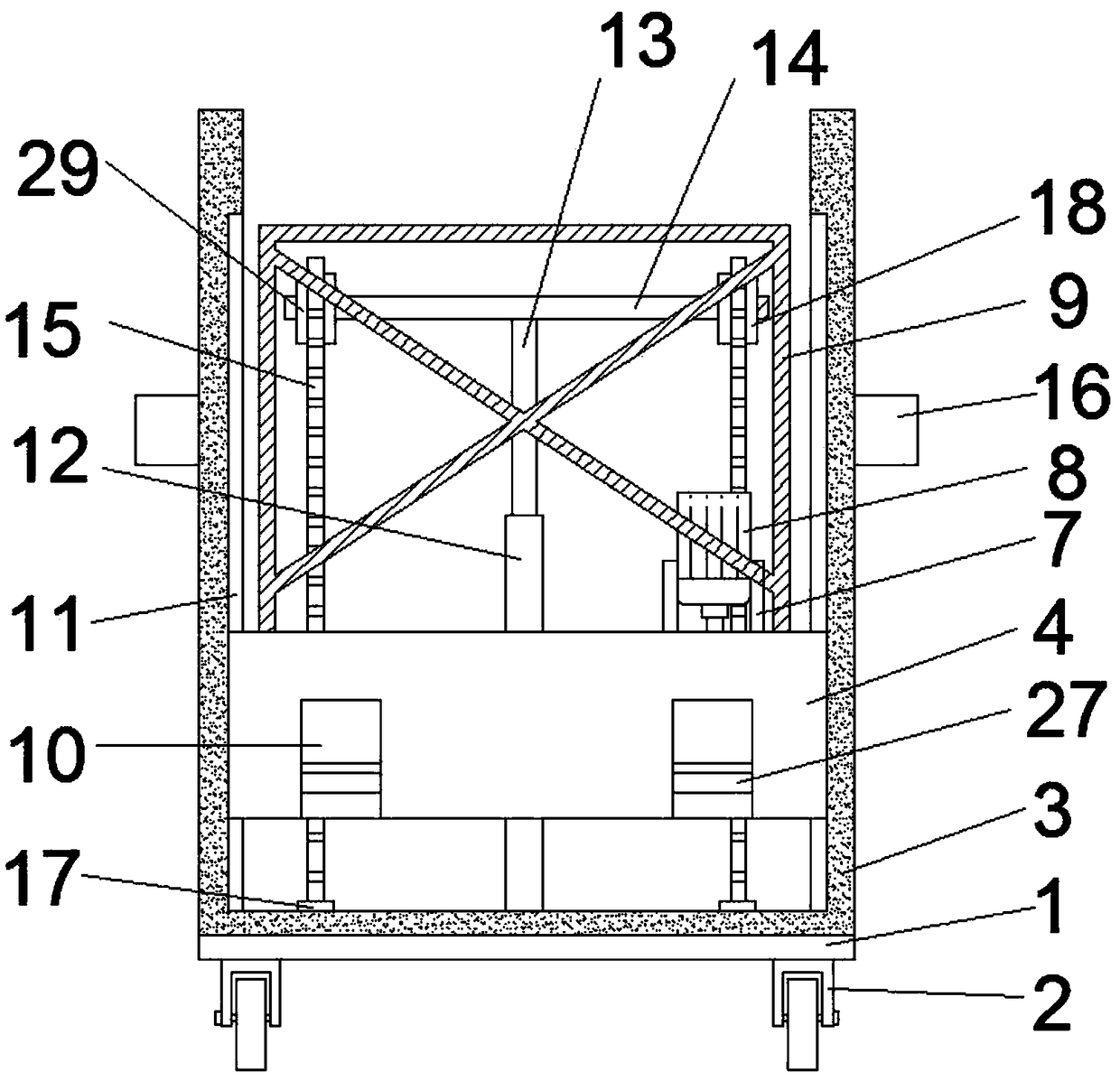

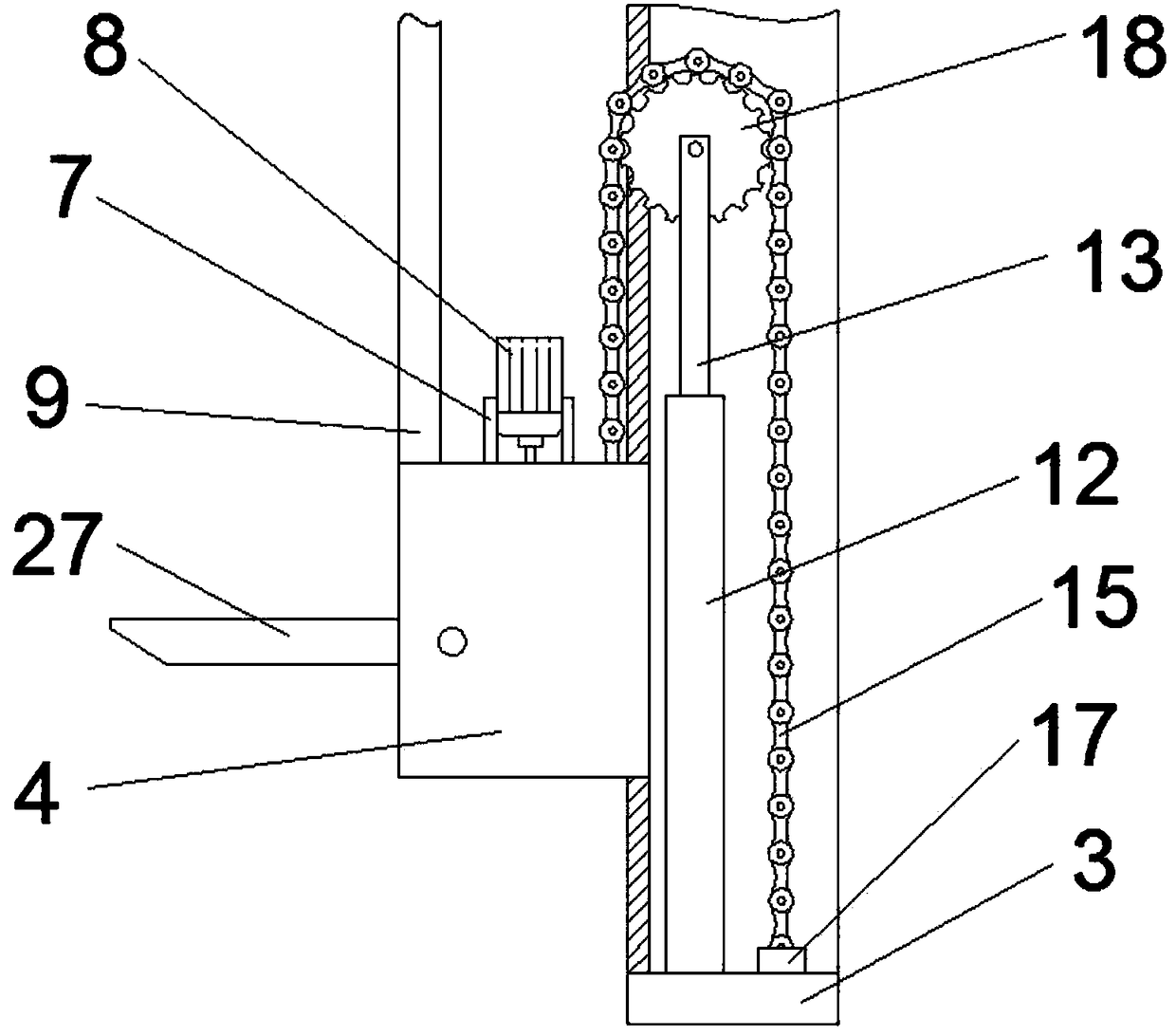

Electric forklift

ActiveCN107215822ASimple structureReasonable designPhotovoltaic supportsBatteries circuit arrangementsElectricityEngineering

Owner:XIAN AERONAUTICAL UNIV

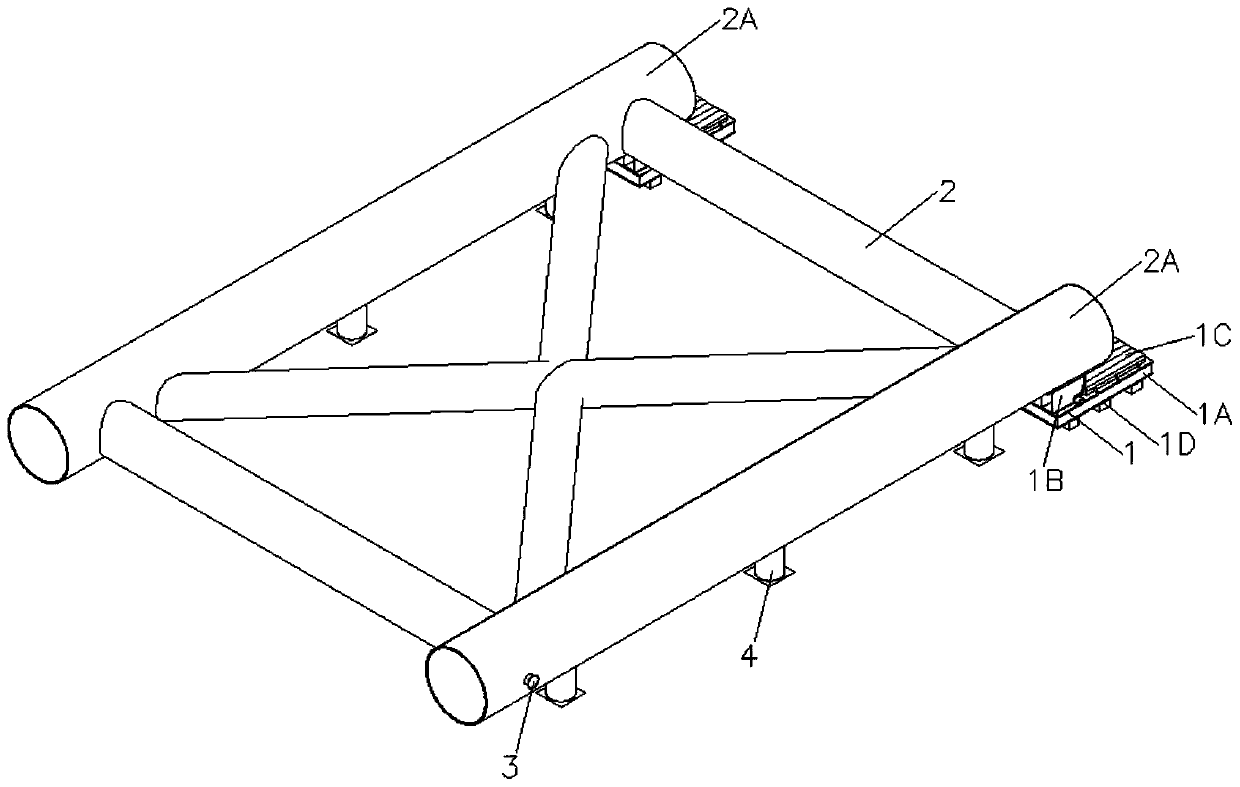

Rudder blade supporting frame and rudder blade mounting trolley

Owner:上海外高桥造船海洋工程项目管理有限公司

Stable AGV with fastening function based on internet of things

InactiveCN108358121AReduce the chance of tippingImprove lifting performanceLifting devicesLifting capacityThe Internet

Owner:深圳市中科智诚科技有限公司

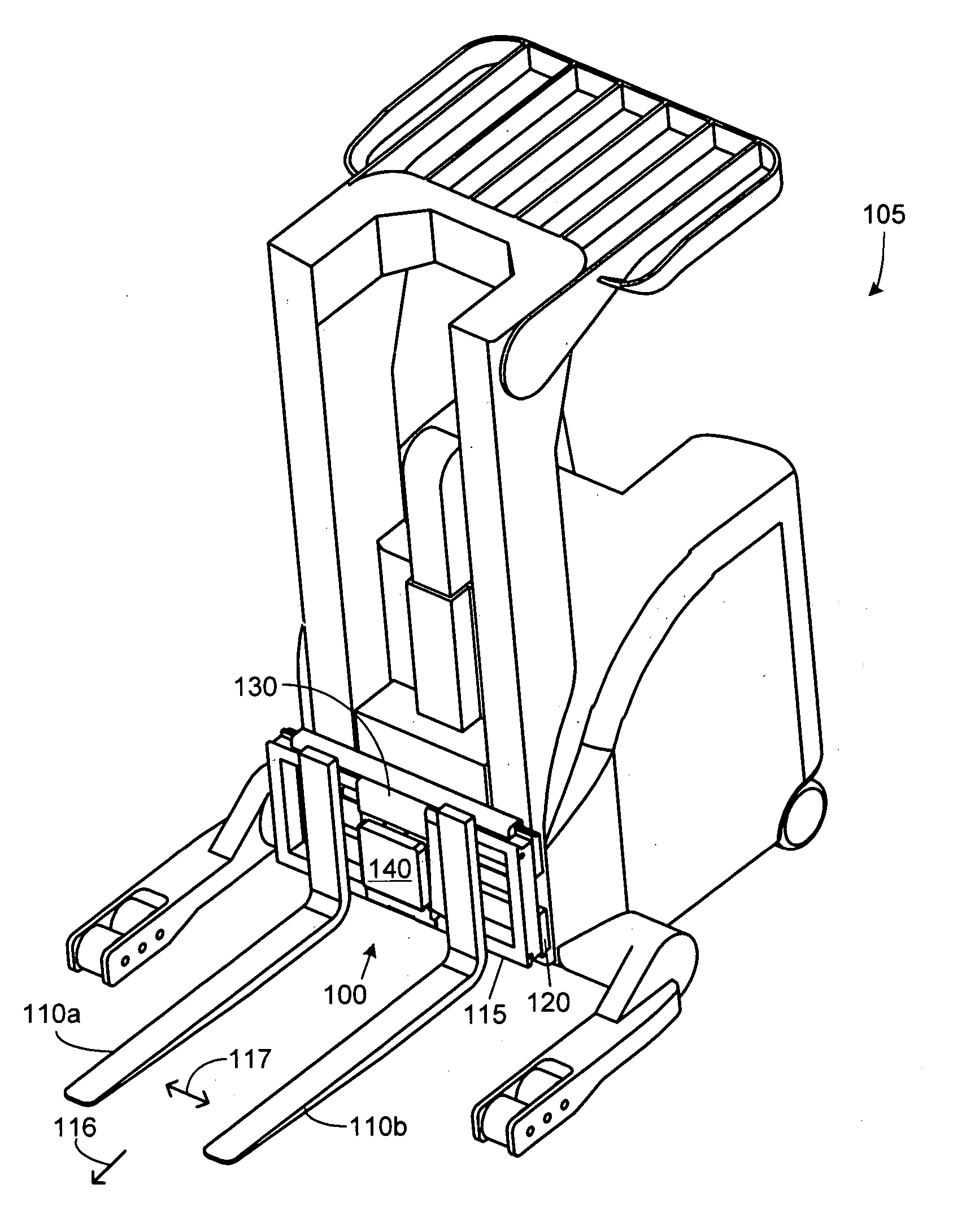

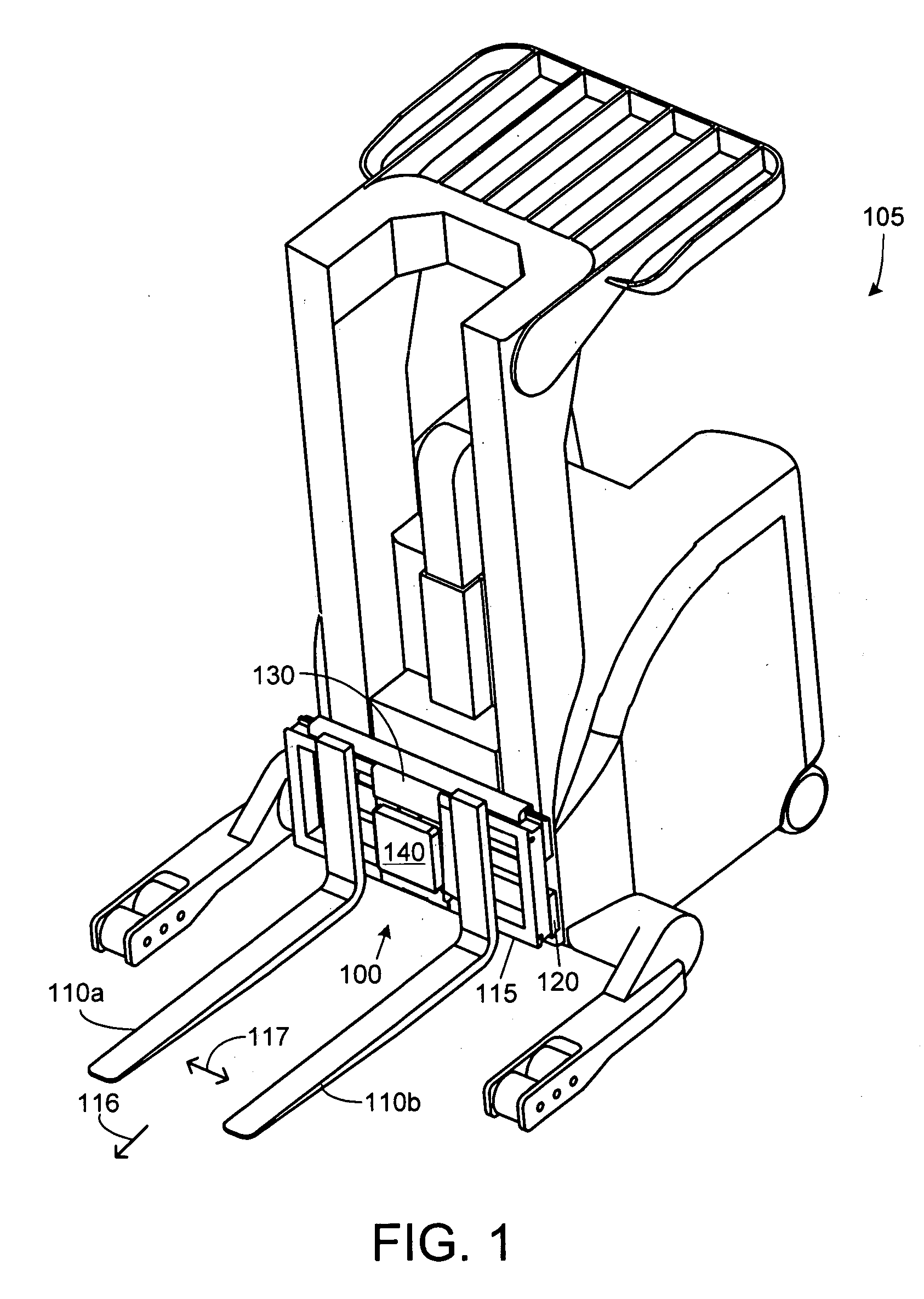

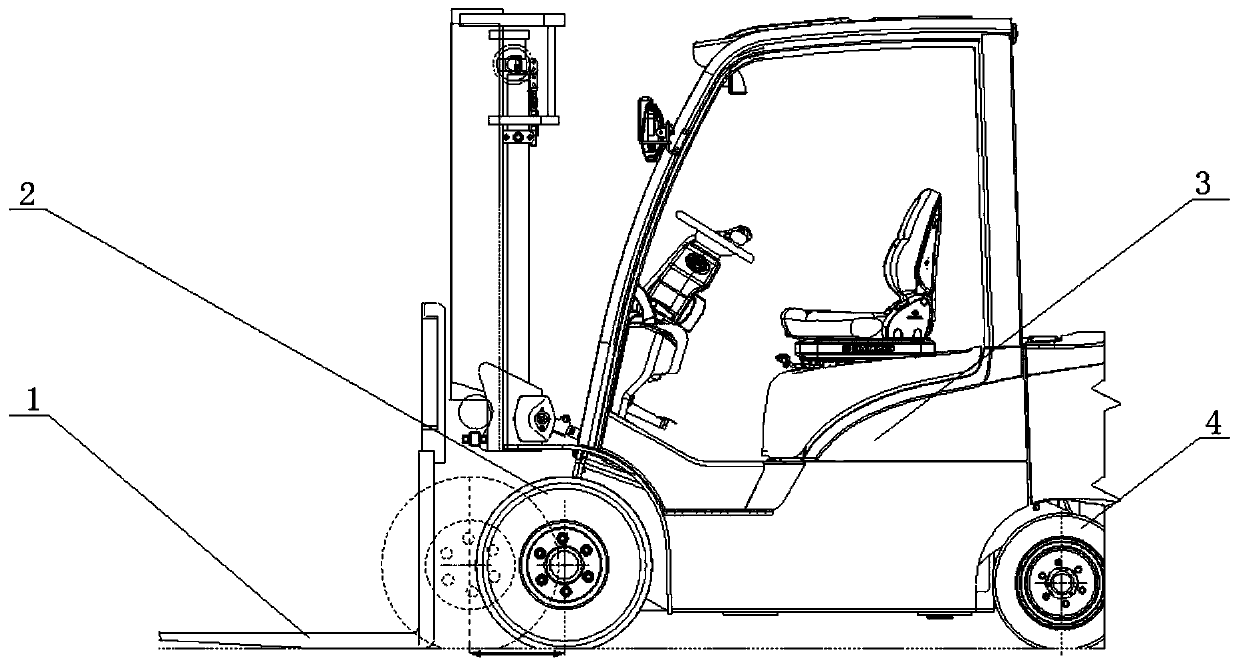

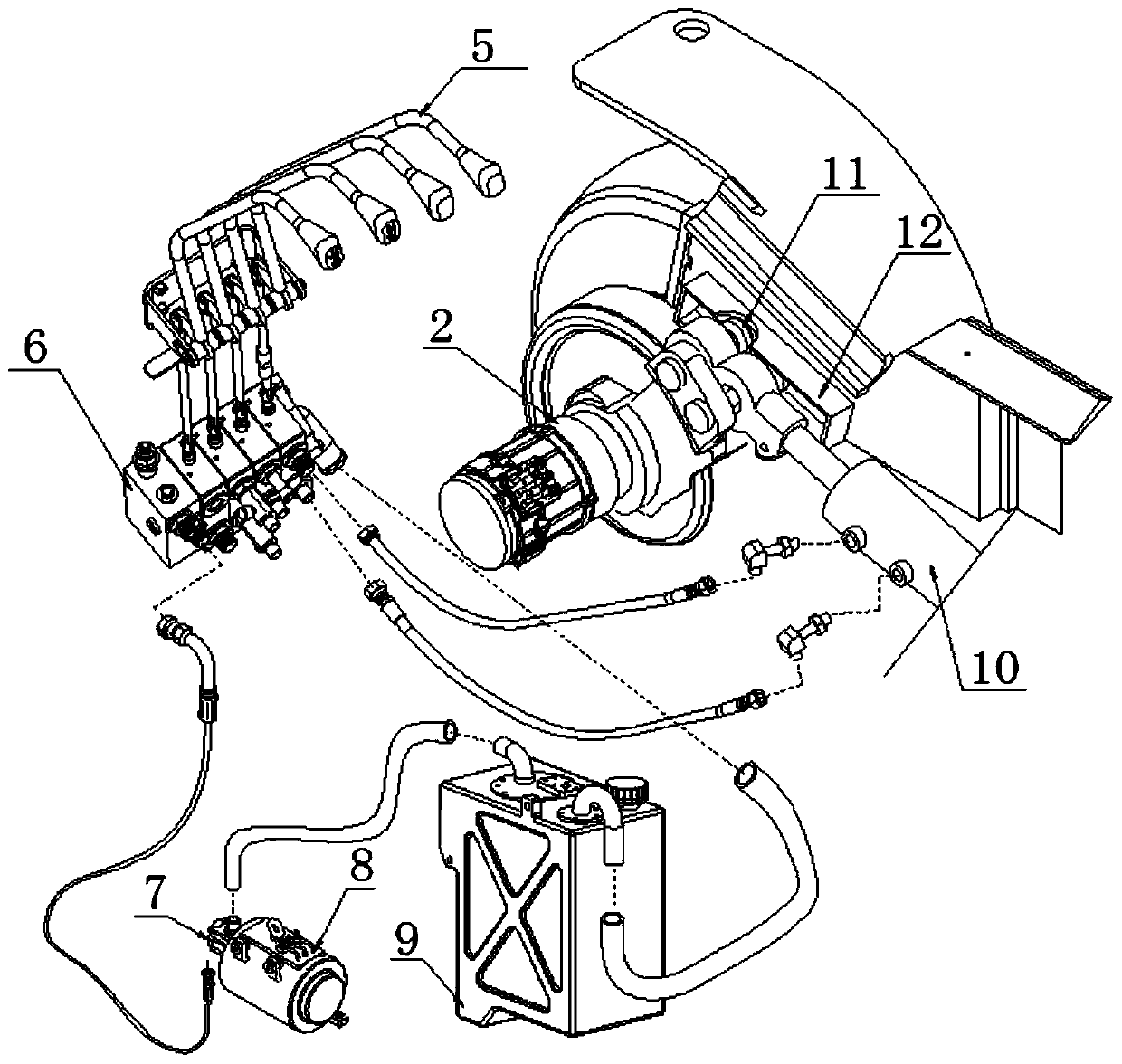

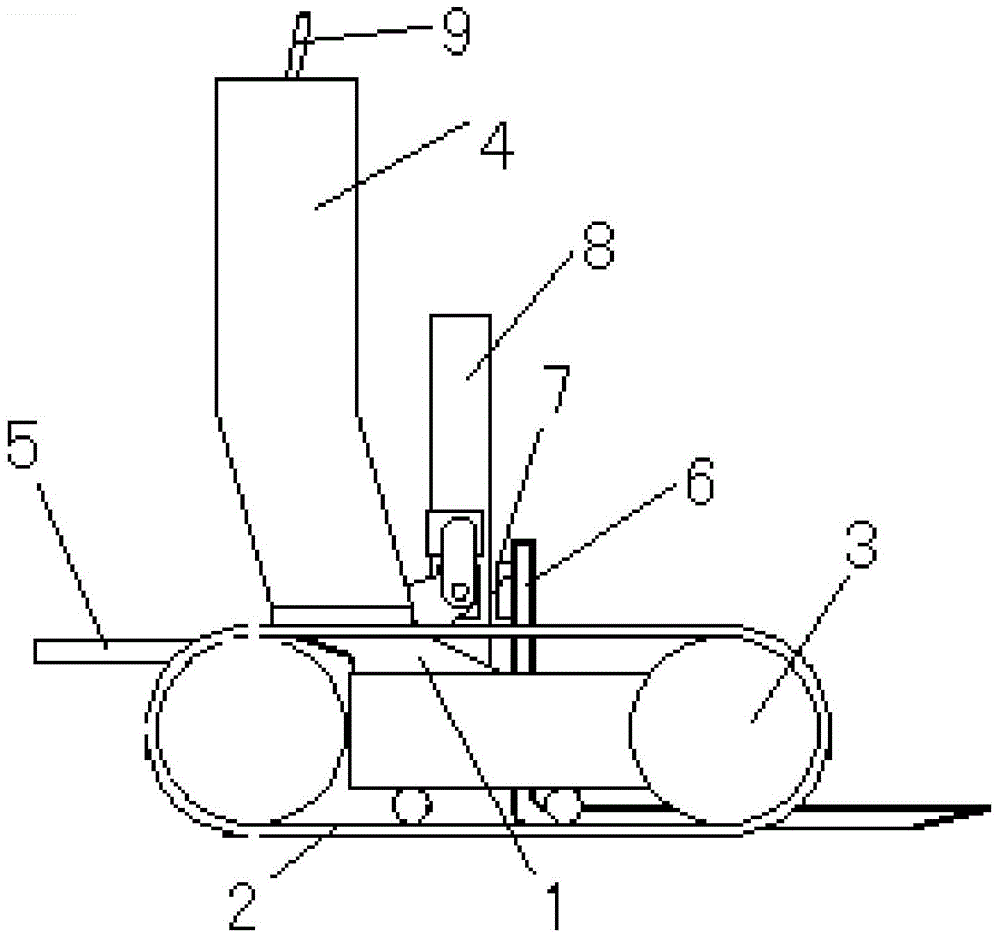

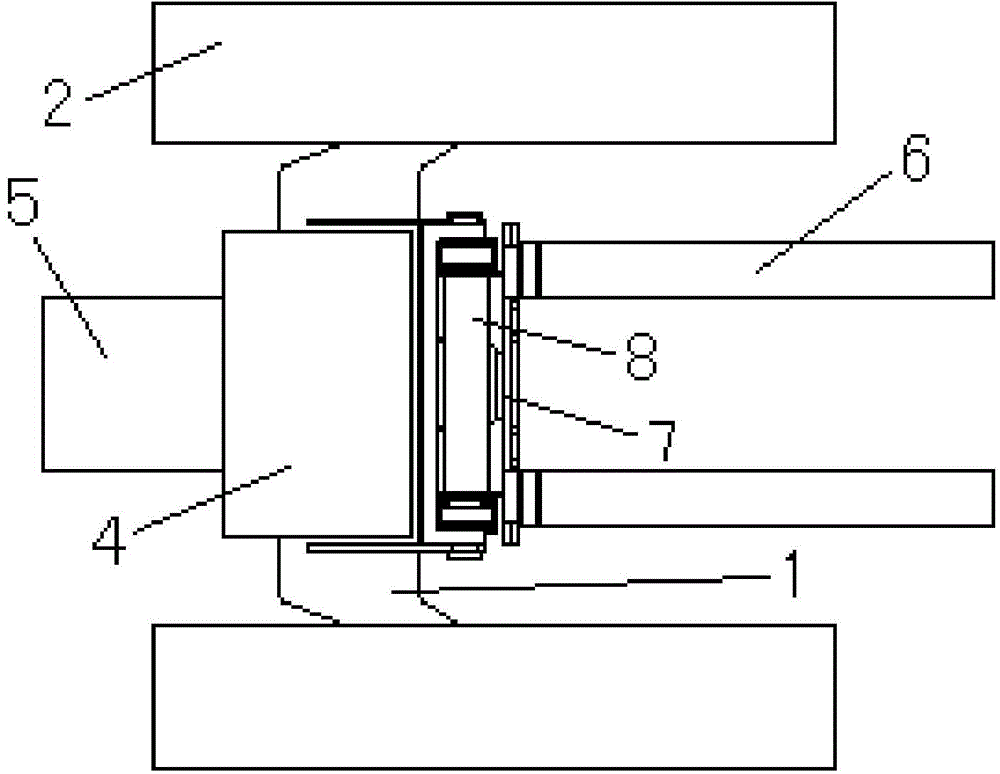

Forklift with adjustable wheelbase

Owner:HANGCHA GRP

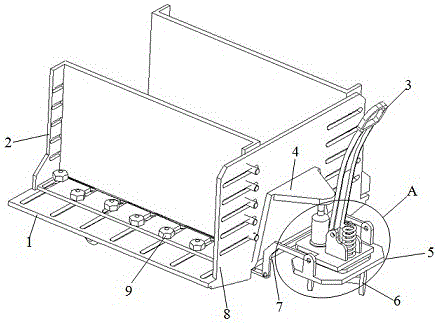

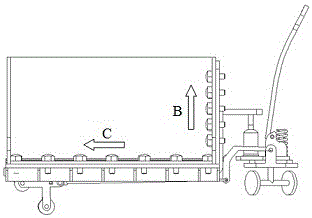

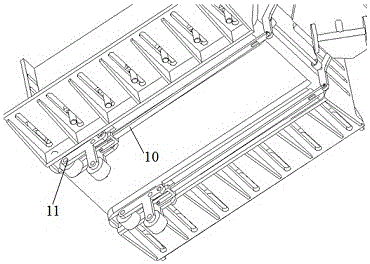

In-plant full-grade-level multifunctional minitype carrying trolley

Owner:STATE GRID CORP OF CHINA +2

Overturning detection device for overhead working truck

Owner:ANHUI LIUGONG CRANE

Quantitative feeding device for building decoration material

Owner:安徽稀饭智能家居有限公司

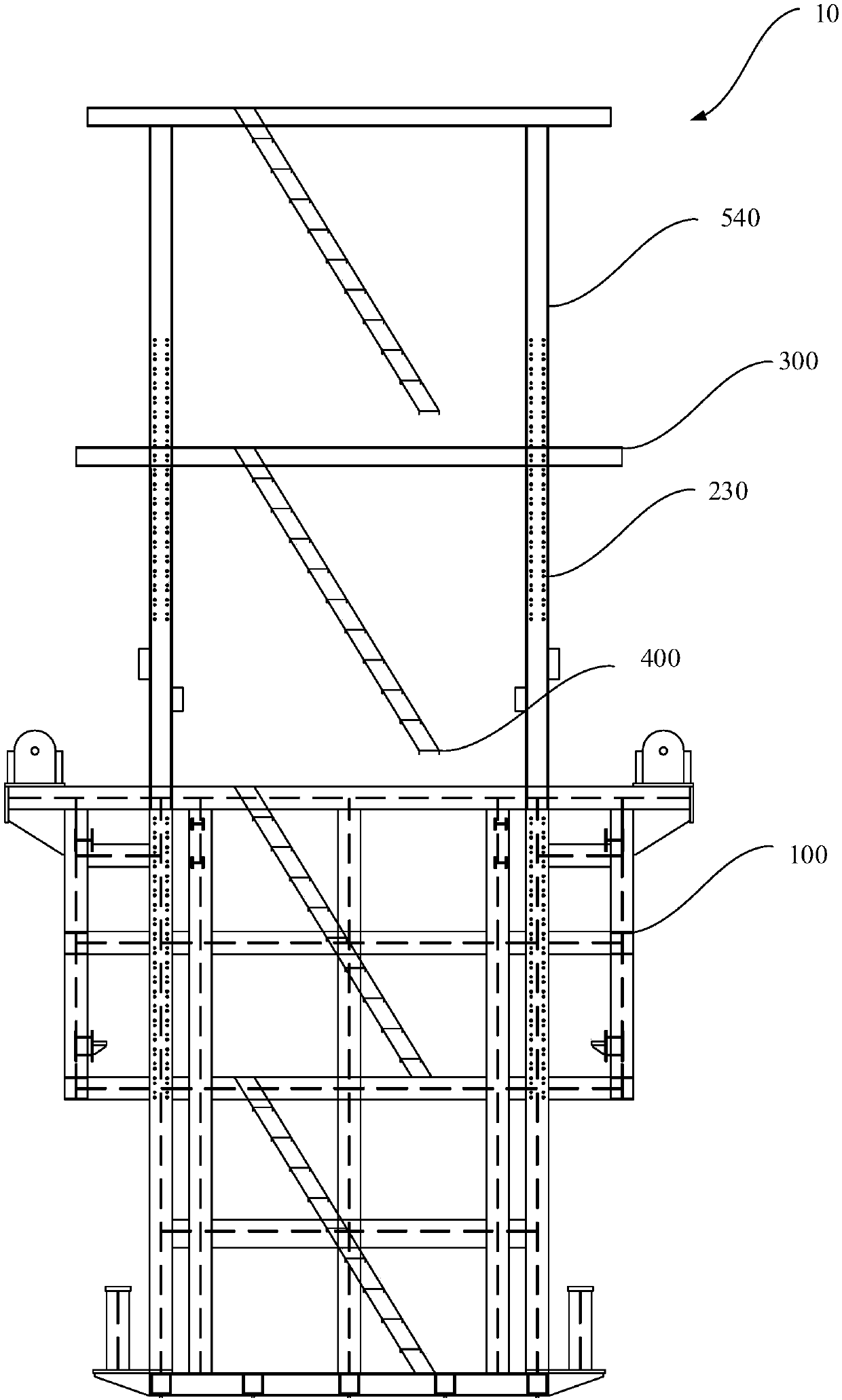

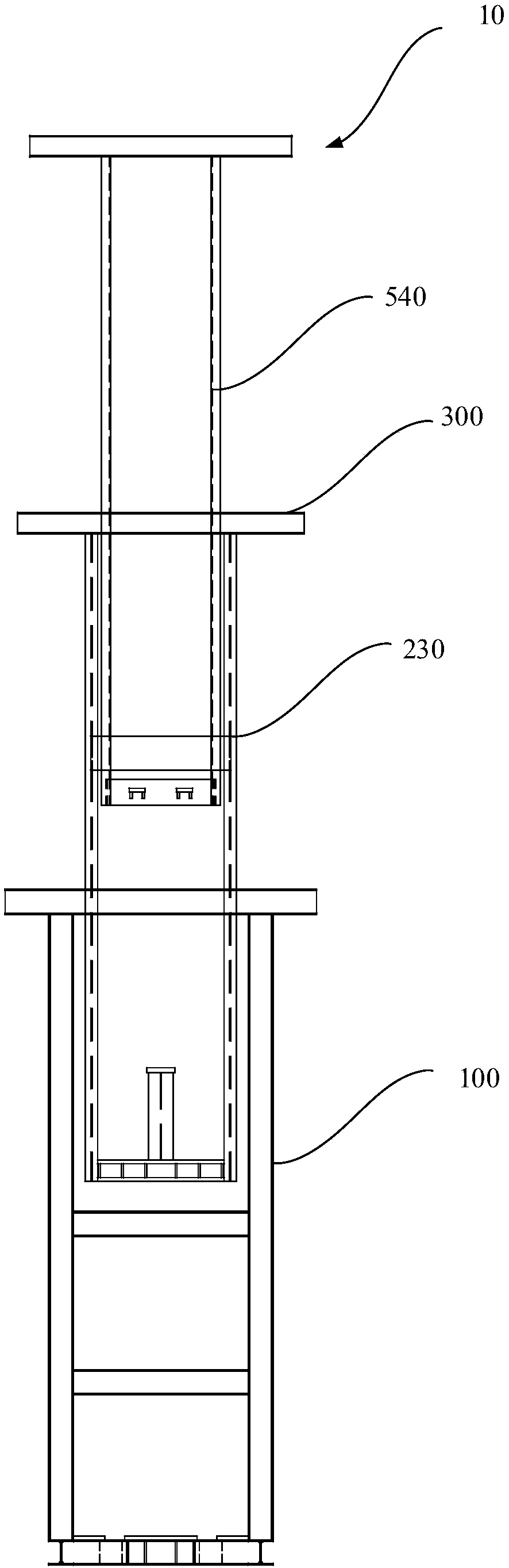

Climbing mechanism and climbing system

Owner:SANY ELECTRIC CO LTD

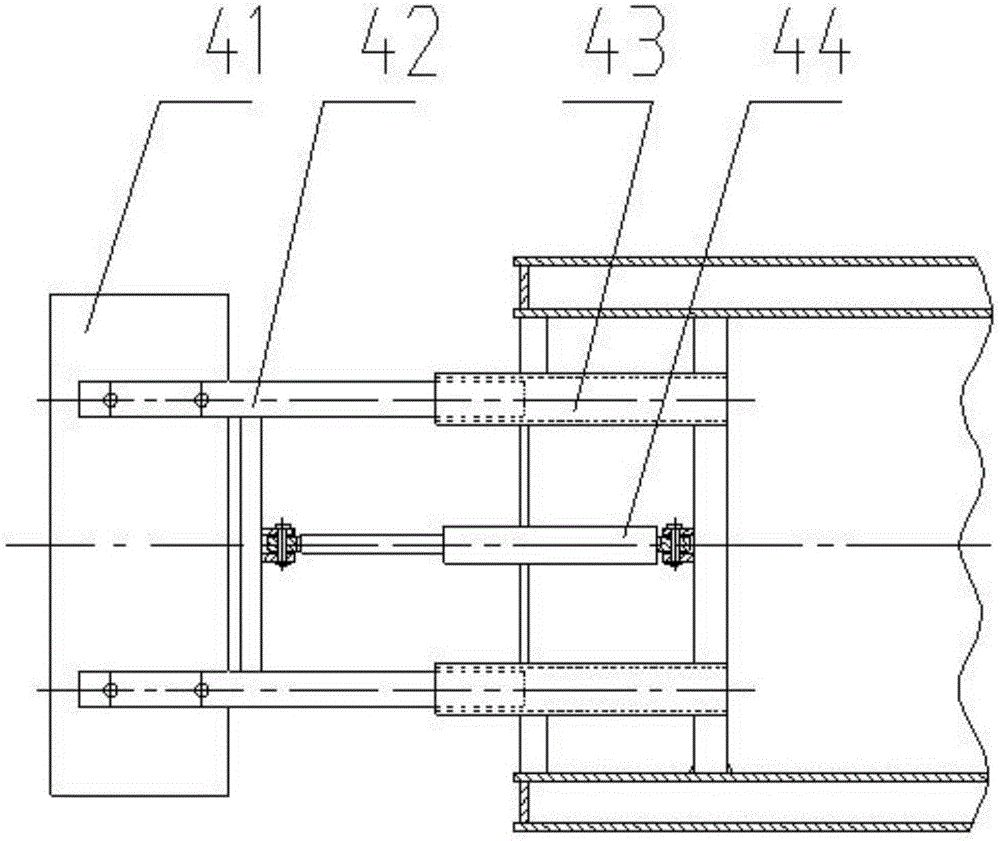

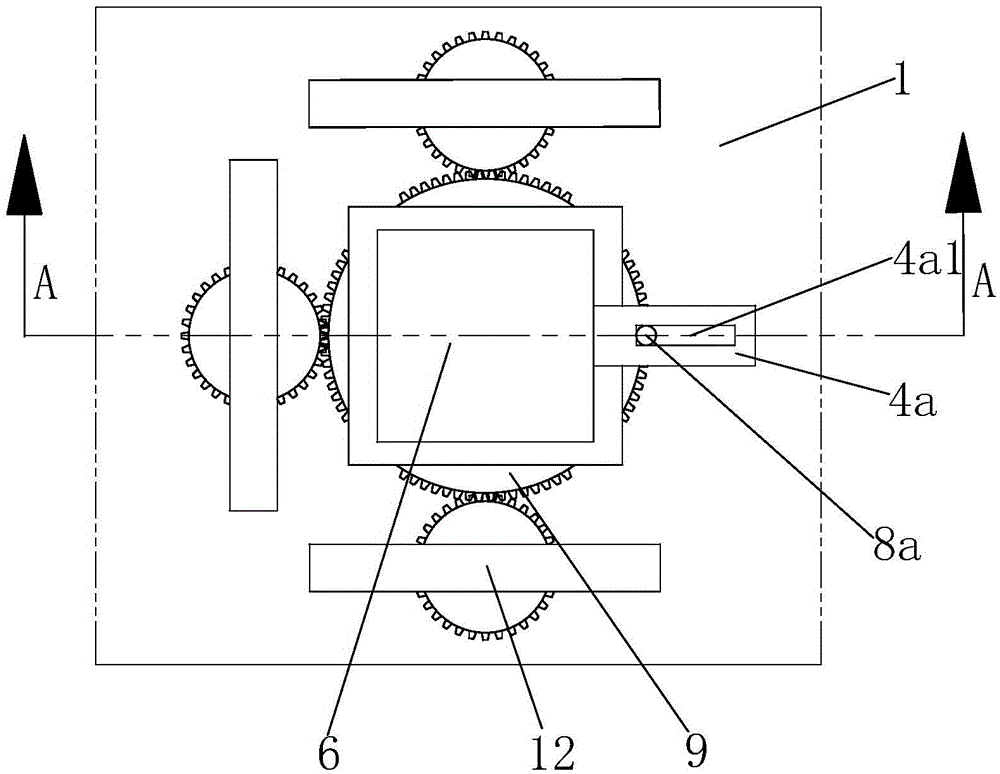

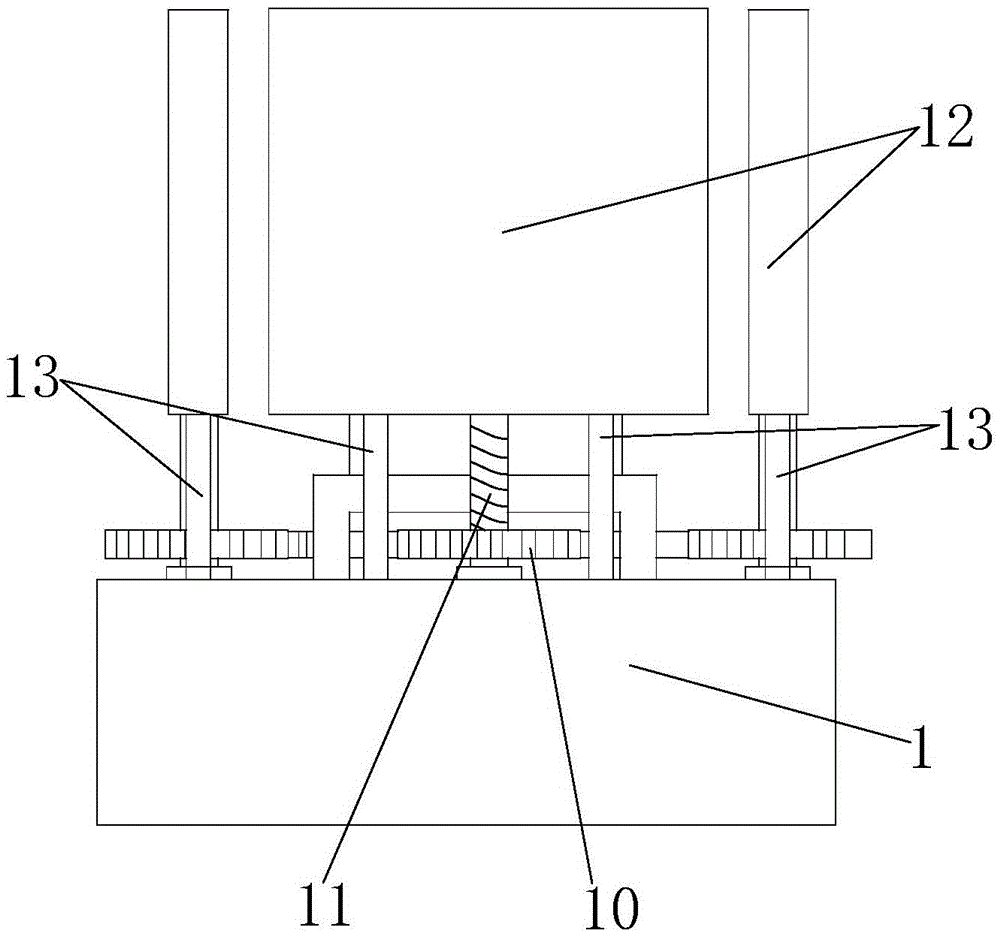

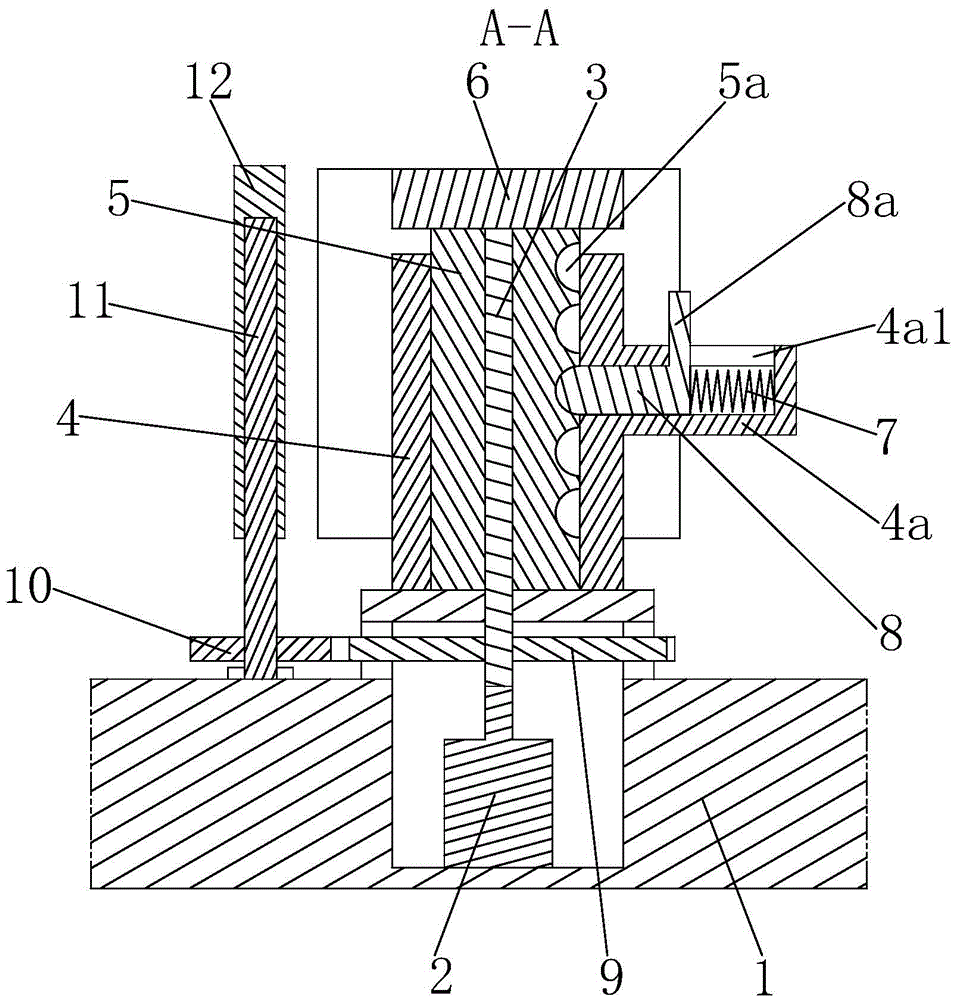

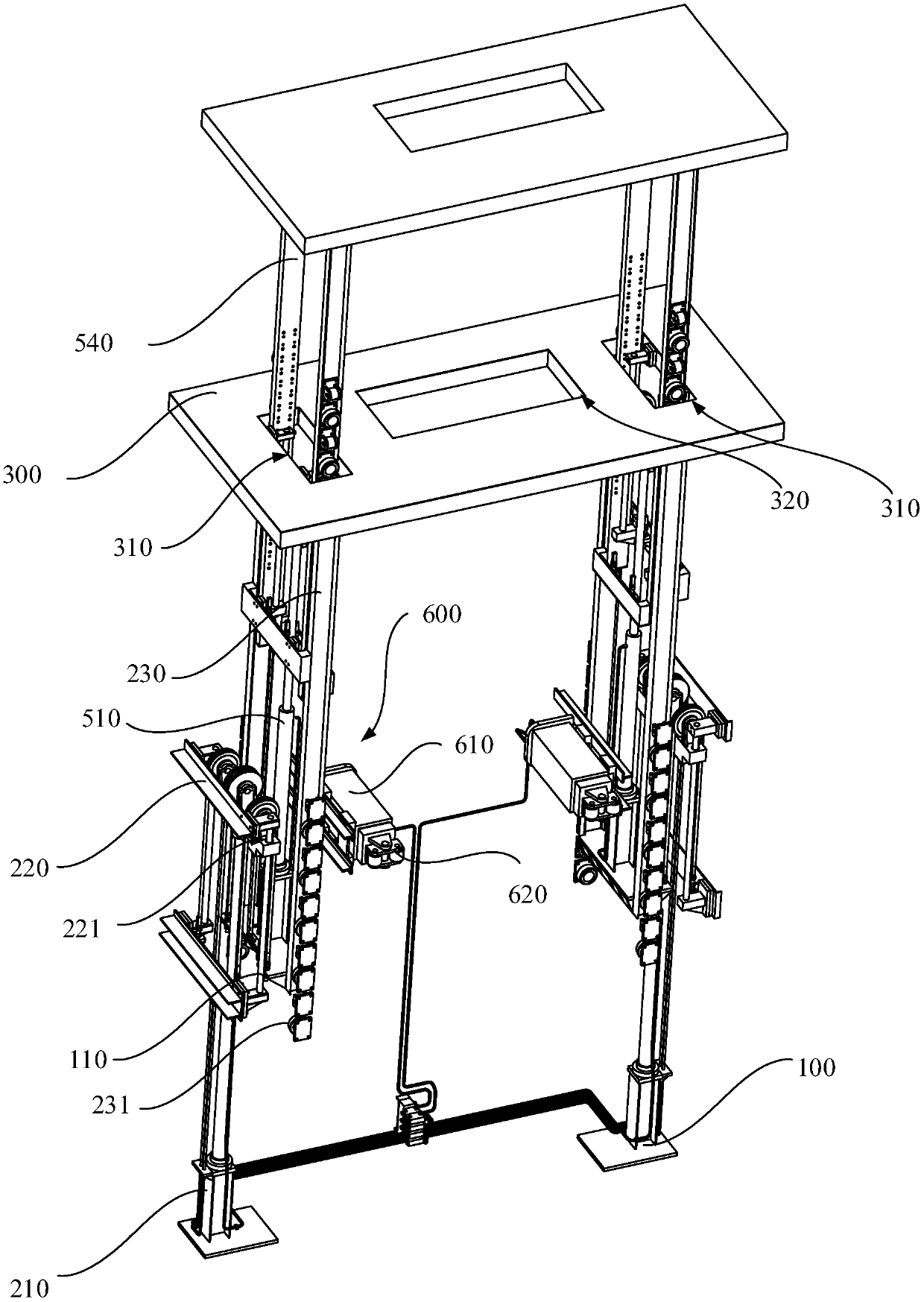

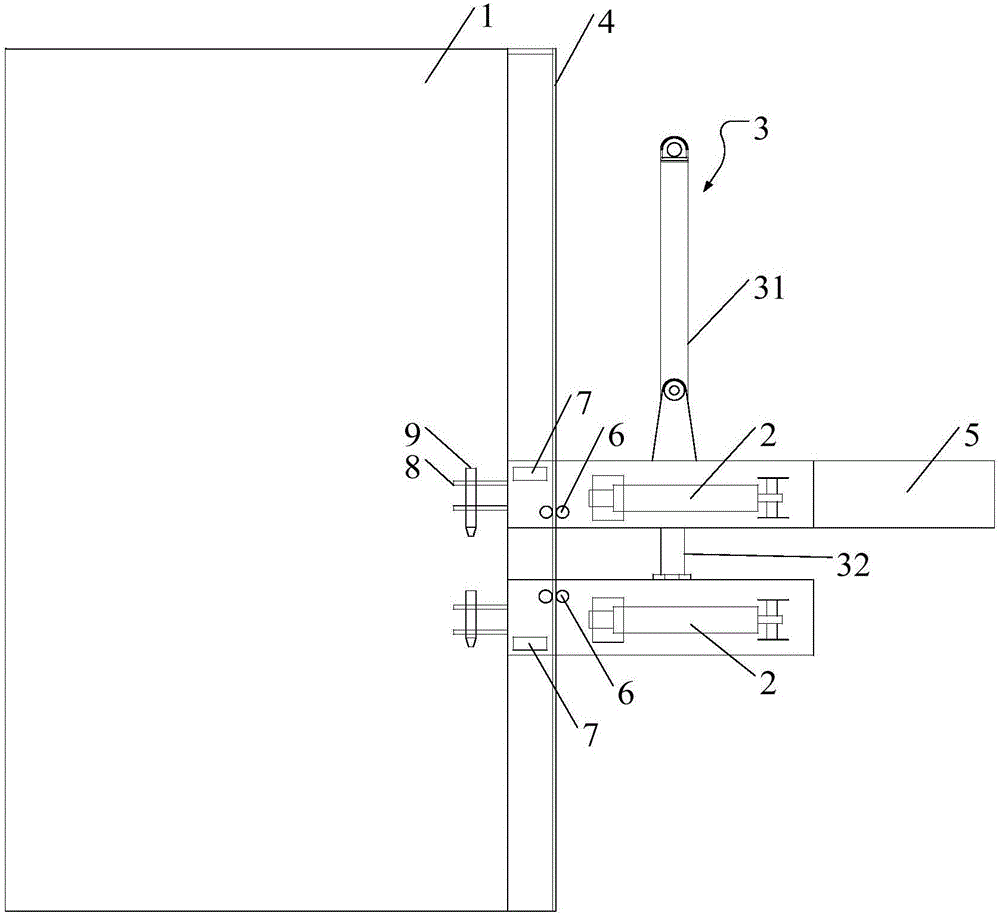

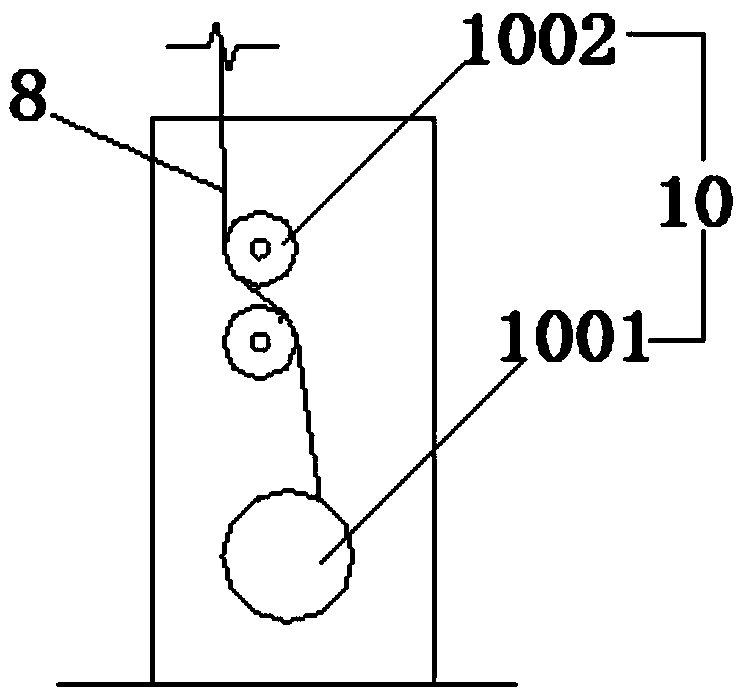

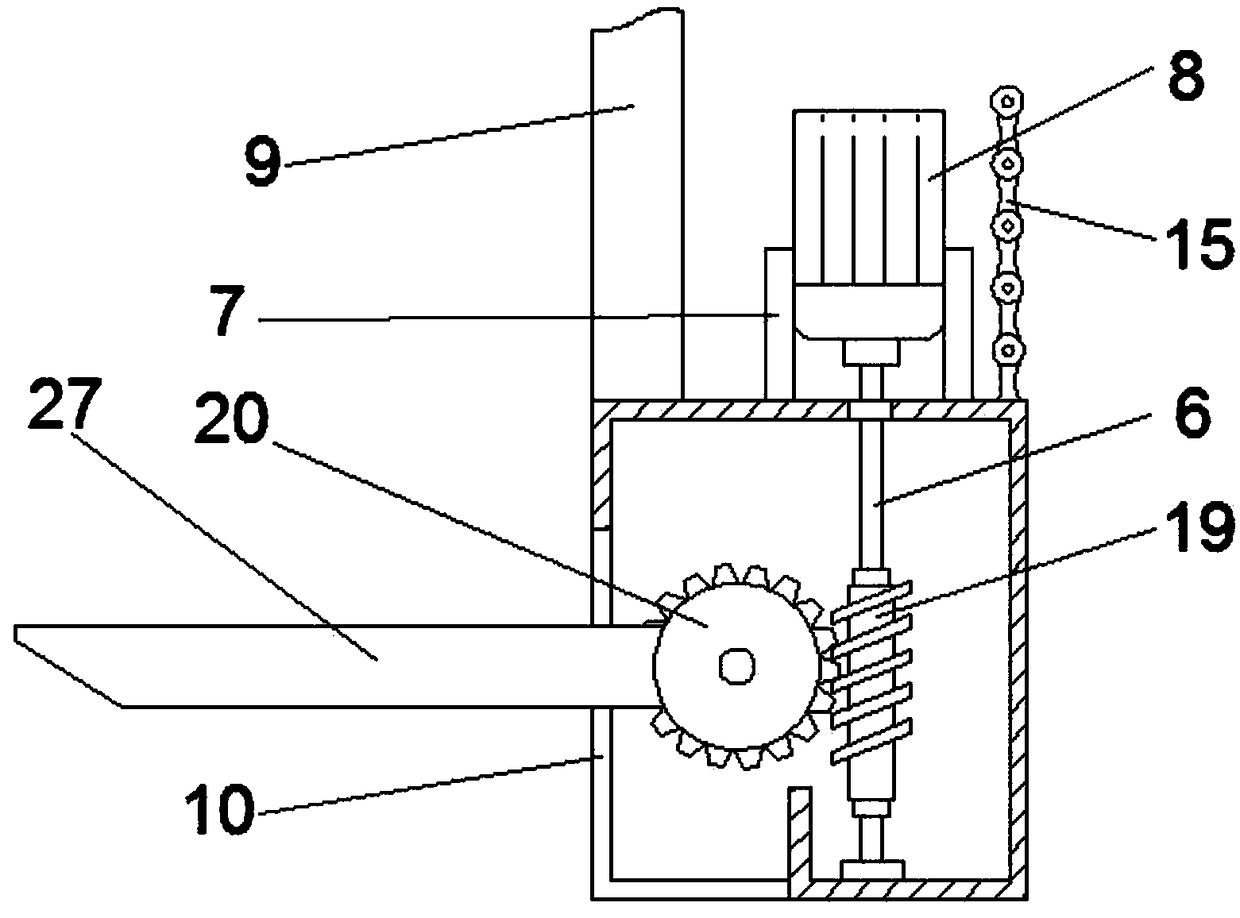

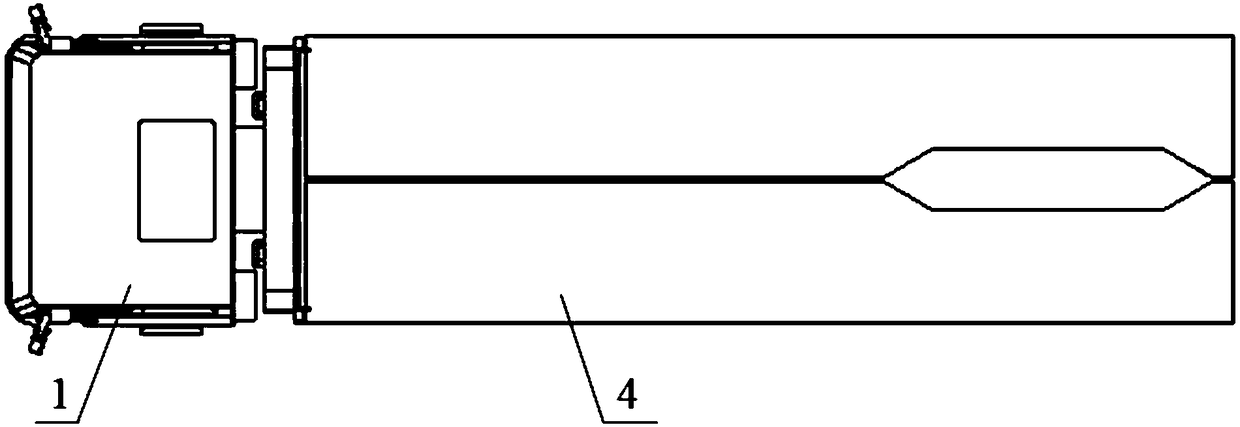

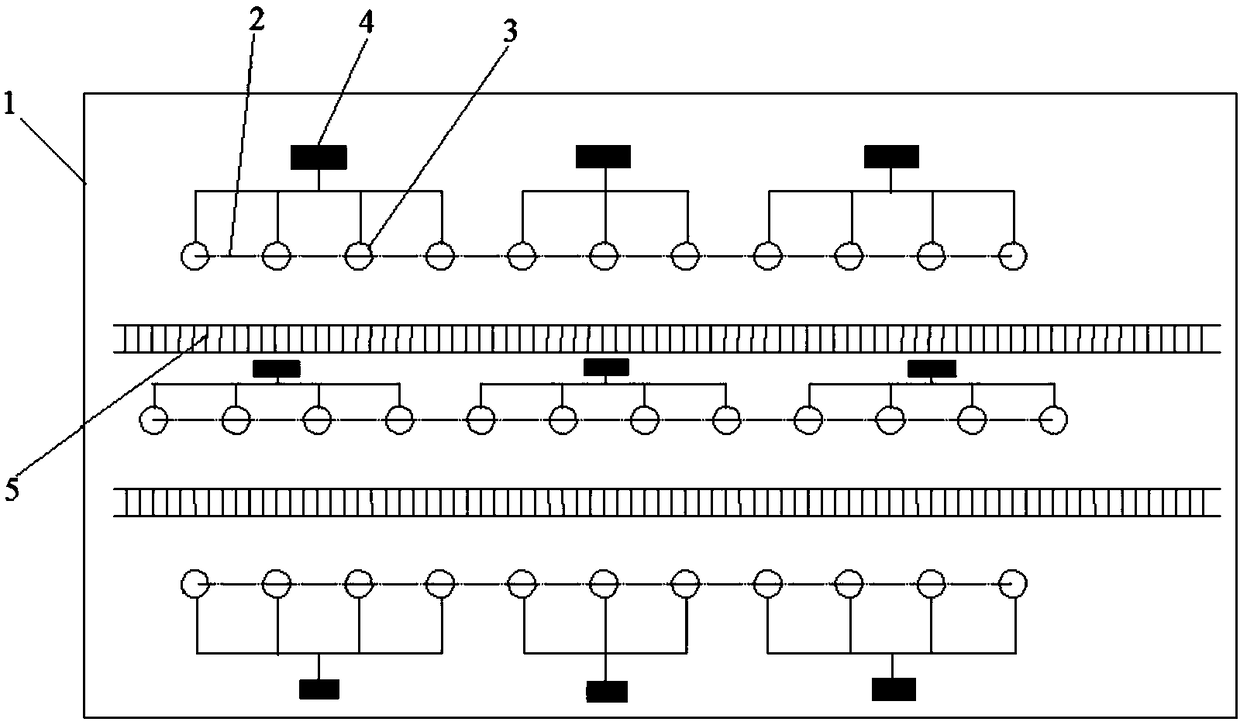

Forward moving system of portal frame

The invention discloses a forward moving system of a portal frame. The forward moving system comprises a frame, an outer portal frame and a forward moving cylinder, wherein a first cylinder head of the forward moving cylinder is fixedly arranged at the lower part of the outer portal frame; a second cylinder head of the forward moving cylinder is fixedly arranged at the lower part of the frame; a left channel steel and a right channel steel are respectively arranged on the two sides of the frame; two rollers are respectively arranged on the external side surfaces of the left side and the right side of the outer portal frame; and the rollers can roll and be positioned in the left channel steel and the right channel steel under an effect of the forward moving cylinder. The forward moving system has the advantages as follows: during the use process, the outer portal frame can be indirectly driven to move forwards and backwards in the frame through the extension and compression of the forward moving cylinder, so that the flexibility of the outer portal frame in the frame is enhanced and the flexibility of a carrier using the forward moving system of the portal frame is further enhanced.

Owner:SUZHOU PIONEER MATERIAL HANDLING EQUIP & TECH

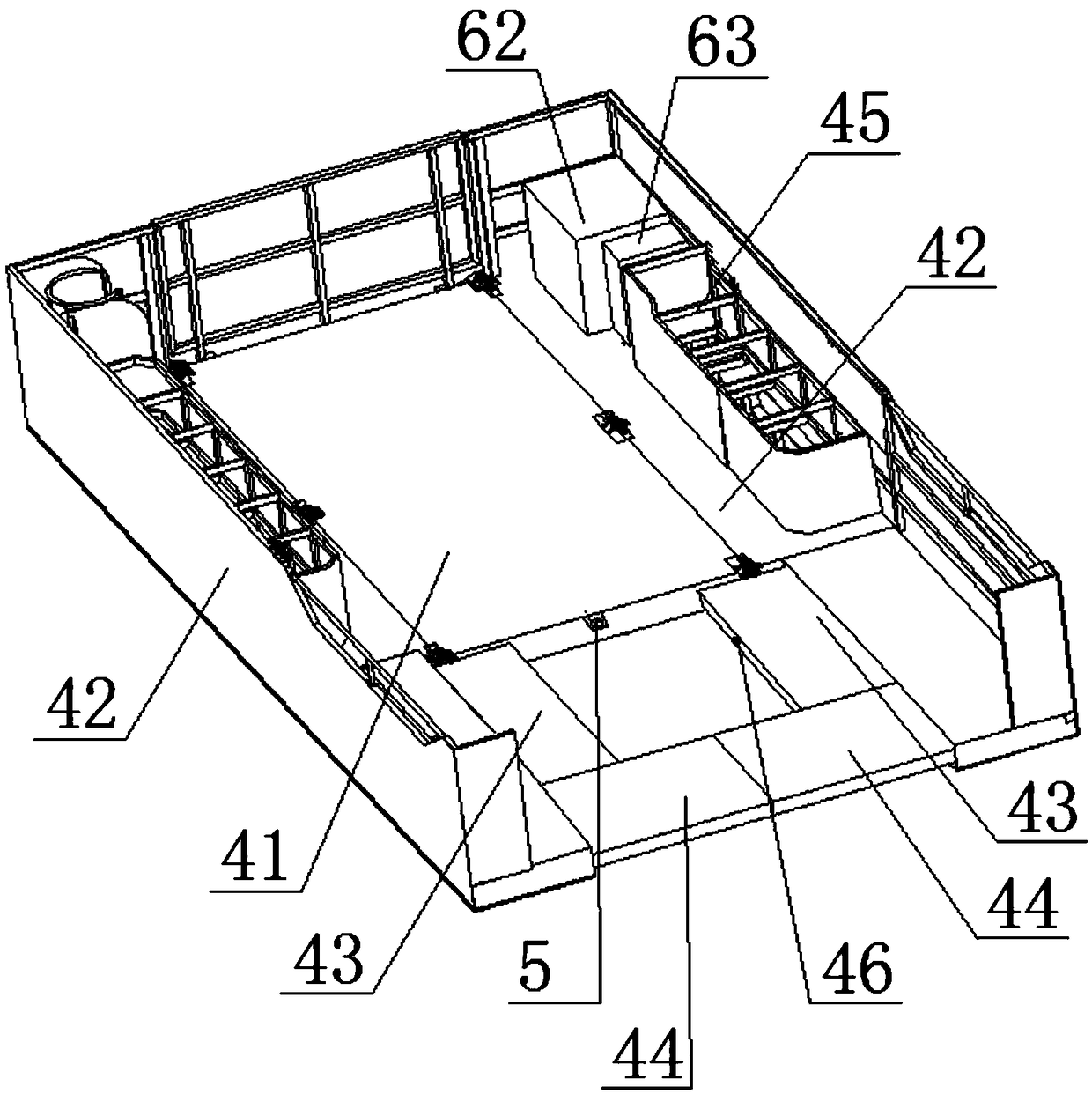

Lifting platform

Owner:STATE NUCLEAR ELECTRIC POWER PLANNING DESIGN & RES INST CO LTD

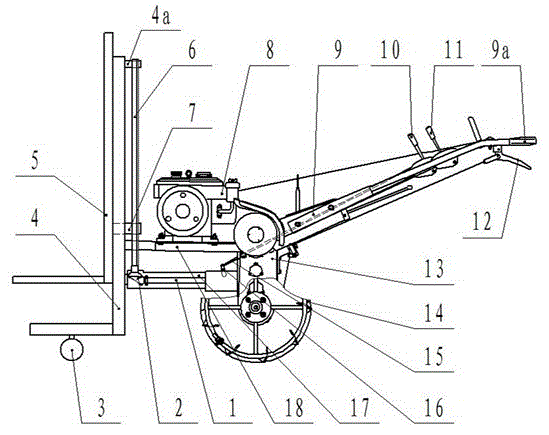

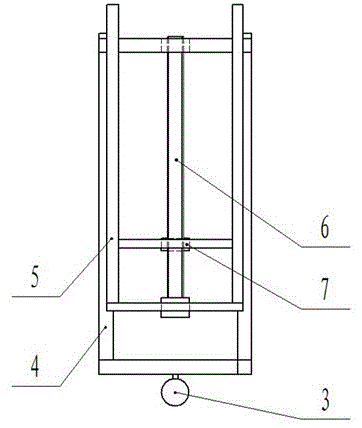

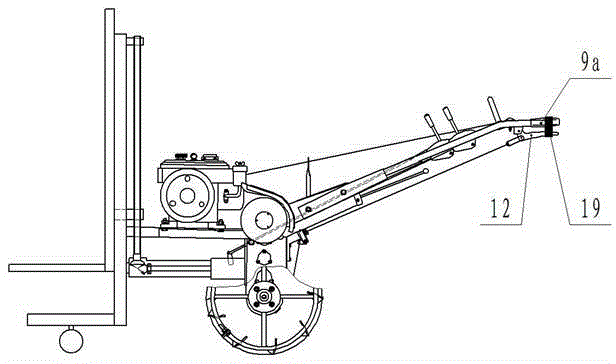

Stacking car driven by mini-tiller

Owner:庞桂福

Wind power generator automatic turning lifter and mounting method

ActiveCN105936470AReasonable structureEasy to installLifting devicesLoad-engaging elementsTurn angleWind force

Owner:CHINA MCC17 GRP

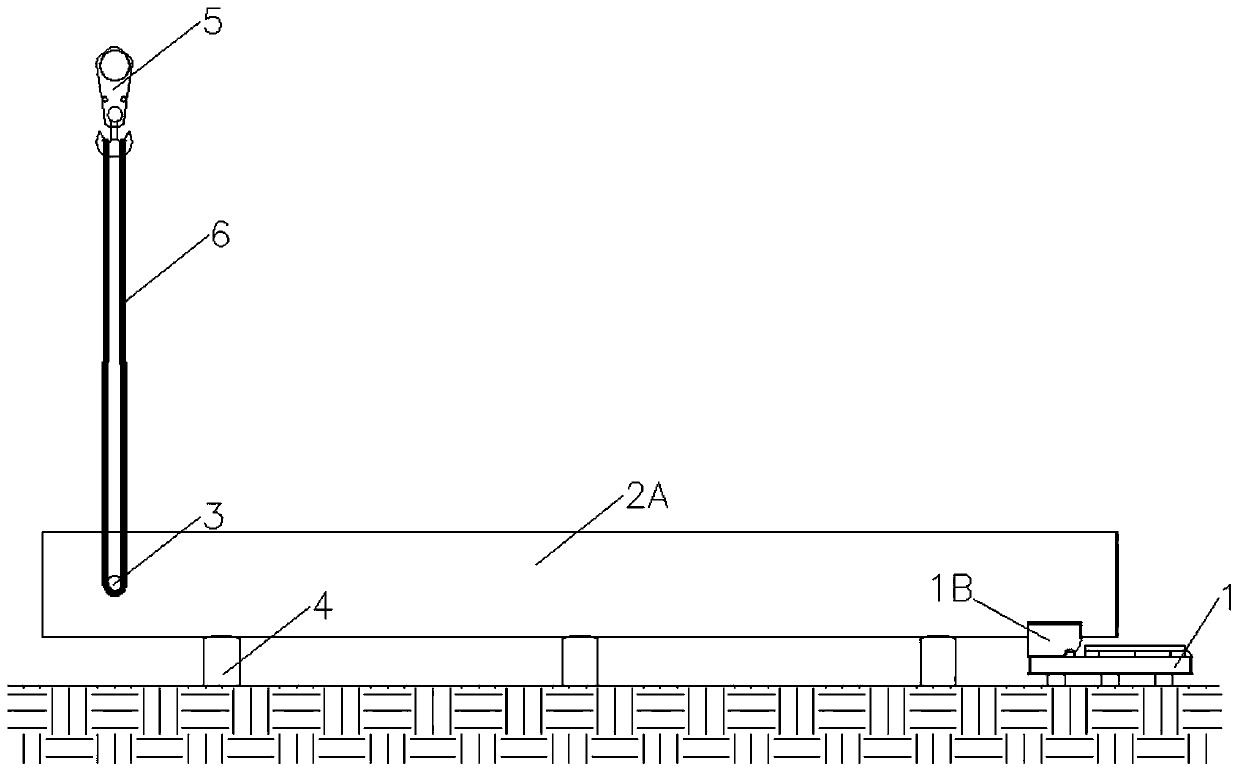

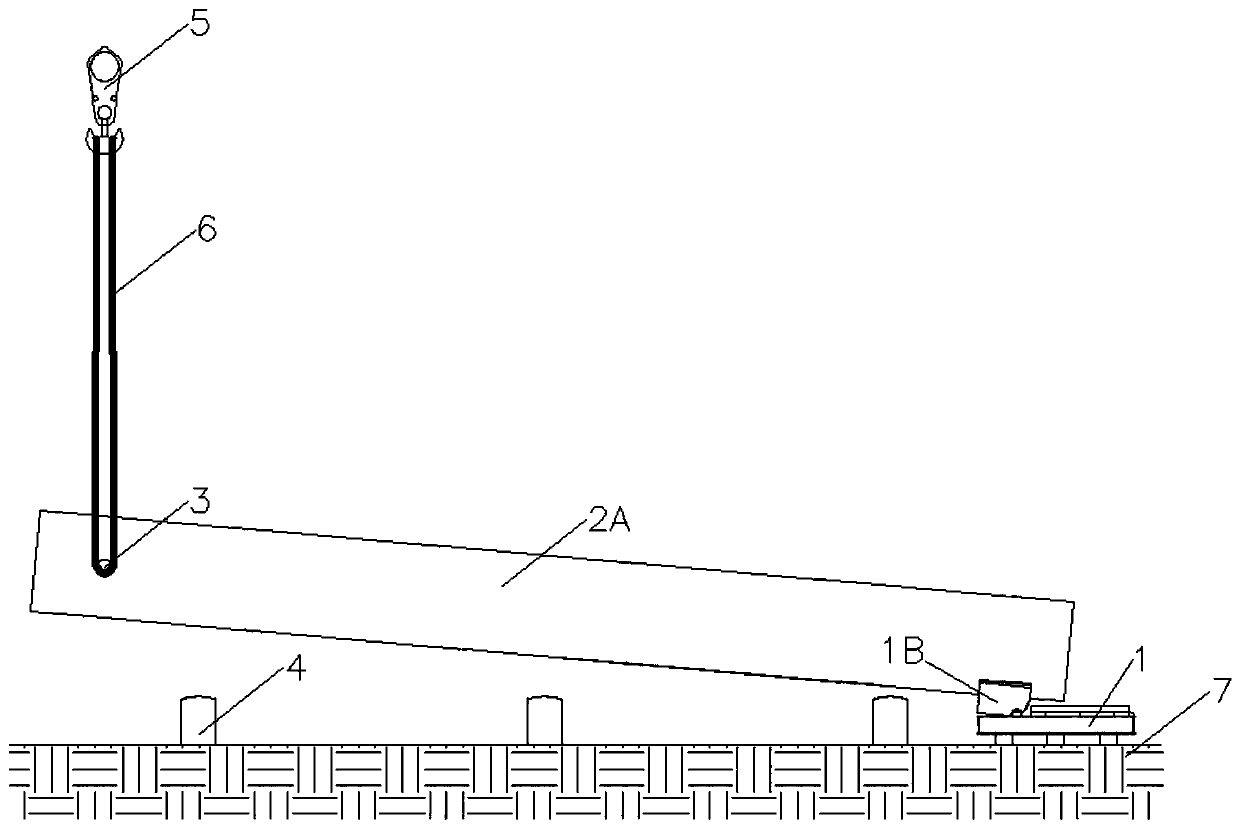

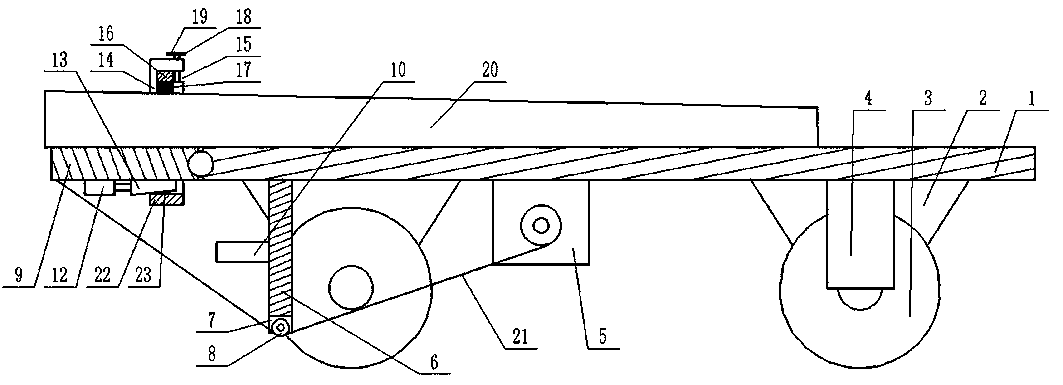

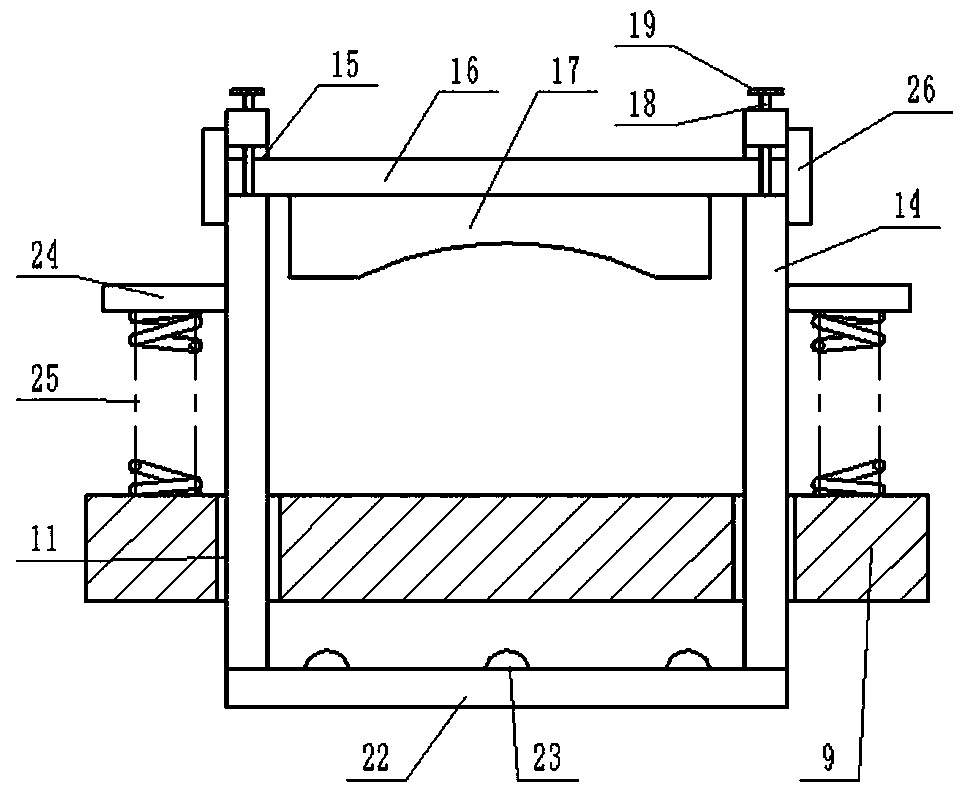

Guide pipe frame shaft line whole piece turnover hoisting process

Owner:OFFSHORE OIL ENG QINGDAO +1

Device convenient to plant telegraph poles

Owner:GUANGDONG POWER GRID CO LTD +1

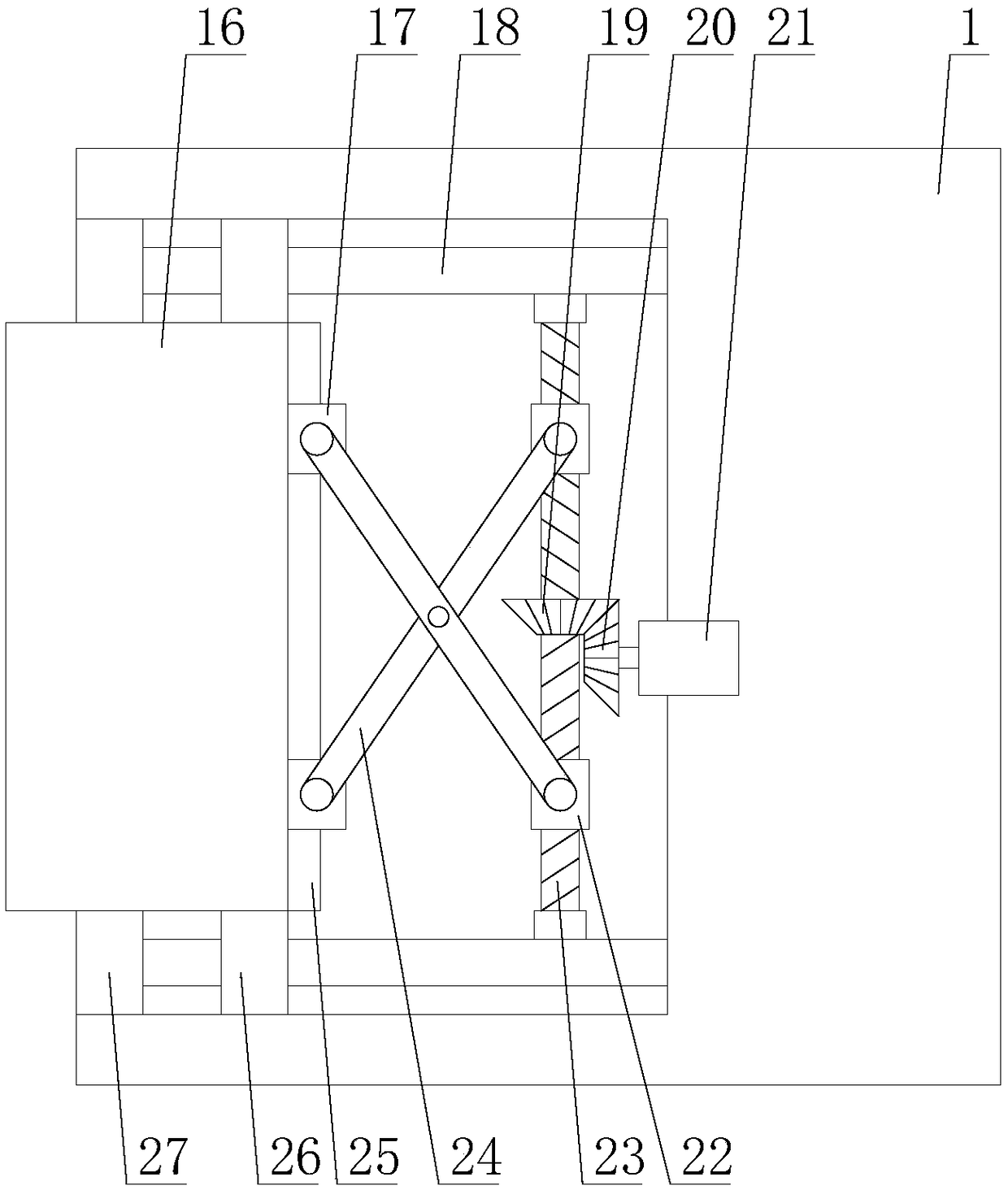

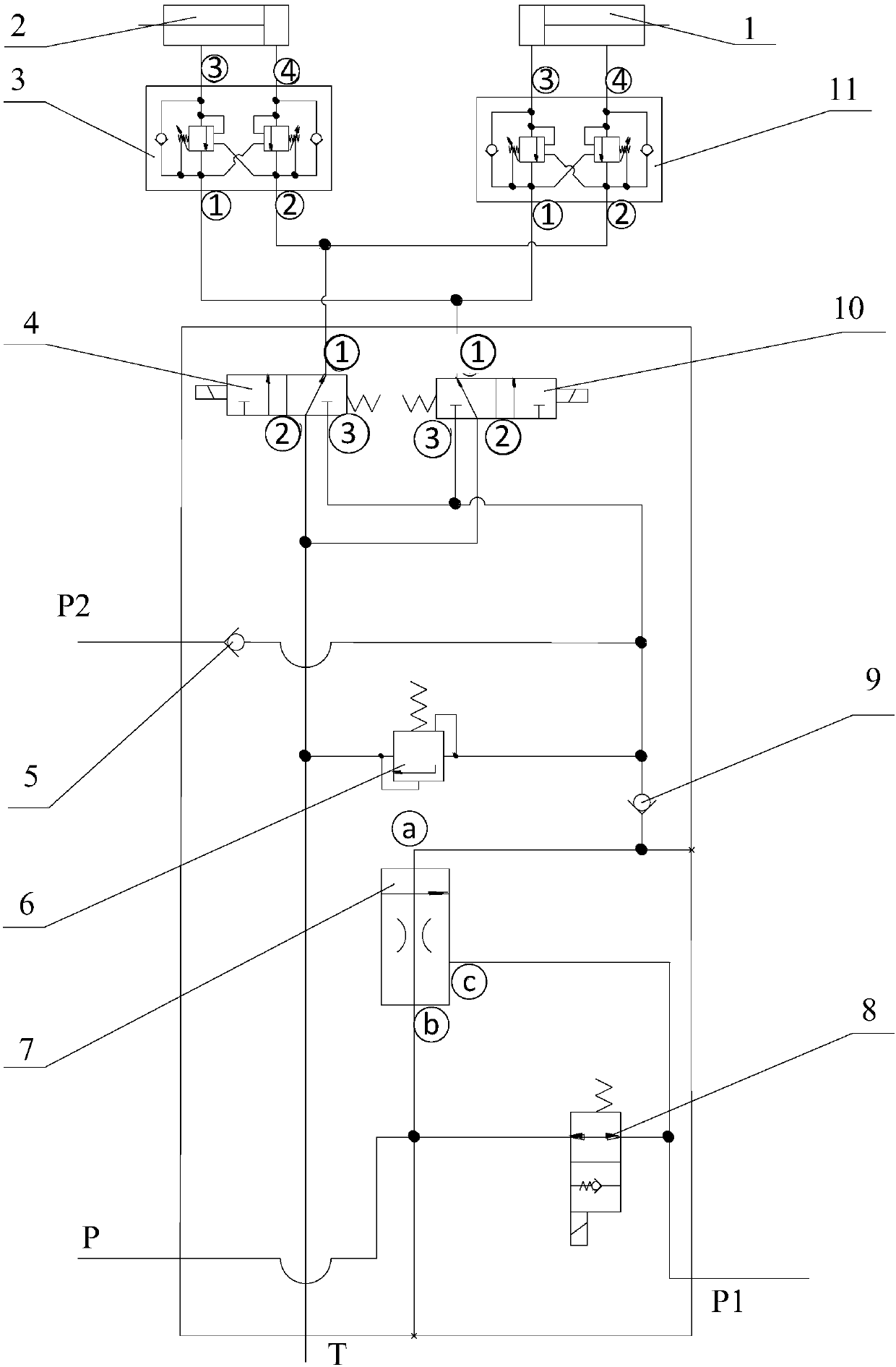

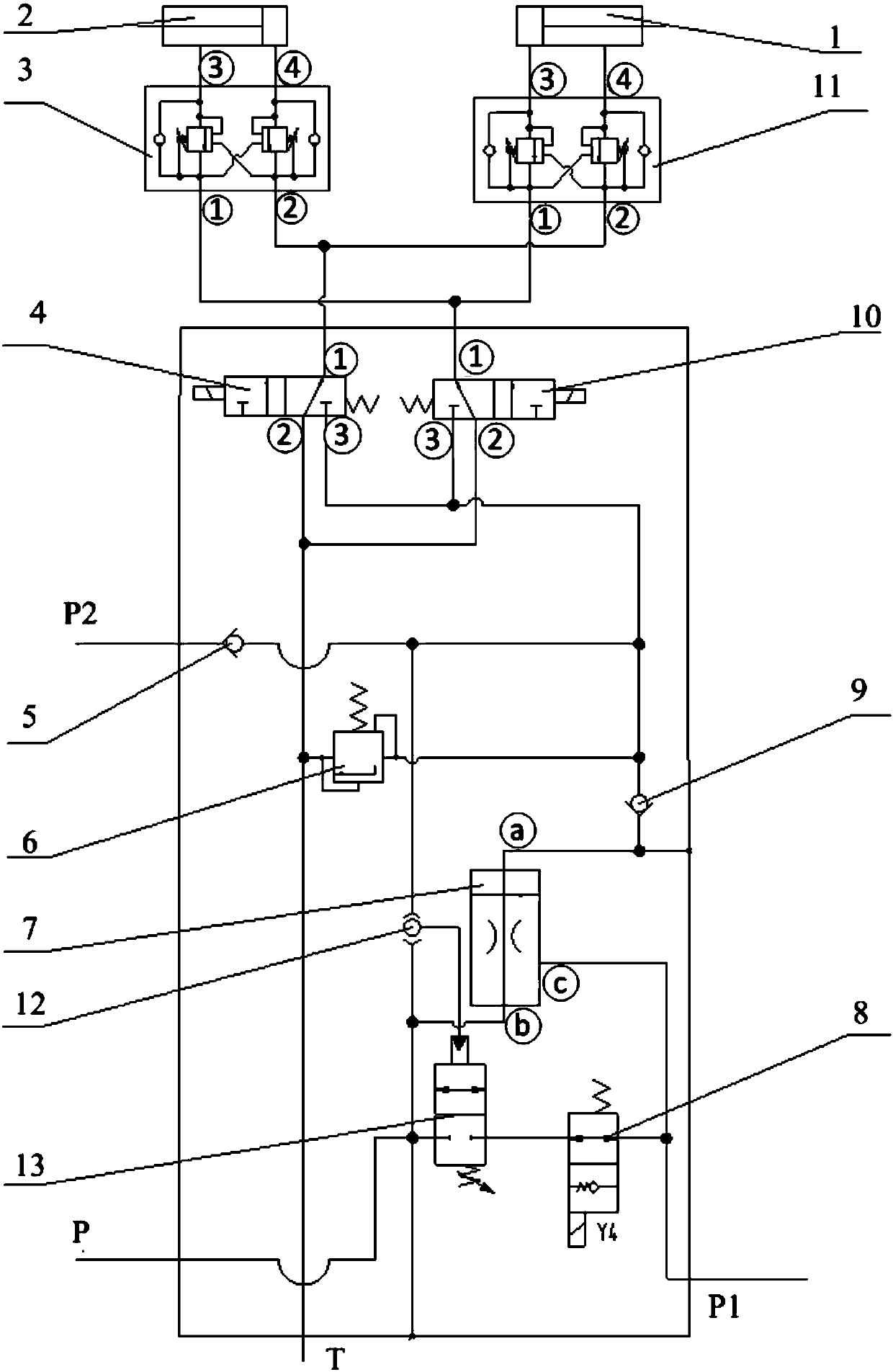

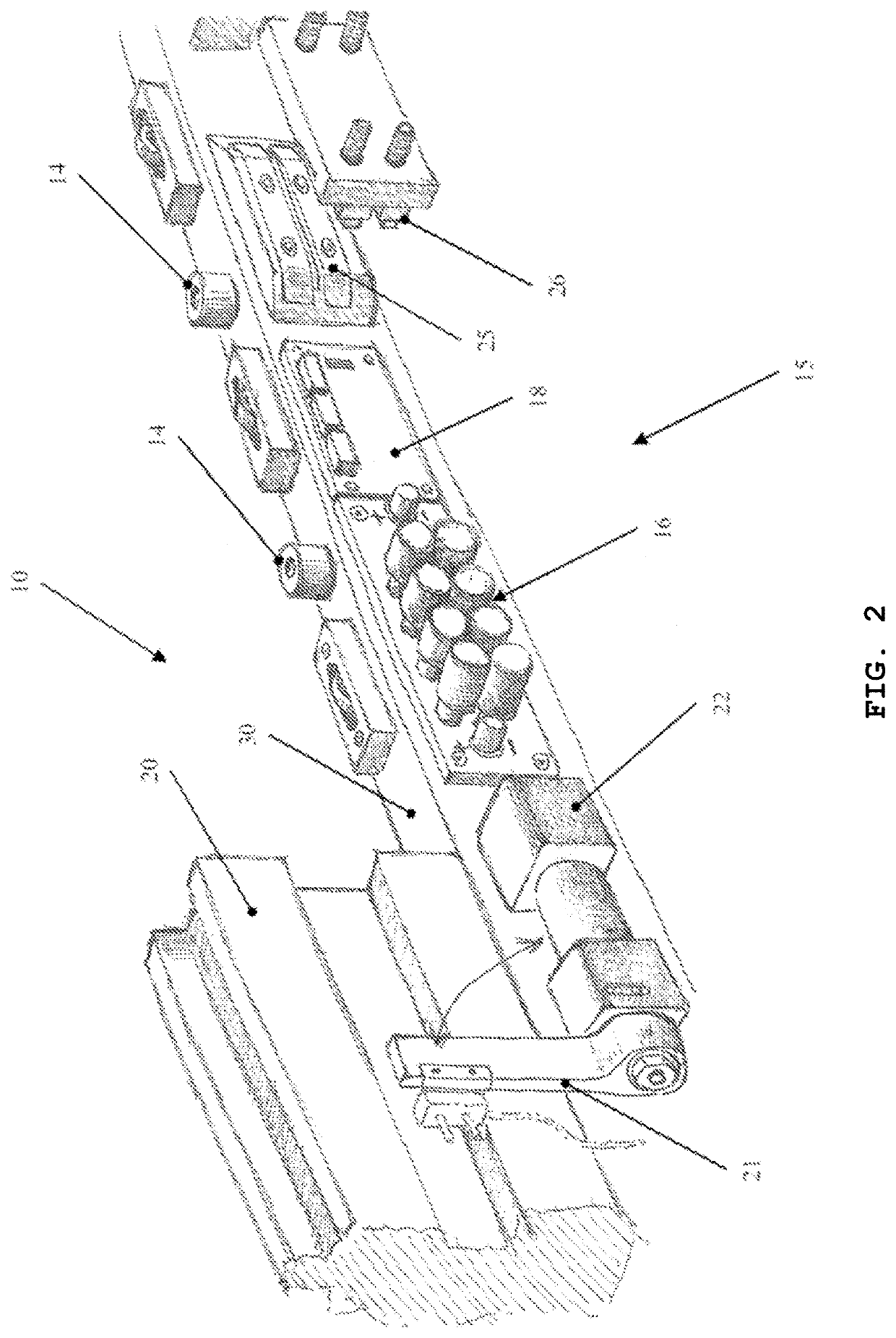

Scissors fork type aerial work platform and hydraulic system thereof

Owner:HUNAN SINOBOOM HEAVY IND

Automated system for handling containers

Owner:LHD SPA

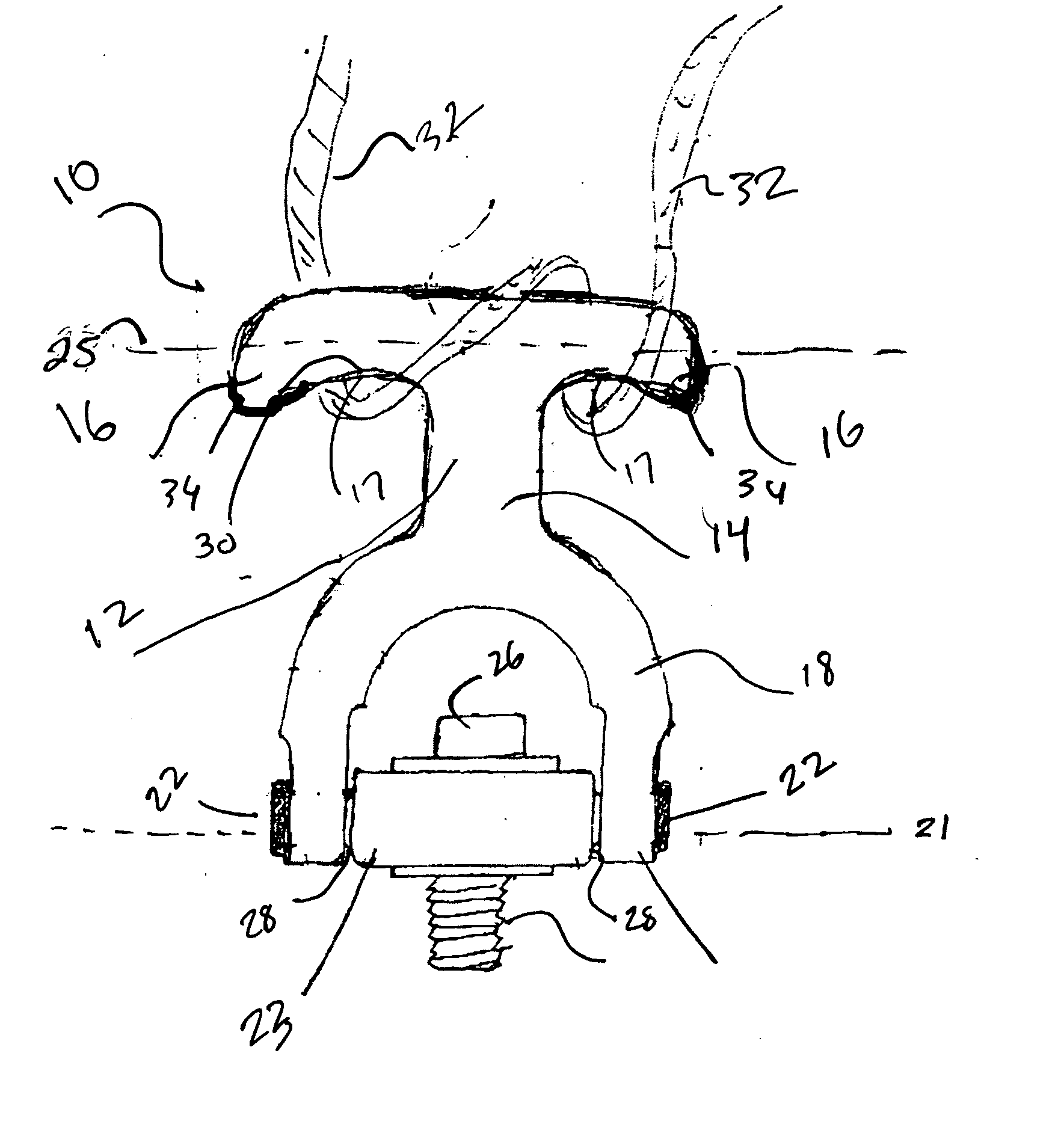

Hoist ring

Owner:MA SHU LAN

Multifunctional forklift portal

Owner:合肥仨力机械制造有限公司

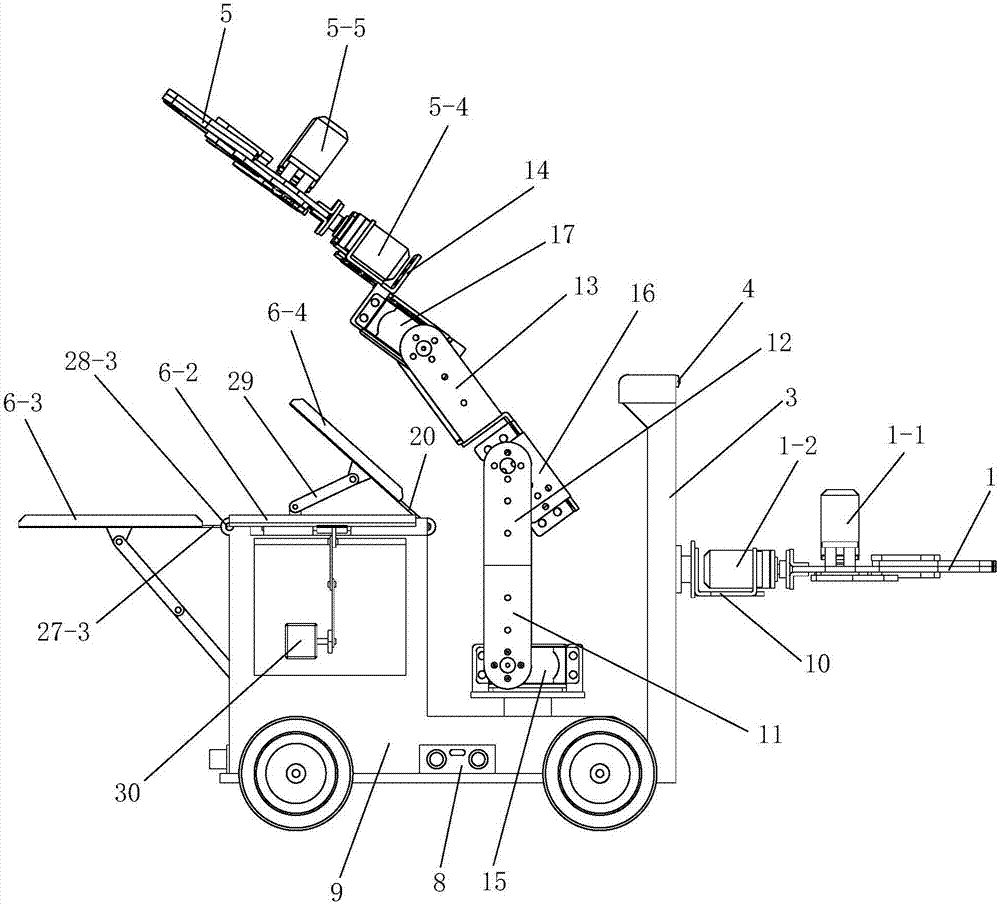

Operating method of multifunctional light operating vehicle based on folding working platform

ActiveCN108751060AAvoid scratchesImprove cleaning efficiencyLifting devicesMouth shapeElectrical and Electronics engineering

Owner:XUZHOU HANDLER SPECIAL VEHICLE

AGV with rapid conversion function

Owner:海神机器人科技有限公司

Seawater semi-submerged ship hydraulic lifting method

ActiveCN108100925AImprove adaptabilityImprove efficiencyLifting devicesUsing optical meansMarine engineeringSeawater

Owner:上海海塔机械制造有限公司 +1

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap