Simulation method, system and equipment for transverse beam assembly of drill

A drilling machine and beam technology, applied in the field of data processing, can solve problems such as high cost and long development cycle, and achieve the effects of improving product quality, shortening development cycle, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

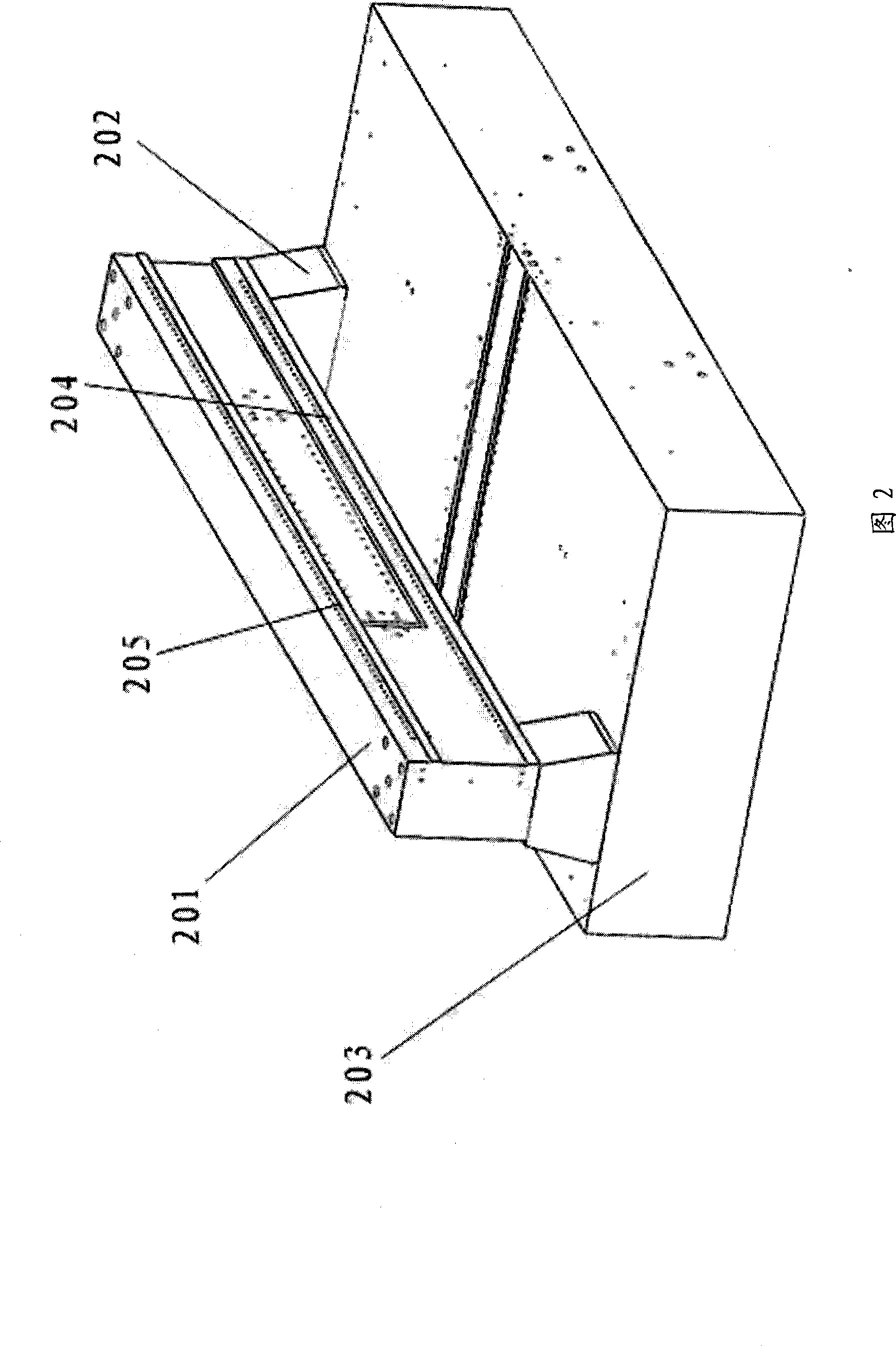

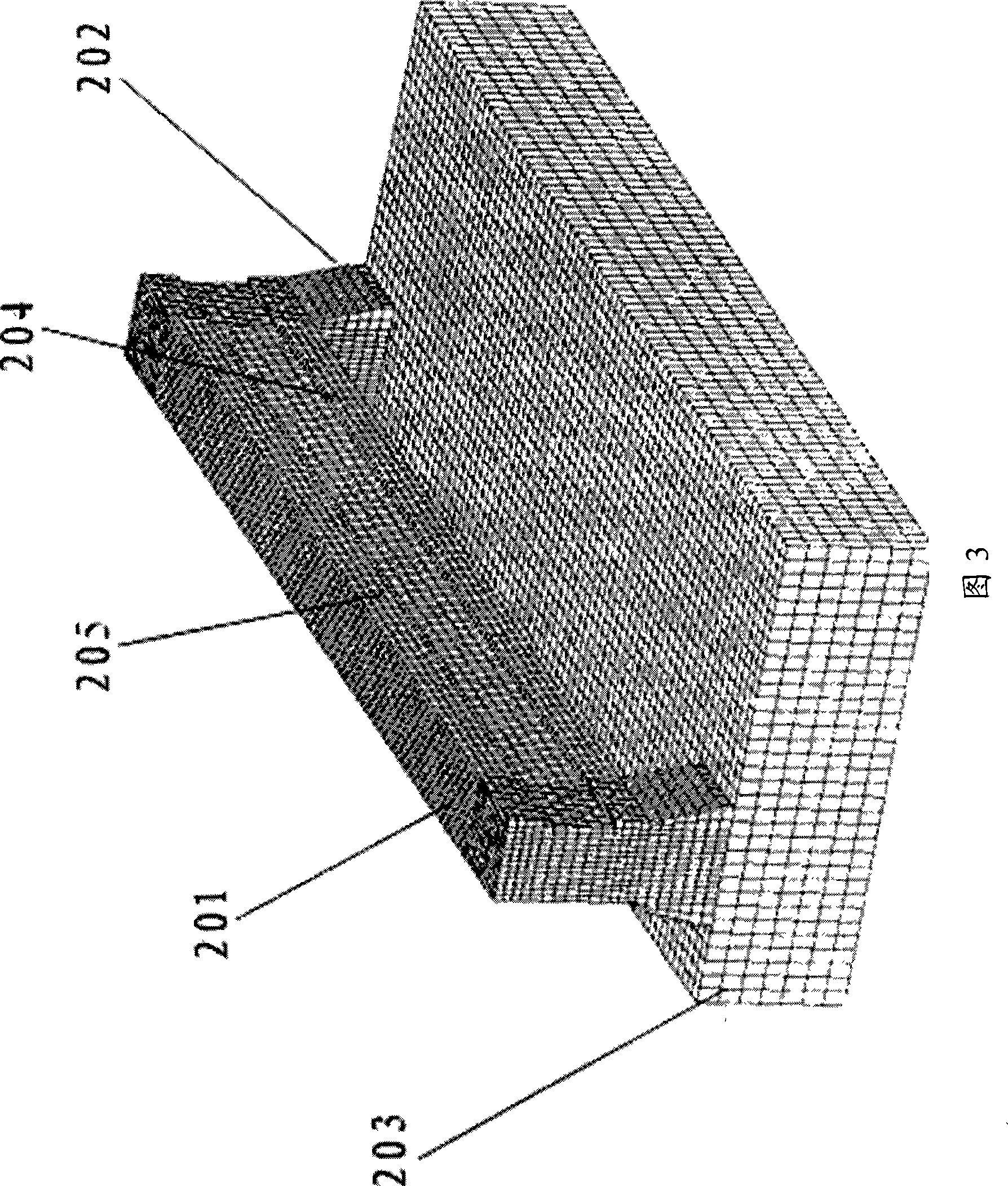

[0025] In the embodiment of the present invention, by analyzing the accuracy and verticality of the installation base surface of the guide rail of the beam model, and modifying the stored analysis parameters and model data according to the analysis results, a simulation method for assembling the beam of the drilling machine is realized.

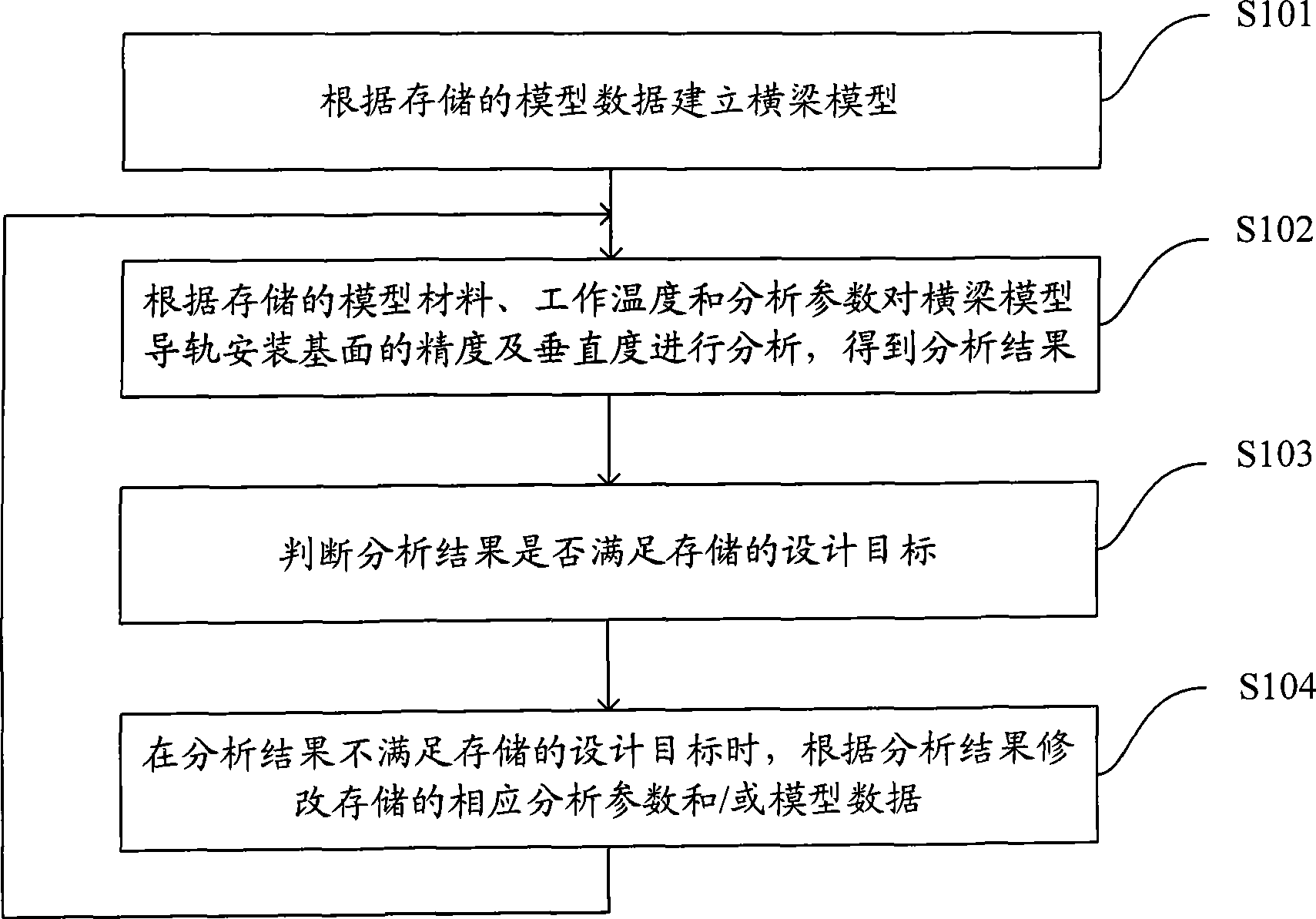

[0026] figure 1 The implementation flow of the simulation method for drilling beam assembly provided by the embodiment of the present invention is shown, and the details are as follows:

[0027] In step S101, a beam model is established according to stored model dat

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap