Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

18 results about "Hearth" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In historic and modern usage, a hearth /hɑːrθ/ is a brick- or stone-lined fireplace, with or without an oven, used for heating and originally also used for cooking food. For centuries, the hearth was such an integral part of a home, usually its central and most important feature, that the concept has been generalized to refer to a homeplace or household, as in the terms "hearth and home" and "keep the home fires burning".

Method and its device for producing catalyst grade super high purity Sb2O3

ActiveCN1683250AReduce energy consumptionReduce manufacturing costAntimony compoundsHearthAntimony trioxide

Owner:锡矿山闪星锑业有限责任公司

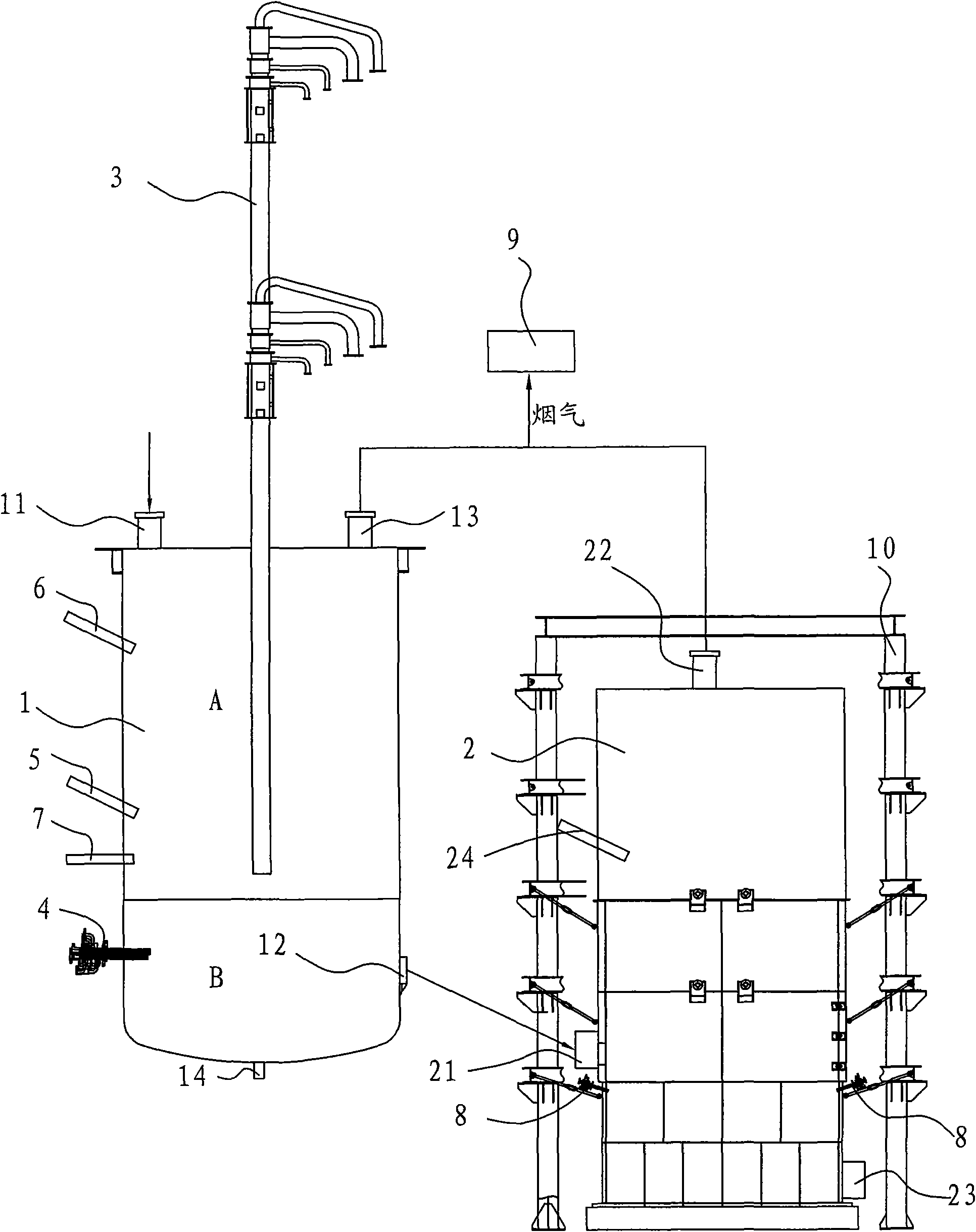

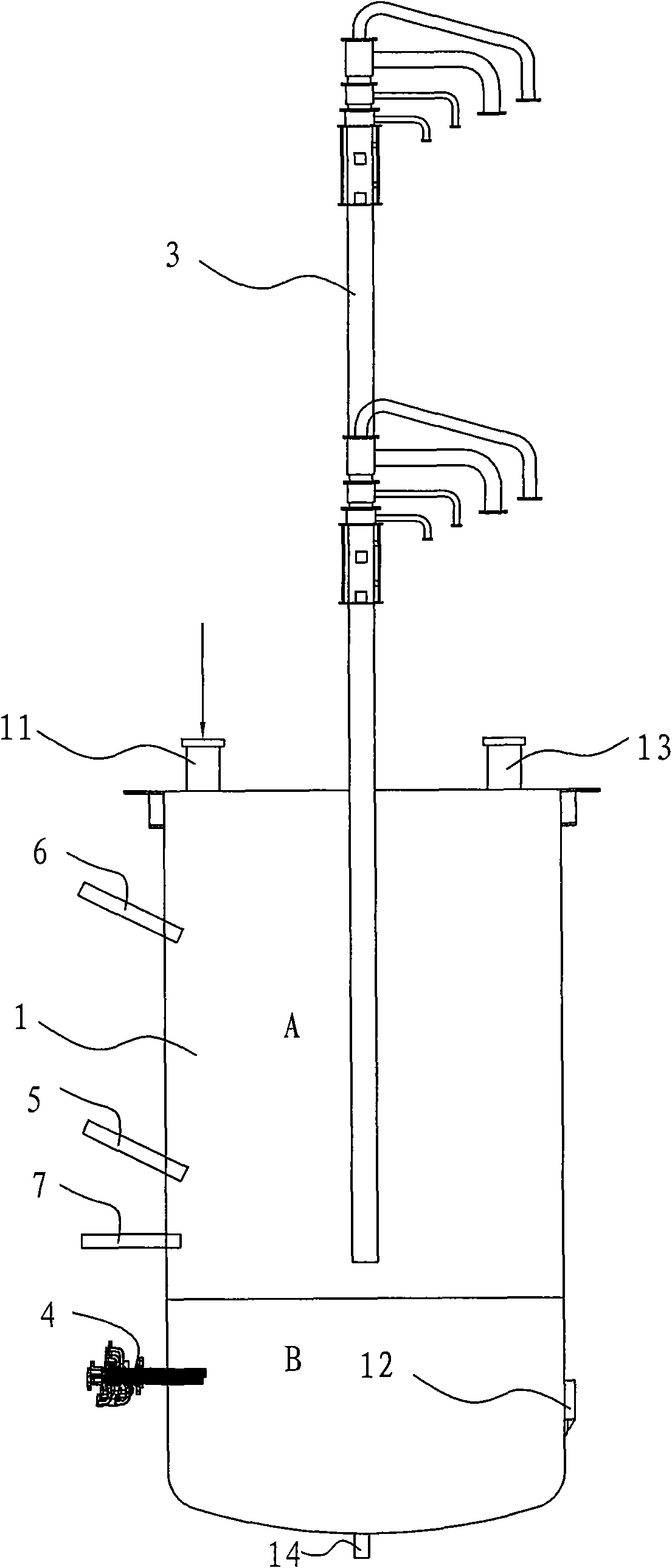

Process for recovering valuable metal from residues containing zinc

ActiveCN101845551AReduce contentRealize continuous operationProcess efficiency improvementHearthOxygen

Owner:CHINA ENFI ENGINEERING CORPORATION +1

Device for testing contamination characteristic of segmental temperature control coal burning boiler

InactiveCN102879415AImprove stabilityIncrease flexibilityMaterial thermal analysisTemperature controlCombustor

Owner:中国东方电气集团有限公司

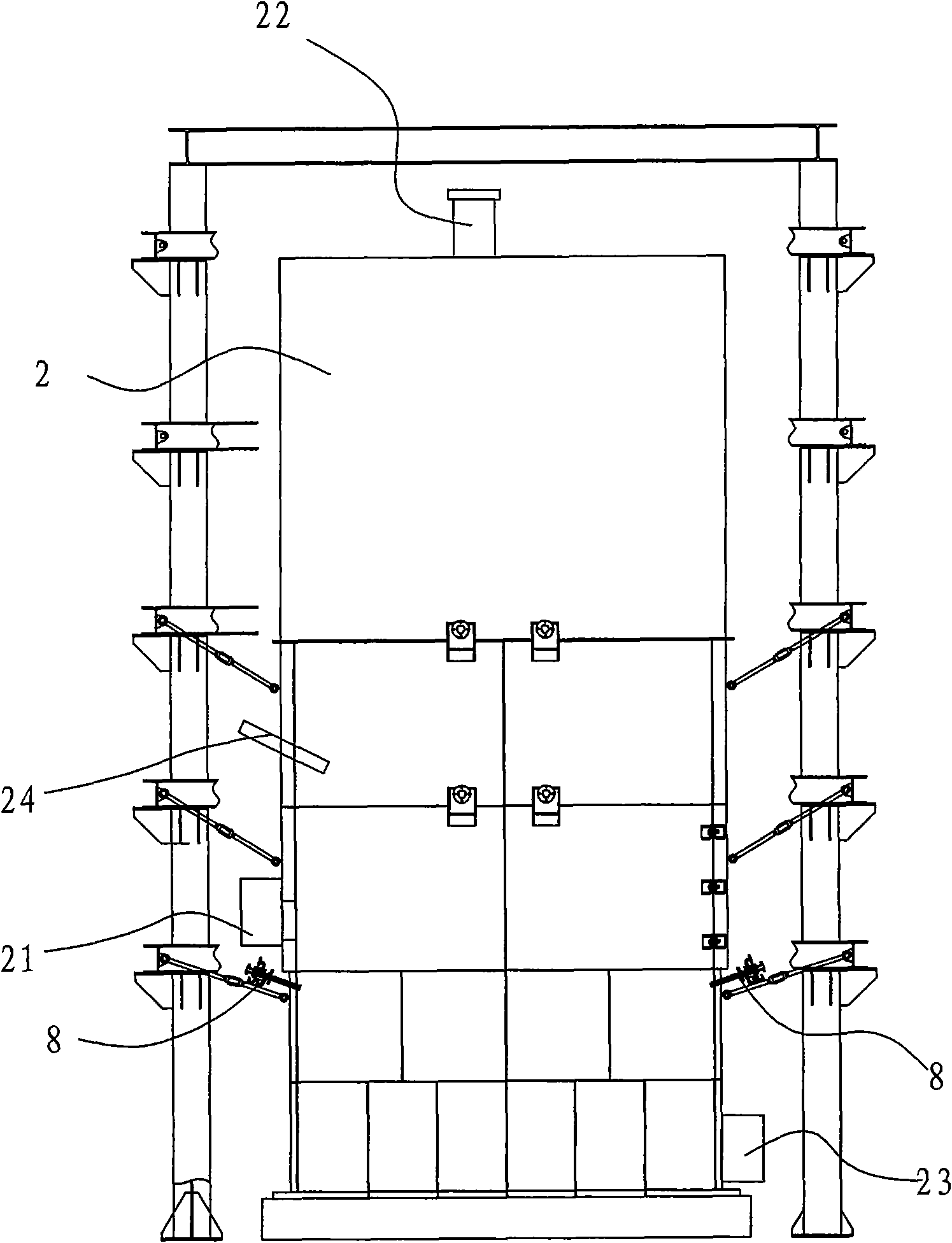

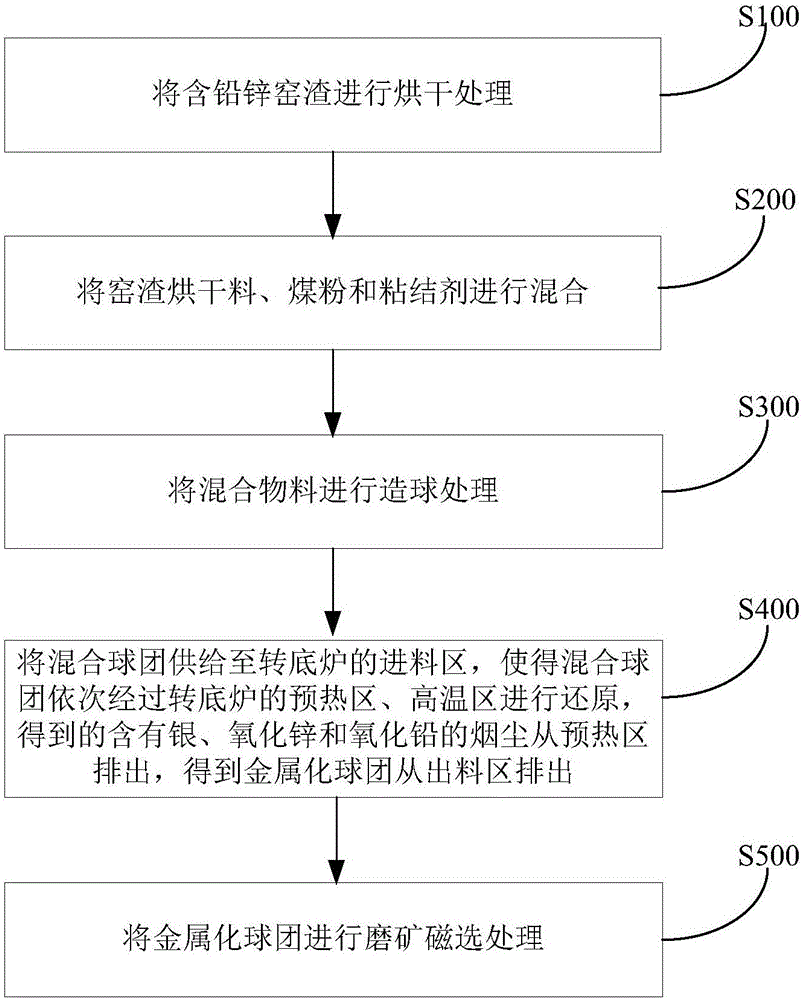

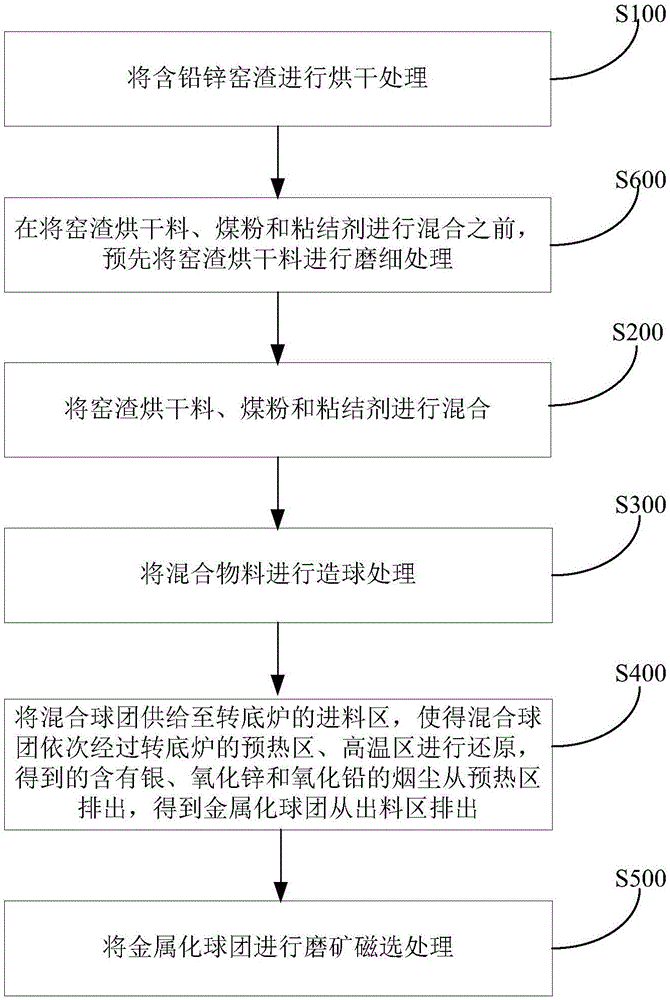

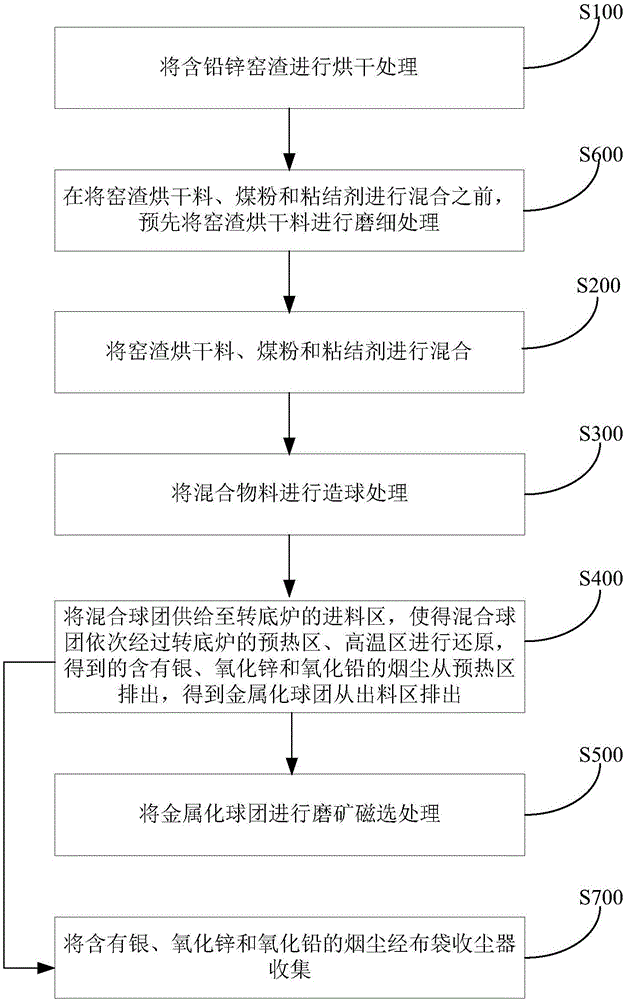

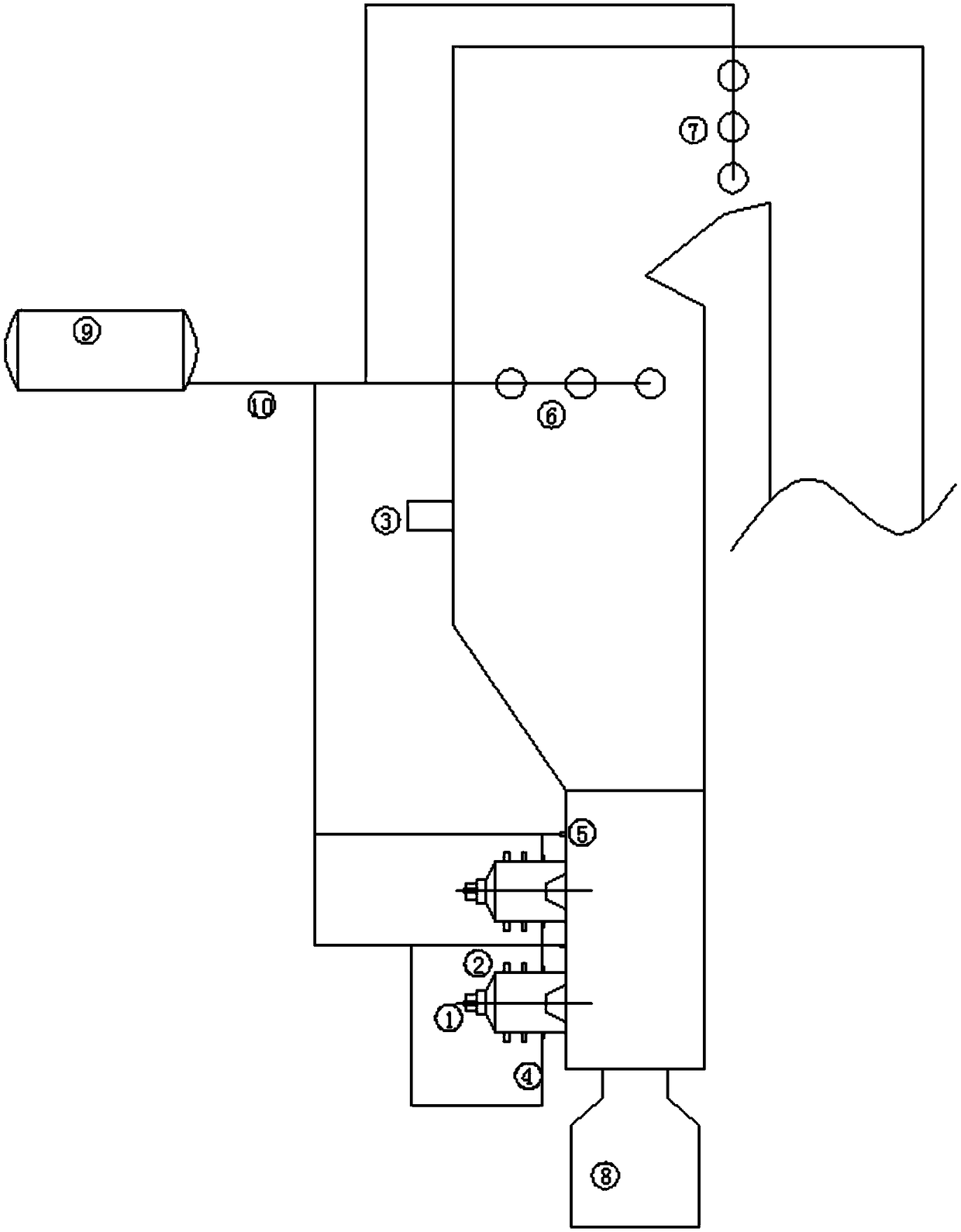

Method and system for treatment of kiln slag including lead and zinc

InactiveCN106148715AAchieve recyclingRealize resource utilizationProcess efficiency improvementIron powderSlag

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

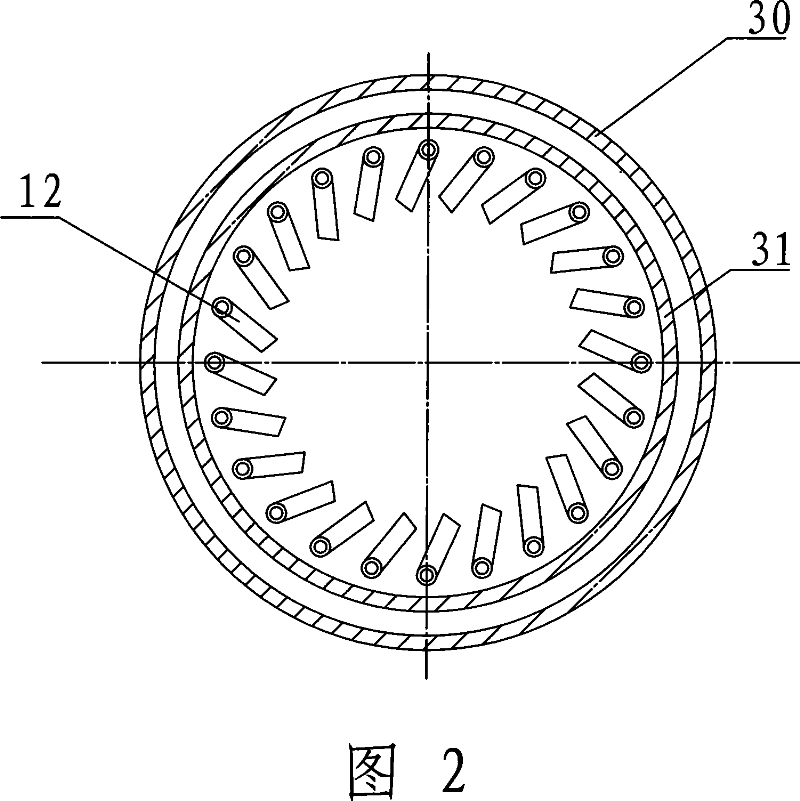

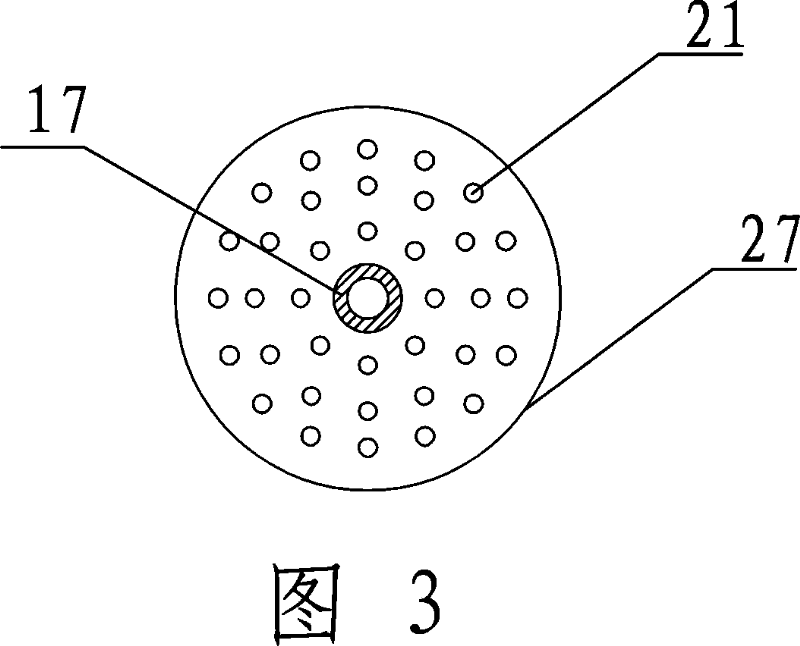

Cyclone furnace denitration system and method

PendingCN109058979AEmission reductionImprove economyCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustorHearth

Owner:CHINA HUANENG GRP CO LTD +1

Efficient coal furnace

ActiveCN105135480AImprove flammabilityBurn fullyDomestic stoves or rangesLighting and heating apparatusPulp and paper industryHearth

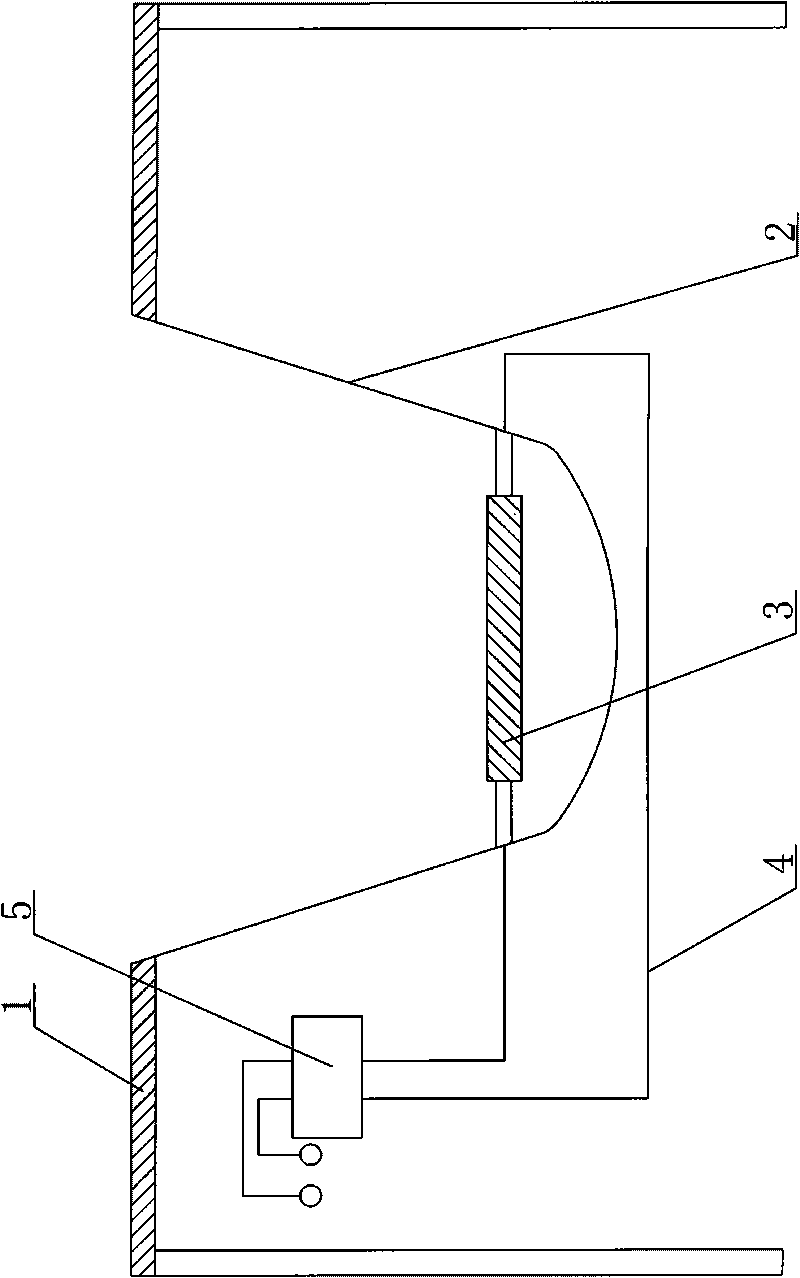

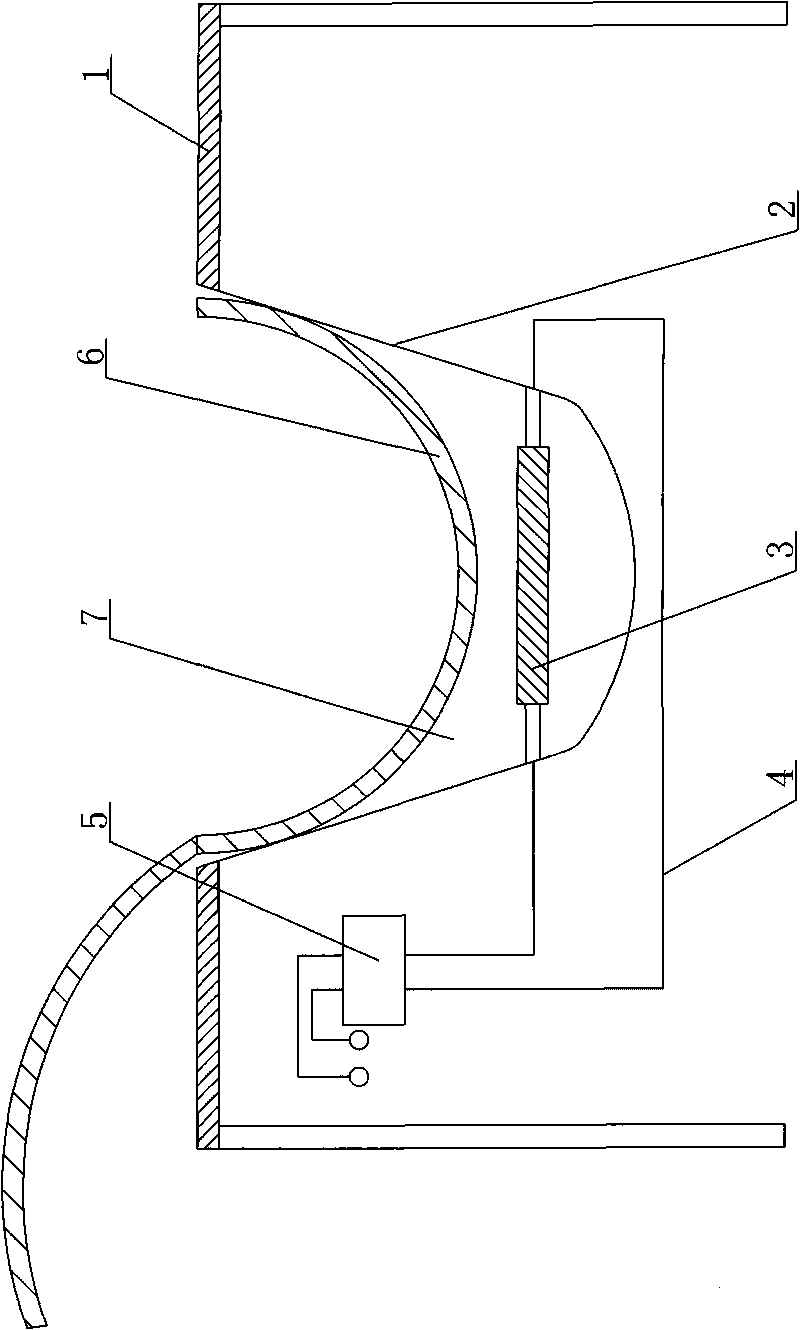

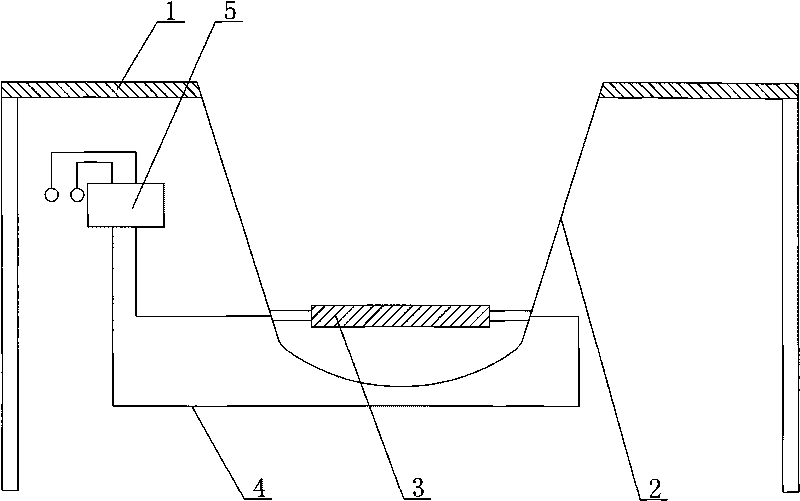

The invention aims to provide an efficient coal furnace. Grates comprise a fixed grate and a rotating grate; a fixed plate is fixed in a hearth, the fixed grate is fixed between the fixed plate and a furnace body, the furnace body is further sleeved with a rotating shaft, one side of the rotating grate is fixedly connected onto the rotating shaft, and a support plate for supporting the rotating grate is further arranged on the furnace body corresponding to the other side, opposite to the one side, of the rotating grate; the fixed plate and the rotating shaft are adjacent and located in the middle of the lower part of the hearth. When the efficient coal furnace is used, coke is added to the fixed grate firstly and burnt sufficiently, then coal is added to the rotating grate, the rotating grate can be rotated in a coal burning process to pour part of the coal on the rotating grate onto the sufficiently burnt coke, so that coal burning is accelerated, gaps of the coal can be increased through the action, the sufficient burning rate of the coal is increased integrally, and environmental pollution caused by soot emission is reduced.

Owner:SHANDONG YUJIE FLOUR CO LTD

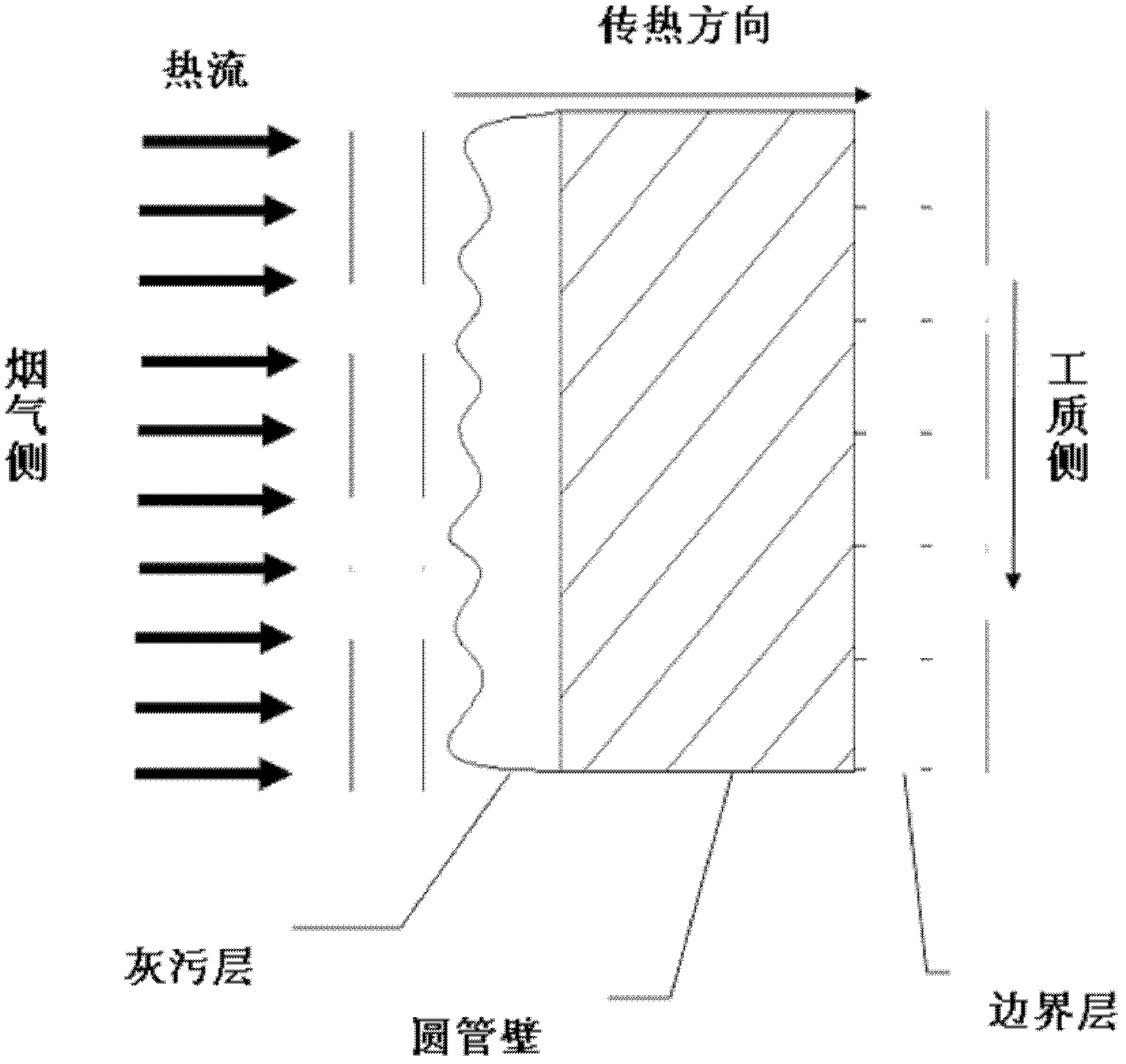

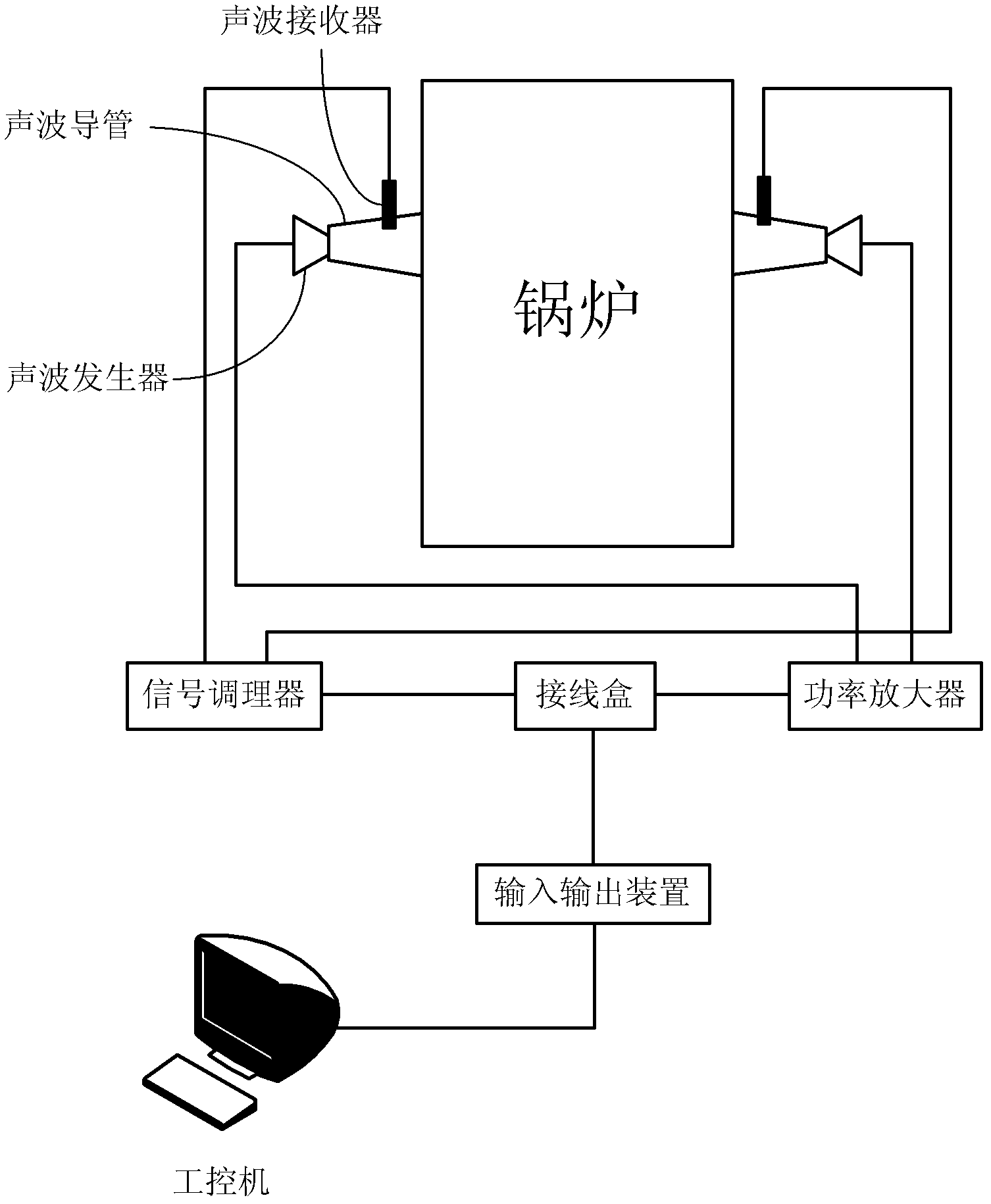

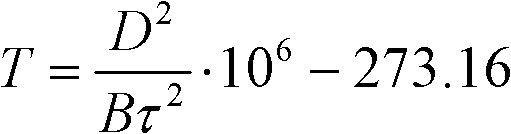

Method and device for monitoring ash dirt on convection heating surface of boiler

InactiveCN102353720AAvoid economic lossEasy to operateAnalysing solids using sonic/ultrasonic/infrasonic wavesEngineeringHearth

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

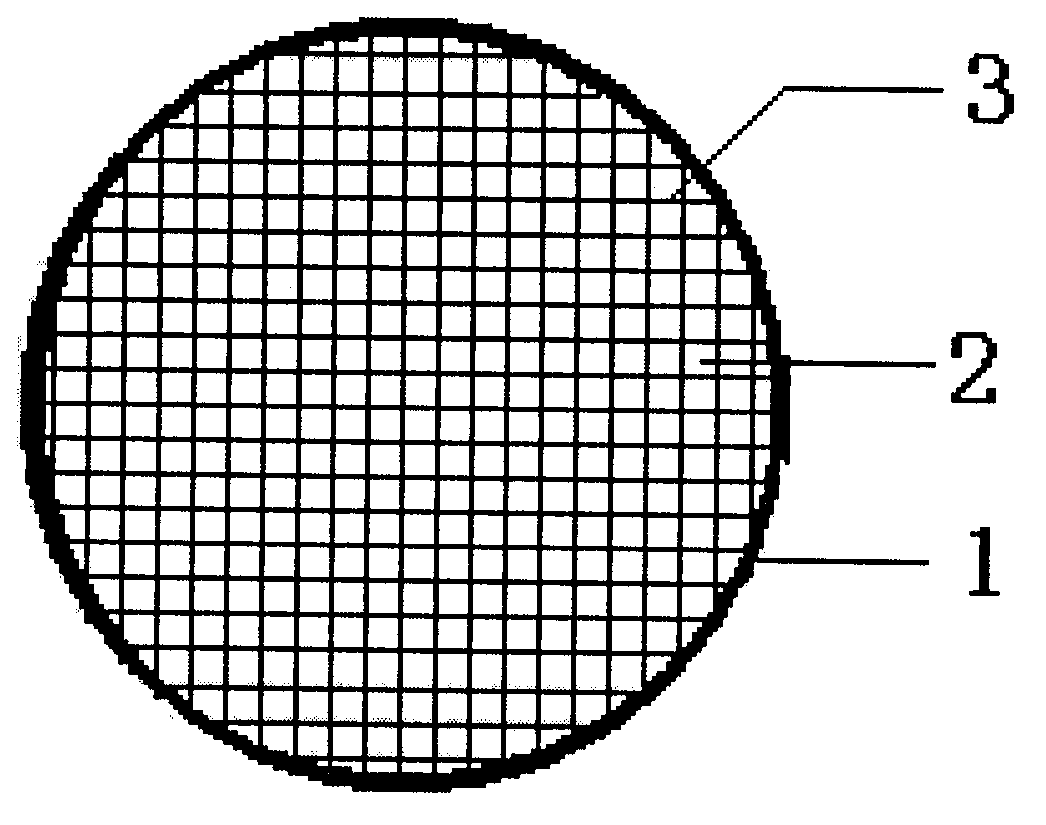

Non-metal honeycomb combustion plate for Chinese food kitchen range

InactiveCN103574608AReduce manufacturing costShorten the processing cycleGaseous fuel burnerEngineeringHearth

Owner:缪传云

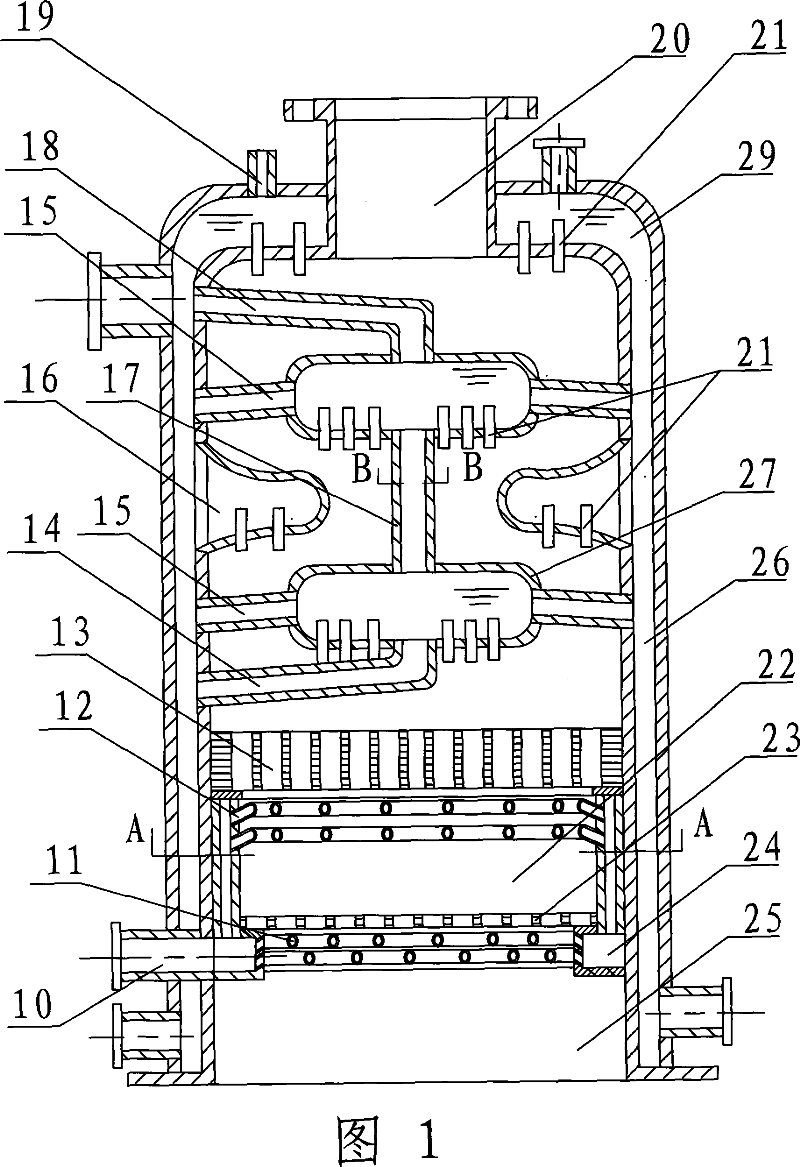

Vertical atmospheric superconductive quick heat supply boiler

InactiveCN101038106AInnovative designFast heat exchangeStorage heatersWater heatersCombustion chamberSlag

Owner:李玉臣

Gas stove of novel structure

InactiveCN106949502AIncrease profitHigh thermal efficiencyDomestic stoves or rangesStoves/ranges topsProcess engineeringHearth

Owner:上海郅洪节能科技有限公司

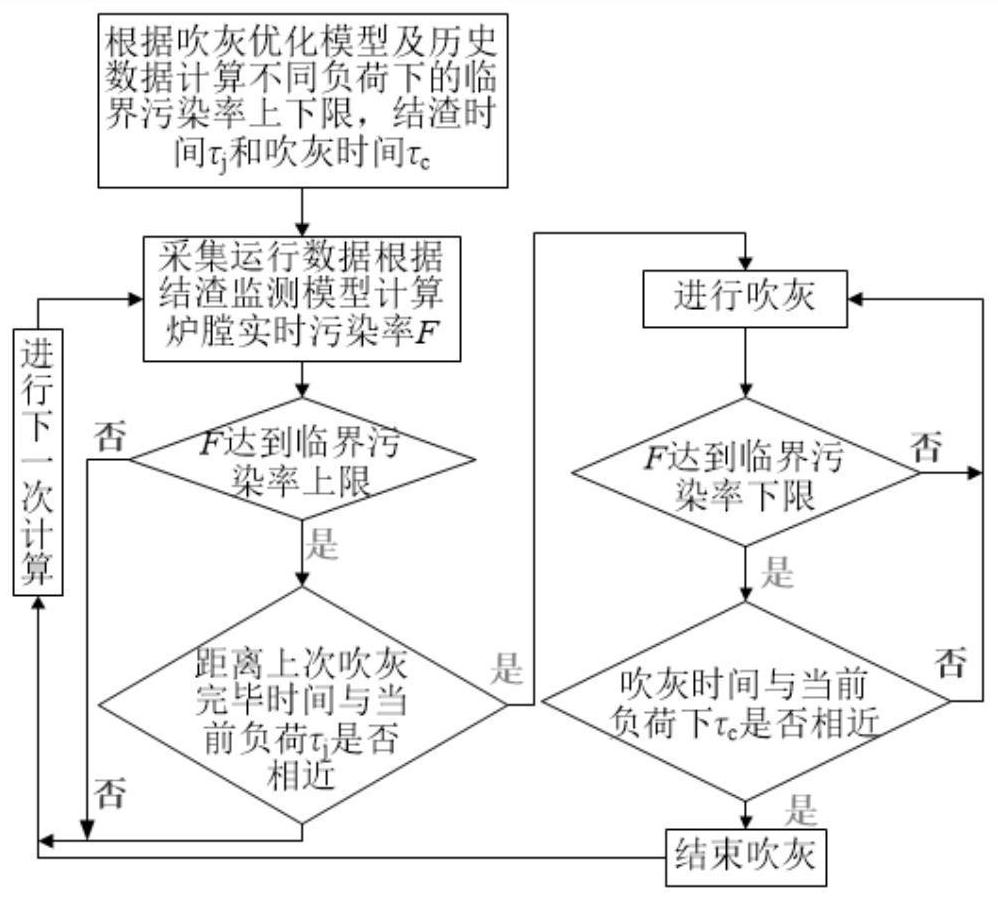

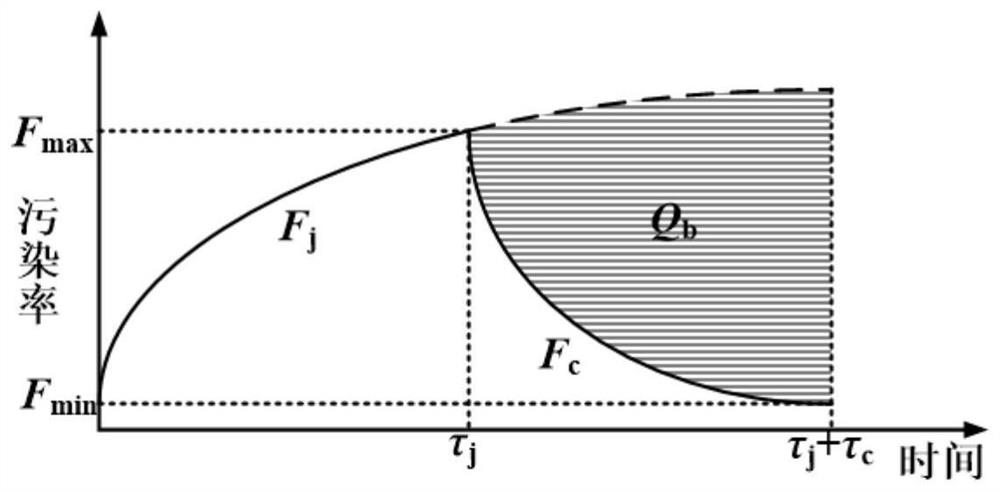

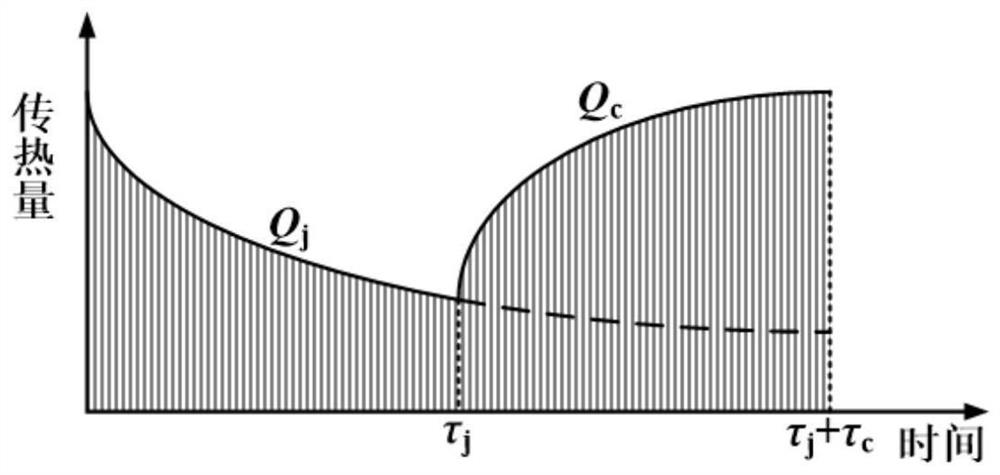

Hearth ash blowing method

InactiveCN111637478AProper timing of soot blowingAppropriate blowing timeSolid removalChamber safety arrangementEngineeringHearth

Owner:JIANGSU FRONTIER ELECTRIC TECH +1

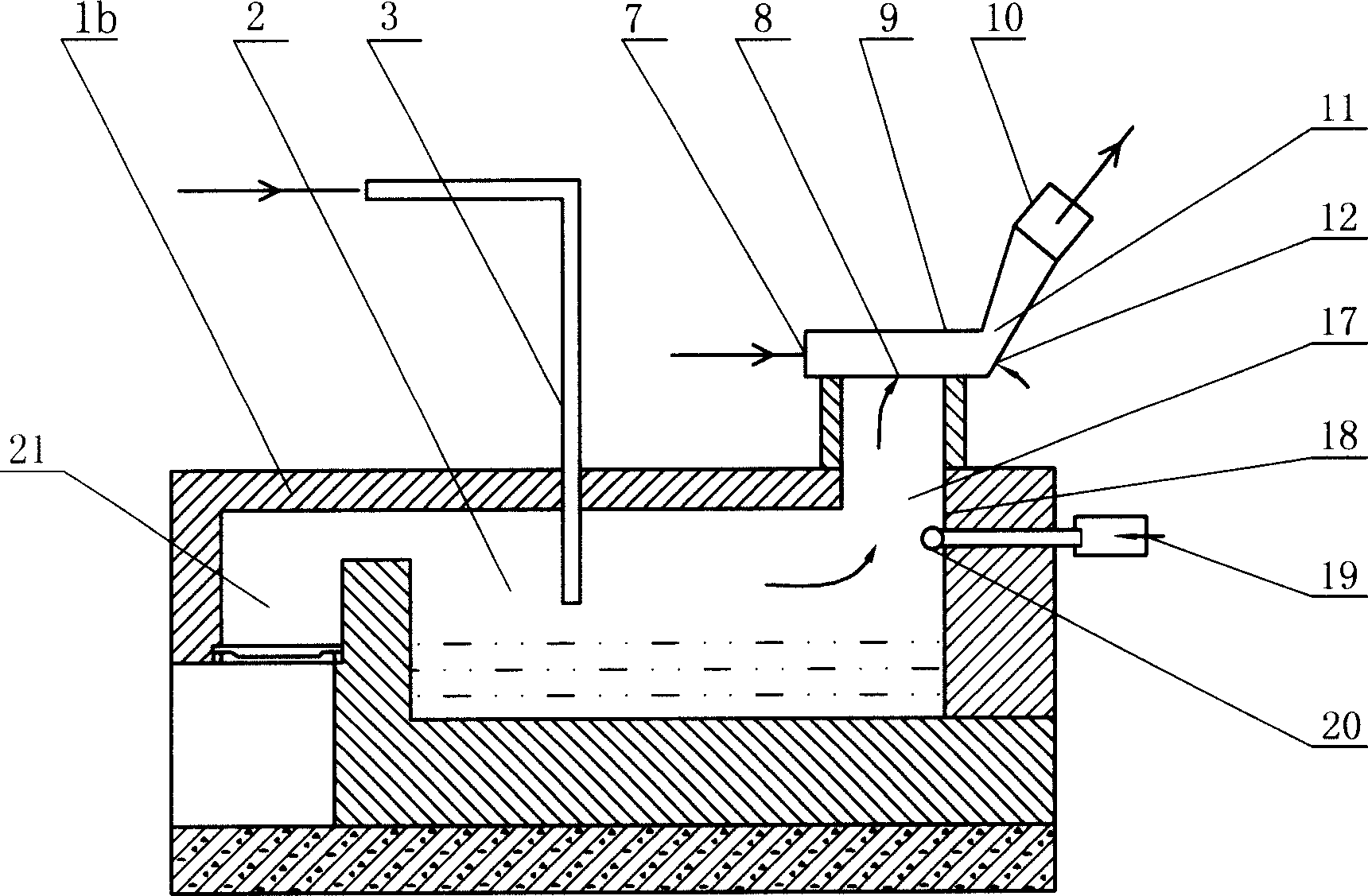

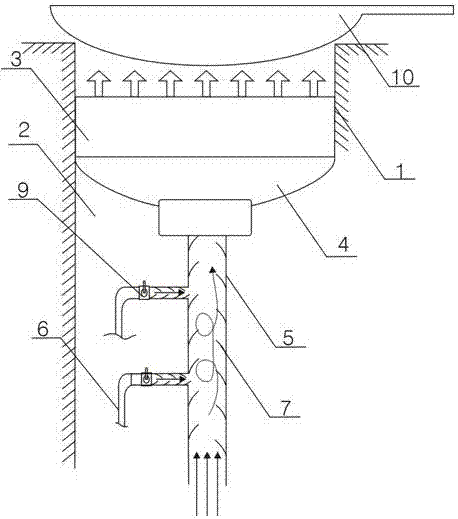

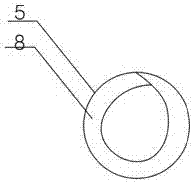

Solar cell printing drying furnace

InactiveCN102506562ASimple structureCompact and reasonableDrying solid materials with heatFinal product manufactureAir cycleTransport system

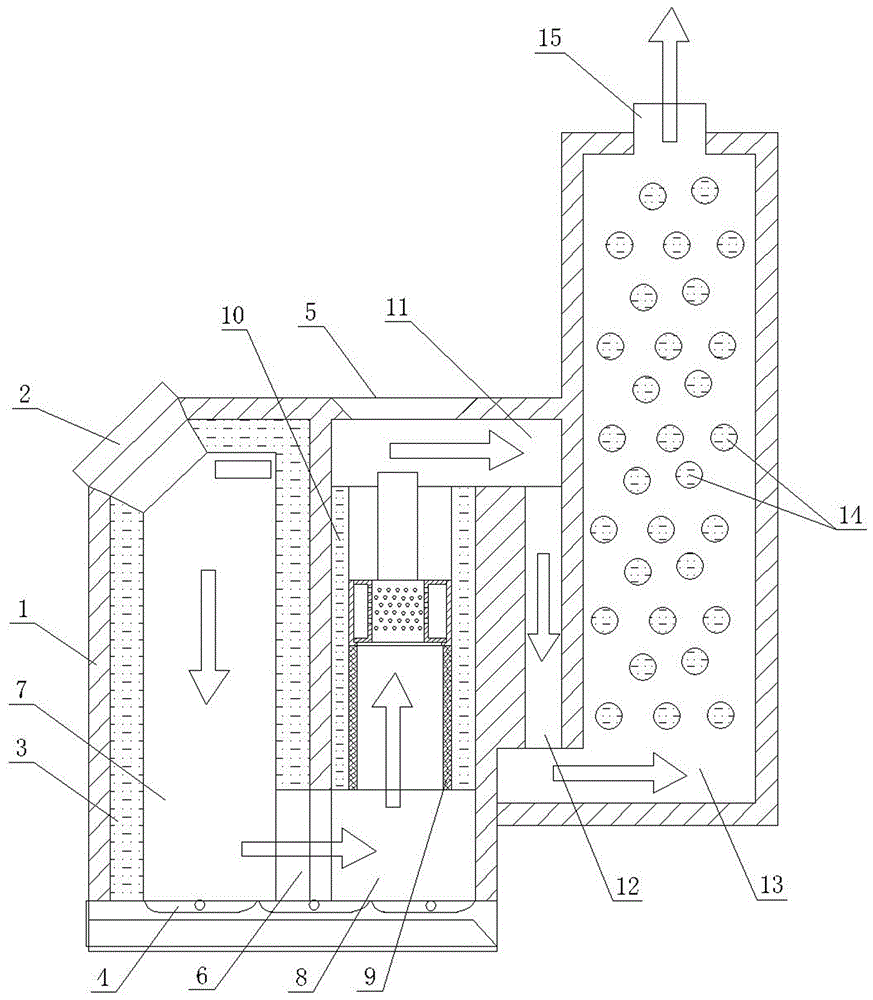

The invention relates to the technical field of drying furnaces, in particular to a solar cell printing drying furnace. The solar cell printing drying furnace comprises a frame, an air circulation system, a hearth, a transport system, an electric control system and a lower hearth lifting system, wherein the air circulation system is arranged on the upper side in the frame; the hearth is arranged below the air circulation system; the transport system is arranged below the hearth; one side of the transport system is provided with the electric control system; and the hearth is connected with the lower hearth lifting system. The solar cell printing drying furnace has a simple, compact and reasonable structure, is convenient to assemble and maintain, has reliable connection, high temperature controllability and high temperature adjustability, saves energy, and accords with a high damping characteristic of temperature, so that a temperature curve is smoother, the working reliability of the drying furnace is greatly improved, and the drying furnace is easy to use and popularize.

Owner:CHANGZHOU TQ TECH

Light-wave stove

InactiveCN101749761AReduce consumptionNo pollution in the processStoves/ranges foundationsDomestic stoves or rangesLight energyHearth

Owner:杜为山

Method for adjusting metal wall temperature deviation of high-temperature reheater of opposed firing coal boiler

ActiveCN113339782AReduce unevennessAccurate adjustment effectSuperheating controlIndirect carbon-dioxide mitigationHearthComponents of crude oil

The invention provides a method for adjusting metal wall temperature deviation of a high-temperature reheater of an opposed firing coal boiler. The method comprises the following steps that flue gas components of an inlet flue section of an SCR system and metal wall temperature data of the high-temperature reheater are collected; the flue gas components of the inlet flue section of the SCR system are tested, and if opposed firing combustors in opposed firing combustion sets at the corresponding positions of low O2 content and high CO content are insufficient combustion positions in a hearth, the opening degree of secondary air doors outside the opposed firing combustors is turned up; if the opposed firing combustors in the opposed firing combustion sets at the corresponding positions of high O2 content and low CO content are sufficient combustion positions in the hearth, the opening degree of the secondary air doors outside the opposed firing combustors is turned down; and opposed firing over-fire air combustors in opposed firing over-fire air sets corresponding to the overtemperature point or the high point of the metal wall temperature of the high-temperature reheater are obtained, the opening degree of secondary air doors in the opposed firing over-fire air combustors are turned up, and the opening degree of central air of the opposed firing over-fire air combustors is turned up. According to the adjusting method, the positions of the overtemperature point and the high point of the metal wall temperature of the heating surface of the high-temperature reheater are adjusted and controlled, the thermal load deviation of the heating surface is reduced, and the reheating steam temperature is increased.

Owner:SUZHOU XIRE ENERGY SAVING ENVIRONMENTAL PROTECTION TECH CO LTD +1

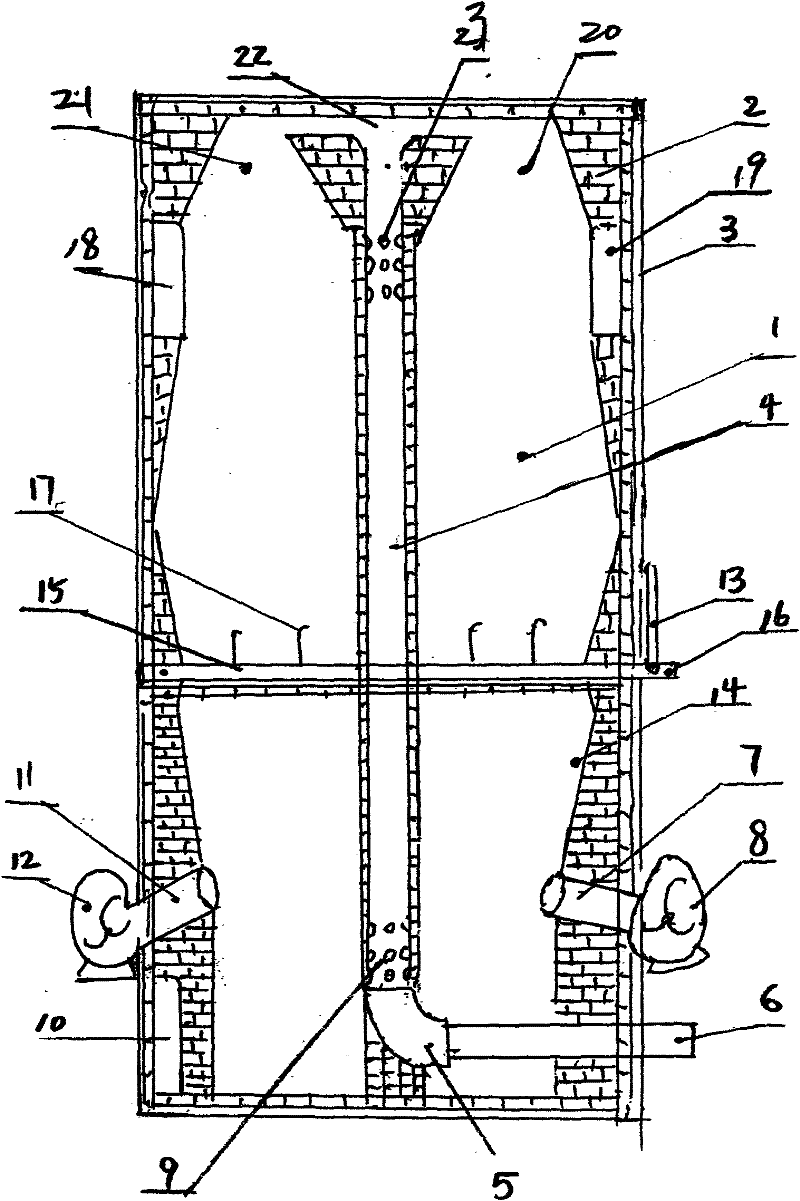

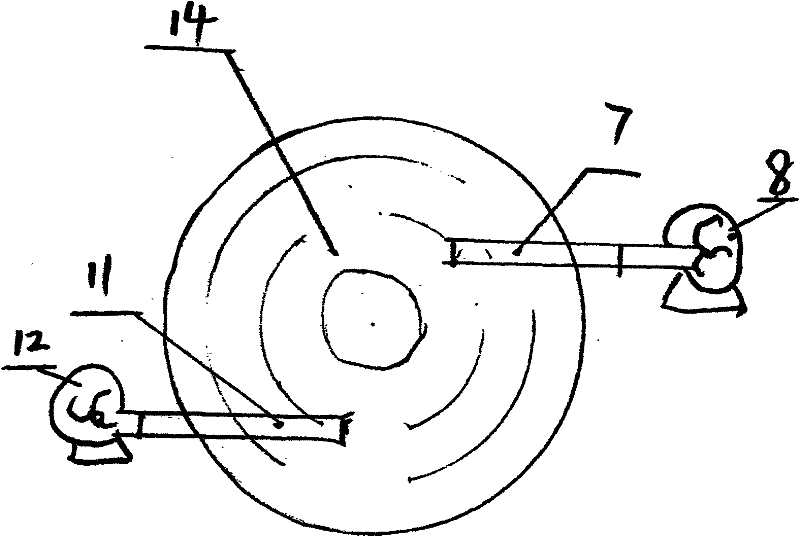

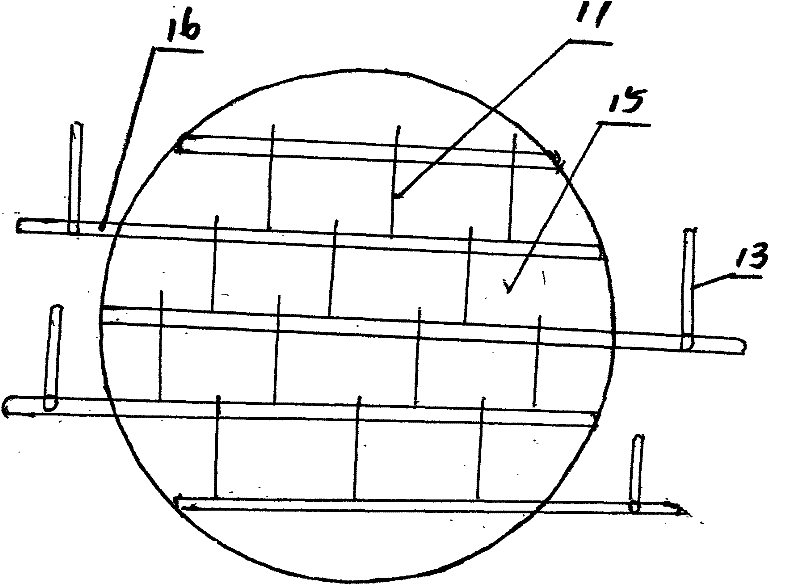

Multi-return-trip cooking and heating stove

InactiveCN105953269AIncrease heat output ratioFully gasified combustionLighting and heating apparatusStove/ranges for heating waterCombustion chamberCombustor

Owner:SHIJIAZHUANG ZHONGJIA HEATING EQUIP

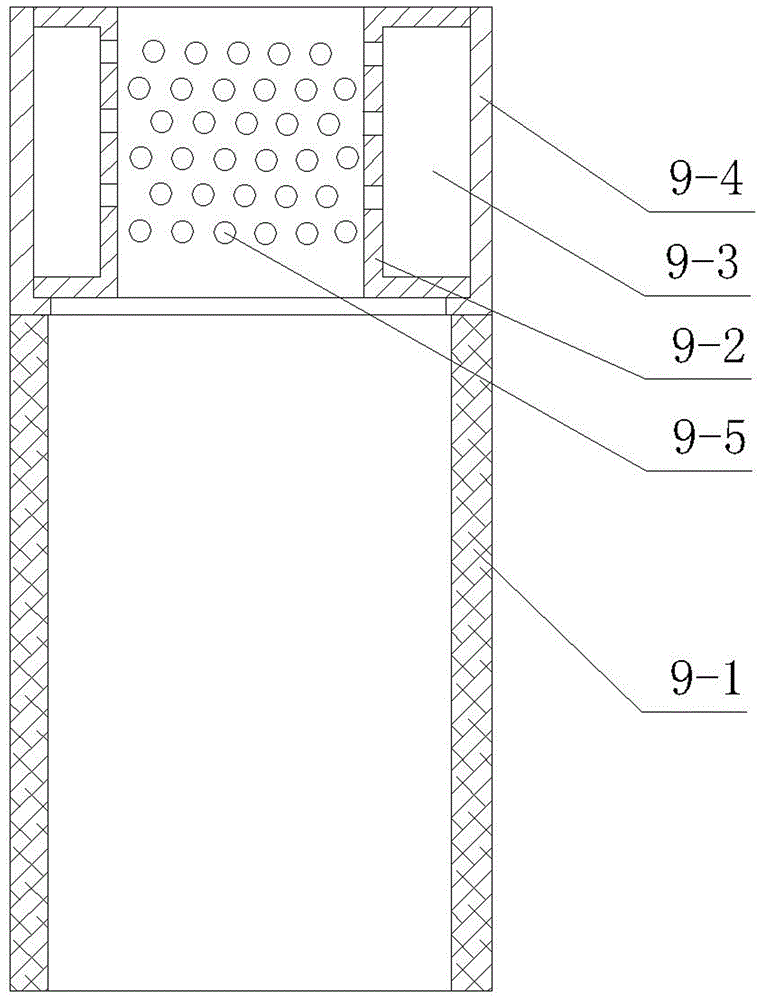

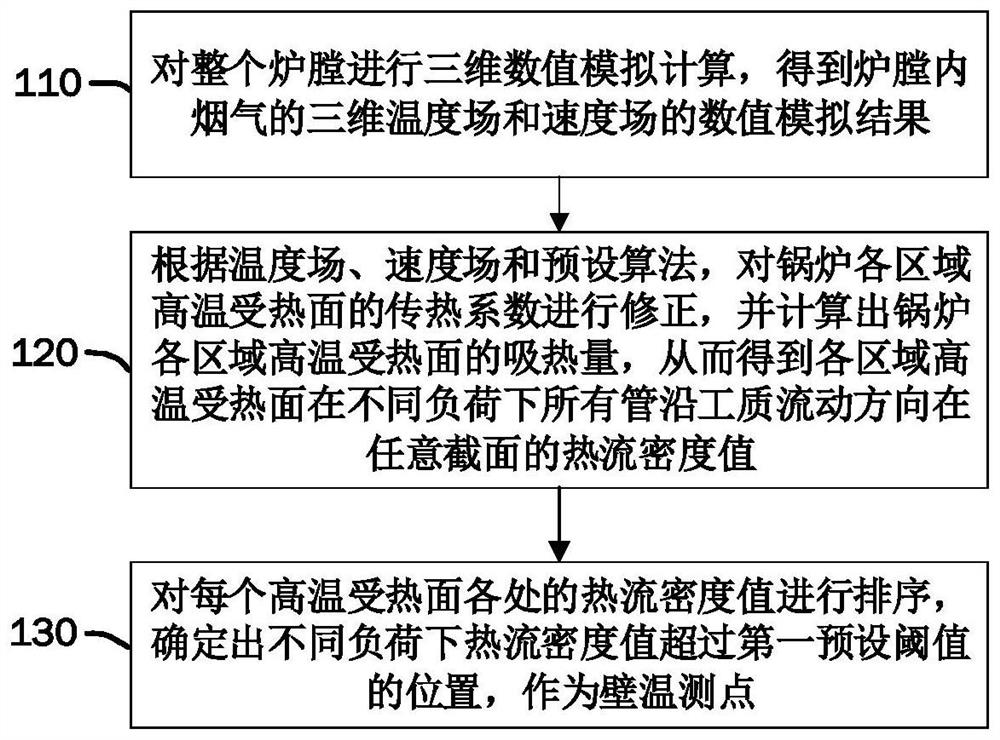

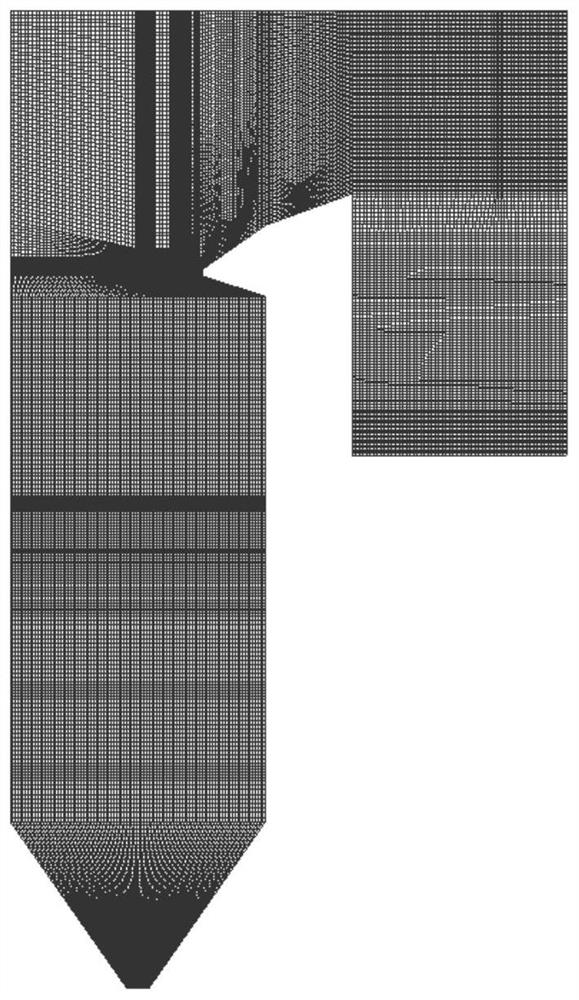

Boiler high-temperature heating surface outer wall temperature measuring point arrangement method and temperature detection system

ActiveCN113358692AAccurate predictionMaterial heat developmentBoiler indication operationsThermodynamicsHeat flow

Owner:YANTAI LONGYUAN POWER TECH

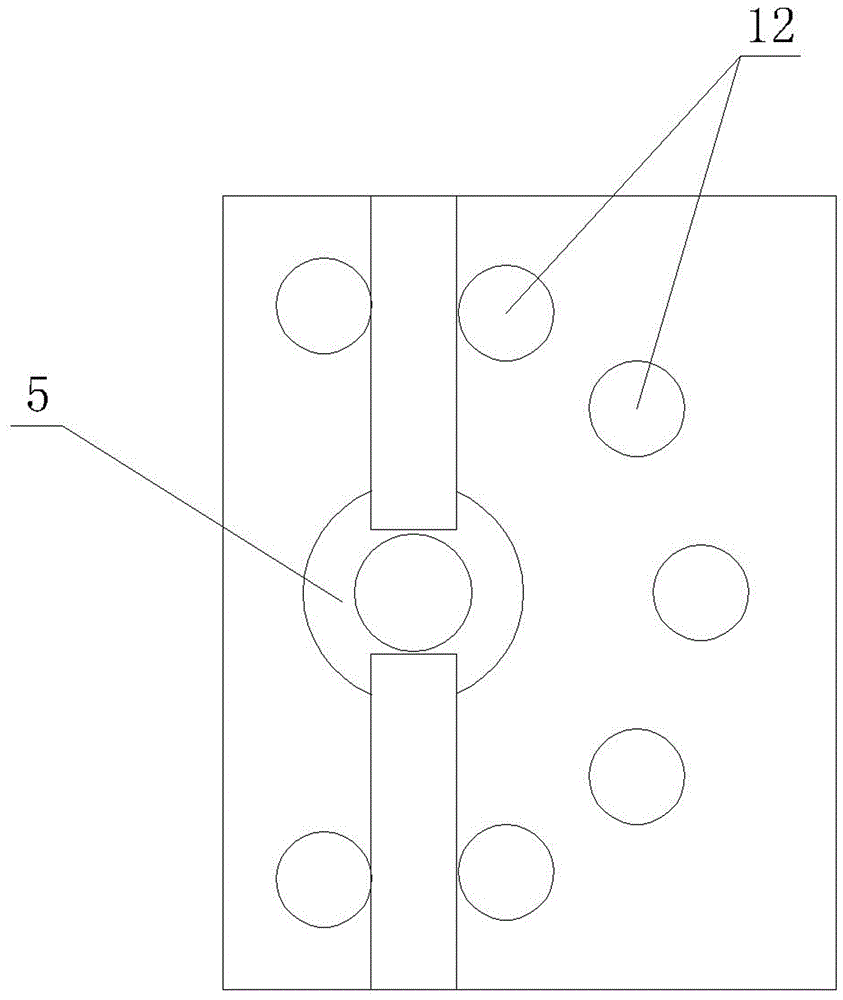

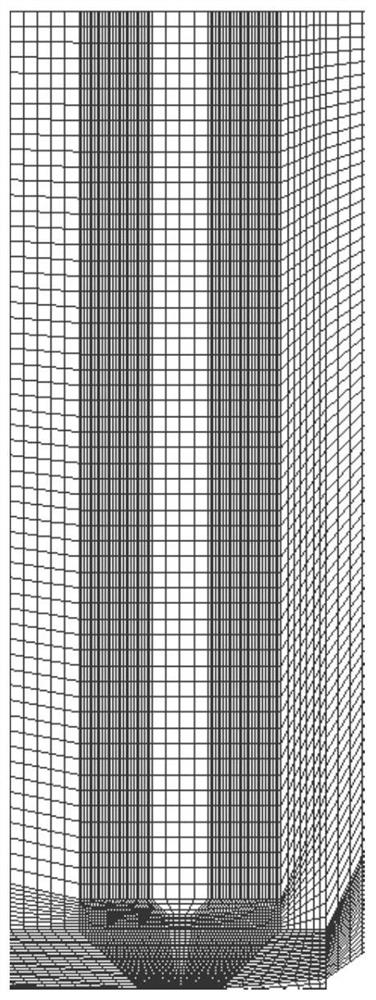

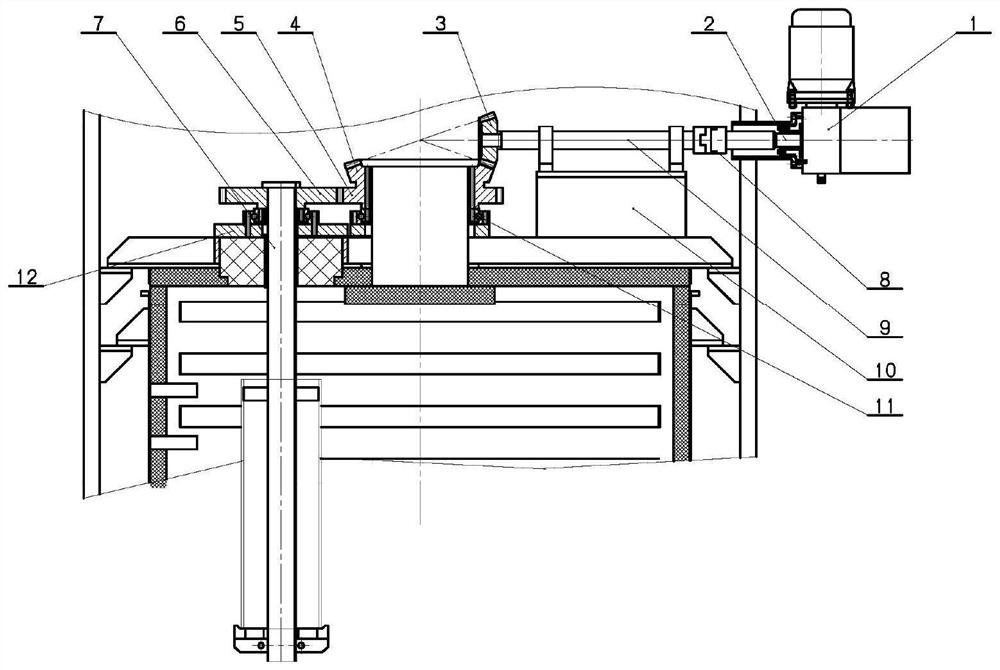

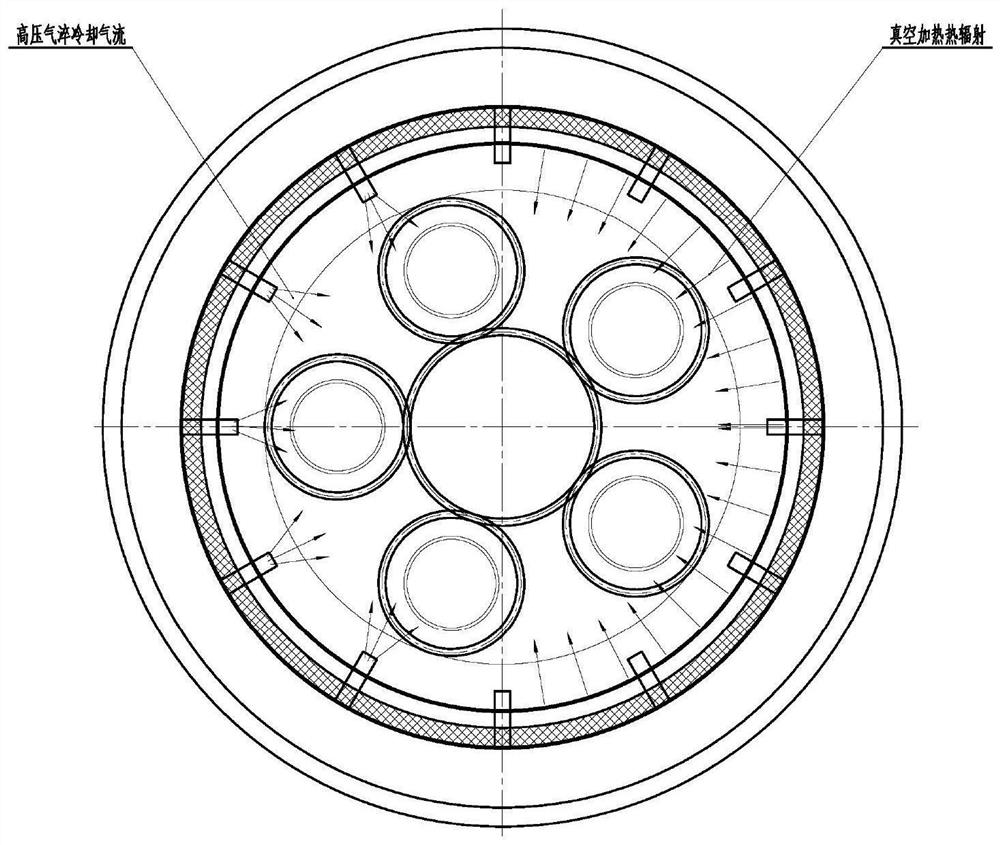

Transmission and clamping structure capable of realizing self-rotation of workpiece in vacuum furnace

ActiveCN112725596AImprove temperature uniformityImprove consistencyFurnace typesHeat treatment furnacesGear driveGear wheel

Owner:BEIJING RES INST OF MECHANICAL&ELECTRICAL TECH

Popular searches

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap