Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

23 results about "Drill" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A drill is a tool primarily used for making round holes or driving fasteners. It is fitted with a bit, either a drill or driver, depending on application, secured by a chuck. Some powered drills also include a hammer function.

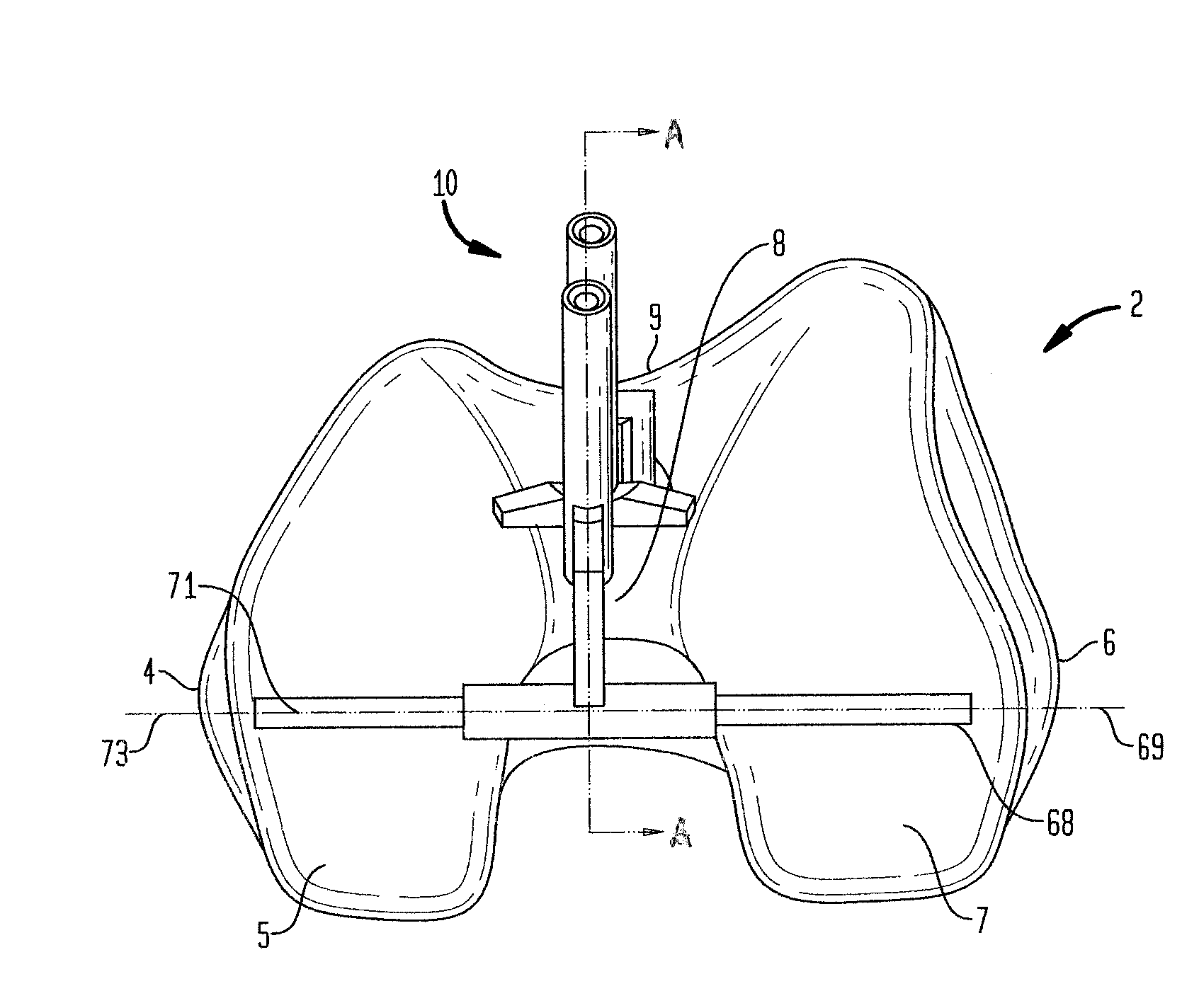

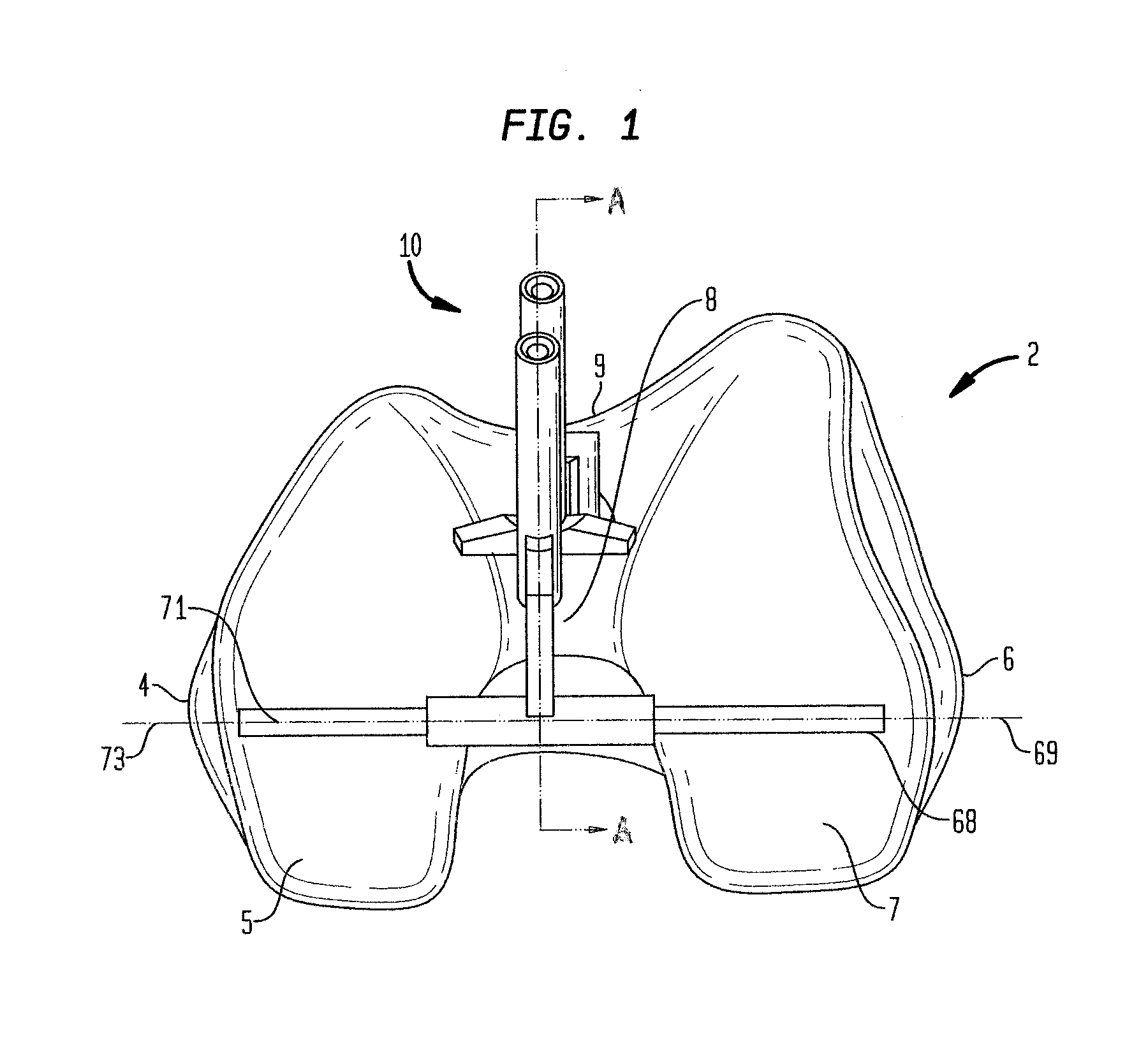

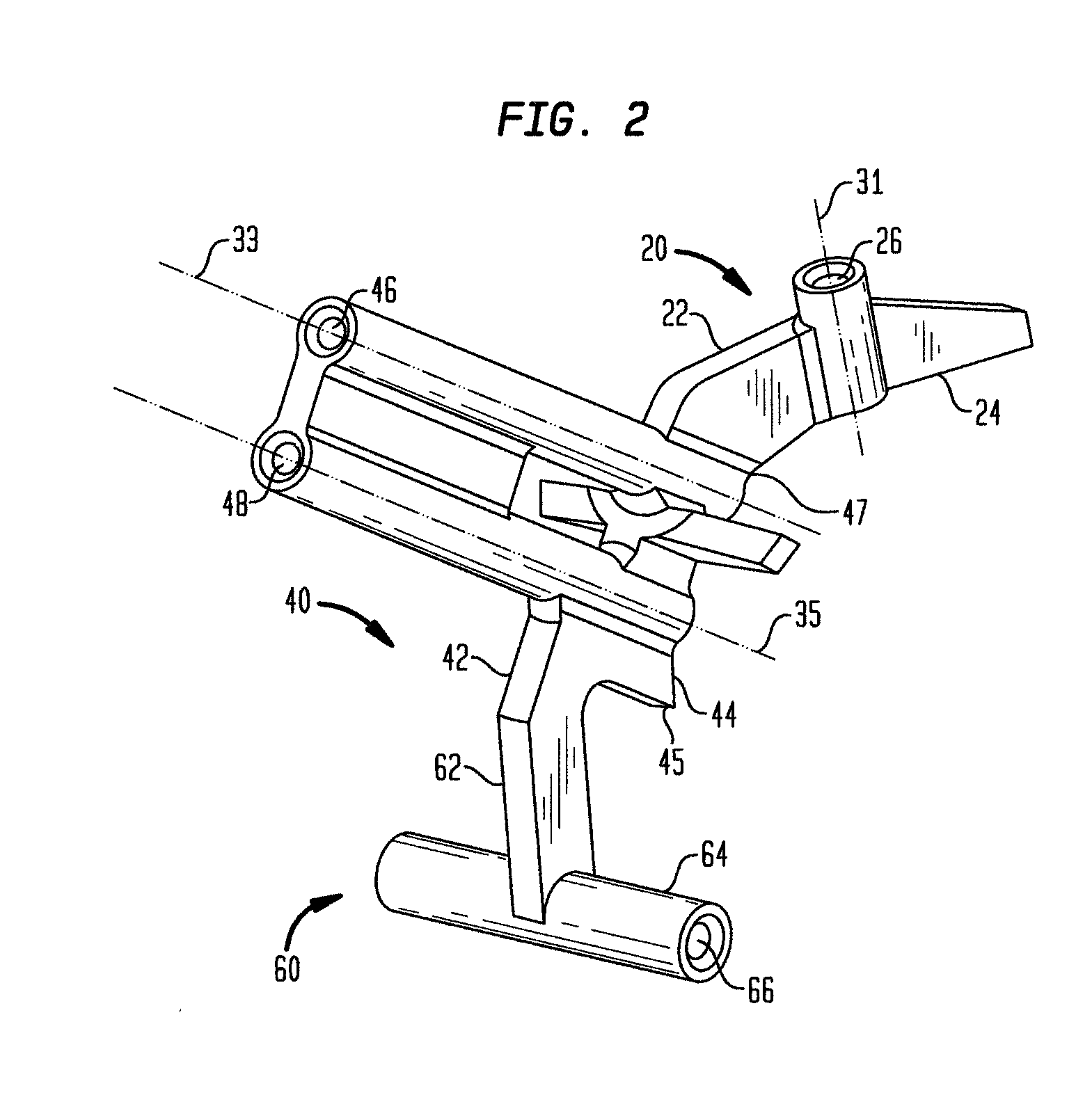

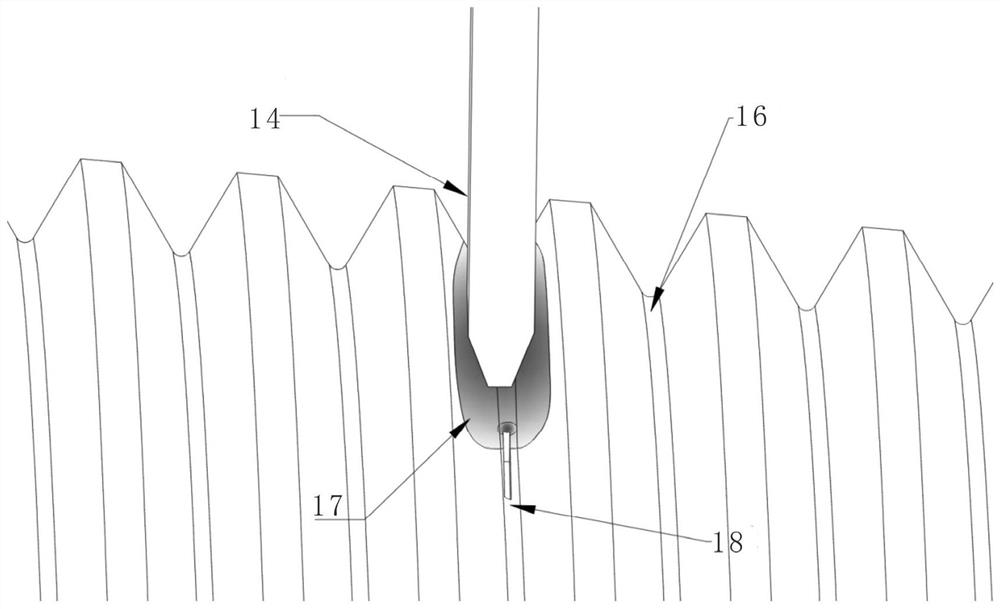

Spot facing trochlear groove

InactiveUS20100222782A1Restore accuratelyPrecise positioningKnee jointsOsteosynthesis devicesProsthesisReamer

Owner:HOWMEDICA OSTEONICS CORP

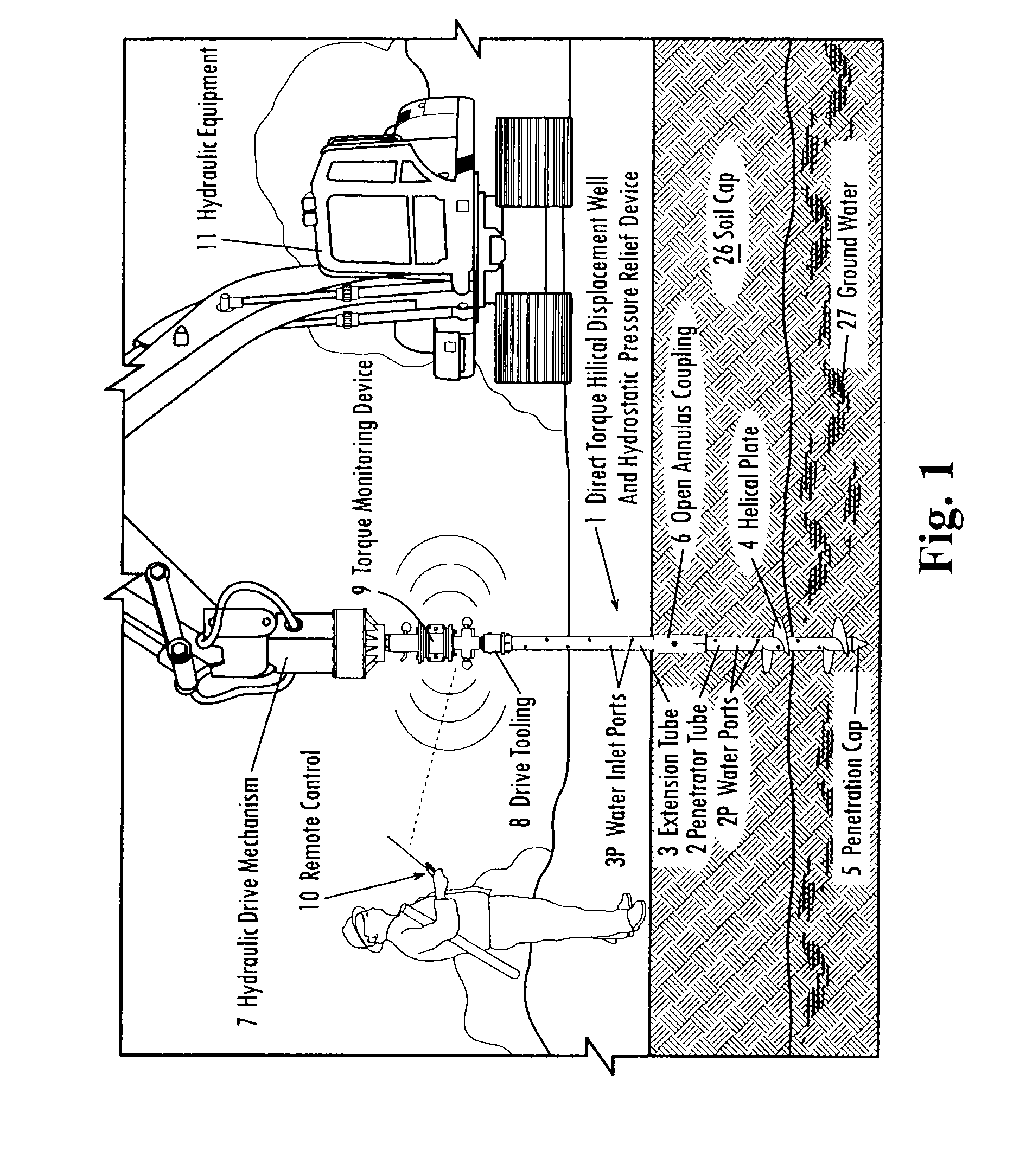

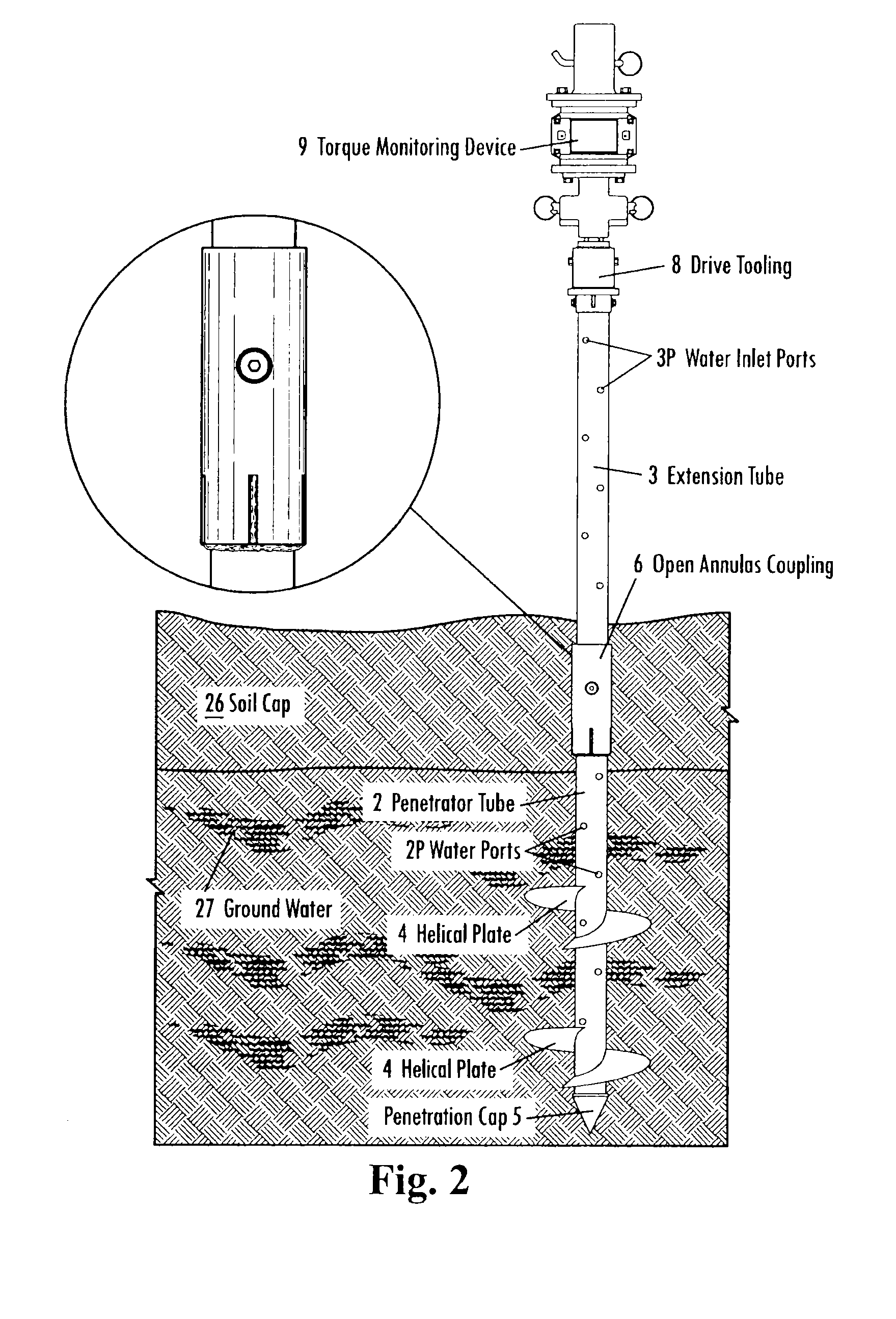

Direct Torque Helical Displacement Well and Hydrostatic Liquid Pressure Relief Device

Owner:QUEEN FRIE A R

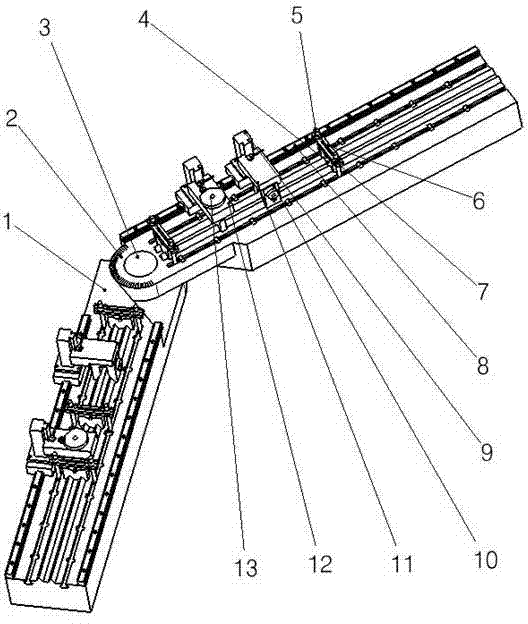

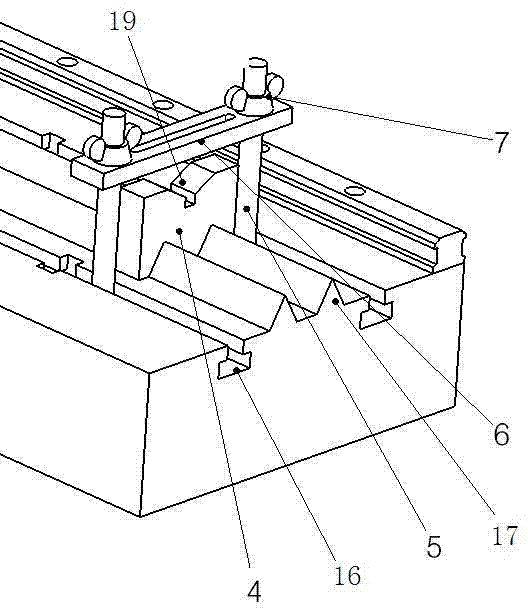

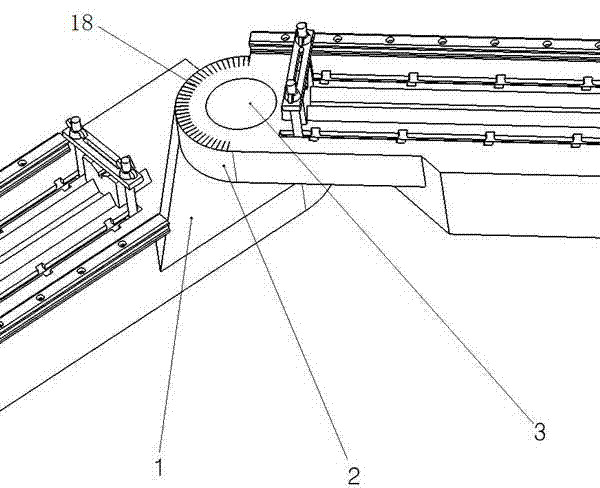

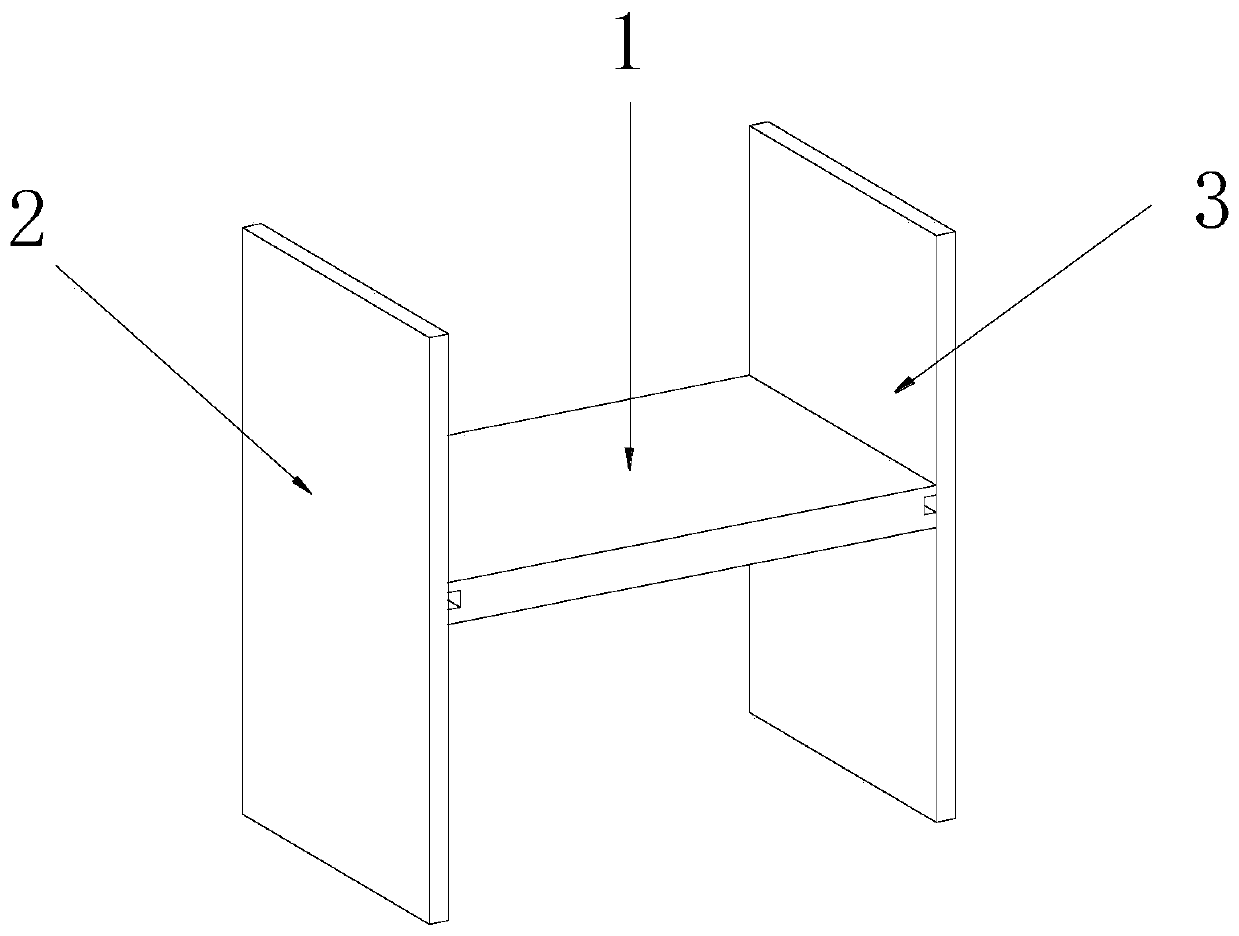

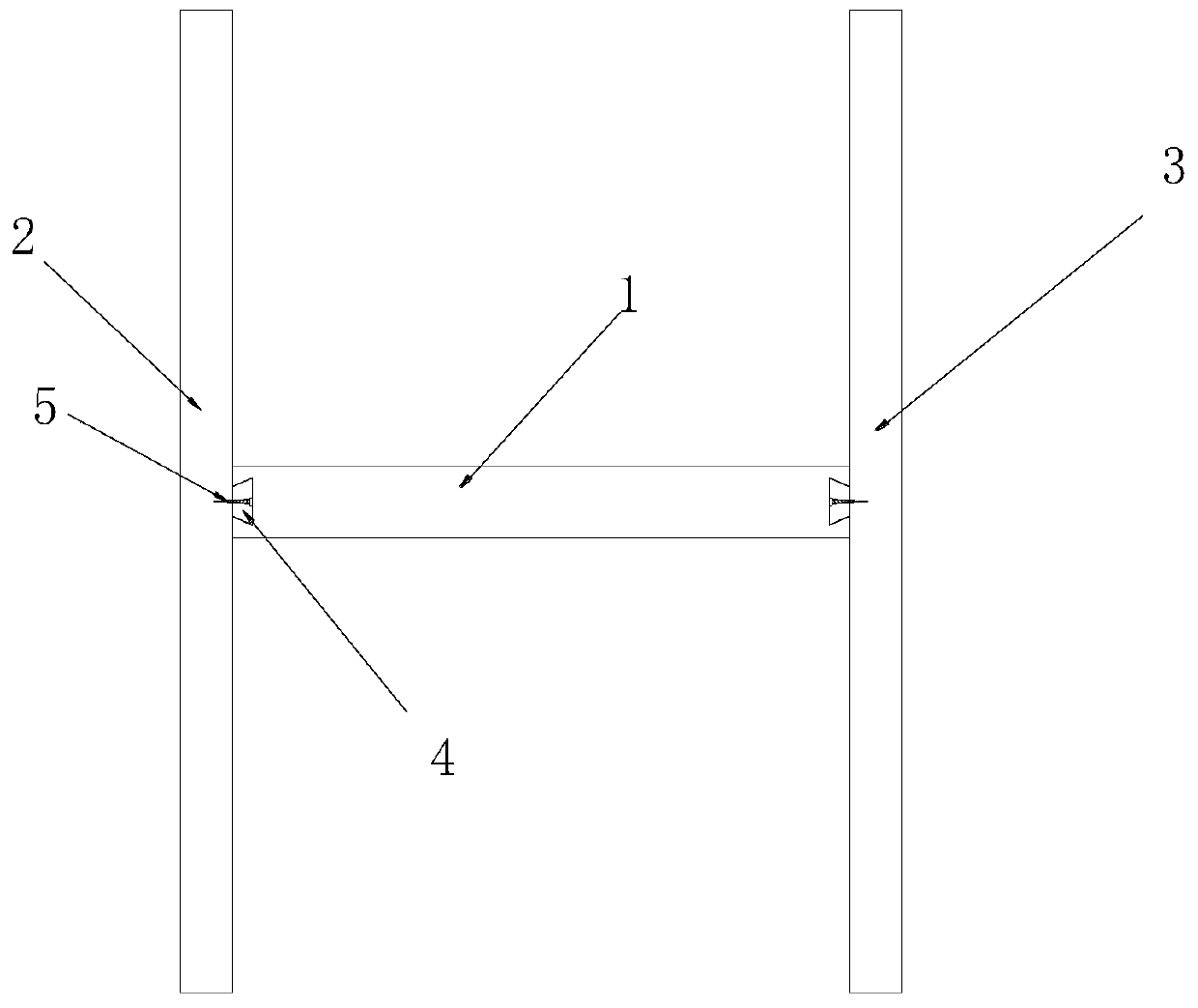

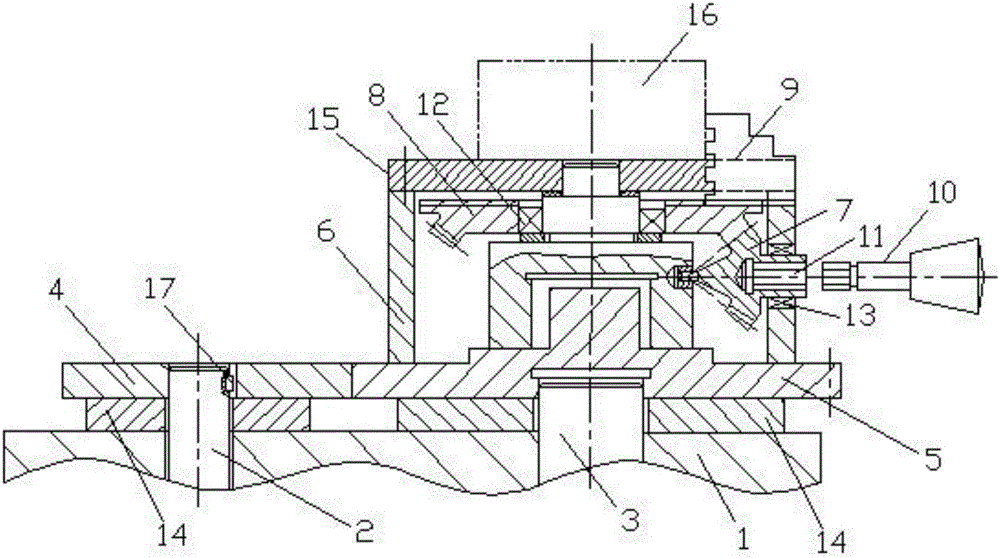

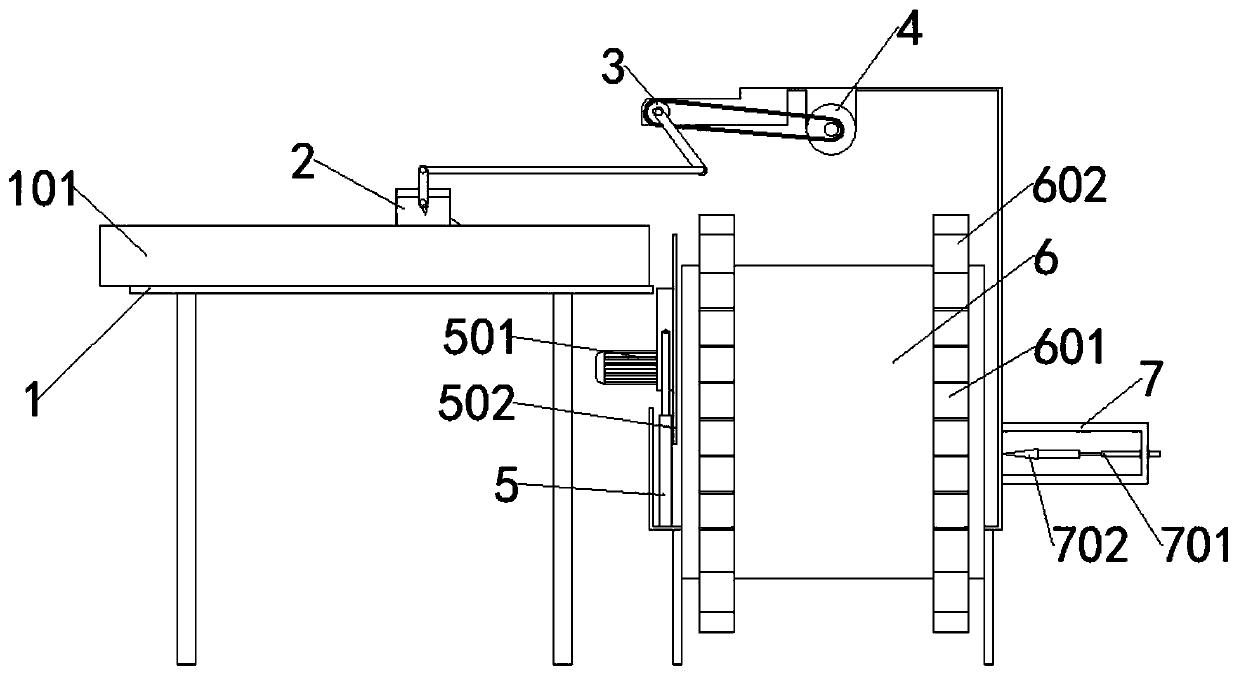

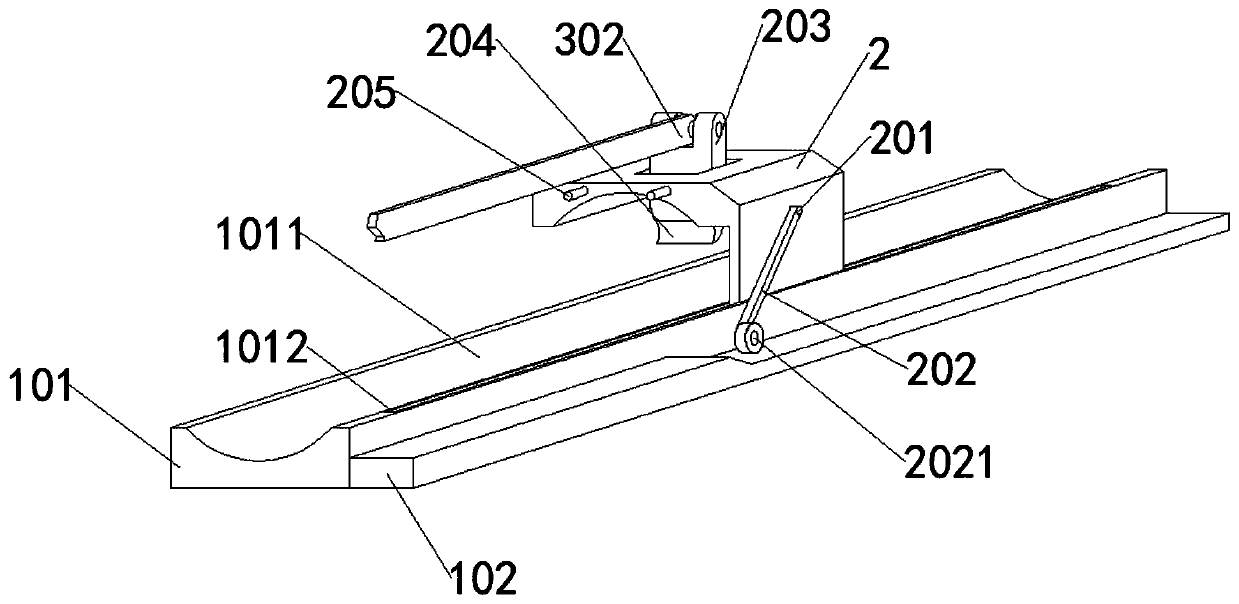

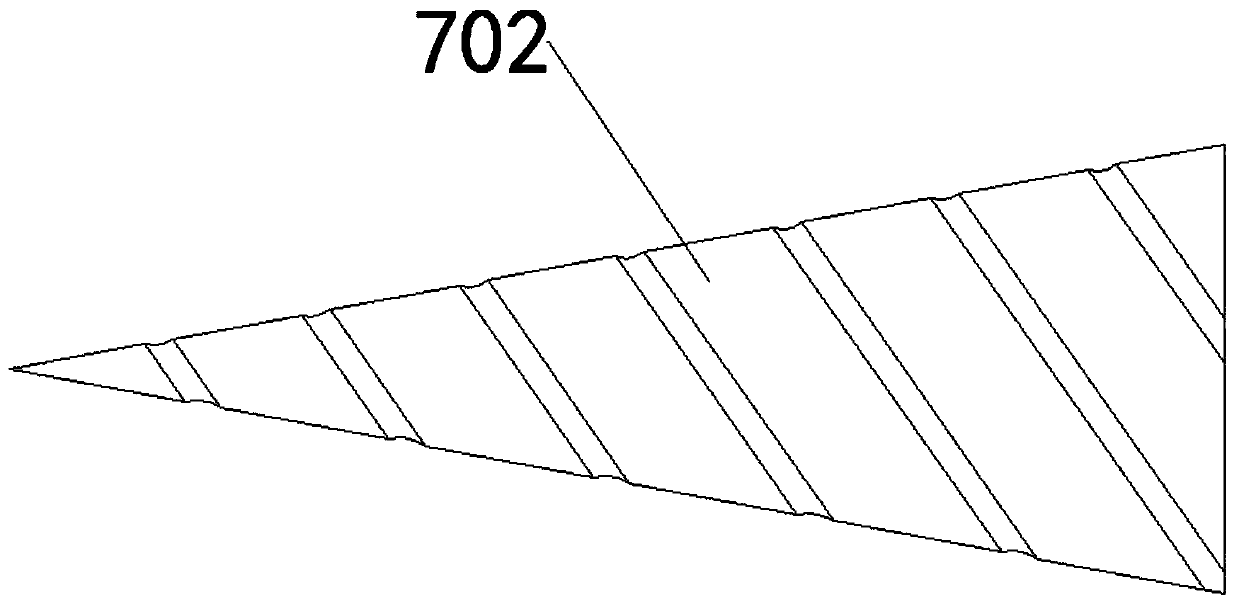

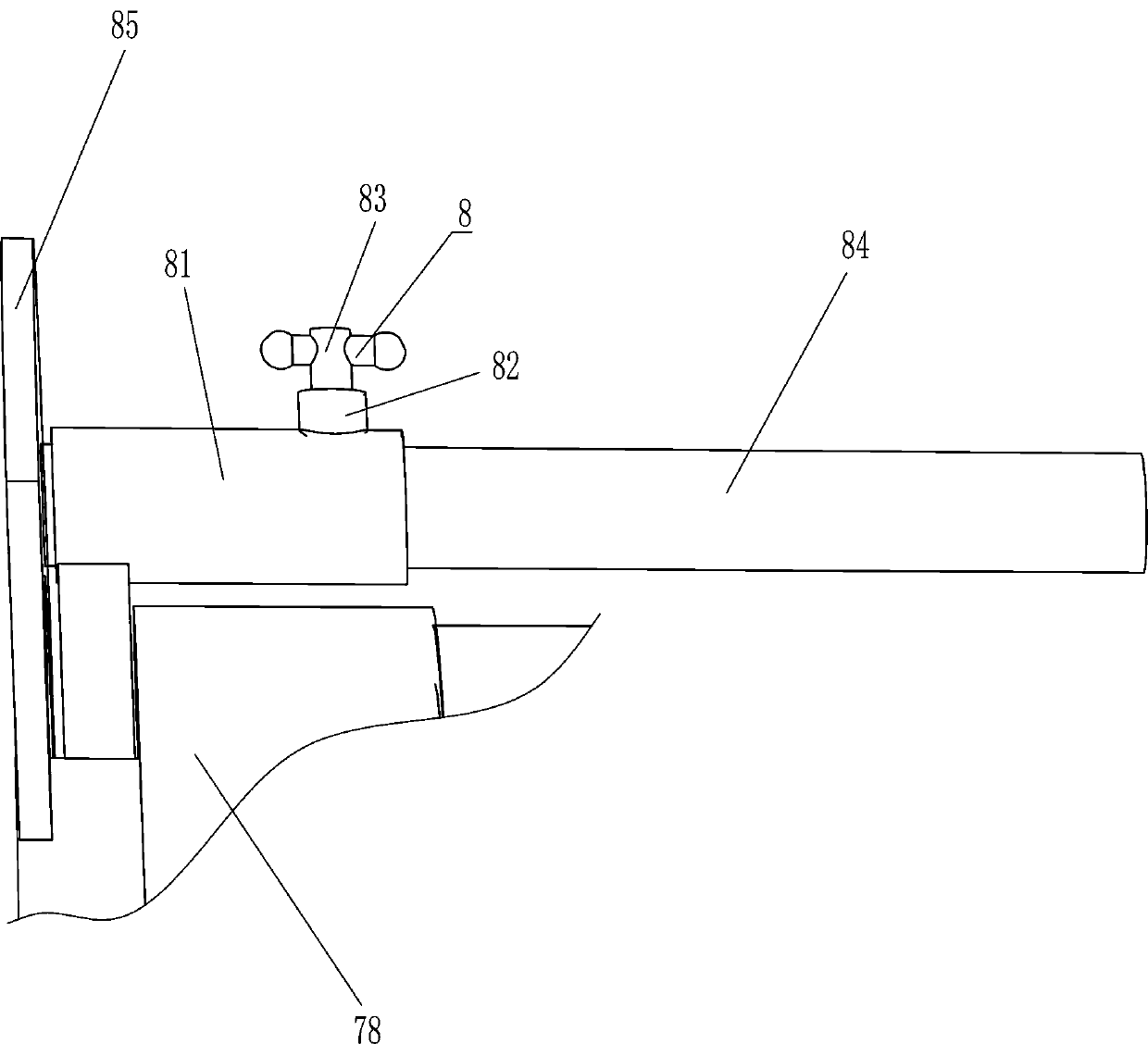

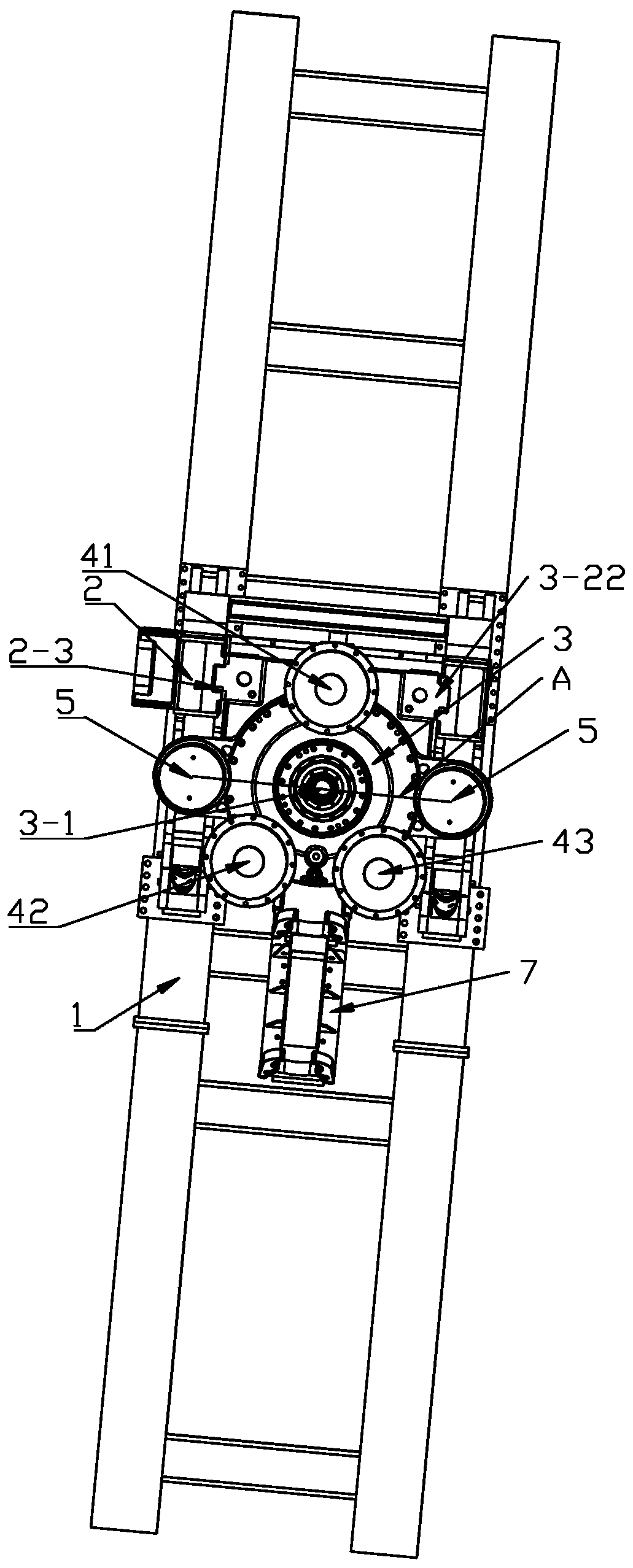

Device for testing feeding force and lifting force of top-drive power head drill

InactiveCN102539047ANeutral goodReduce test errorApparatus for force/torque/work measurementFeeding forceDrill

The invention relates to a device for testing feeding force and lifting force of a top-drive power head drill. At present, a device for testing the feeding force and the lifting force of the top-drive power head drill is required to reliably fix the drill, as well as ensuring the center of the power head of the drill is concentric with the testing device, but both are hard to realize, which results in that the drill shaft is likely to arch to influence the testing precision during testing the feeding force. The device comprises an oil cylinder, a force transmission core bar, a hinge bearing and a base plate, wherein the oil cylinder is arranged on the hinge bearing, and the base plate is mounted at the bottom of the hinge bearing; a piston rod of the oil cylinder is of a hollow structure and is provided internally with the force transmission core bar, and a pulling pressure sensor is mounted at the tail end of the force transmission core bar; the bottom of the base plate of the testing device is arranged on a guide rail on the drill body through a holder bearing; and a testing drilling rod held by the power head of the drill is connected with the pulling pressure sensor. With the testing device provided by the invention, the drill fixation is unnecessary; centering of the device relative to the power head of the drill is good, and thus the testing error is reduced.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

Cylindrical part bending angle measuring and horizontal and vertical surface drilling jig

InactiveCN103692251APrecise positioningConvenient bending angle measurementMeasurement/indication equipmentsPositioning apparatusHorizontal and verticalDrill

Owner:SHENYANG AEROSPACE UNIVERSITY

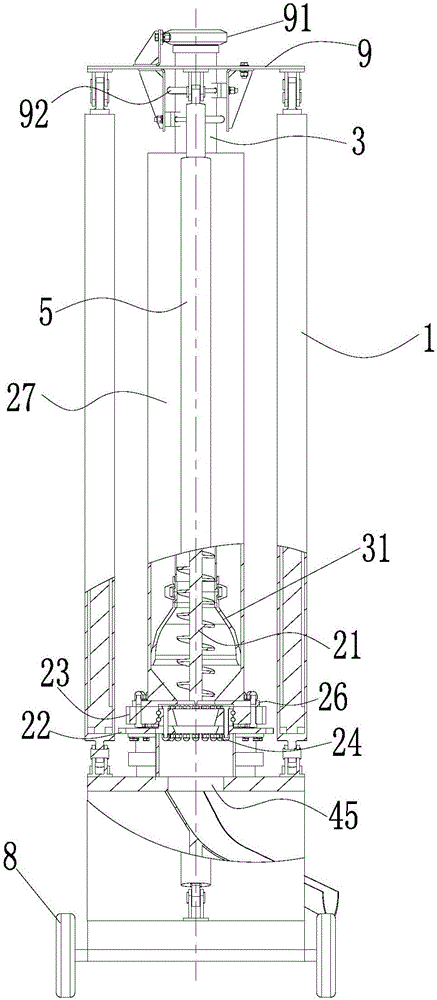

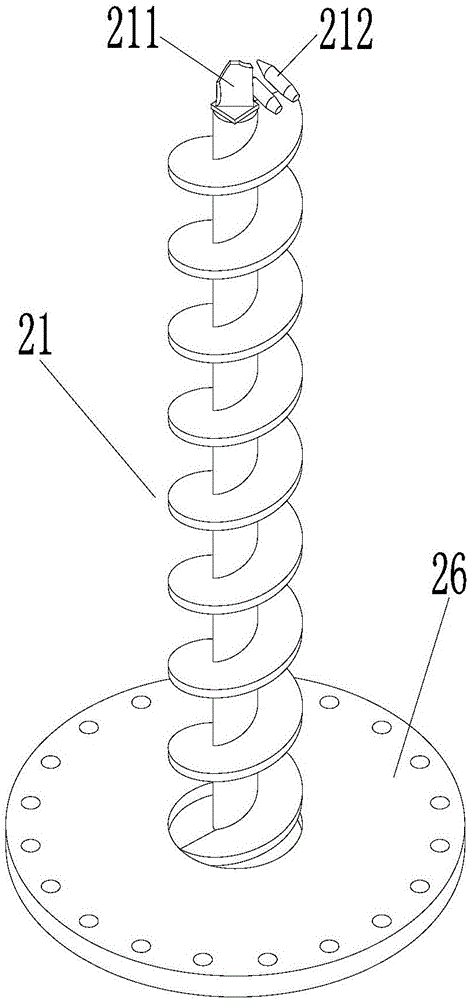

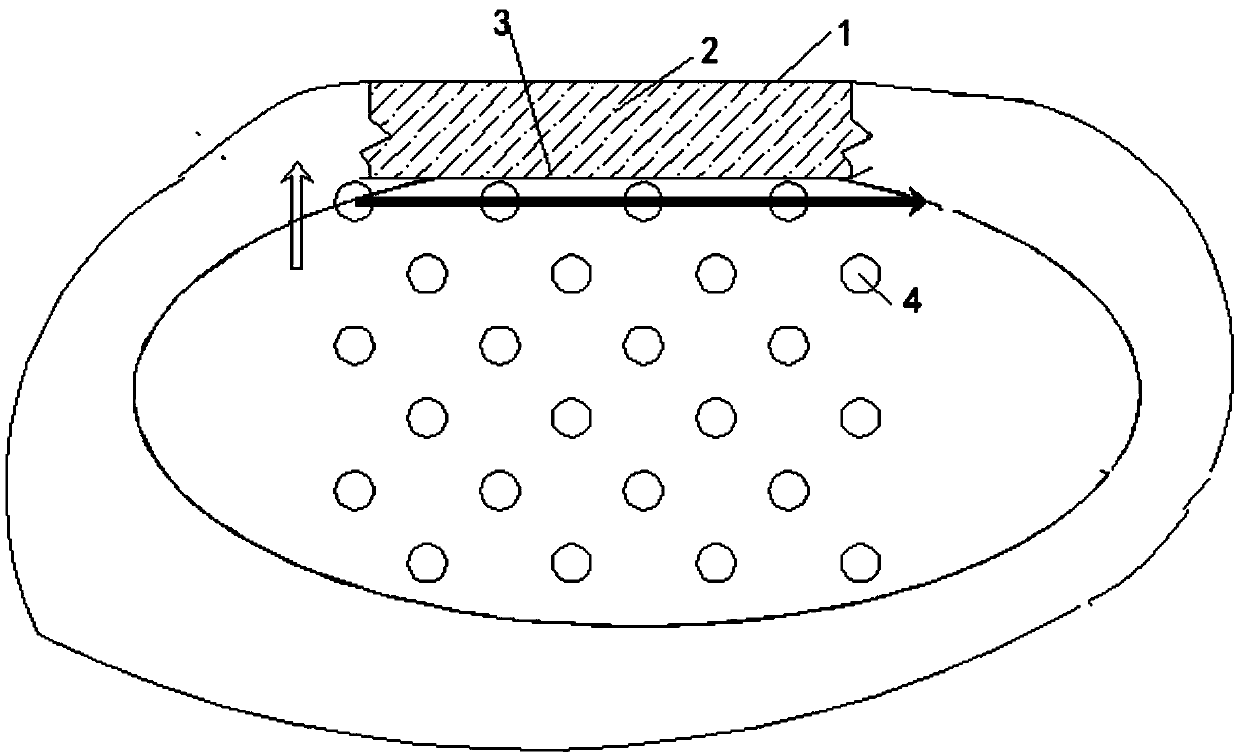

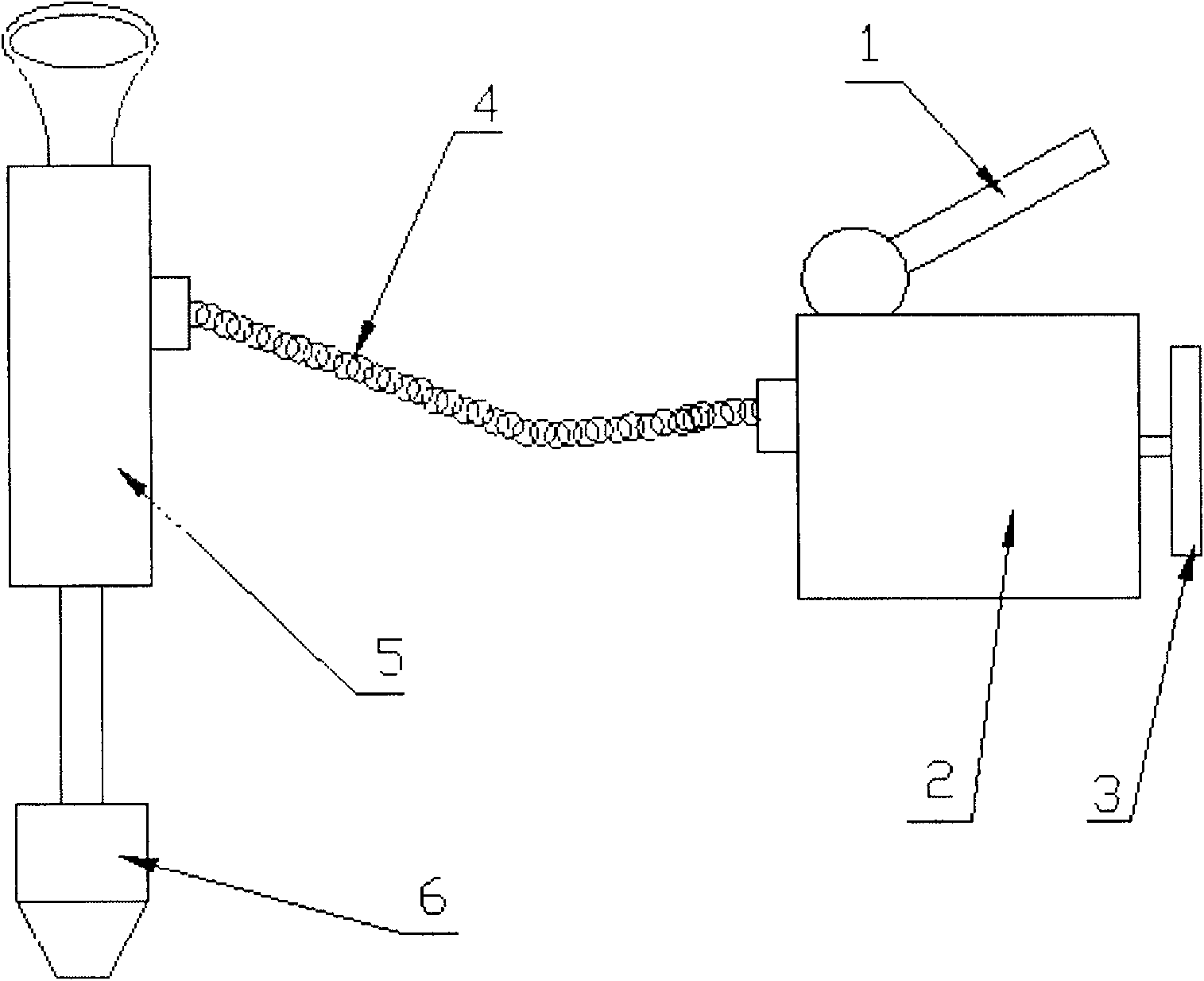

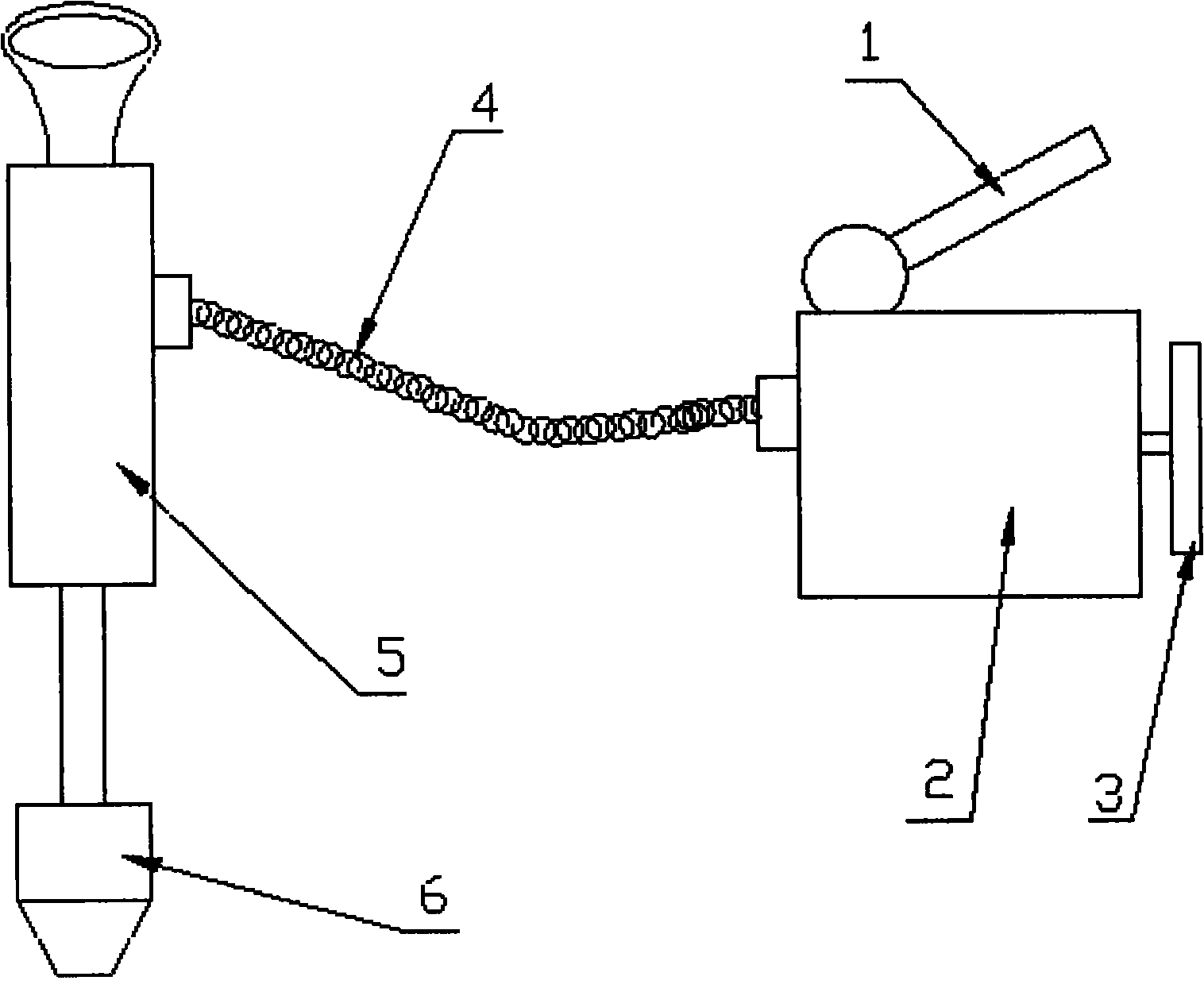

Material delivery pipe mechanism for bottom-mounted power drill rod

The invention belongs to the technical field of building, and relates to a material delivery pipe mechanism for a bottom-mounted power drill rod. The material delivery pipe mechanism comprises a drill rod and a length adjusting rod. A power mechanism is disposed between the drill rod and the length adjusting rod; the power mechanism is in driving connection with the drill rod, and is capable of driving the drill rod to rotate circumferentially. A delivery passage is formed within the drill rod, and a discharge hole is formed in the bottom of the drill rod and is communicated with the delivery passage. A slurry delivery pipe is disposed in the length adjusting rod, and extends into the power mechanism. A slurry delivery connecting pipe is disposed on the outer wall of the power mechanism, and one end of the slurry delivery connecting pipe is detachably connected to the slurry delivery pipe, while the other end of the slurry delivery connecting pipe is detachably connected to the delivery passage. The invention provides a delivery pipe mechanism capable of realizing bottom-mounted power of the drill rod, thereby guaranteeing that material can be delivered to the drill rod when power for the drill rod is mounted at bottom so as to obtain a high-strength cement soil mixing pile; no disturbance is produced for the power structure; and reliable and stable work is achieved.

Owner:ZHEJIANG ZHAODI TECH CO LTD

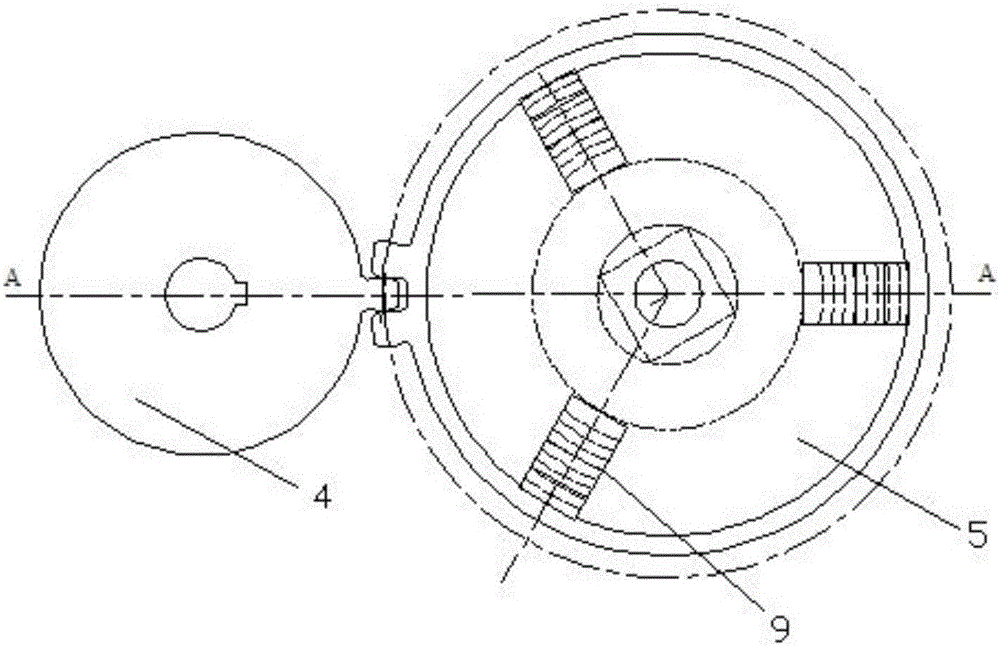

Automatic pipe bender

The invention relates to an automatic pipe bender which comprises a base, a left support, a right support, a speed reducing mechanism, an output torque amplifying mechanism and a pipe bending implementing mechanism. The left support and the right support are fixed on the base, an input end of the speed reducing mechanism is connected with an output end of an electric drill through a first shaft, an output end of the speed reducing mechanism is connected with an input end of the output torque amplifying mechanism, and an output end of the output torque amplifying mechanism is connected with the pipe bending implementing mechanism. The electric drill is taken as a power source, the rotating speed of the electric drill is adjusted to be suitable for pipe bending operations through the electric drill, the output torque amplifying mechanism is adopted to enable a torque force applying point to be extended outwards from the input end of the output torque amplifying mechanism to the output end of the same and transfer the torque force applying point to the pipe bend implementing mechanism, a force arm is added, and amplifying of output torque is realized through a force amplifying mechanism to drive the same to rotate and force a pipe to be bent so as to bend the pipe into a certain angle.

Owner:SHENYA AUTOMATION EQUIP LAIZHOU CO LTD

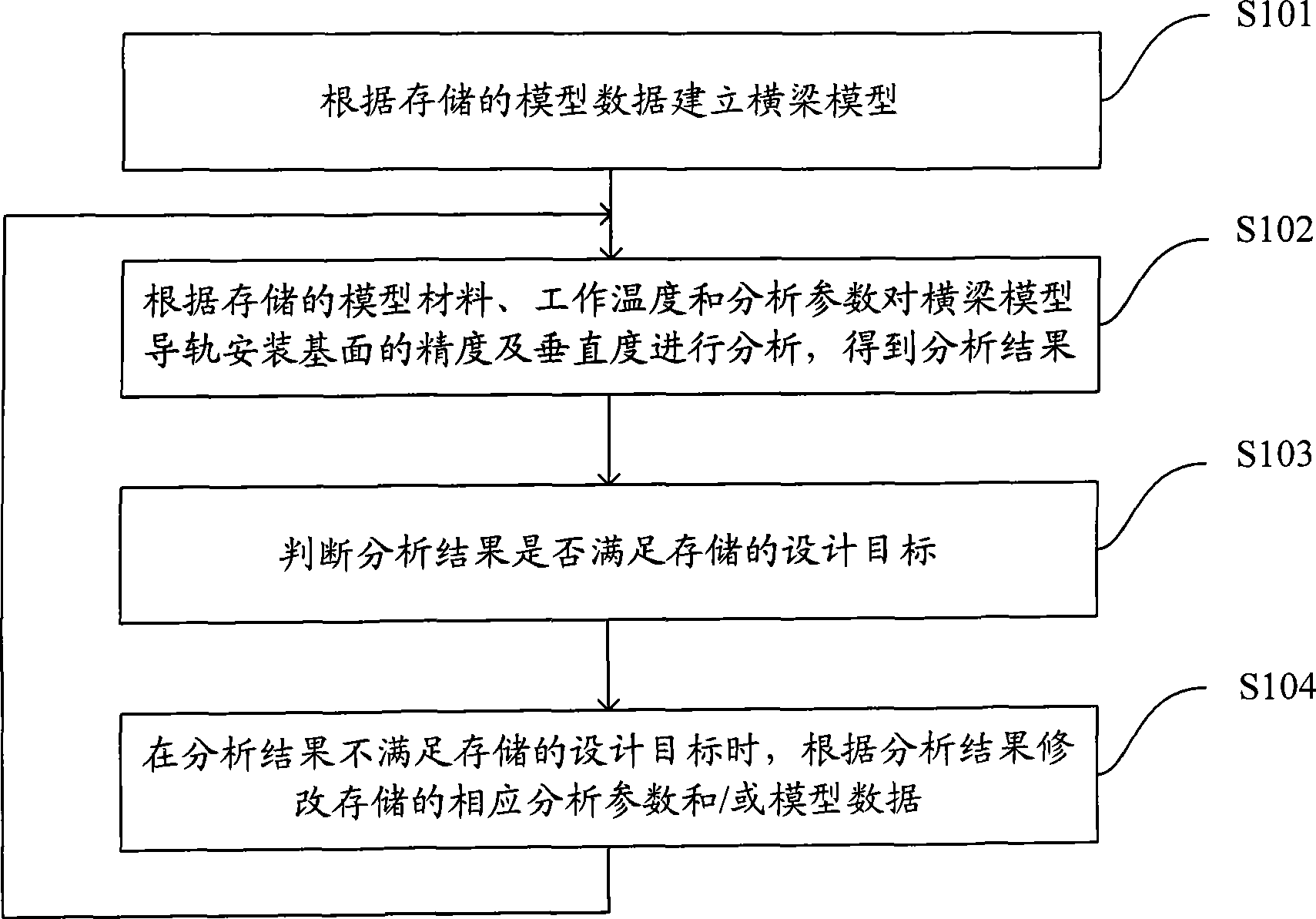

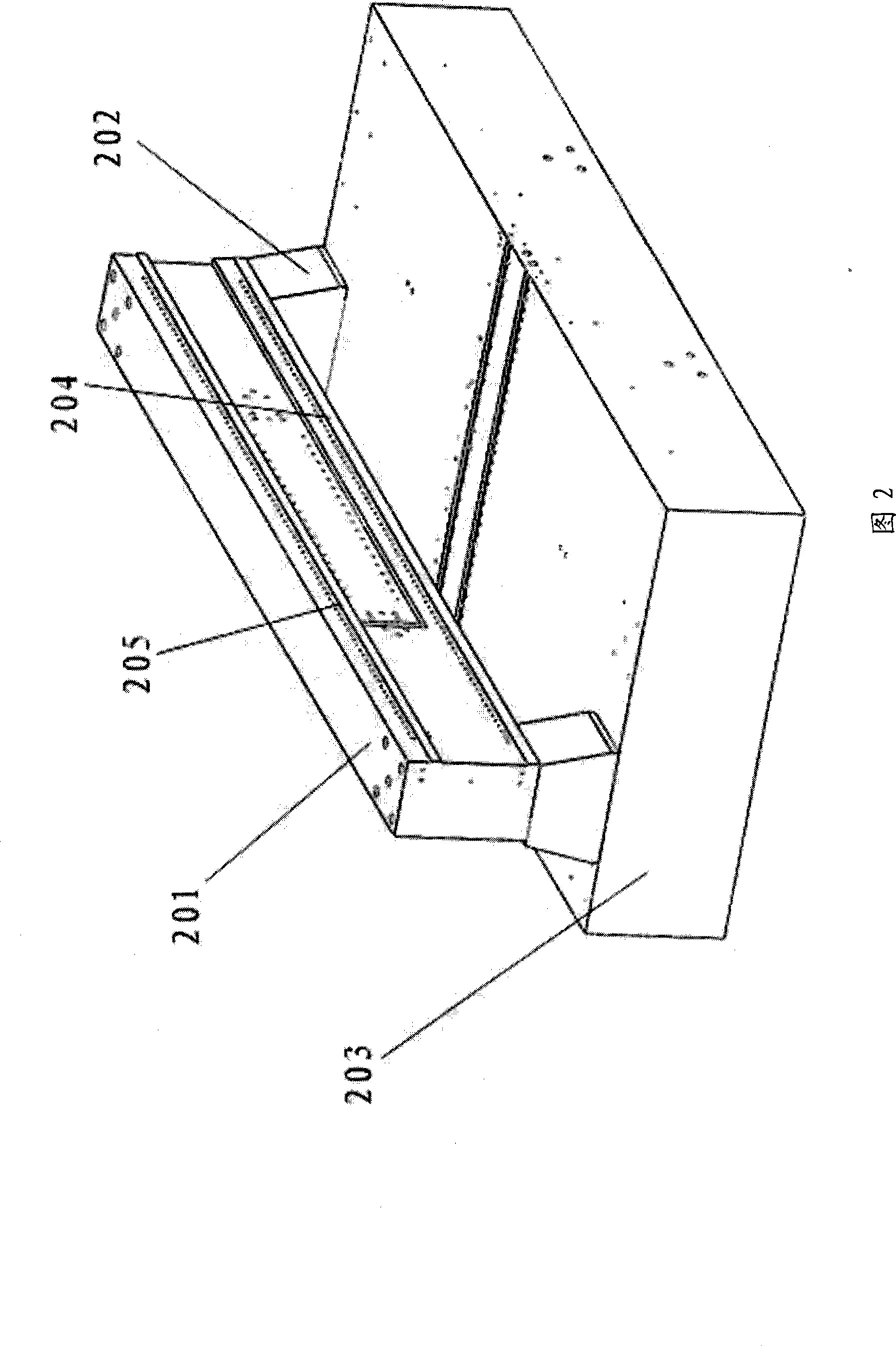

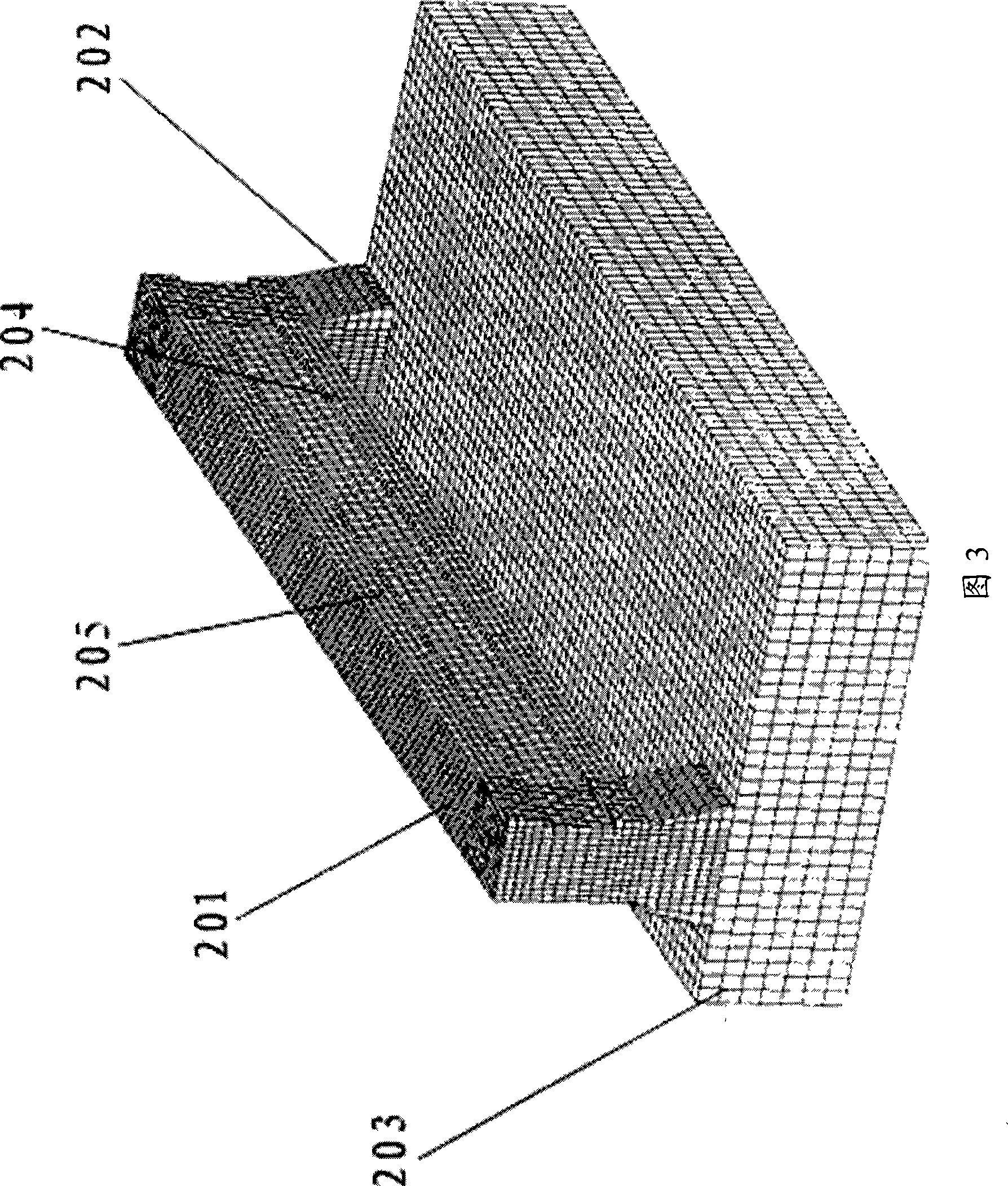

Simulation method, system and equipment for transverse beam assembly of drill

ActiveCN101430734AImprove product qualityShorten the development cycleSpecial data processing applicationsWorking temperatureEngineering

Owner:HANS CNC SCI & TECH

Conveying pipe cleaning device

Owner:河北雷萨重型工程机械有限责任公司

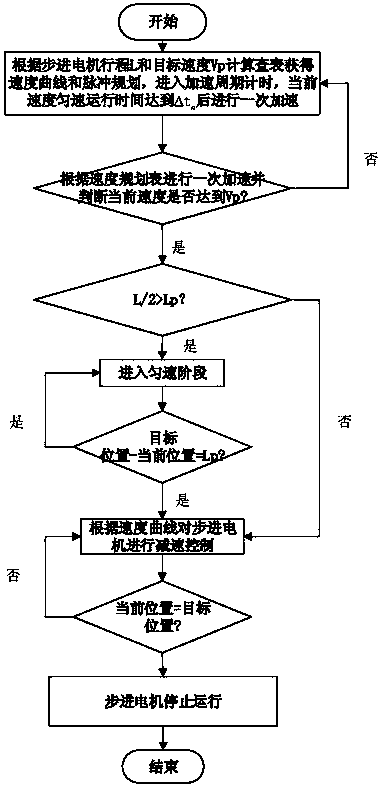

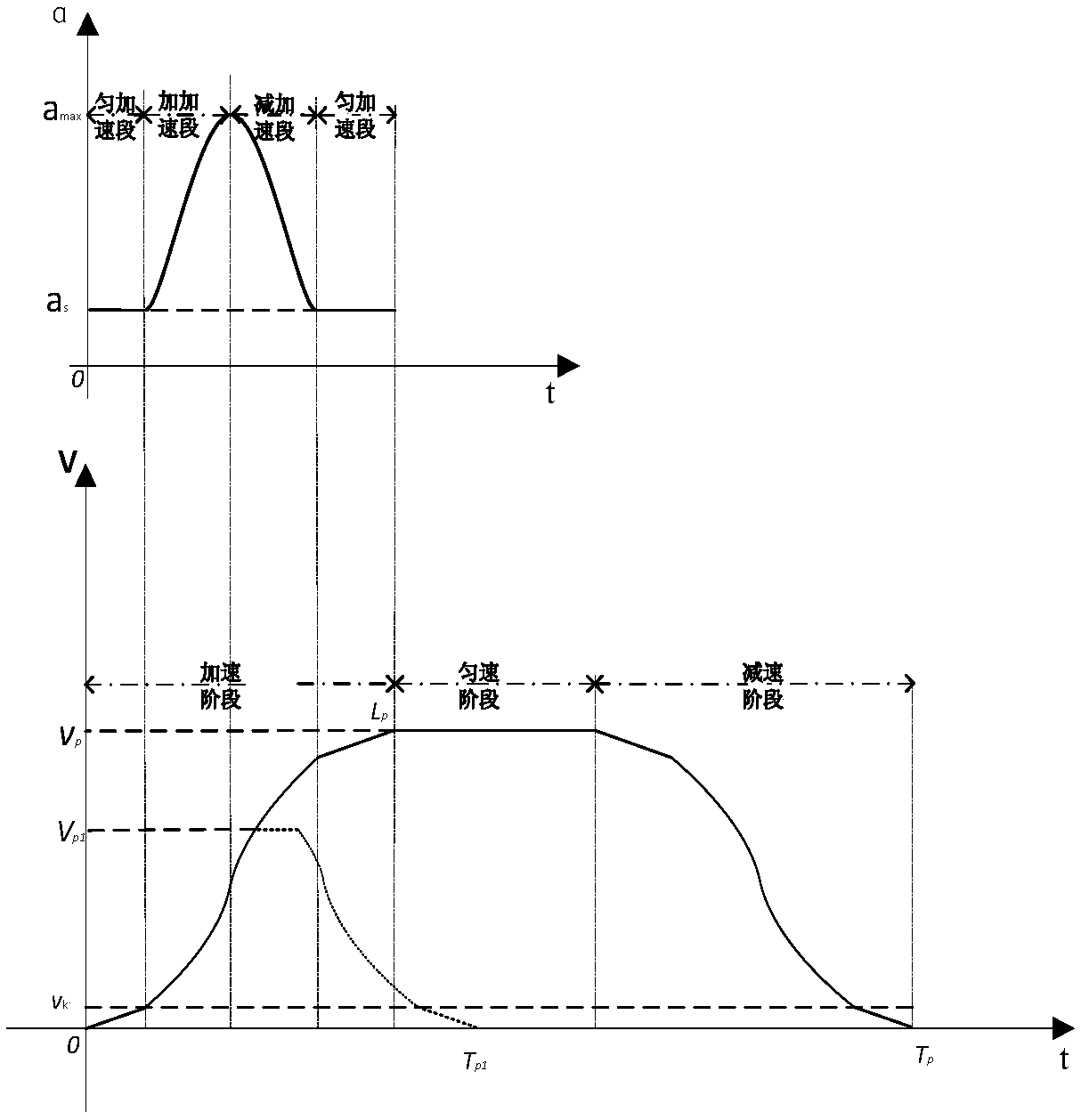

Automatic spot drill motor speed control method

ActiveCN109508050APrevent the drill from falling offAvoid positionSpeed/accelaration control using electric meansMotor speedCurrent velocity

Owner:ZHEJIANG UNIV OF TECH

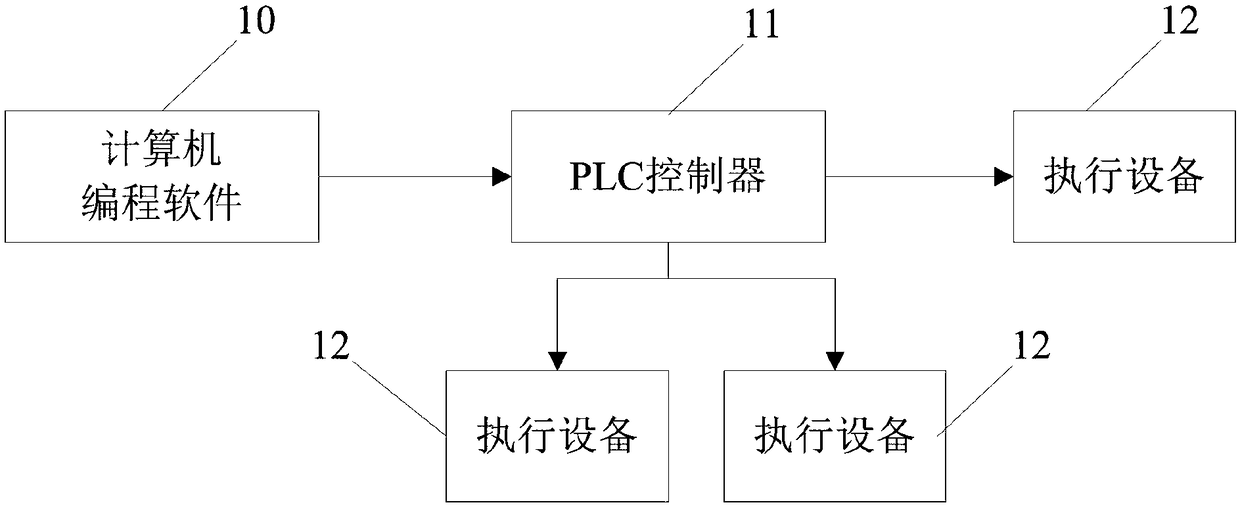

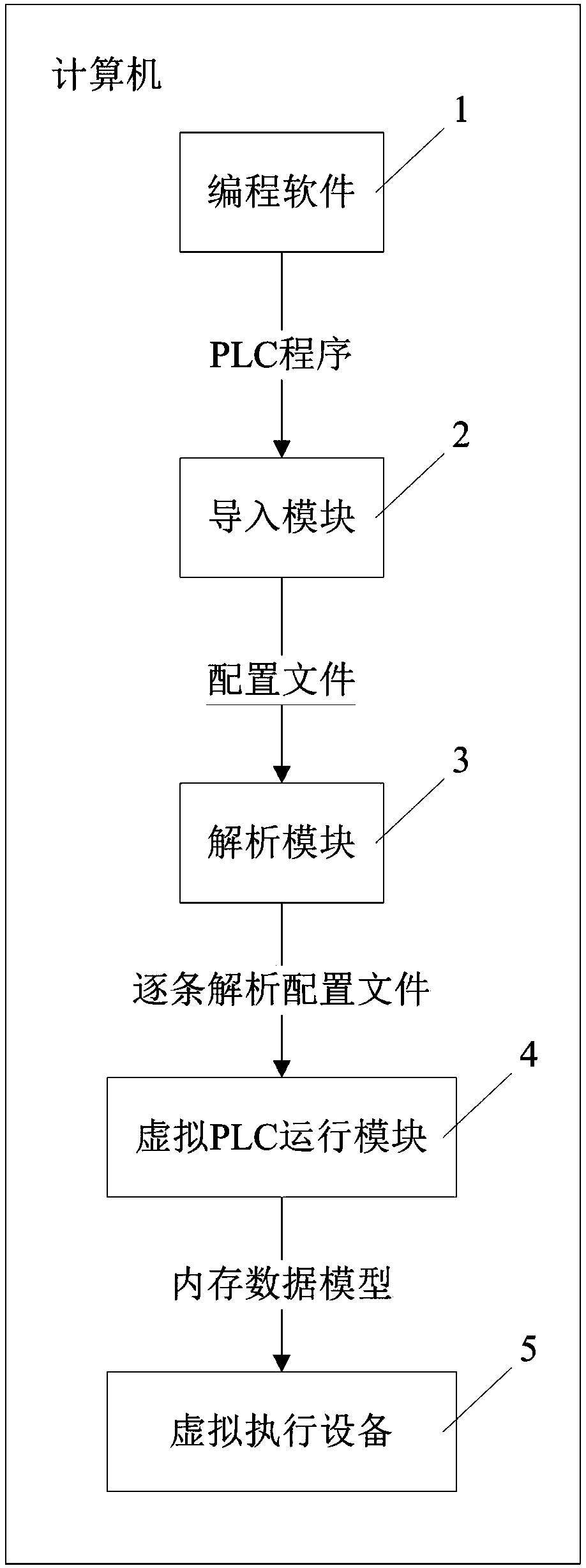

Virtual PLC simulation system and method

InactiveCN108614516AIncrease the feasibilityEasy to meet control requirementsProgramme control in sequence/logic controllersComputer scienceLogic analysis

Owner:SHENZHEN CUBESPACE TECH CO LTD

Novel process for cabinet product laminate assembling

InactiveCN110355851AReduce use costShort production processWood working apparatusTransverse planeEngineering

Owner:肇庆市现代筑美家居有限公司

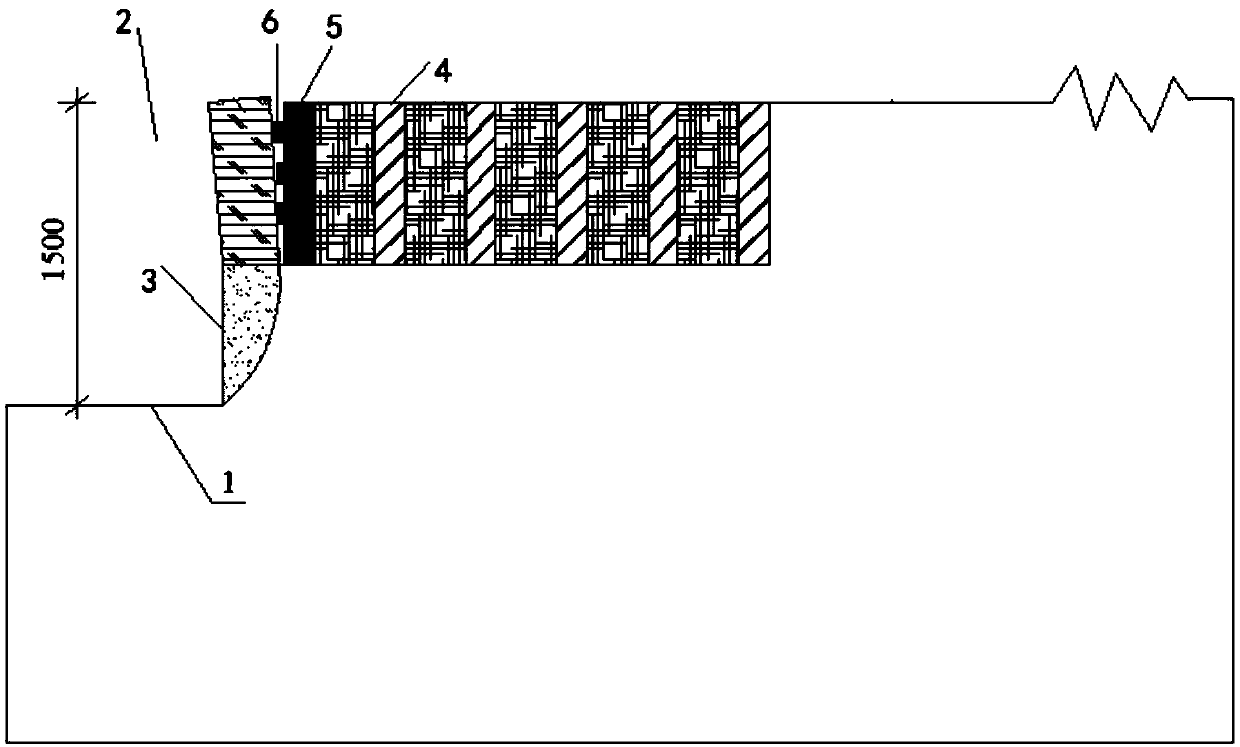

High-strength rock splitting method and a splitting device based on a weak surface

PendingCN109522623AEasy constructionEasy to operateBlastingDesign optimisation/simulationClassical mechanicsEngineering

Owner:CHINA RAILWAY 12TH BUREAU GRP +1

Heating processing technology for deep sea petroleum drill by adopting conduit joint

InactiveCN103215425AUniform heating effectUniform thermal deformationDrilling rodsFurnace typesFurnace temperatureWater cooling

The invention discloses a heating processing technology for a deep sea petroleum drill by adopting a conduit joint. The technology comprises the following steps: charging: vertically putting the conduit joint in a well type quenching furnace in the way that a welding neck end faces down, maintaining space between the periphery and upper and lower layers, keeping the furnace temperature at 871-910 DEG C for at least 80 minutes, hoisting out from a hearth and 15 seconds later, feeding into a quenching pool with water temperature of 40-48 DEG C for quenching; performing water cooling for at least 15 minutes; then feeding into the furnace for normalizing treatment at the normalizing temperature of 899-940 DEG C, performing tempering treatment within four hours from the beginning of quenching at the tempering temperature of 575-620 DEG C, wherein the tempering holding time at least lasts 160 minutes; and then hoisting the conduit joint blank out of the hearth and directly placing into a water tank, and cooling to normal temperature. The technology is reasonable in parameter and easy to implement; product quality is stable, and the pass percent is more than 96%.

Owner:JIANGSU SHUGUANG OIL DRILLING EQUIP CO LTD

Claw-type chuck drill jig for disc sleeve type parts

Owner:SUZHOU VOCATIONAL UNIV

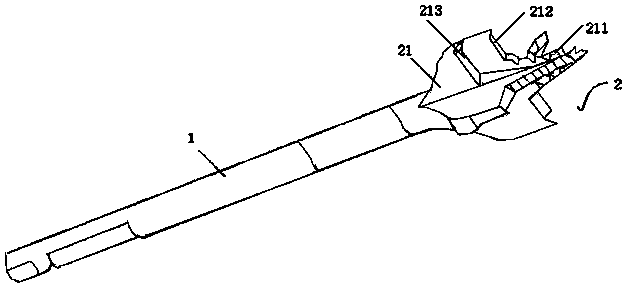

Electric breakover device and using method

PendingCN108222923AGuaranteed normal transmissionEfficient conductionSurveyMeasuring instrumentEngineering

The embodiment of the invention provides an electric breakover device and a using method. The device is used for transmitting an electric signal between a while-drilling measuring instrument and a non-magnetic drill collar and comprises a guiding shaft, an elastic piece and limiting parts. The two ends, in the longitudinal direction, of the guiding shaft are provided with the limiting parts correspondingly, the length of the elastic piece is larger than that of the guiding shaft, and the two ends of the elastic piece are inserted into the limiting parts at the two ends of the guiding shaft correspondingly to form radial expansion. The elastic piece is made of a conducting material. When the device is specifically used, the elastic piece is connected with the limiting parts, and thus the limiting parts are connected with electrodes of the while-drilling measuring instrument; and when the device is put into a well, the radially-expanded elastic piece makes contact with the non-magnetic drill collar to be electrically connected with the non-magnetic drill collar, thus measuring data collected by the while-drilling measuring instrument can be transmitted to the non-magnetic drill collar through contact between the elastic piece and the non-magnetic drill collar, and the technical problem that breakover cannot be efficiently and conveniently achieved between the while-drilling measuring instrument and the non-magnetic drill collar is solved accordingly.

Owner:CHINA NAT PETROLEUM CORP +2

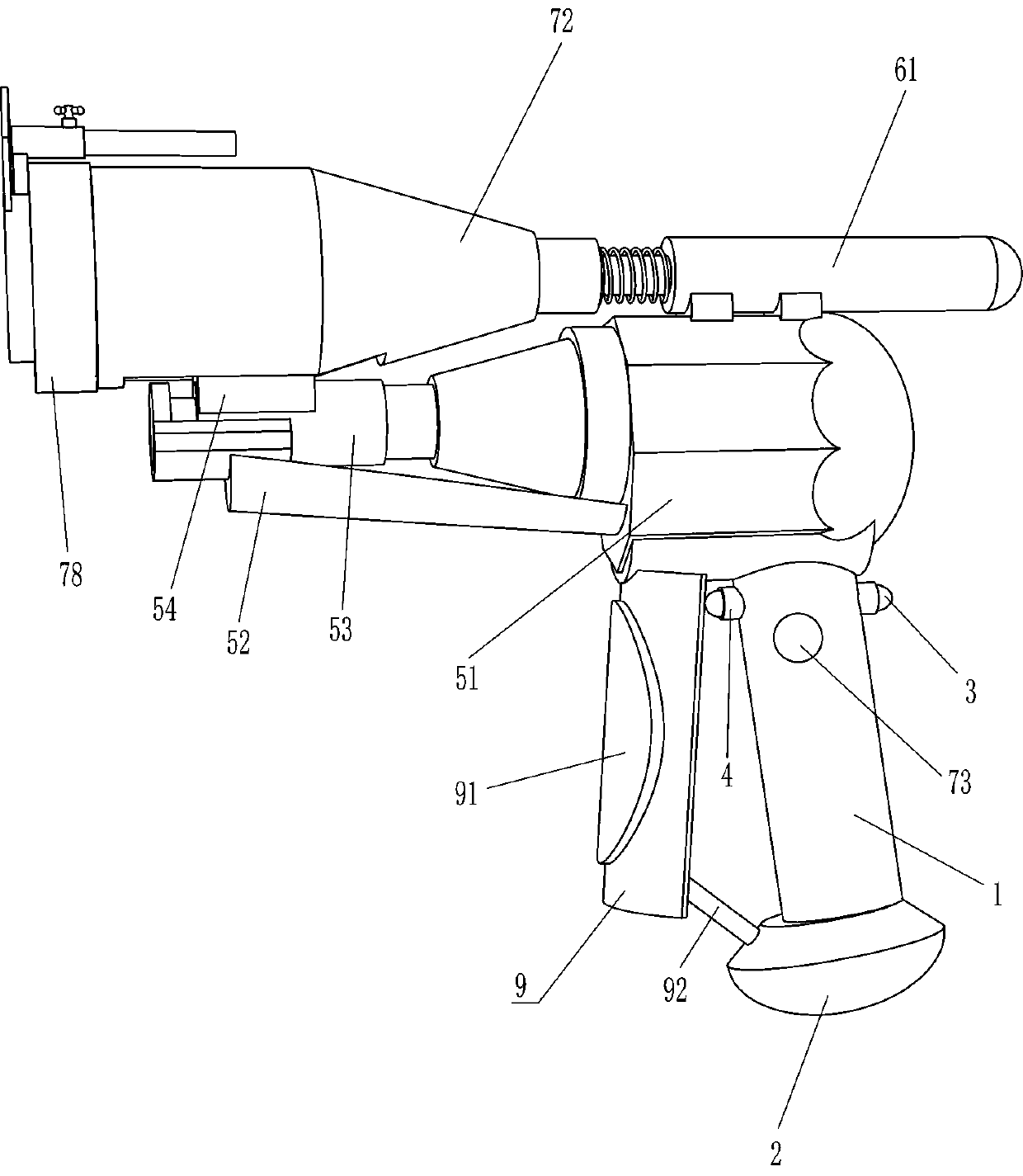

Novel foot-operated hand drill

InactiveCN102451927ASuitable for installationSuitable for maintenance work needsPortable drilling machinesEngineeringFlywheel

Owner:郑忠民

Woodworking flat drill

InactiveCN108501142AExtended service lifeHigh speedWood turning toolsWood boring toolsEngineeringDrill

Owner:如皋千骏工具有限公司

Fir log cutting and separating all-in-one machine with function of occlusive push

Owner:ANHUI SUNMIRO AGRI TECH

Cold mounting device for interference bolts

ActiveCN111515615AEasy to operateInhibit sheddingPortable percussive toolsMetal working apparatusStructural engineeringDrill

Owner:平邑经发科技服务有限公司

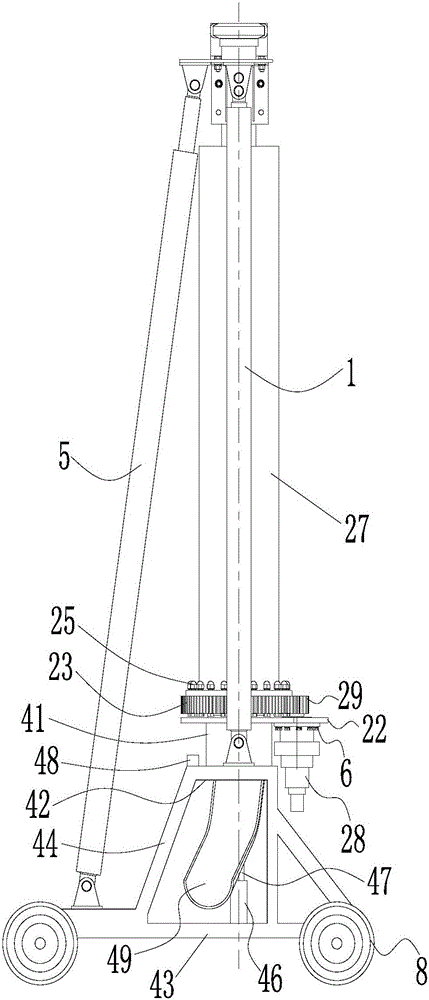

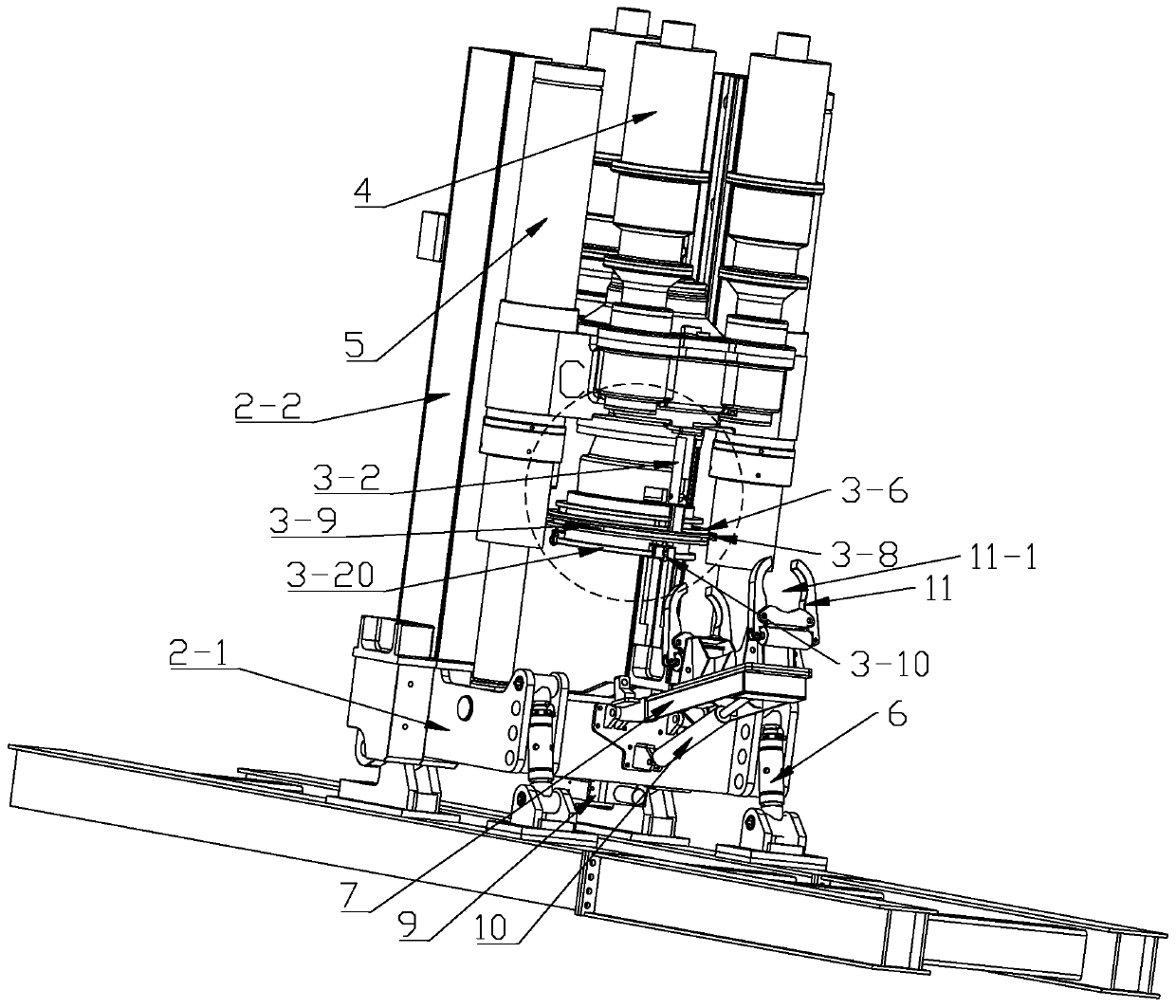

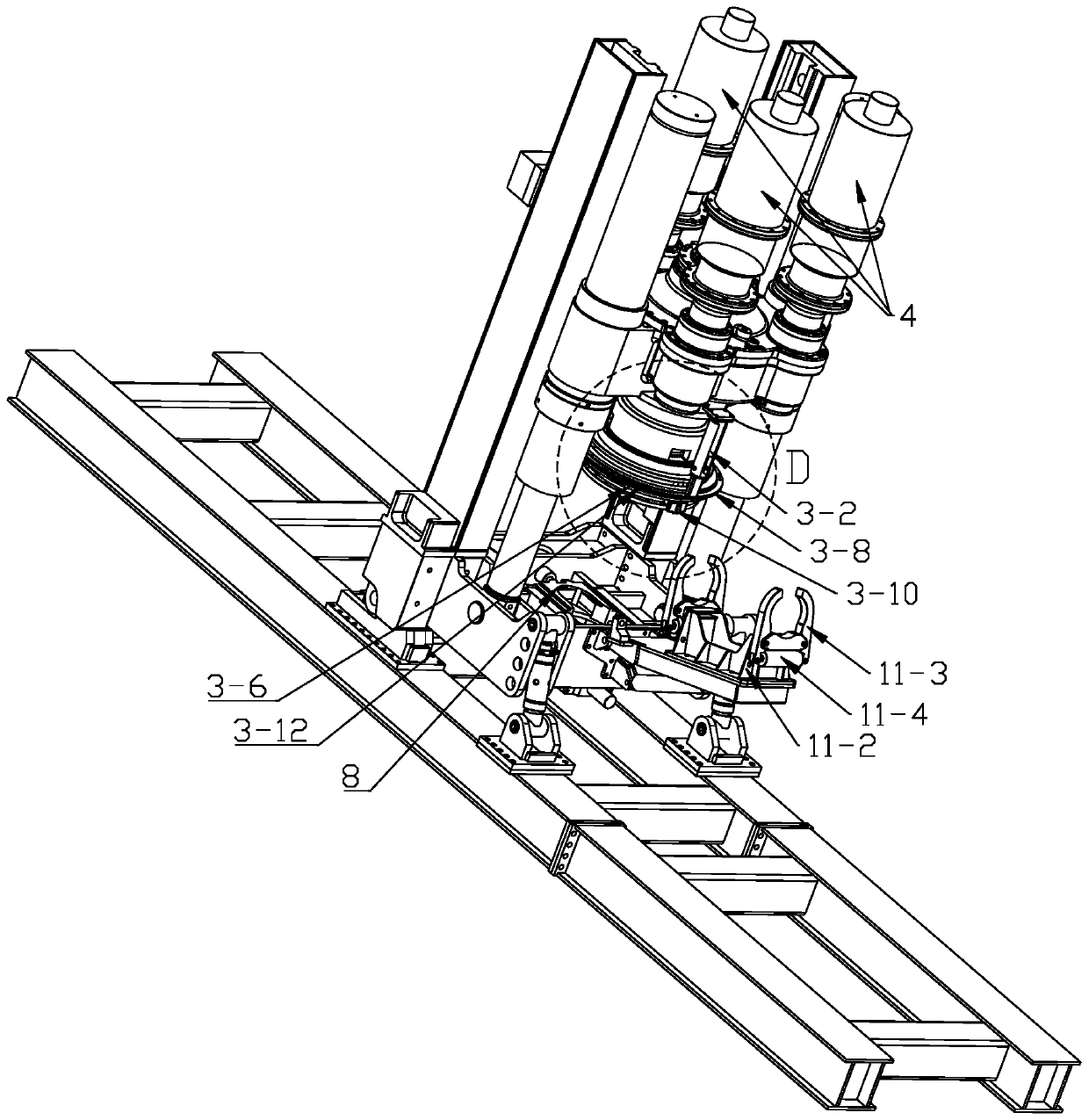

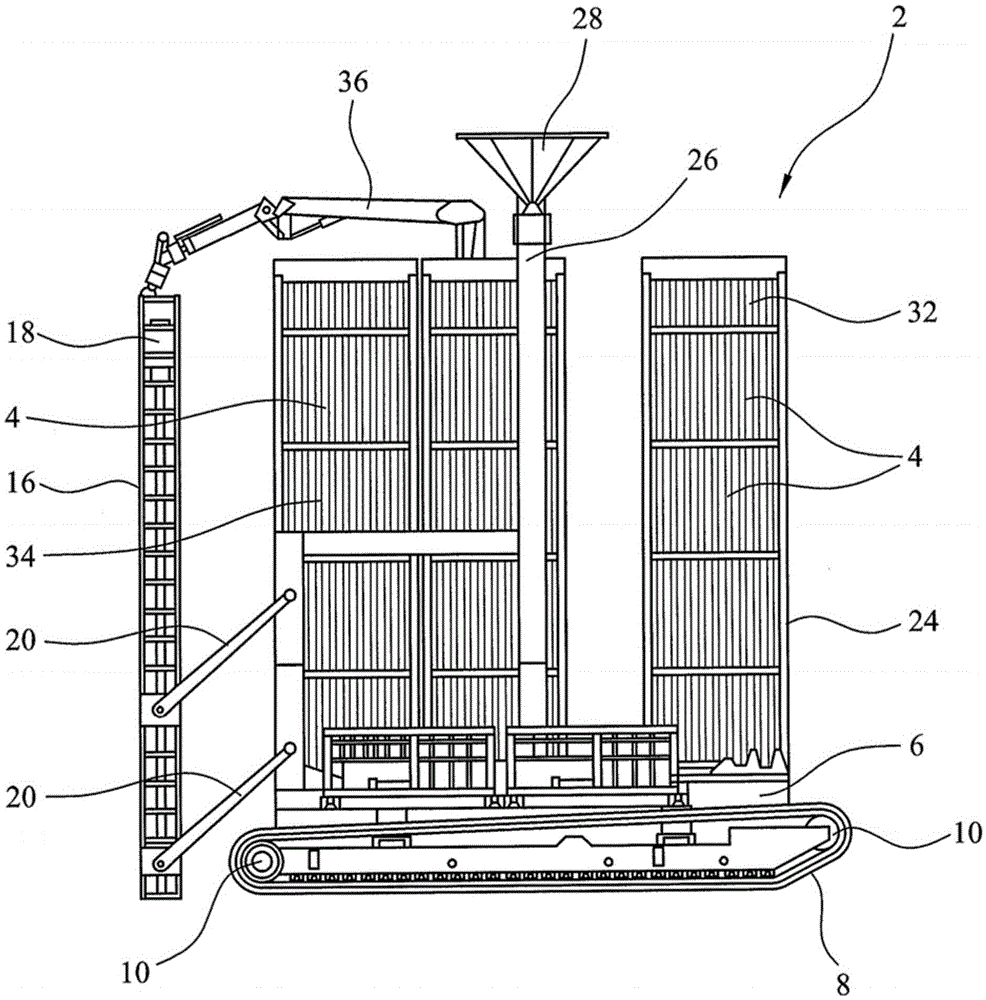

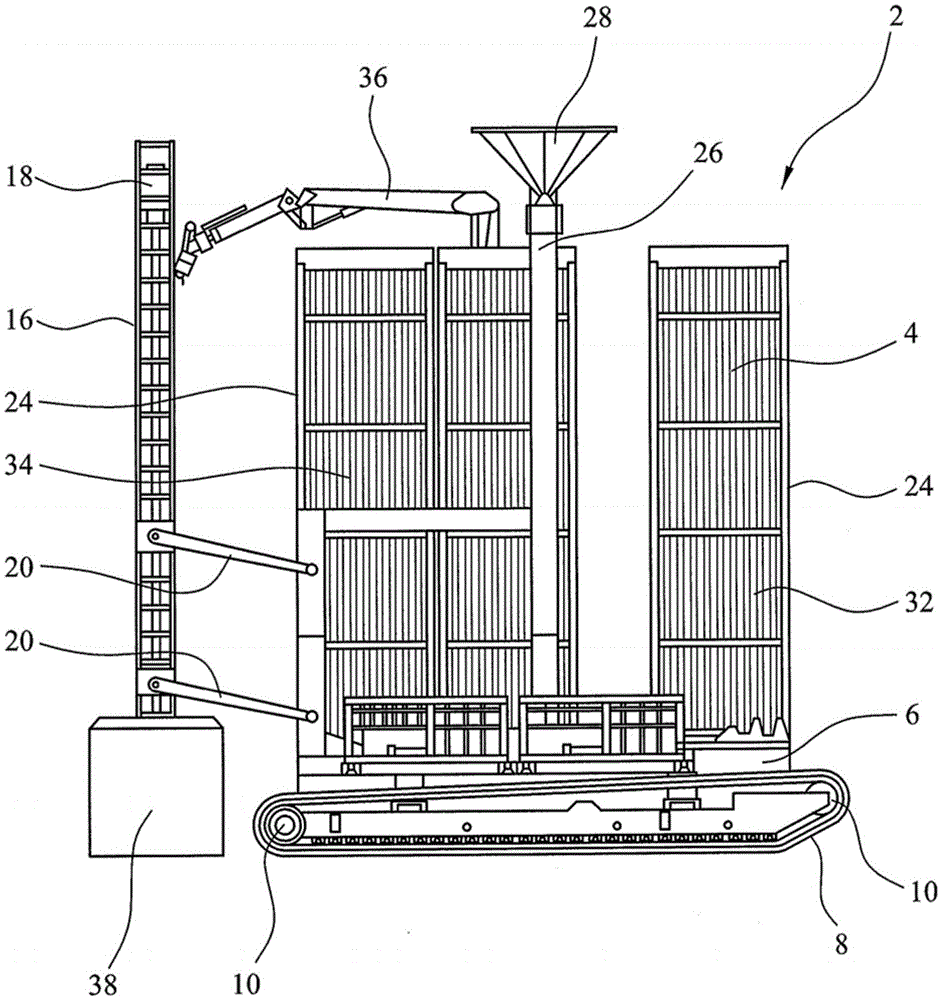

Intelligent electric drive raise boring machine and drilling control method thereof

PendingCN111287751AEasy maintenanceSmooth startConstructionsDerricks/mastsElectric machineReciprocating motion

Owner:BEIJING CHINA COAL MINE ENG CO LTD

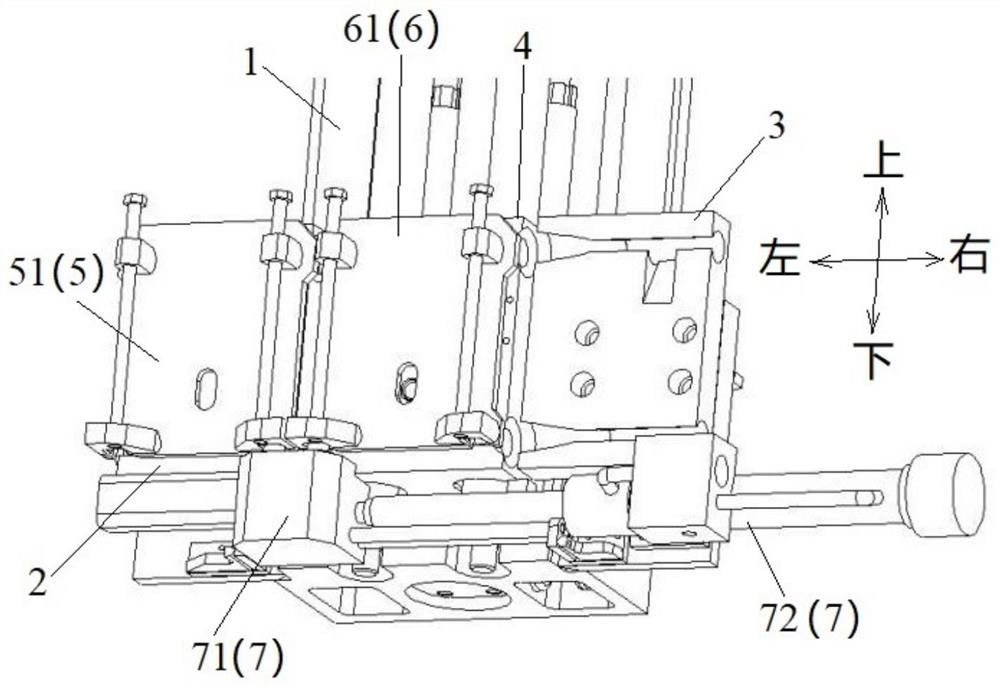

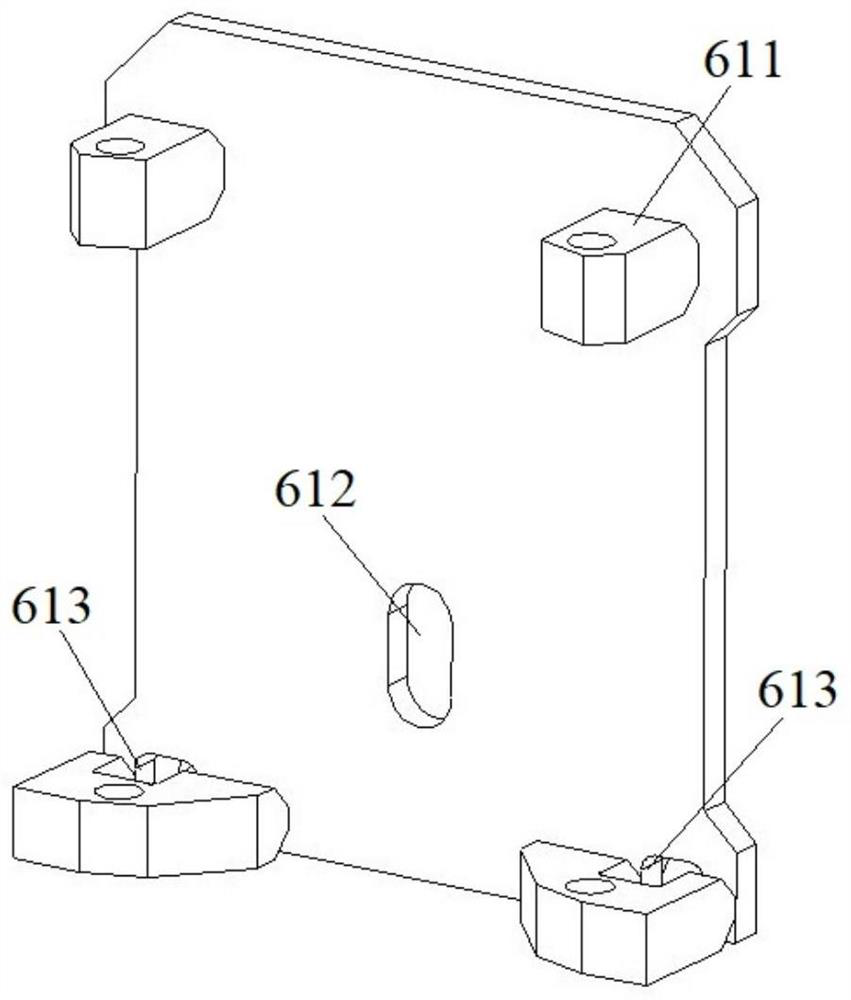

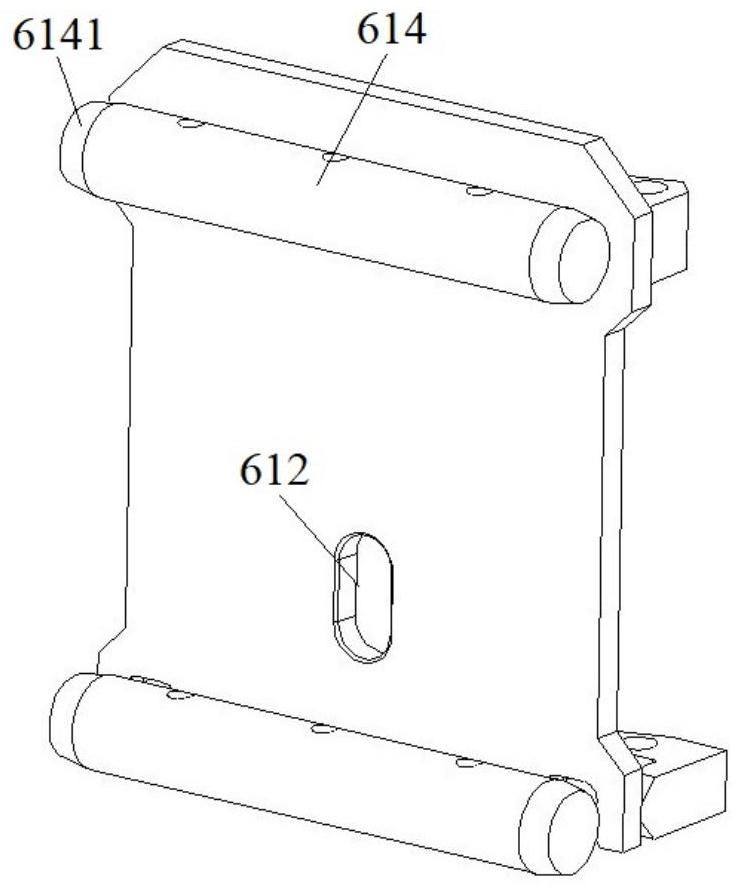

Drilling box and anchor box switching assembly and anchor rod drill carriage

PendingCN113685135ASmall footprintRealize switchingDrilling rodsDrilling casingsSlide plateRock bolt

Owner:TAIYUAN INST OF CHINA COAL TECH & ENG GROUP +1

Subsea support apparatus for supporting drive means, and driving apparatus incorporating such support apparatus

Owner:索尔机械动力有限公司

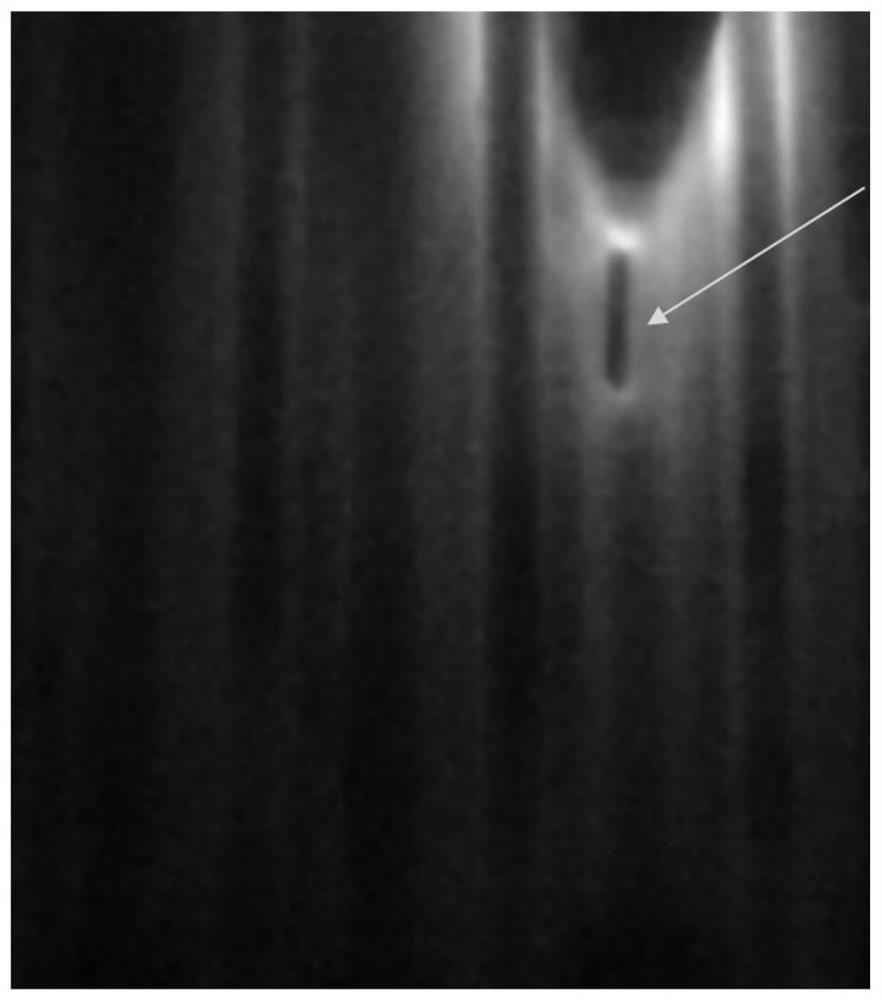

Drill rod thread detection device and method based on ferrite eddy current thermal imaging

PendingCN112114030ANo pollution in the processHigh speedElectric/magnetic position measurementsUsing electrical meansThermographic cameraManganese

Owner:成都鳌峰机电设备有限责任公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap