Sludge suction system of sewage suction truck

A suction system and sewage suction truck technology, which is applied to mechanically driven excavators/dredgers, earth movers/shovels, construction, etc., can solve the problem of not being able to visually observe whether the suction pipe is blocked by impurities and waste resources , high cost and other issues, to achieve the effect of low cost, resource saving and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention is described in detail below in conjunction with accompanying drawing and specific embodiment:

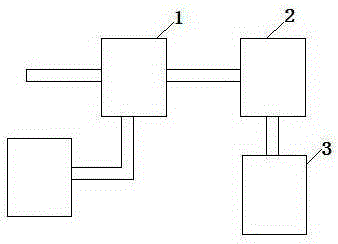

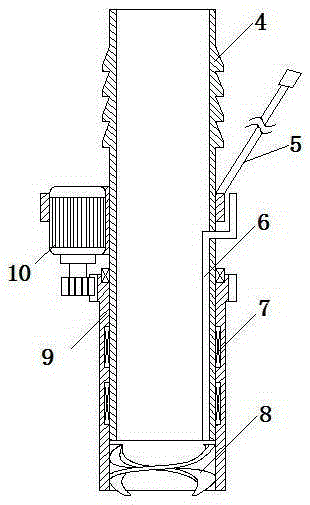

[0029] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, the sludge suction system of the sewage suction truck of the present invention includes a suction device 1, a connection device 2 of the suction device 1 and an exhaust device 3 for sucking engine exhaust of the sewage truck. The suction device 1 includes a suction pipe 4 , a transmission sleeve 9 , a motor 10 , a crushing knife 8 and an air pipe 6 . The transmission sleeve 9 is set on the inlet end of the suction pipe 4 . Needle rollers or bearings 7 may be arranged between the transmission sleeve 9 and the suction pipe 4 for reducing the frictional force between the transmission sleeve 9 and the suction pipe 4 . The motor 10 is fixedly connected to the suction pipe 4 and the rotating shaft of the motor is connected to the transmission sleeve 9 in transmission. The cru

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap