Overturning detection device for overhead working truck

A technology of aerial work vehicle and detection device, which is applied in the direction of lifting device, transportation and packaging, load hanging components, etc., which can solve the problems of difficult replacement, inconvenient replacement, high cost, etc., and achieve simple installation, convenient maintenance and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

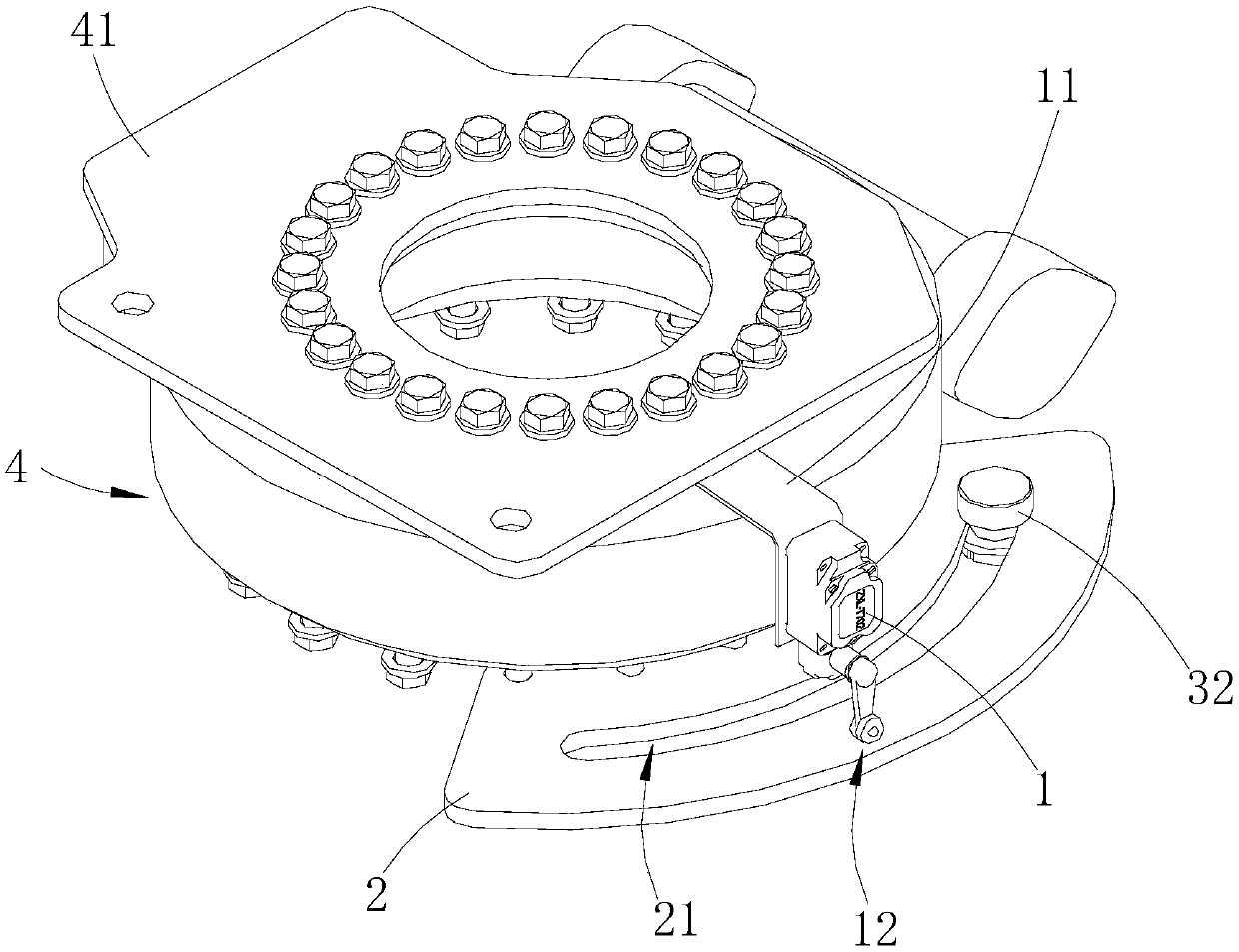

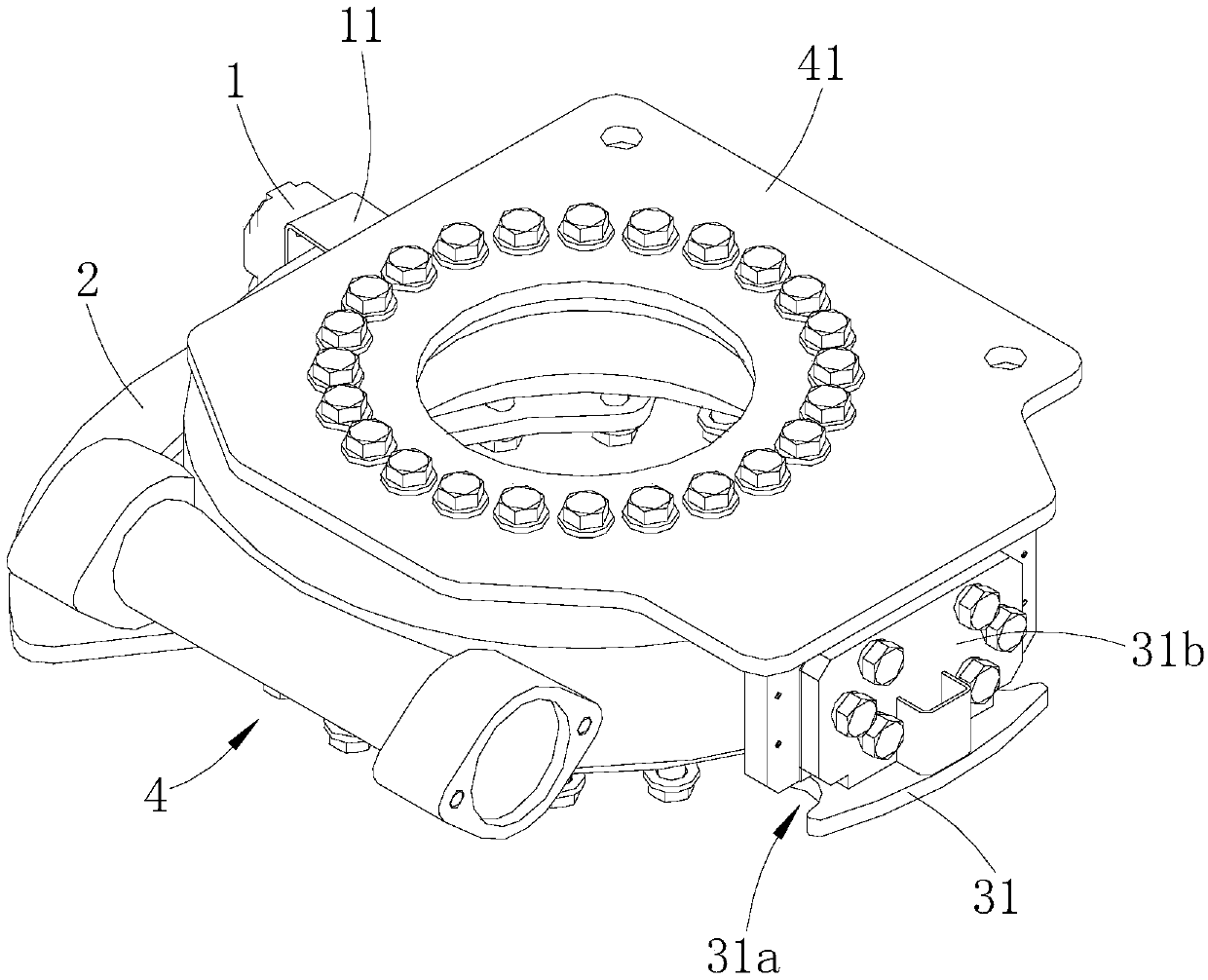

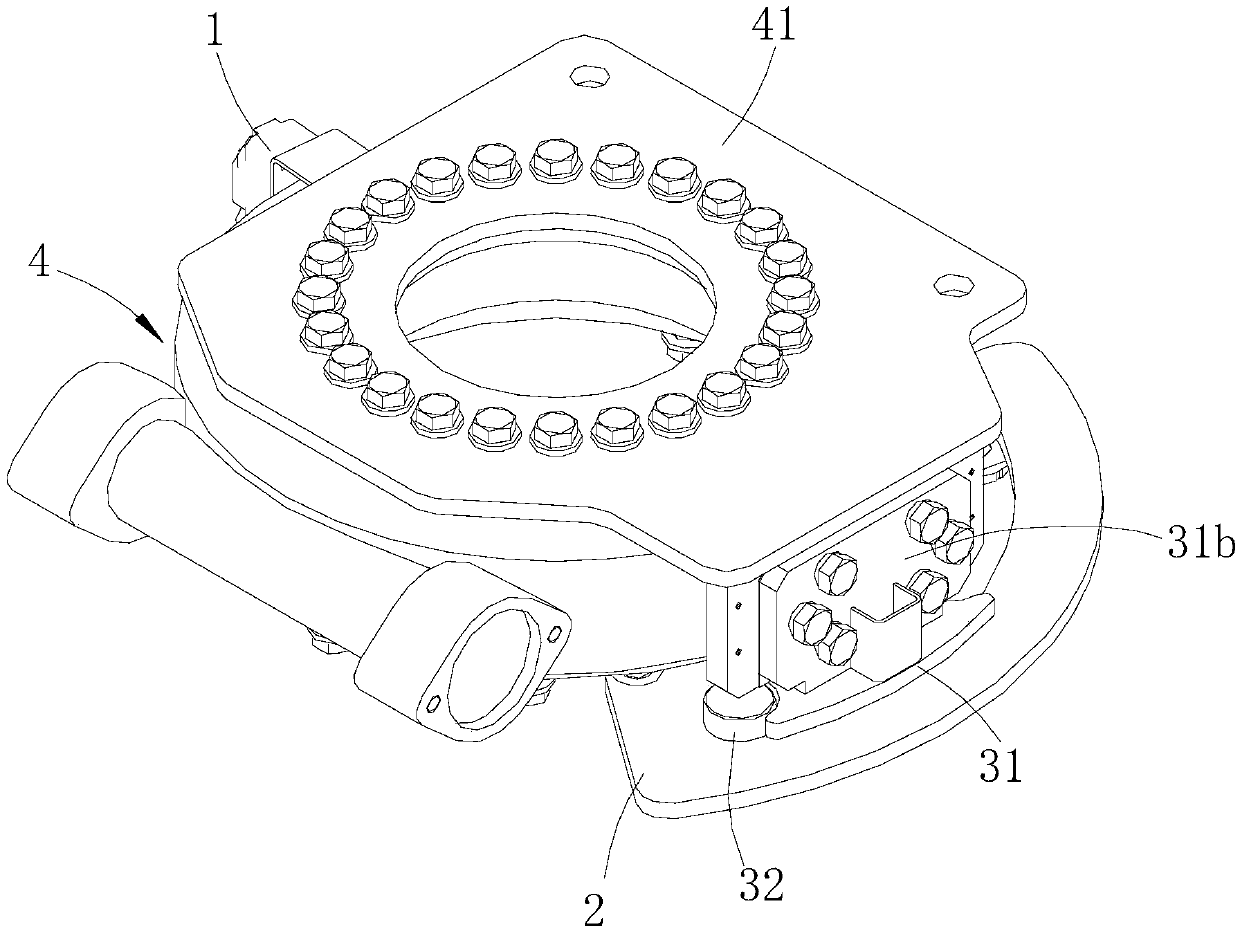

[0018] Such as Figures 1 to 4 shown

[0019] The rotation detection device includes a detection switch 1, an area detection board 2 and a limit assembly.

[0020] The detection switch 1 is fixed with the rotating part 41 of the aerial work vehicle turning mechanism 4 by the first mounting plate 11, and the detecting switch 1 follows the rotating part 41 of the aerial working vehicle turning mechanism 4 to rotate synchronously, and the contact end of the detecting switch 1 is equipped with a roller 12.

[0021] The area detection plate 2 is a fan-shaped plate, and the area detection plate 2 is welded to the fixed part of the slewing mechanism 4 of the aerial work vehicle. There is an arc-shaped chute 21 on the area detection plate 2. The direction of the chute 21 is consistent with the direction of the aerial work vehicle. The rotation tracks of the slewing mechanism 4 are consistent, the area detection plate 2 of the contact end of the detection switch 1 cooperates, and the rol

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap