Metal cutting equipment for manufacturing computer radiator

A metal cutting and radiator technology, applied in other manufacturing equipment/tools, manufacturing tools, etc., can solve problems such as low cutting efficiency and cumbersome processes, and achieve the effect of improving work efficiency, shortening time, and eliminating grinding processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment

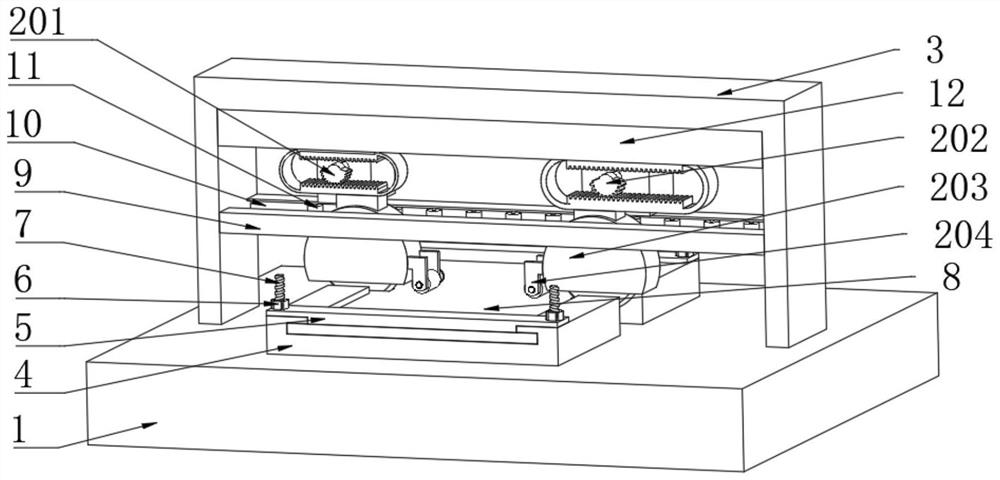

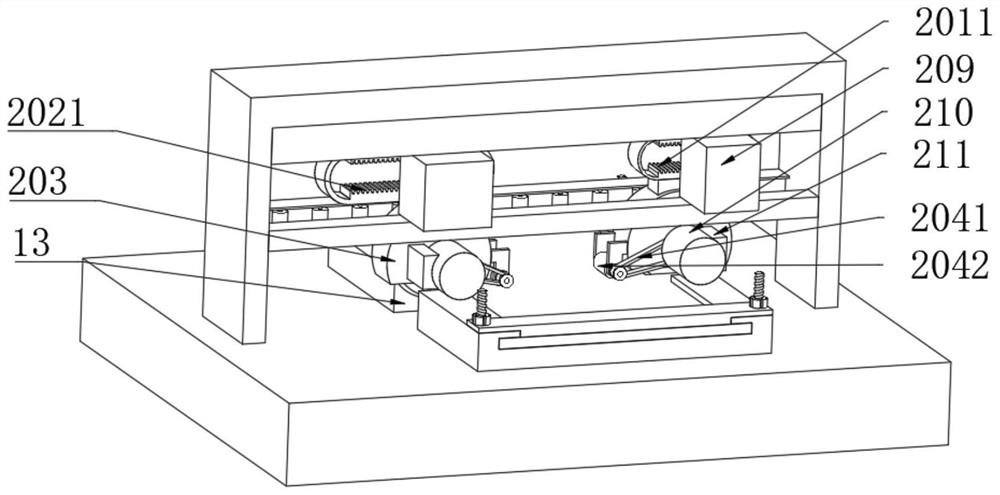

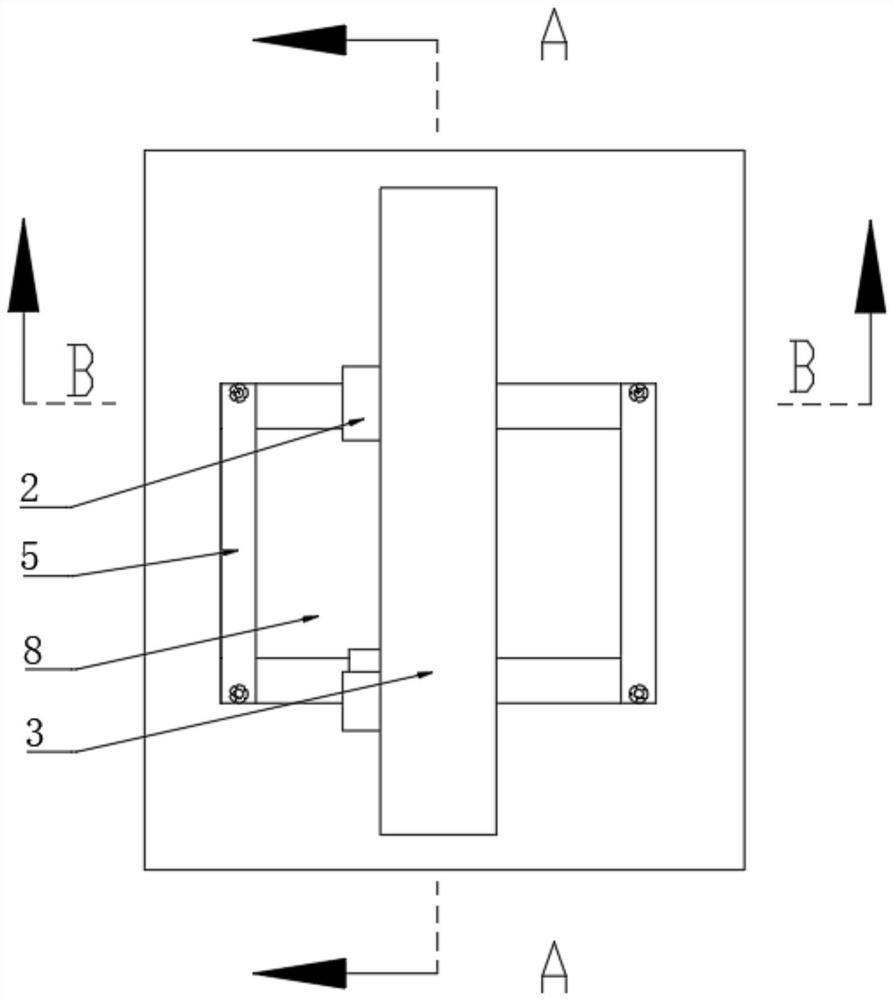

[0030] Such as Figure 1-6 As shown, a metal cutting device for the manufacture of computer radiators includes a workbench 1, a placement table 4 is fixedly installed on the upper surface of the workbench 1, and a metal plate 8 is fixedly placed inside the placement table 4 through a pressure plate 5. The workbench 1 A gantry 3 is installed on the upper surface and across the placing table 4. A cutting assembly 2 is arranged inside the gantry 3. The cutting assembly 2 includes a first driving structure 201 and a second driving structure 202. The first driving structure 201 and the second driving structure 202 are respectively driven by two first servo motors 208, the first drive structure 201 and the bottom end of the first drive structure 201 are respectively fixedly connected with a protective cover 203 through a fixed block 206, and the inside of the protective cover 203 is rotated by a second servo motor 210. The cutter 207 is provided with a grinding assembly 204 on the oppo

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap