Water Vapor Distillation Apparatus, Method and System

a technology of water vapor distillation and apparatus, applied in the field of water distillation, can solve the problems of large-scale water systems that require both significant infrastructure and highly trained operators, and the techniques are only well suited to centralized water systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

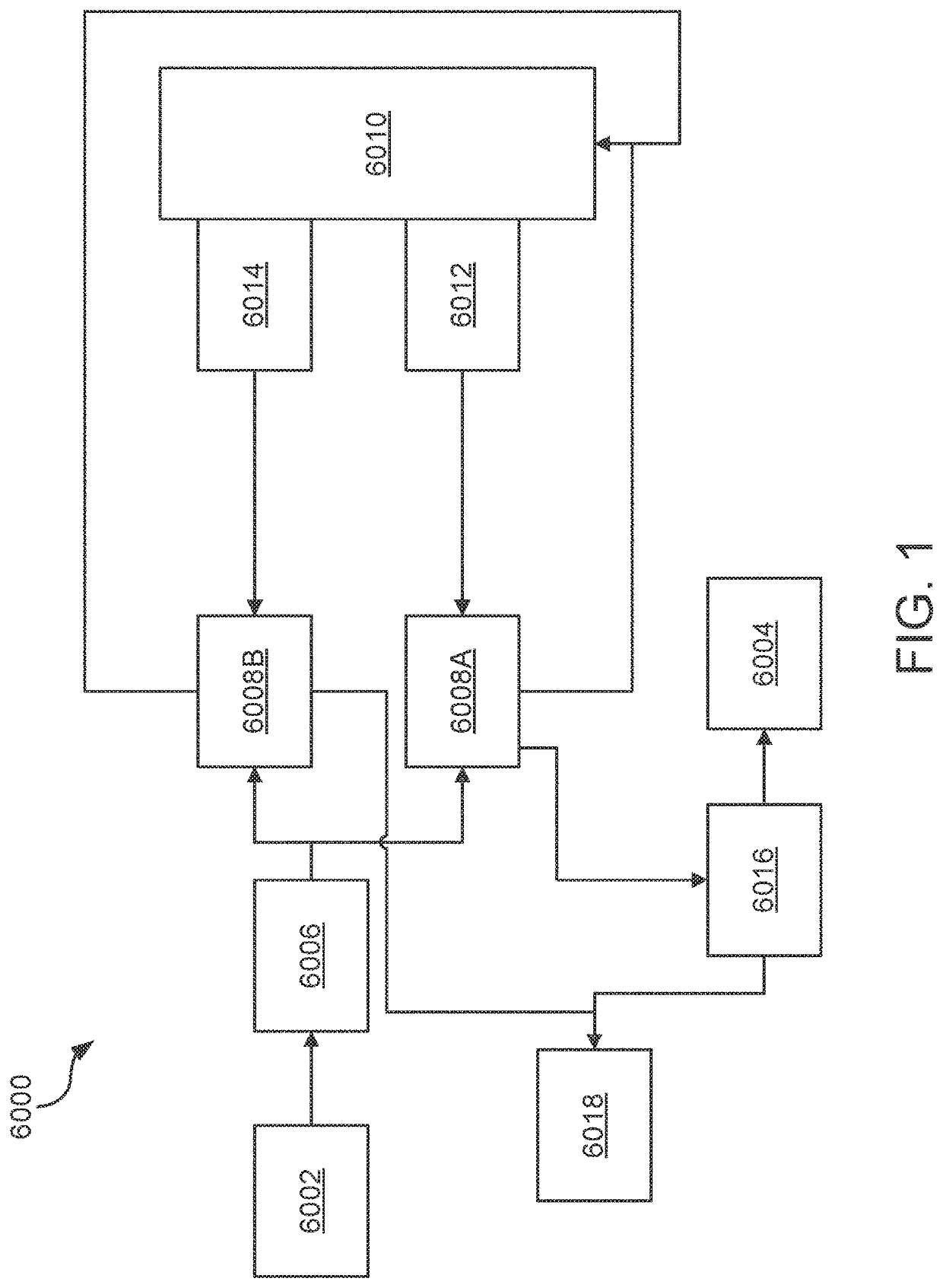

[0163]FIG. 1 depicts a schematic diagram of an exemplary water purification system 6000. The system 6000 may draw water from a source 6002 and purify the water to remove various contaminants making the water fit for consumption at a point of use. The point of use in the exemplary diagram is a medical system 6004. The purified output of the system 6000 may, in certain examples, be used as a component of a medical treatment fluid used by the medical system 6004. The system 6000 may, however, be used to provide water for drinking purposes or for other devices which require water meeting specific quality standards. Medical systems 6004 which may be used with the purification system 6000 may include various dialysis systems. The medical system 6004 may be a system for mixing therapeutic agents such as dialysate. The medical system 6004 may also orchestrate a dialysis (peritoneal or hemo) treatment for a patient. In specific examples, the medical system 6004 may be a peritoneal dialysate mix

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angular velocity | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap