Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

17 results about "Portal frame" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Portal frame structures are designed to span between supports and rely on fixed joints with moment resisting capacity where vertical supports connect to horizontal beams or trusses. Portal frame structures can be constructed using a variety of materials and methods. These include steel, reinforced concrete and laminated timber such as glulam. The connections between the columns and the rafters are designed to be moment-resistant, i.e. they can carry bending forces. "They were first developed in the 1960s, and have now become the most common form of enclosure for spans of 20 to 60 m"

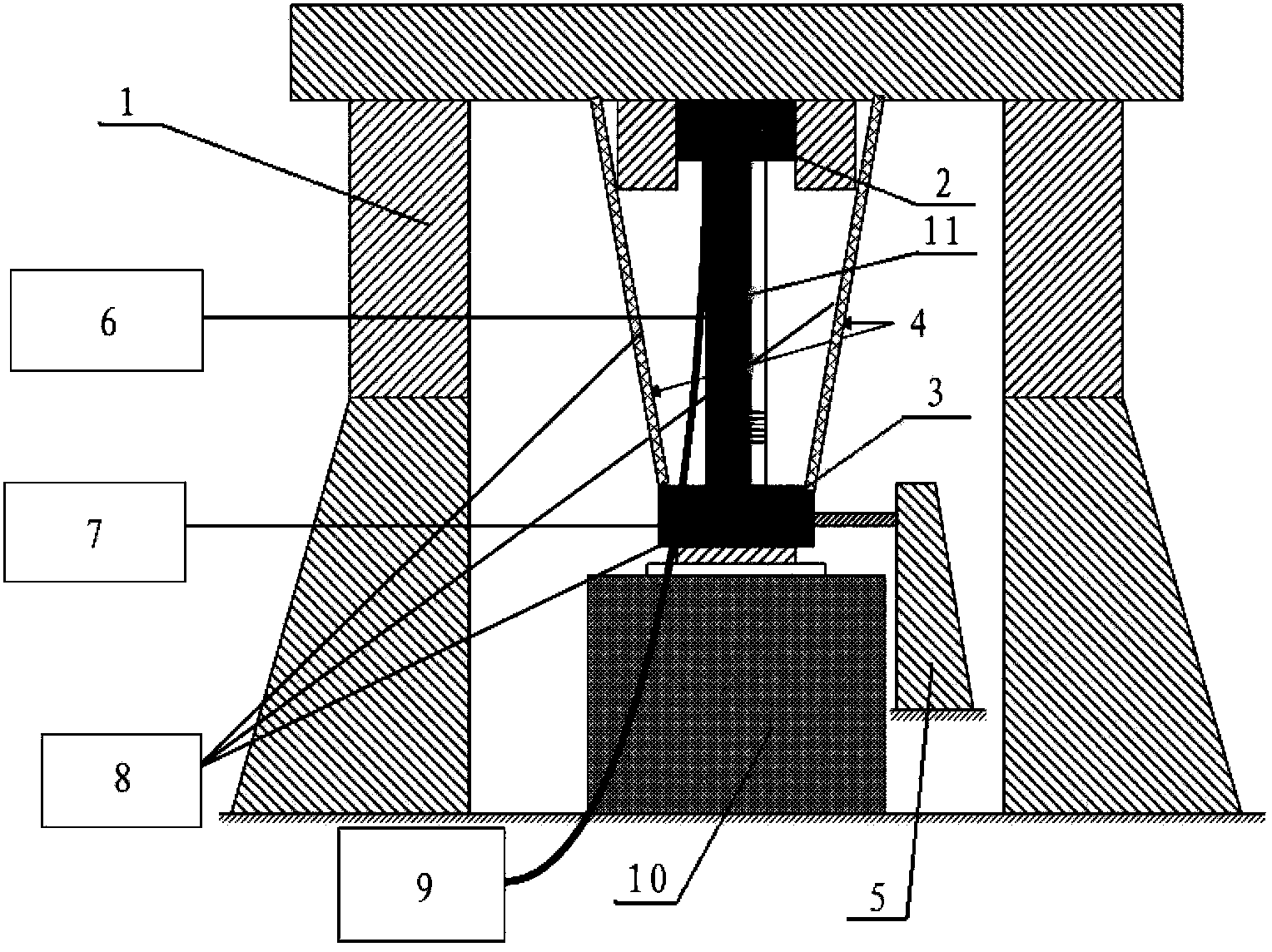

Pressure balancing system and method for rocket conveying pipeline system vibration test

ActiveCN104236836AEnsure degrees of freedomReduce the effect of thrustVibration testingControl systemMonitoring system

Owner:BEIJING INST OF STRUCTURE & ENVIRONMENT ENG +1

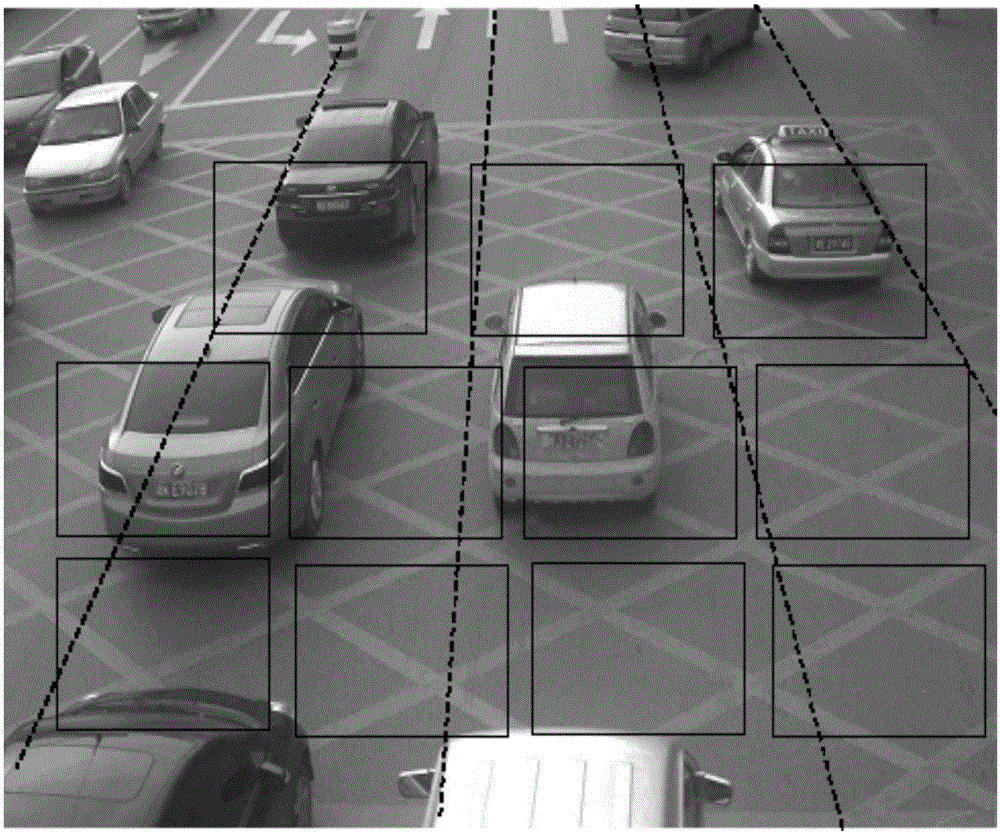

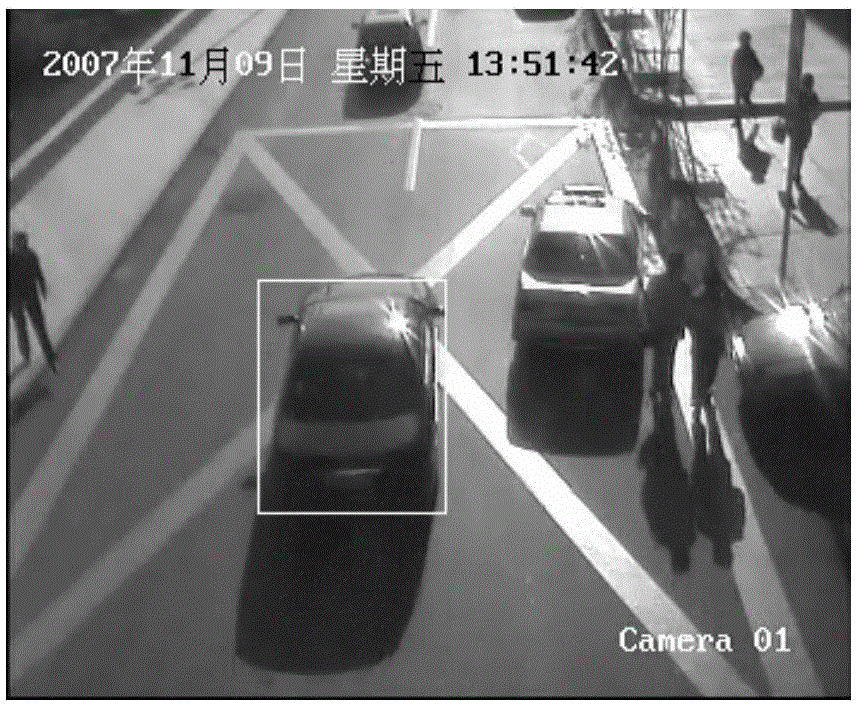

System and method of monitoring illegal traffic parking in yellow grid line area

InactiveCN105046948AEffectively filter out interferenceFilter out noiseDetection of traffic movementComputer monitoringImage segmentation

Owner:TIANJIN UNIV

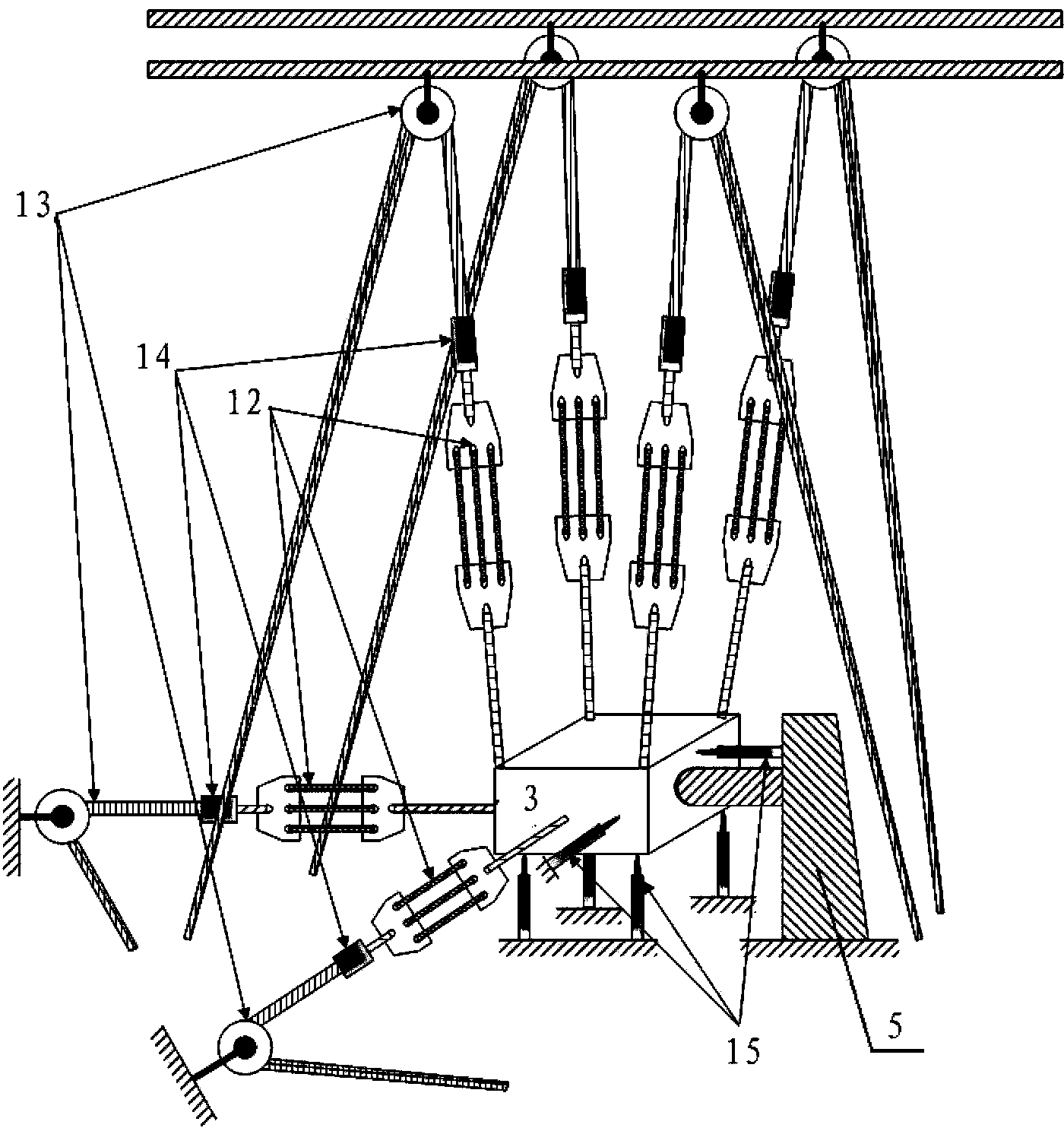

Track suspension type multifunctional orchard mechanical device

PendingCN113228866AIncrease economic benefitsReduce labor intensityWatering devicesCultivating equipmentsFruit treeAgricultural science

Owner:SOUTH CHINA AGRI UNIV

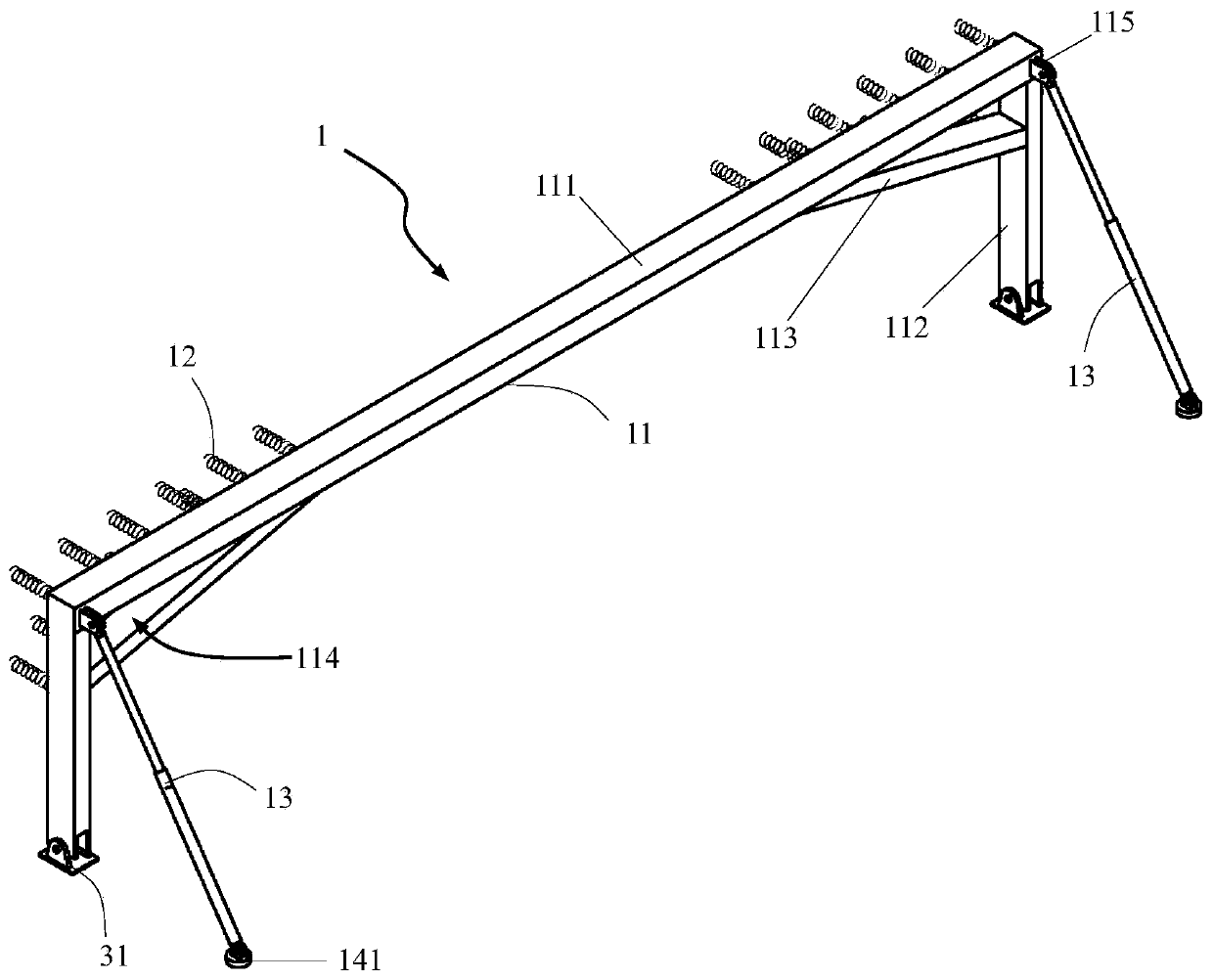

Bridge ship-collision-prevention height limiting frame

PendingCN110528421AEasy to installEasy maintenanceClimate change adaptationShipping equipmentPortal frameCollision prevention

Owner:CHINA MERCHANTS CHONGQING COMM RES & DESIGN INST

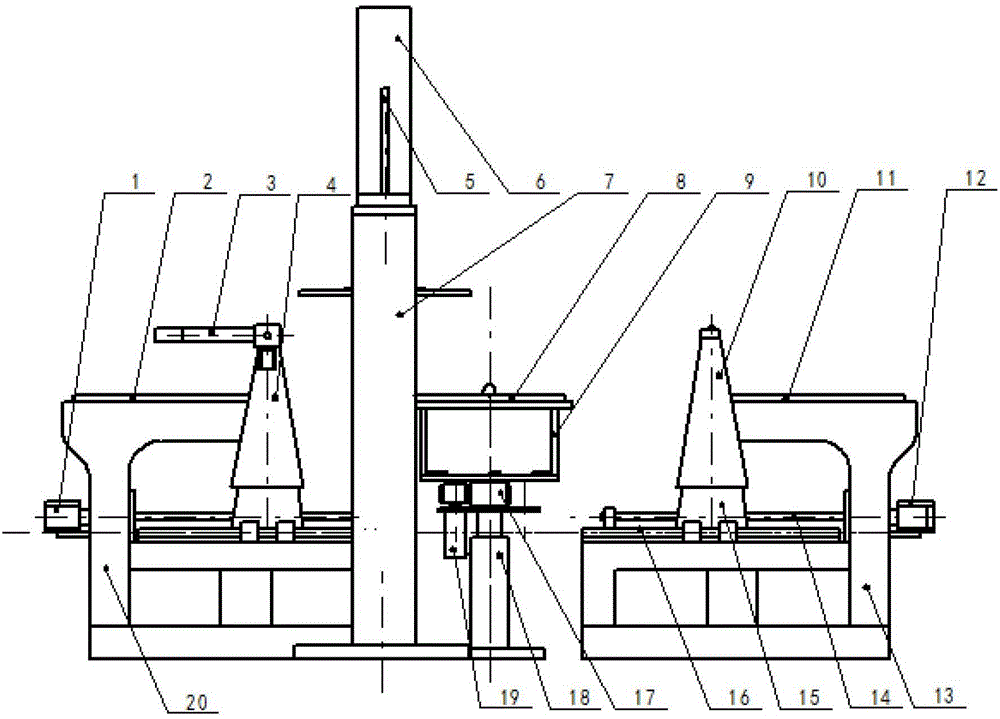

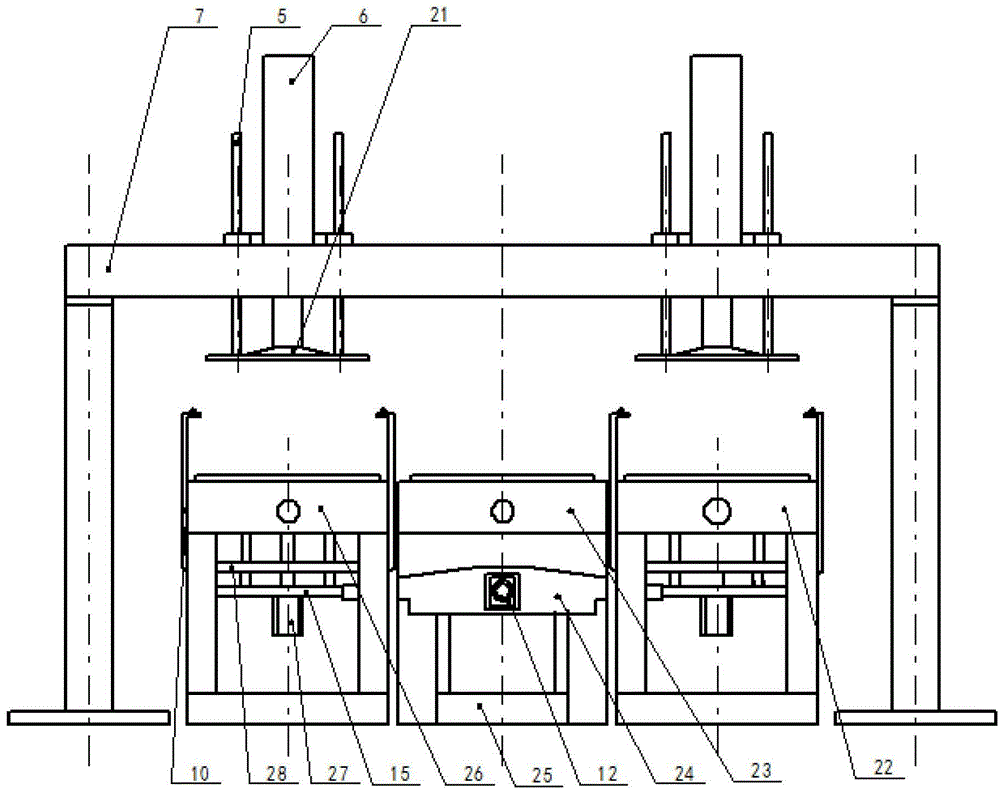

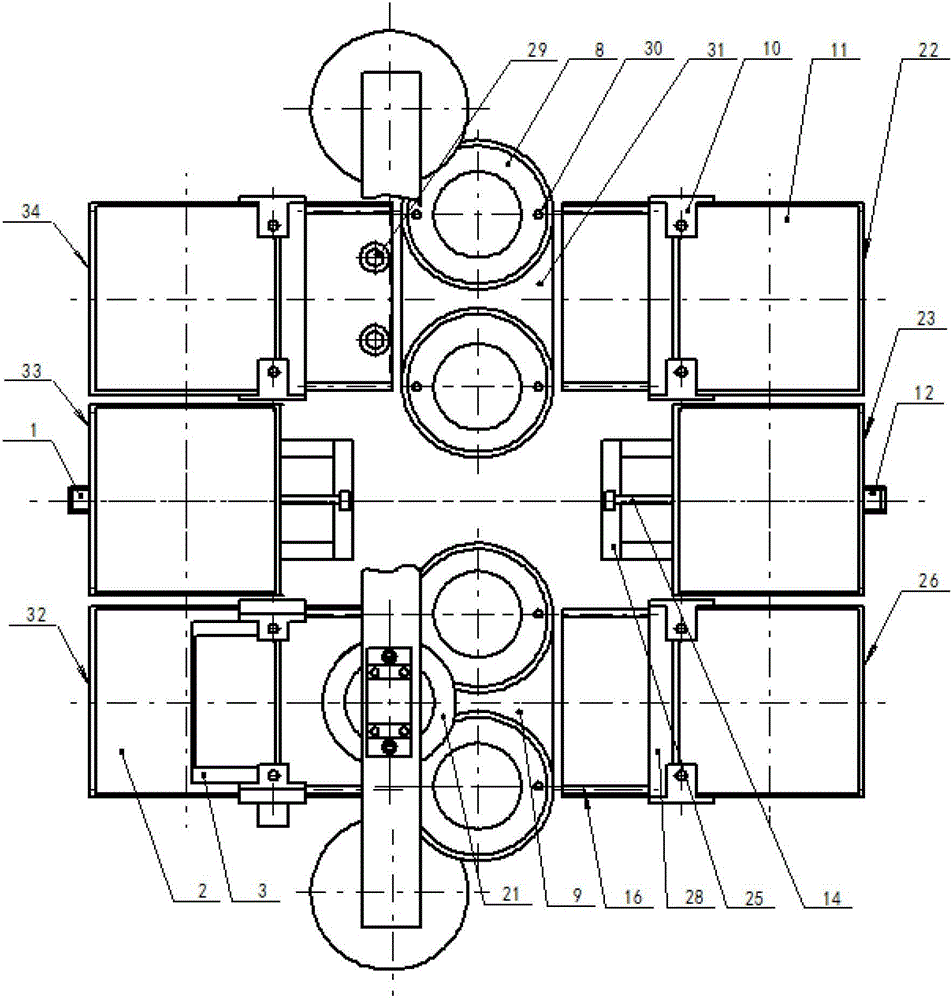

Continuous casting molding machine of rotary castings

ActiveCN102941319AConsistent qualityIncrease productivityMoulding machinesMolding machinePortal frame

Owner:杜丽红

Single-side welding machine used for electrostatic dust collector moving electrode plate

InactiveCN105014214AMeet needsGuaranteed stabilityResistance welding apparatusEngineeringSpot welding

Owner:ENELCO ENVIRONMENTAL TECH ANHUI

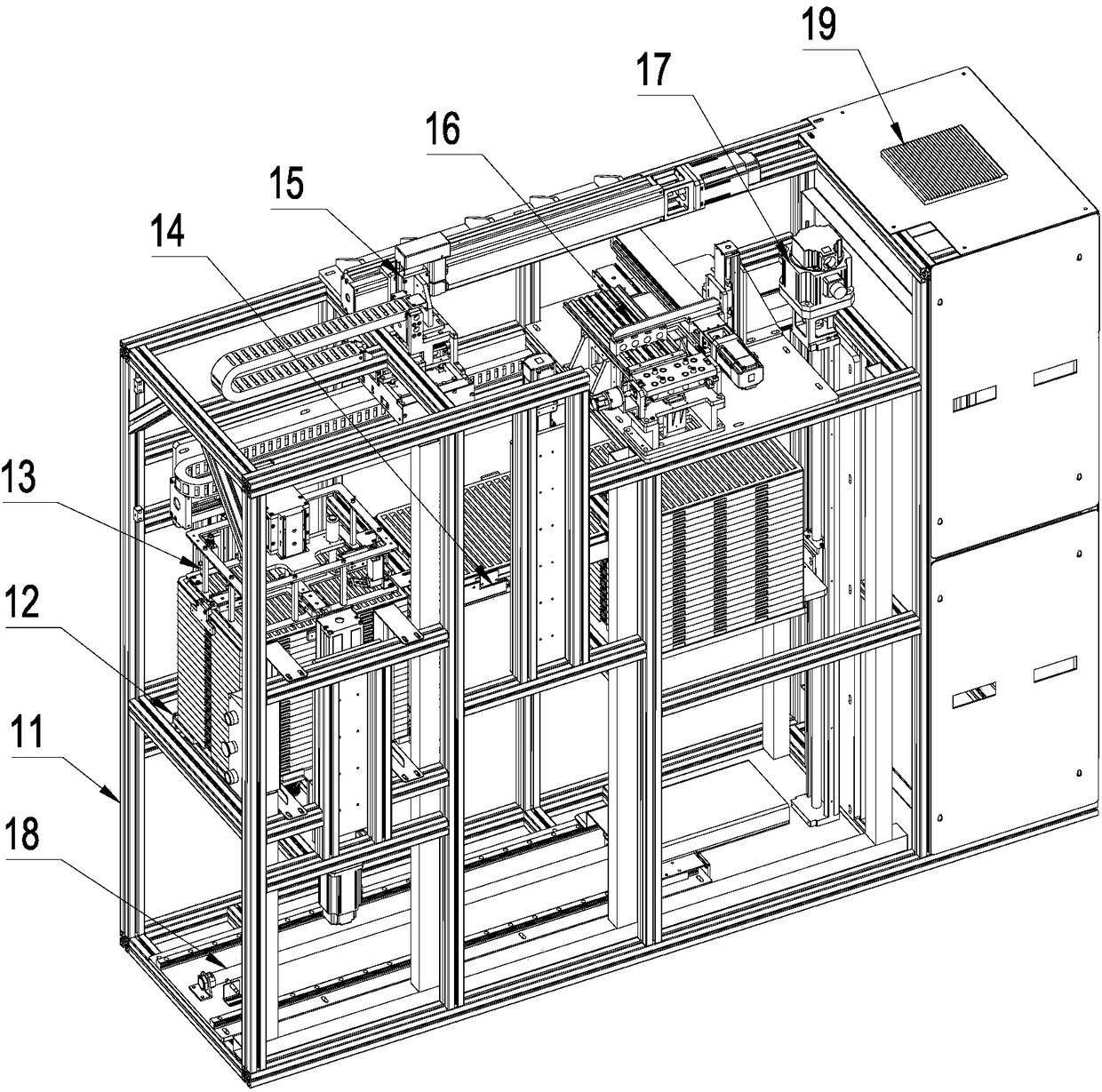

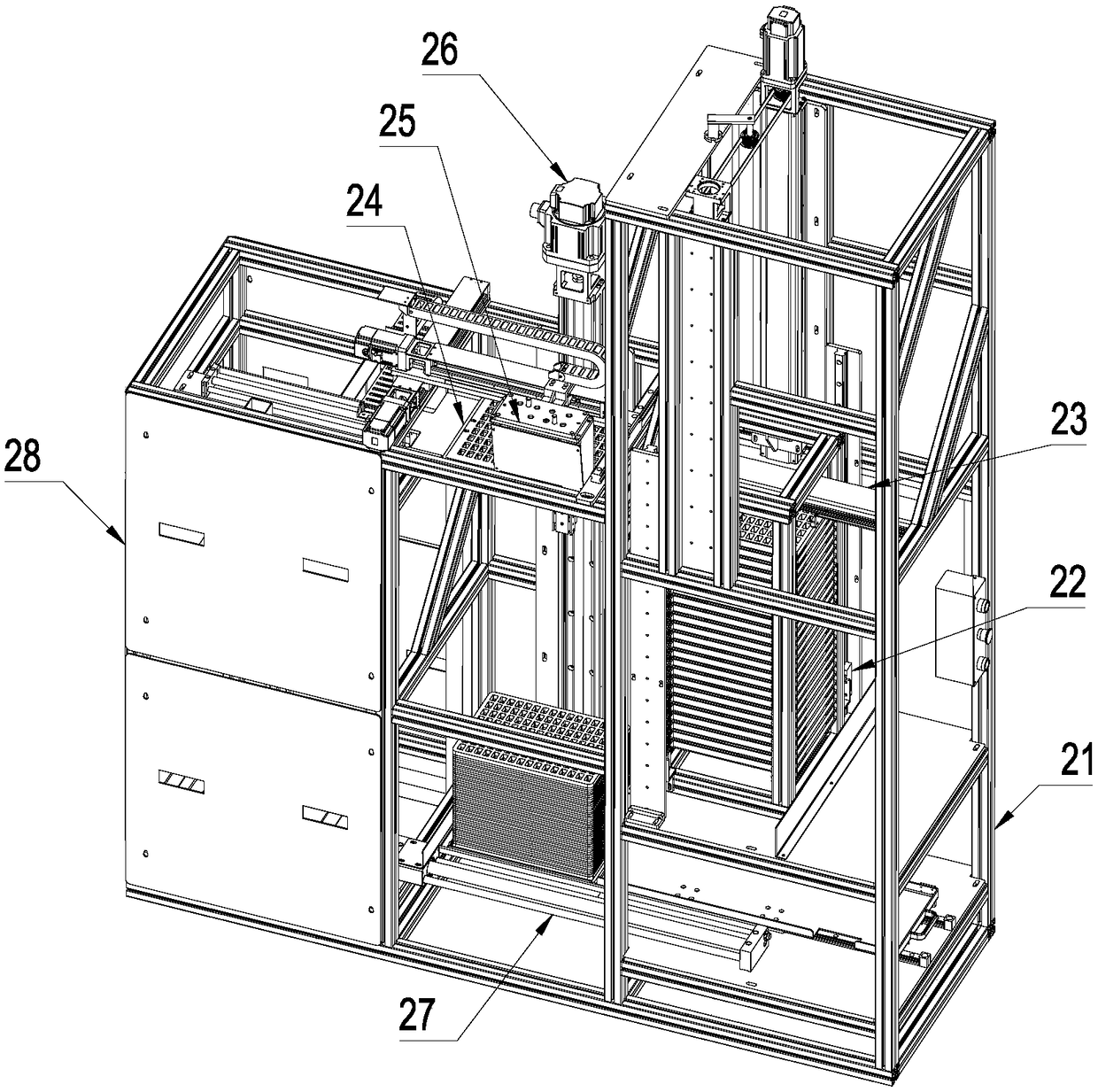

Automatic injection molding system

Owner:成都华聚科技有限公司

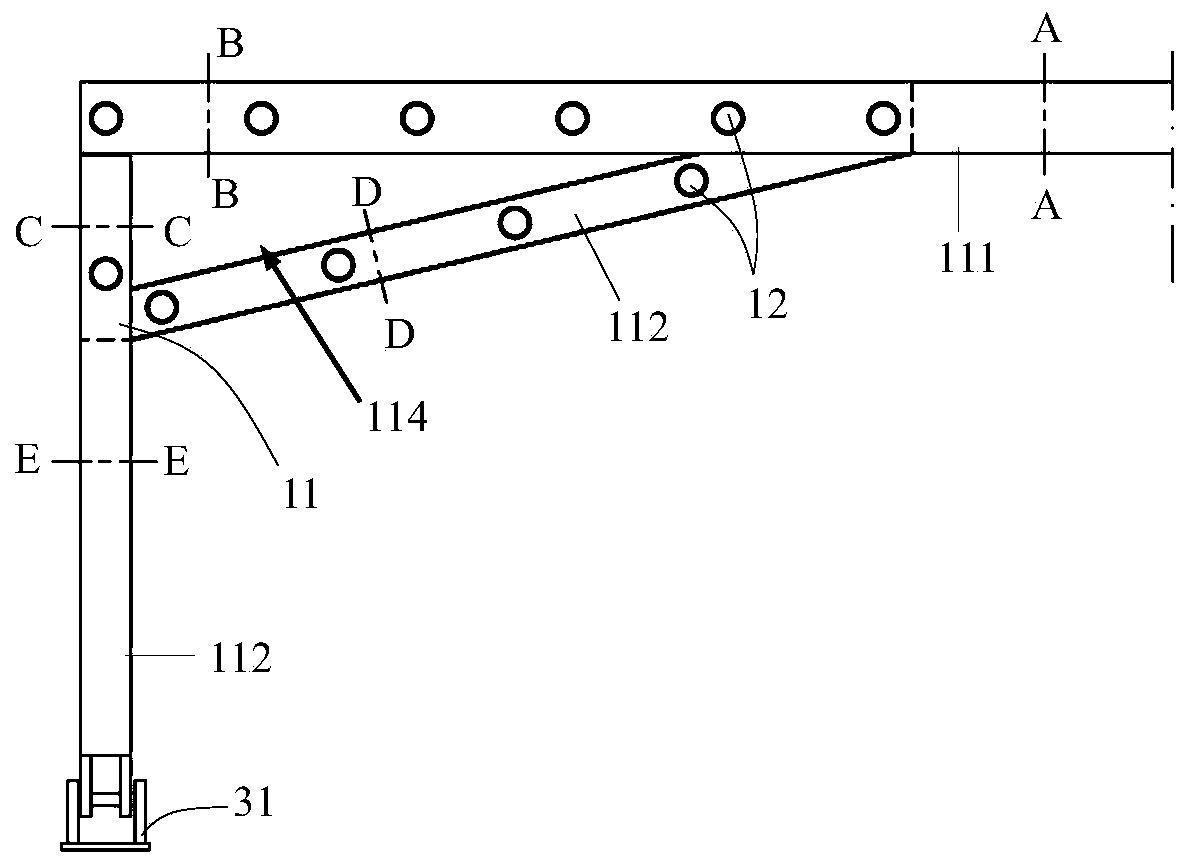

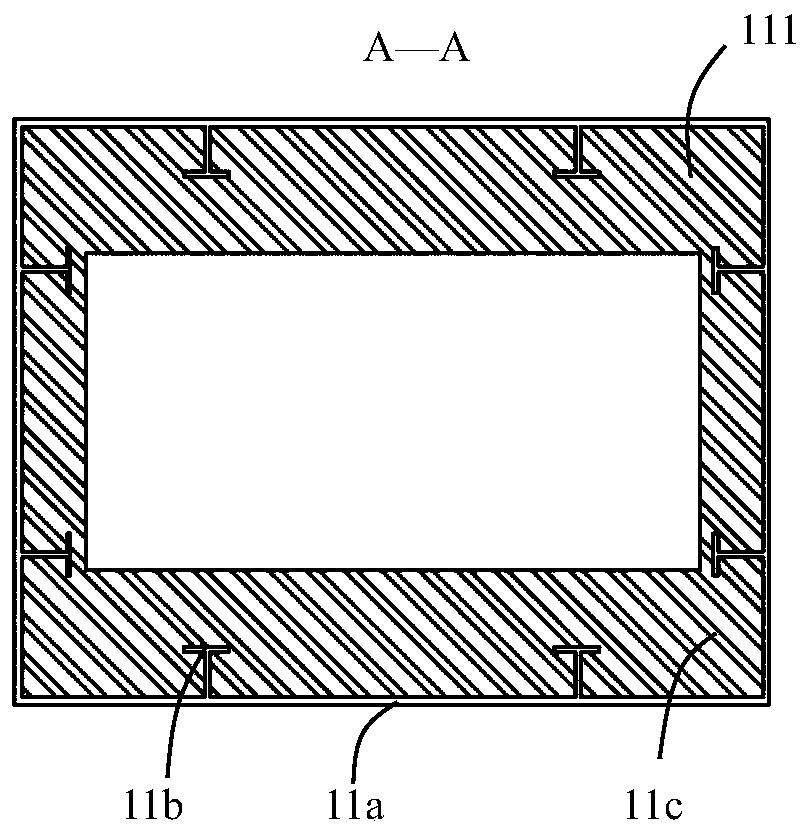

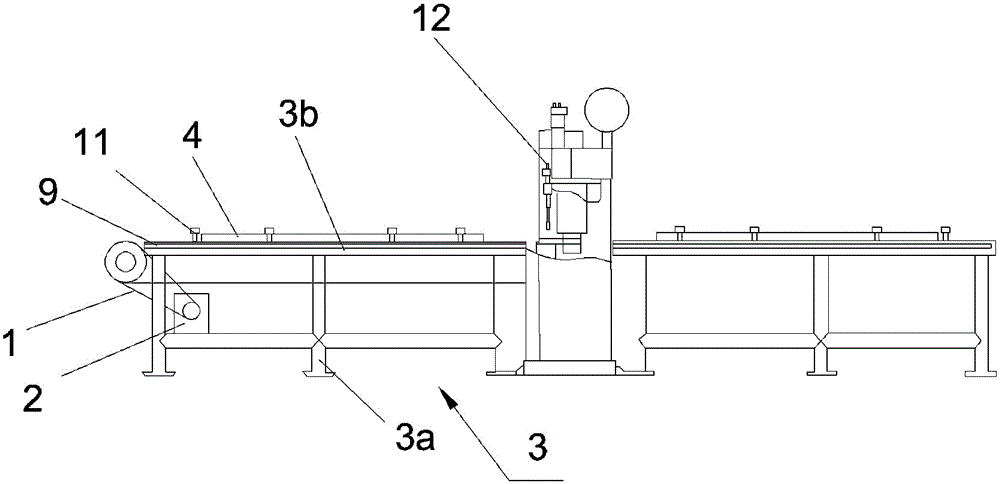

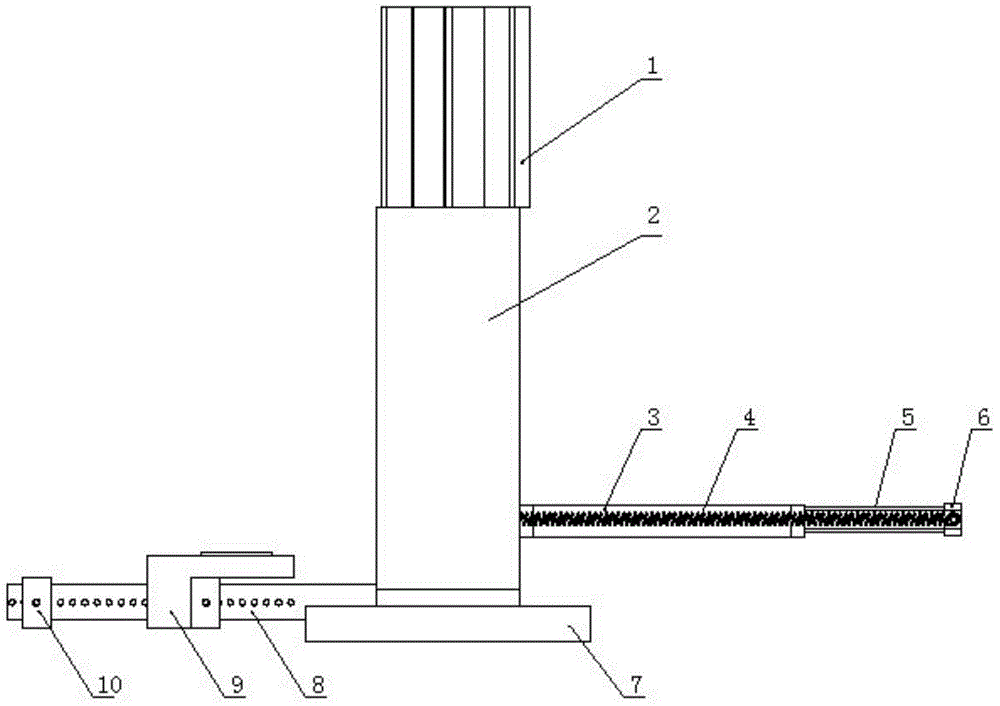

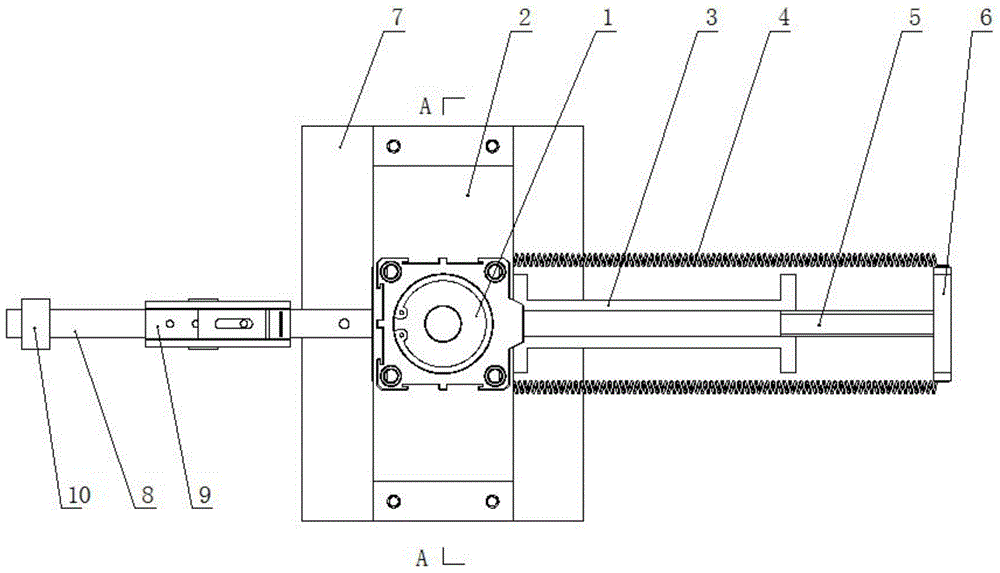

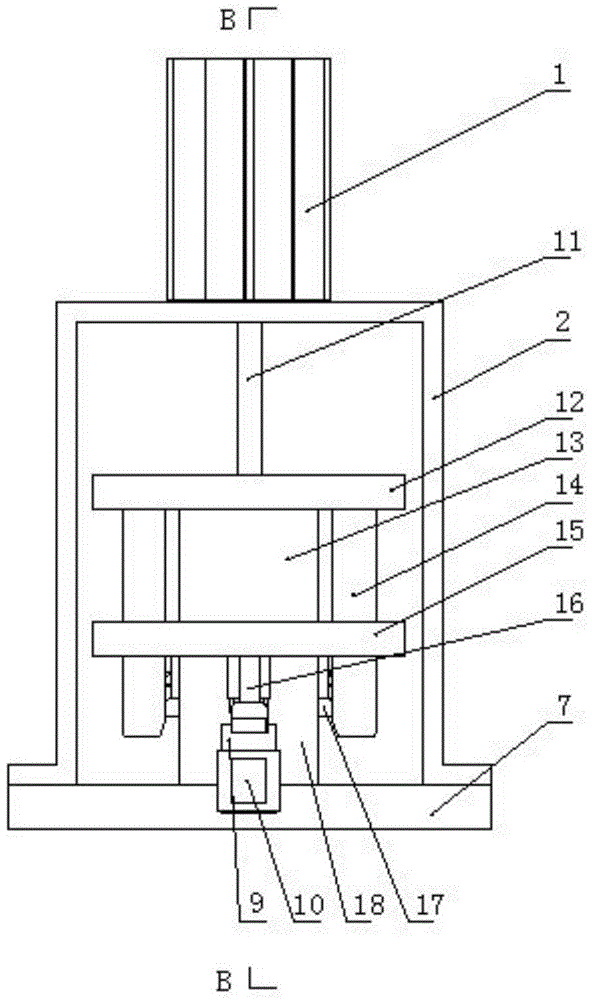

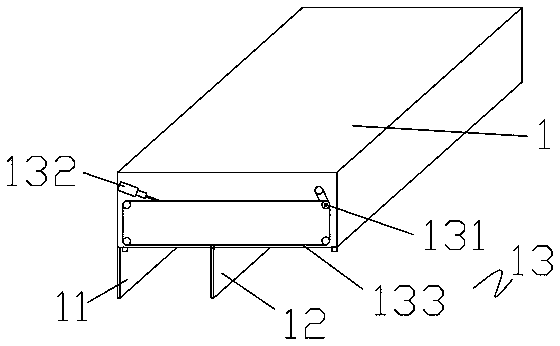

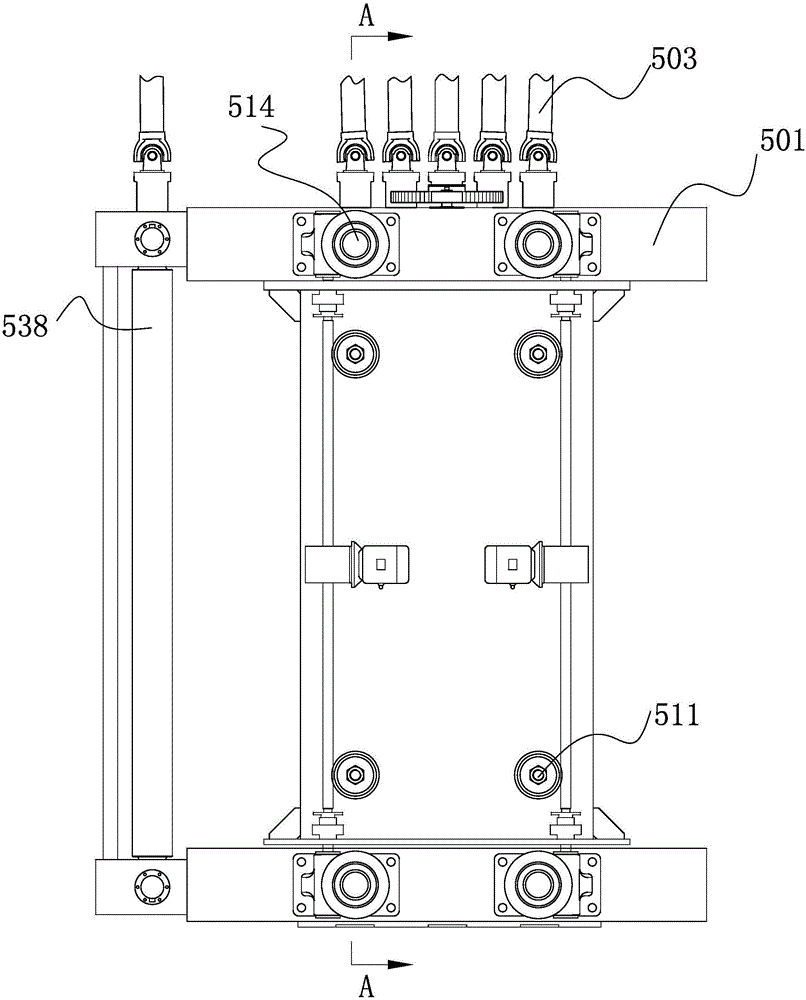

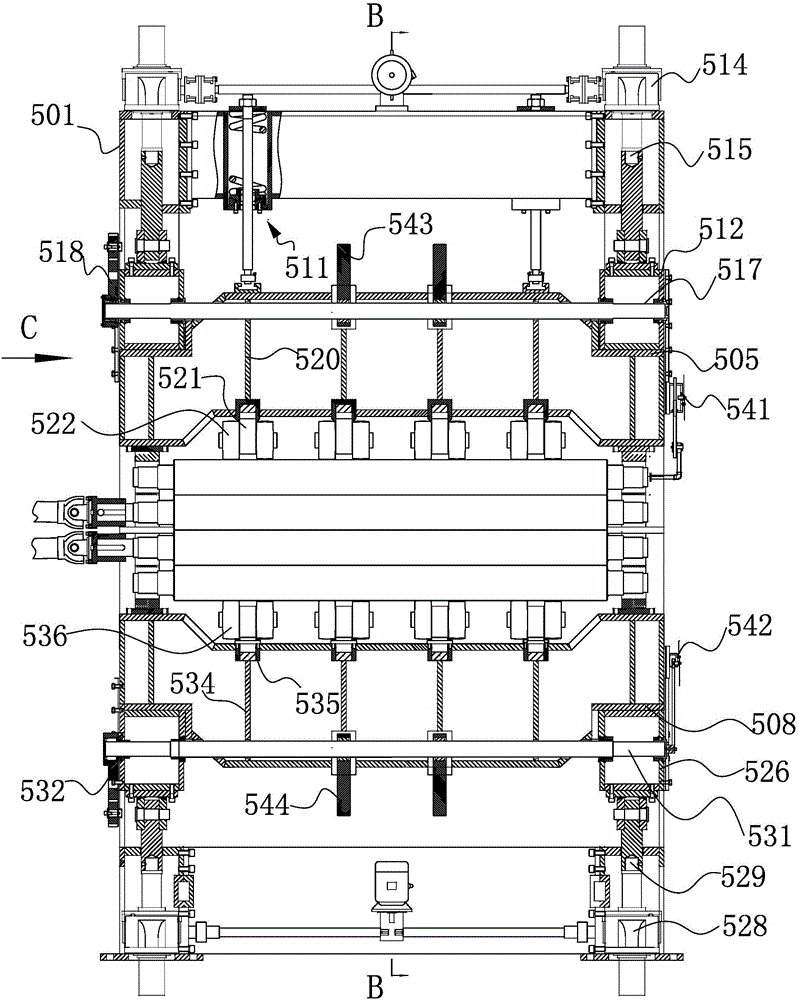

Forward moving system of portal frame

The invention discloses a forward moving system of a portal frame. The forward moving system comprises a frame, an outer portal frame and a forward moving cylinder, wherein a first cylinder head of the forward moving cylinder is fixedly arranged at the lower part of the outer portal frame; a second cylinder head of the forward moving cylinder is fixedly arranged at the lower part of the frame; a left channel steel and a right channel steel are respectively arranged on the two sides of the frame; two rollers are respectively arranged on the external side surfaces of the left side and the right side of the outer portal frame; and the rollers can roll and be positioned in the left channel steel and the right channel steel under an effect of the forward moving cylinder. The forward moving system has the advantages as follows: during the use process, the outer portal frame can be indirectly driven to move forwards and backwards in the frame through the extension and compression of the forward moving cylinder, so that the flexibility of the outer portal frame in the frame is enhanced and the flexibility of a carrier using the forward moving system of the portal frame is further enhanced.

Owner:SUZHOU PIONEER MATERIAL HANDLING EQUIP & TECH

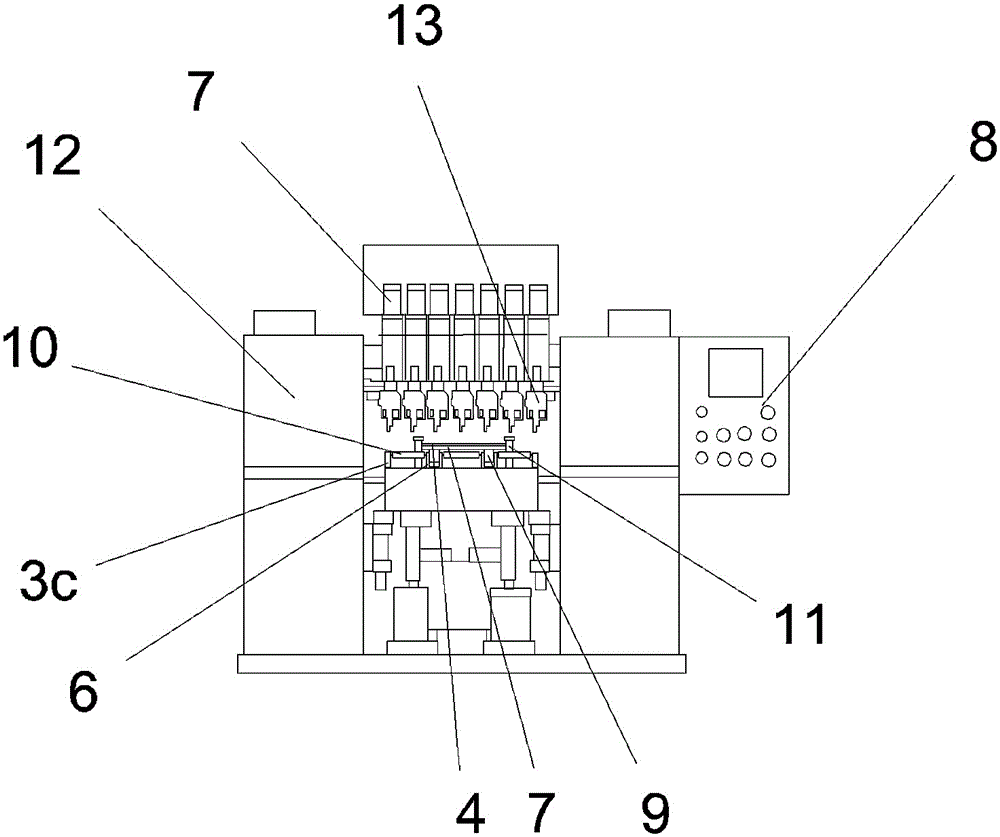

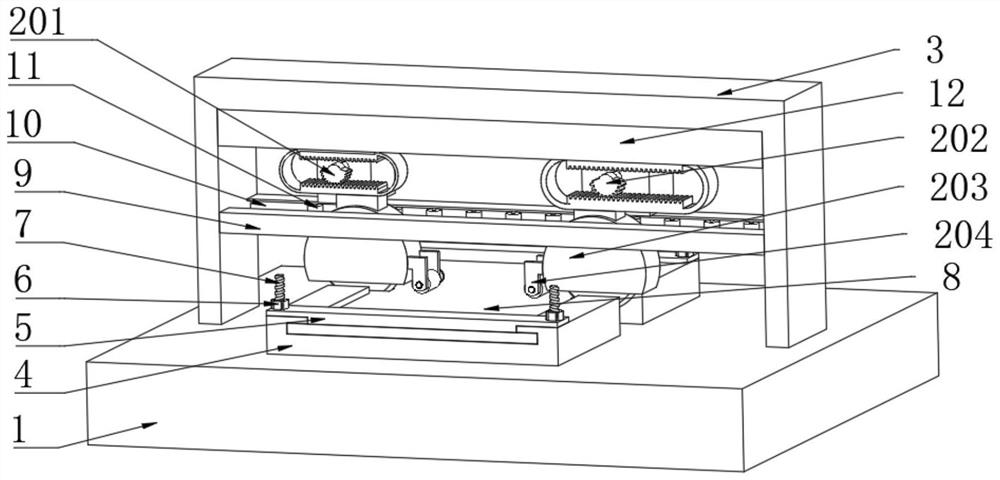

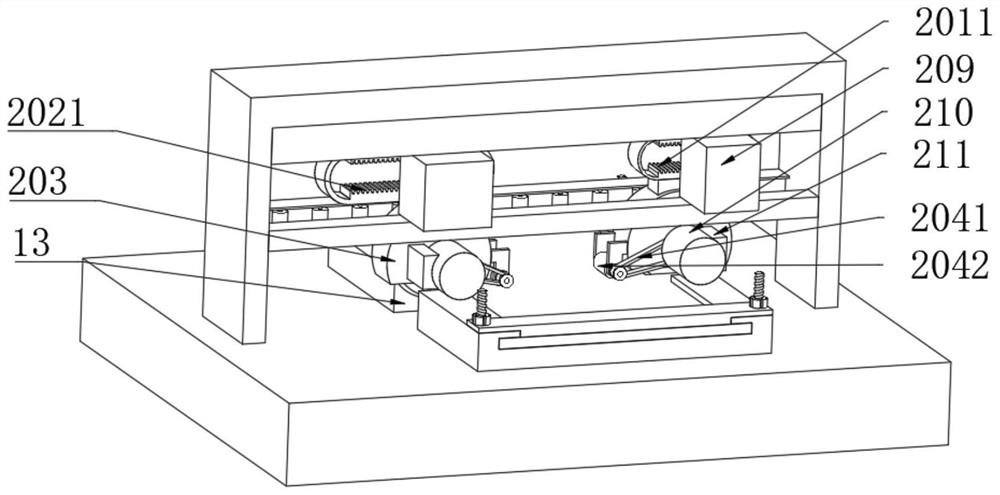

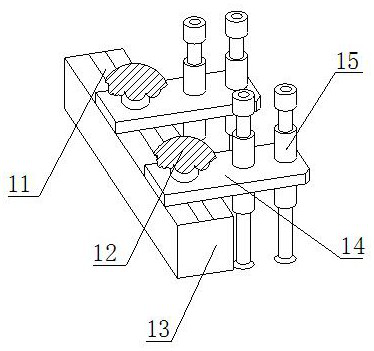

Parallel flow evaporator partition plate assembling and riveting tool and using method

ActiveCN104399828ASimple structureScientific and reasonable designHeat exchange apparatusEngineeringPortal frame

Owner:TIANJIN YAXING RADIATOR

Plate clamping fixture

Owner:罗志琼

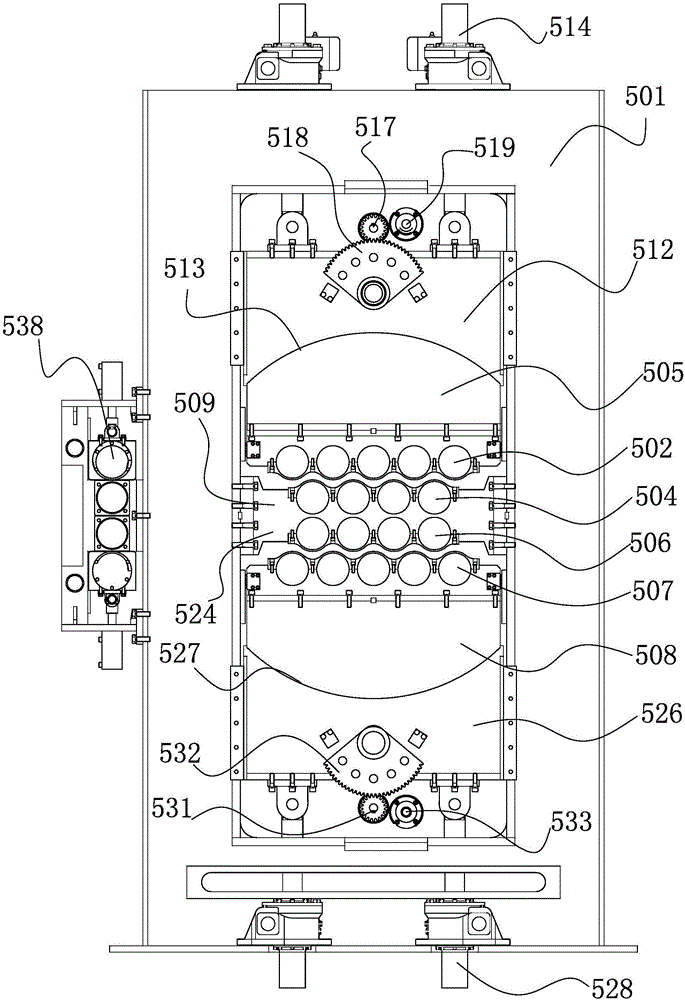

Double-layer composite board leveling machine

Owner:山东易川新材料科技股份有限公司

Metal cutting equipment for manufacturing computer radiator

PendingCN114378582AImprove work efficiencyShorten the timeOther manufacturing equipments/toolsEngineeringPortal frame

Owner:重庆财经学院

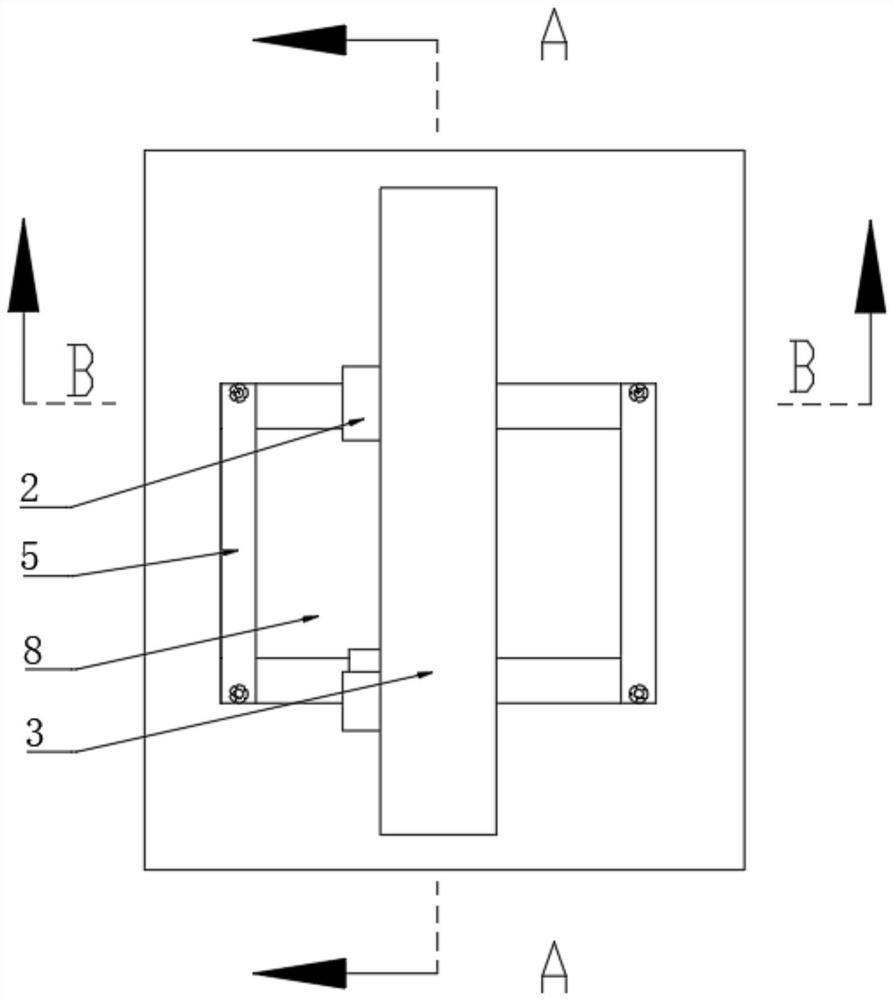

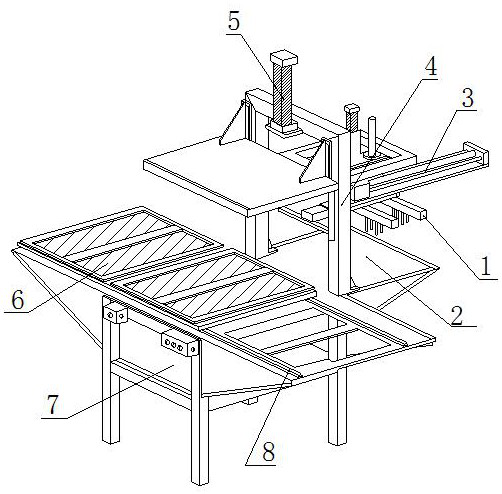

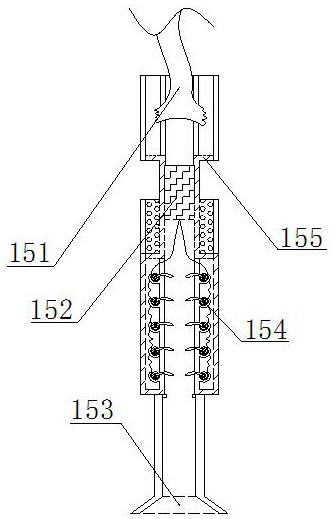

Perpendicularity adjusting device for portal frame type drilling machine

PendingCN107100545AAvoid injuryImprove protectionDerricks/mastsDirectional drillingEngineeringPortal frame

The invention discloses a perpendicularity adjusting device for a portal frame type drilling machine. The device comprises a base, the four corners of the lower portion of the base are each provided with an adjustable supporting leg, and a pair of vertical rods are symmetrically mounted on the two sides of the upper portion of the base; the vertical rods are perpendicular to the base, guiding rails are arranged on the vertical rods, a sliding block is arranged between the two guiding rails and can slide on the two guiding rails in the up-down direction, and an electric motor is arranged in the middle of the sliding block; and an output shaft of the electric motor is used for being connected with a drilling rod, a through hole is formed in the middle of the base, and the drilling rod can penetrate through the through hole. In use, by adjusting the adjustable supporting legs to enable the base to be horizontal, adjustment of the perpendicularity of the drilling rod is achieved; by continuously adjusting the perpendicularity of the drilling rod in the hole drilling process, the phenomenon that a drill bit damages a PE pipe of an adjacent well position is avoided, so that protection of a formed well hole is facilitated; and the device is low in manufacturing cost, obvious in effect and capable of being repeatedly used.

Owner:ANHUI KEEN NEW ENERGY

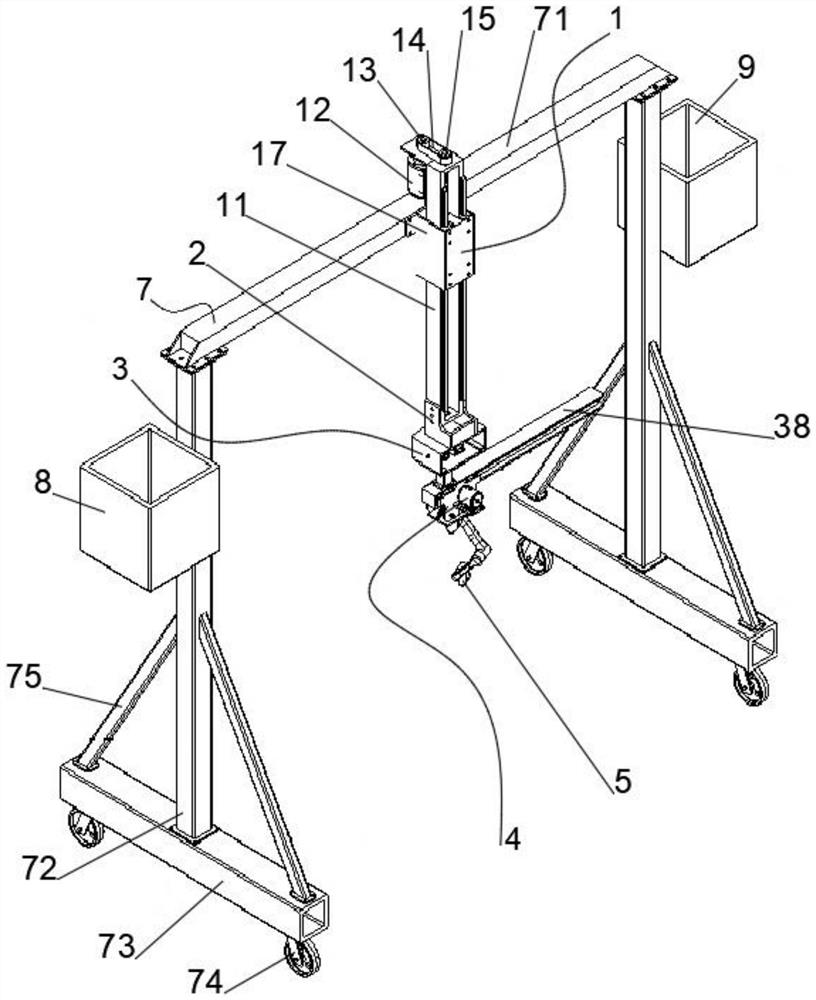

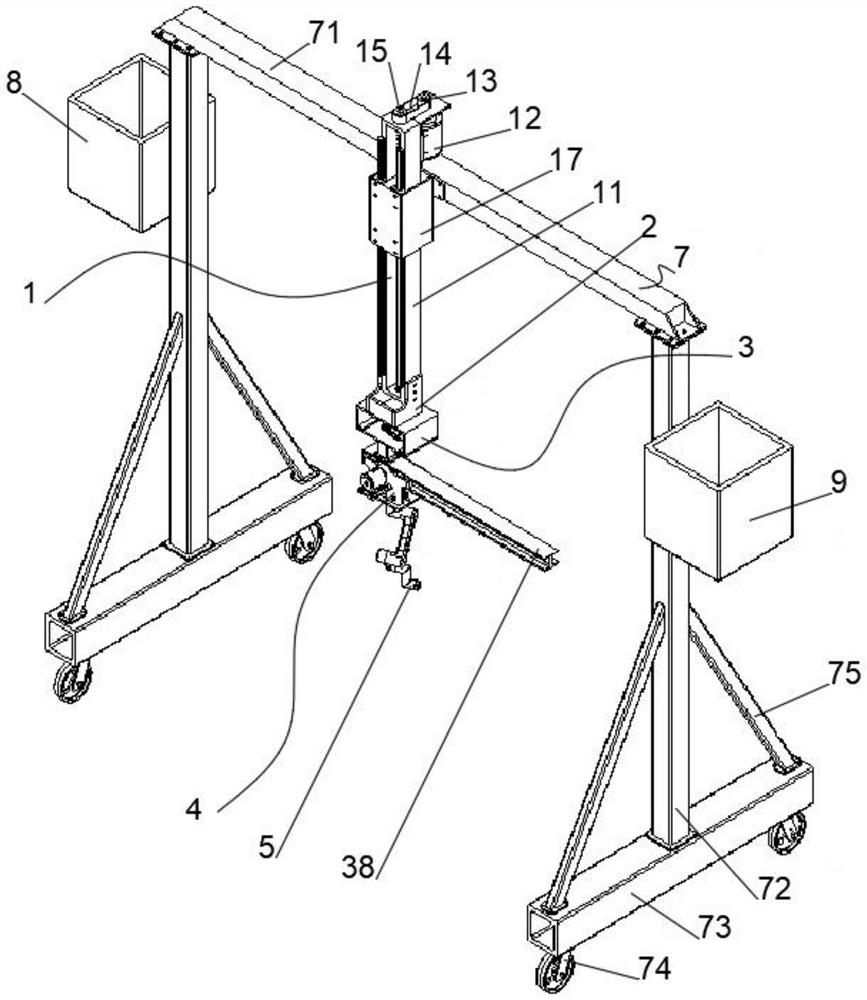

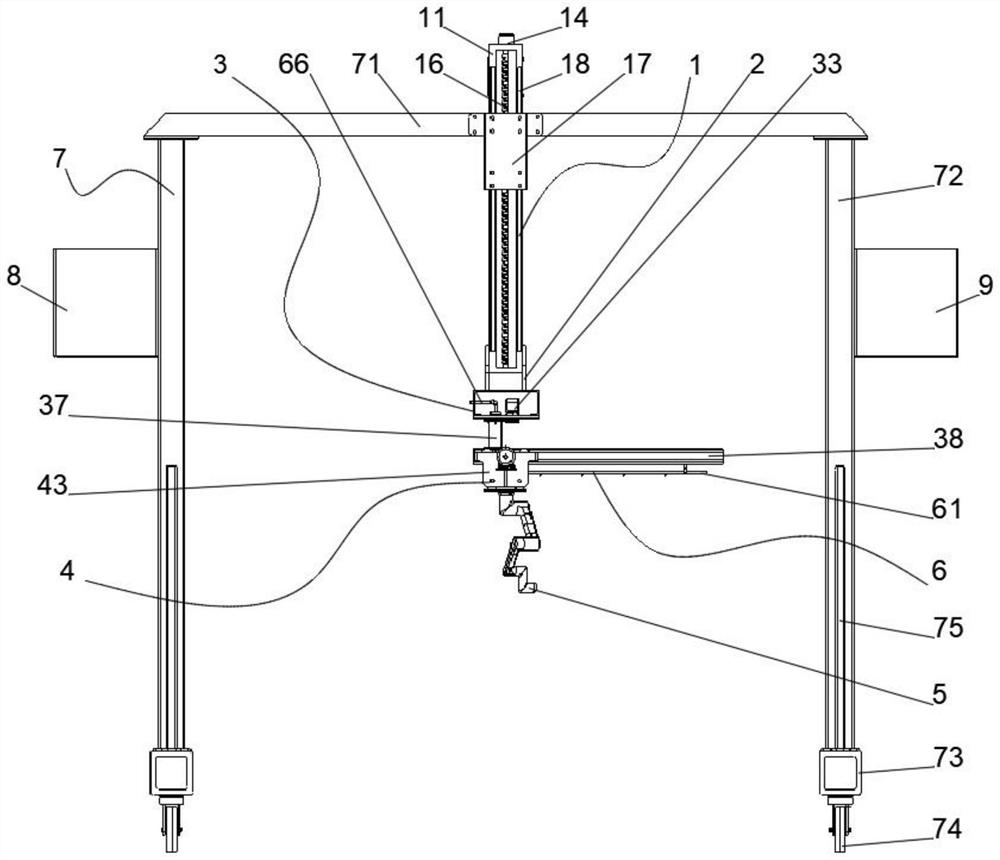

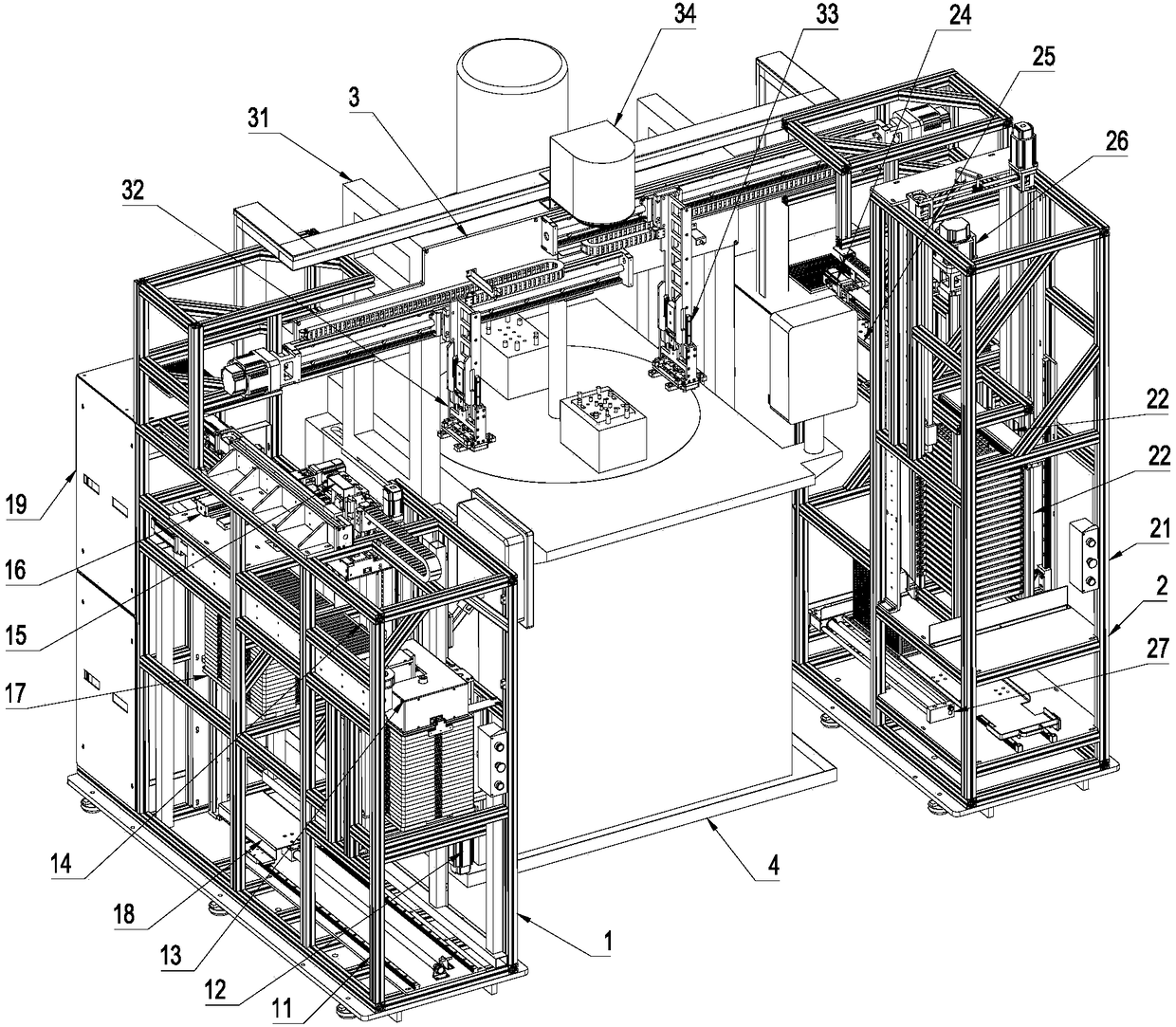

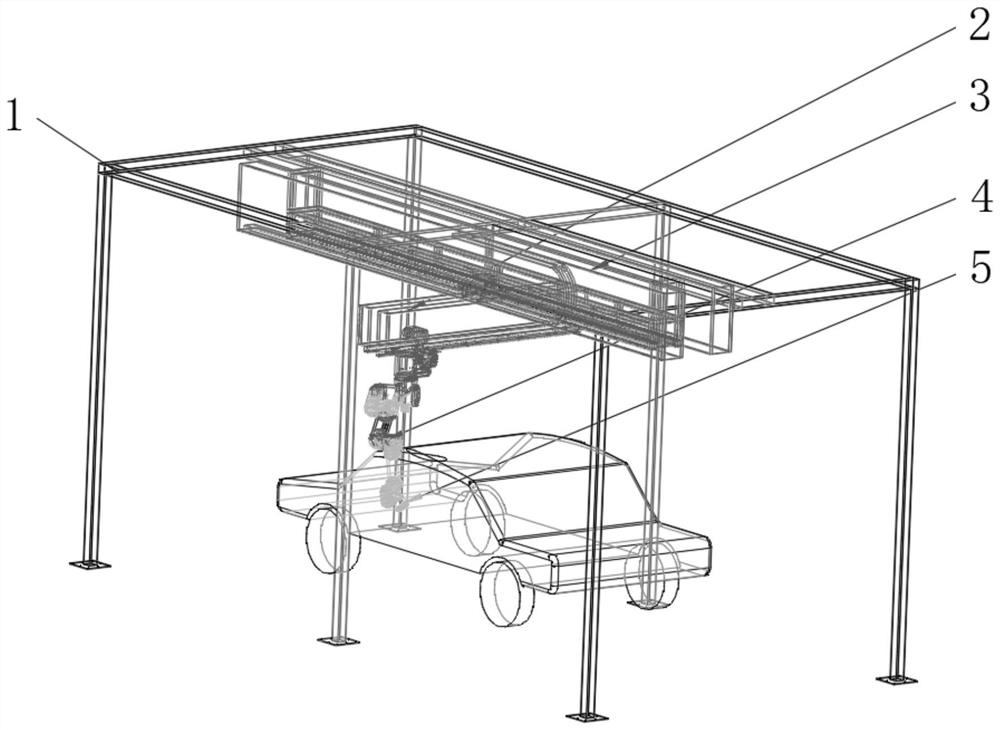

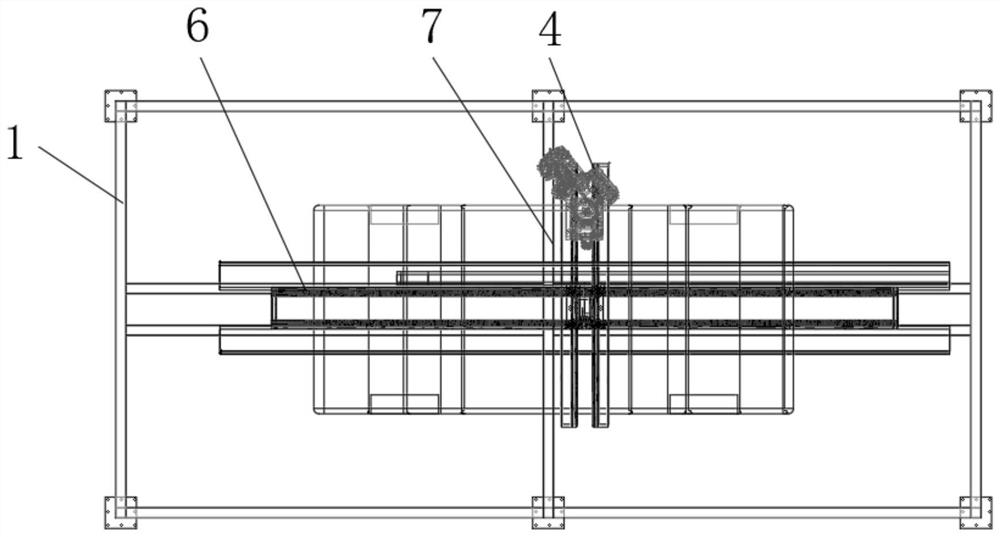

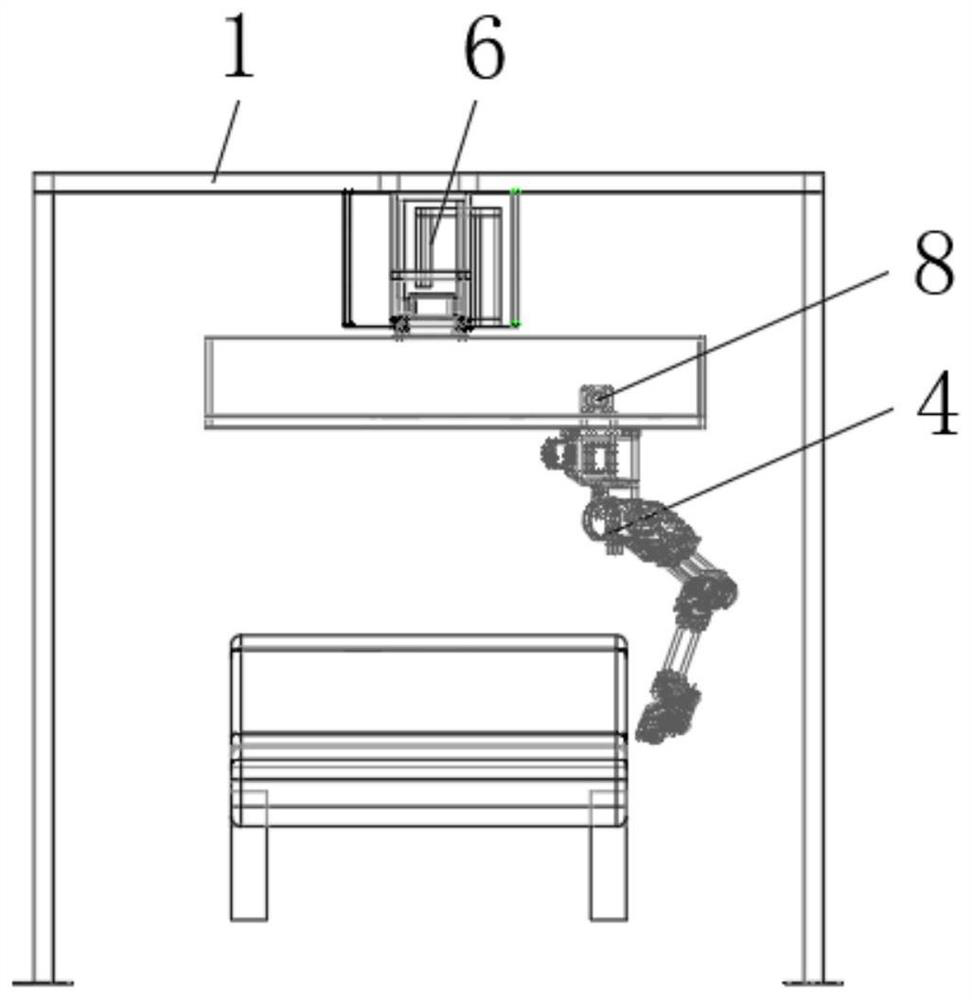

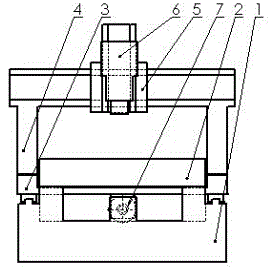

Intelligent car washing system with hoisting eight-axis mechanical arm

PendingCN111891076AIncrease the car wash areaFast car washCleaning apparatus with conveyorsCleaning apparatus for vehicle exteriorsSpray nozzleControl theory

Owner:北京新维盛业科技发展有限公司

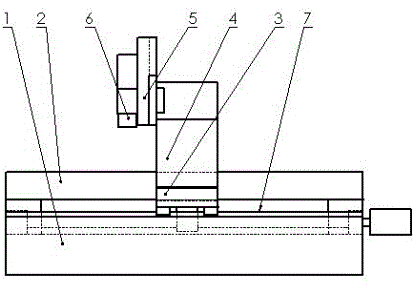

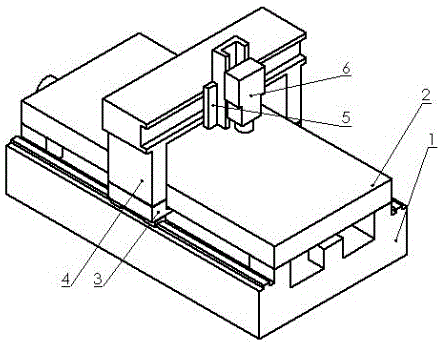

Moving column type gantry milling machine driven by single lead screw and assembling technique thereof

InactiveCN104690565AImprove rigidityIncrease force deformationMilling machinesFeeding apparatusControl systemEngineering

Owner:佛山市南海区精鹰机械有限公司

Feeding and taking equipment for hardware electroplating

Owner:广州九岳天装饰工程有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap