Woodworking flat drill

A flat drill and woodworking technology, used in wood processing tools, wood drilling tools, wood turning tools, etc., can solve the problems of low processing accuracy and production efficiency, low service life of woodworking flat drills, and large cutting resistance. Achieve uniform force, fast speed and sharp cutting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

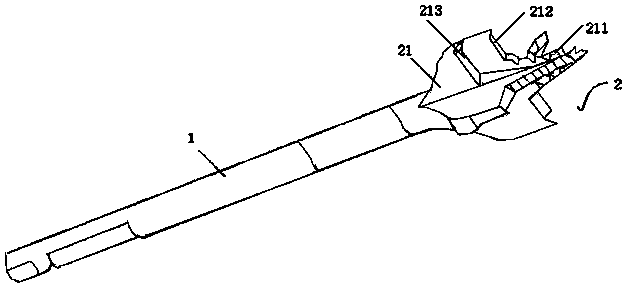

[0015] Present embodiment carpentry flat drill, as figure 1 As shown, it includes a drill shank 1 and a cutting head 2; the cutting head includes three cutting edges 21 that are centered on the axis of the drill shank and are equally spaced and radially distributed; a self-tapping thread groove is opened on the side of the upper end of each cutting edge 21 211, arc-shaped grooves 212 are also provided on the sides of each cutting edge provided with the lower end of the self-tapping thread groove 211, and the arc-shaped grooves 212 include horizontal arc-shaped grooves and drill tip arc-shaped grooves arranged in sequence from the inside to the outside; the arc-shaped grooves A thickened arc-shaped groove 213 is provided on one side of the cutting edge at the lower end of 212. The thickened arc-shaped groove 213 includes an inclined arc-shaped groove, a transverse arc-shaped groove and a drill point arc-shaped groove arranged in sequence from the inside to the outside to form chip

Embodiment 2

[0019] Compared with embodiment 1, present embodiment, as figure 2 As shown, other structures remain unchanged, only the number of cutting edges 21 is changed, and three cutting edges 21 are changed to four cutting edges 21 , compared with three cutting edges 21, four cutting edges 21 have sharper cutting.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap