Moving column type gantry milling machine driven by single lead screw and assembling technique thereof

A single-screw, gantry milling technology, applied in milling machines, feeding devices, milling machine equipment and other directions, can solve the problems of complex manufacturing process of high-precision equipment, difficult synchronization of double-screw, poor equipment accuracy, etc., to achieve simple and easy installation, Simplified assembly process, cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

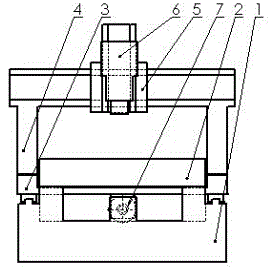

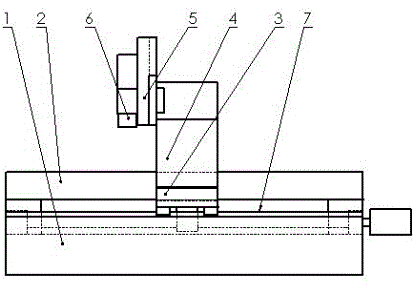

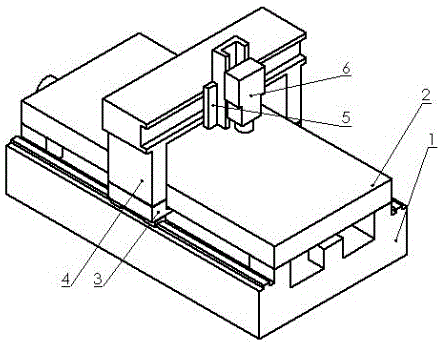

[0020] Such as figure 1 , figure 2 and image 3 As shown, a moving column type gantry milling driven by a single lead screw, including a bed 1, a workbench 2, a sliding table 3, a gantry frame 4, a sliding table 2 5, a spindle assembly 6 and a lead screw 7, the bed Guide rails are provided on both sides of the body 1, the workbench 2 is set above the bed 1 and is rigidly connected with the bed 1, a rectangular gap is provided between the workbench 2 and the bed 1, and the slide table-3 passes through Rectangular gap, and the sliding platform 3 slides along the guide rails on both sides of the bed 1, the gantry 4 is rigidly connected with the sliding platform 3, and is connected into a "mouth"-shaped structure, and the gantry 4 is provided on one s

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap