Automatic spot drill motor speed control method

A technology for speed control and drilling rigs, which is applied in the direction of electric speed/acceleration control, etc., can solve the problems of spot drilling rig material drill drop-off, material drilling position, equipment cost increase, spot drilling rig vibration, etc., to avoid material drill falling off and low cost , to meet the needs of the controller

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

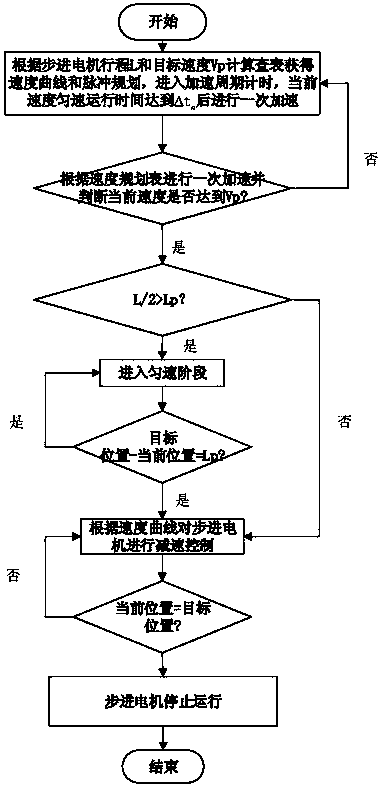

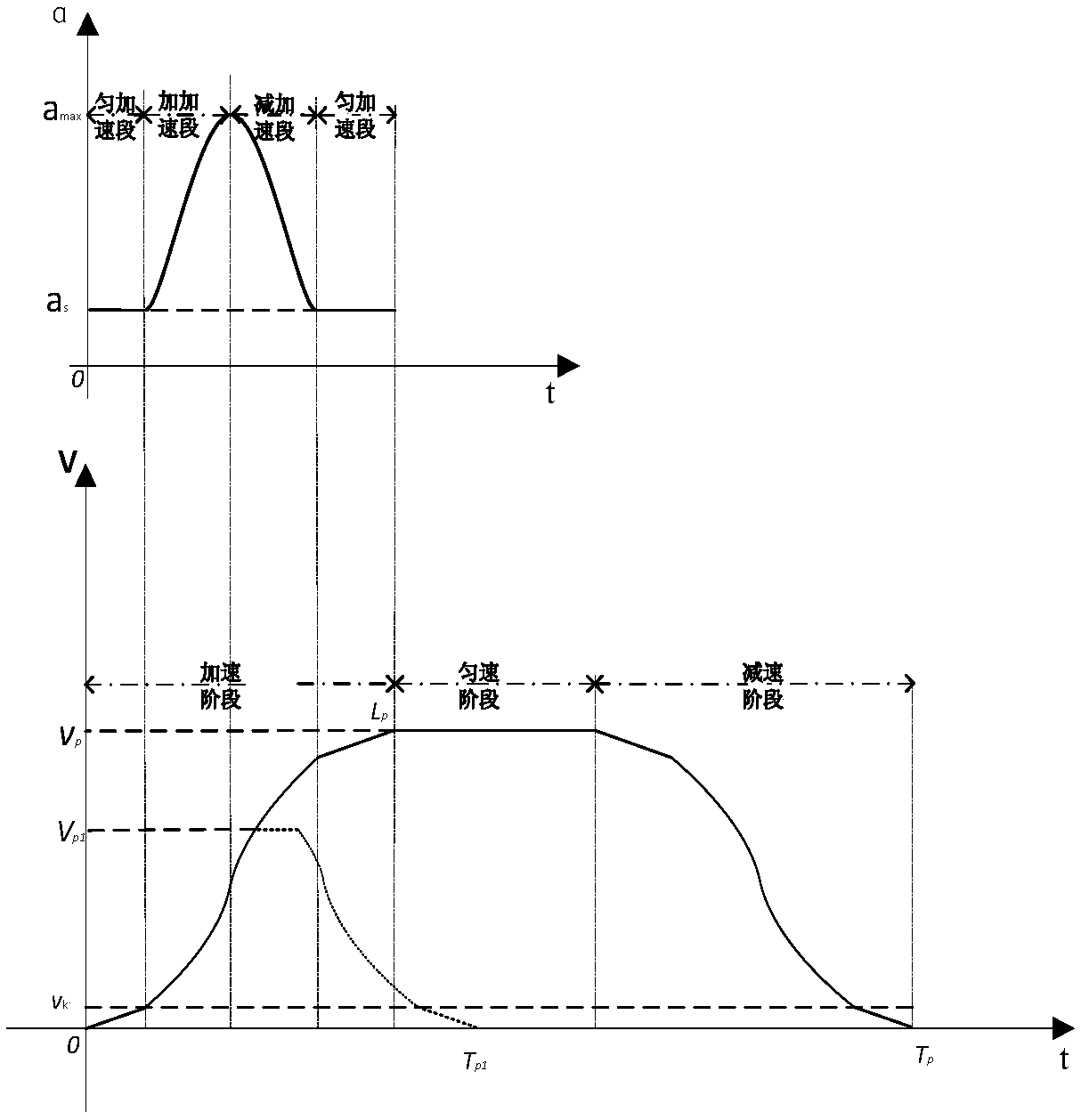

[0015] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings. refer to figure 1 and figure 2 , a kind of automatic point drilling machine speed control method, described method comprises the following steps:

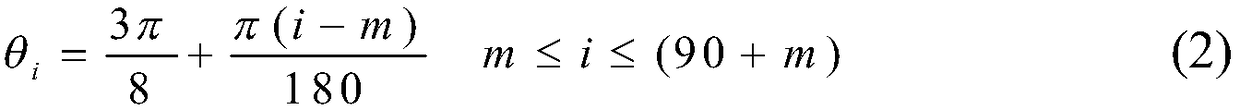

[0016] 1)a max It is the maximum acceleration that can be tolerated according to the torque-frequency characteristics of the spot drill stepper motor and the mechanical structure of the spot drill; acceleration a s Through on-site testing, it can effectively prevent the material drill from falling off and the position of the material drill from shifting; the acceleration planning table (a 1 ,a 2 ,···,a n ), the subscripts 1 to n represent the planning sequence of the acceleration, and a represents the value of the acceleration;

[0017] 2) Point drill motor every acceleration cycle Δt n Perform a speed increase, Δt n is proportional to the current speed of the spot drill stepper motor, combined with step

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap