Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

7 results about "Soot" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Soot /sʊt/ is a mass of impure carbon particles resulting from the incomplete combustion of hydrocarbons. It is more properly restricted to the product of the gas-phase combustion process but is commonly extended to include the residual pyrolysed fuel particles such as coal, cenospheres, charred wood, and petroleum coke that may become airborne during pyrolysis and that are more properly identified as cokes or char.

Efficient coal furnace

ActiveCN105135480AImprove flammabilityBurn fullyDomestic stoves or rangesLighting and heating apparatusPulp and paper industryHearth

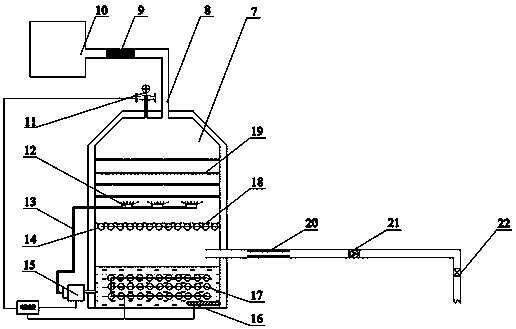

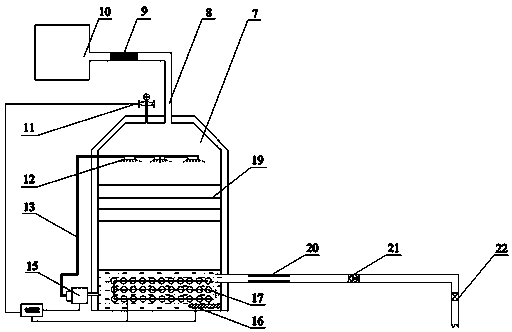

The invention aims to provide an efficient coal furnace. Grates comprise a fixed grate and a rotating grate; a fixed plate is fixed in a hearth, the fixed grate is fixed between the fixed plate and a furnace body, the furnace body is further sleeved with a rotating shaft, one side of the rotating grate is fixedly connected onto the rotating shaft, and a support plate for supporting the rotating grate is further arranged on the furnace body corresponding to the other side, opposite to the one side, of the rotating grate; the fixed plate and the rotating shaft are adjacent and located in the middle of the lower part of the hearth. When the efficient coal furnace is used, coke is added to the fixed grate firstly and burnt sufficiently, then coal is added to the rotating grate, the rotating grate can be rotated in a coal burning process to pour part of the coal on the rotating grate onto the sufficiently burnt coke, so that coal burning is accelerated, gaps of the coal can be increased through the action, the sufficient burning rate of the coal is increased integrally, and environmental pollution caused by soot emission is reduced.

Owner:SHANDONG YUJIE FLOUR CO LTD

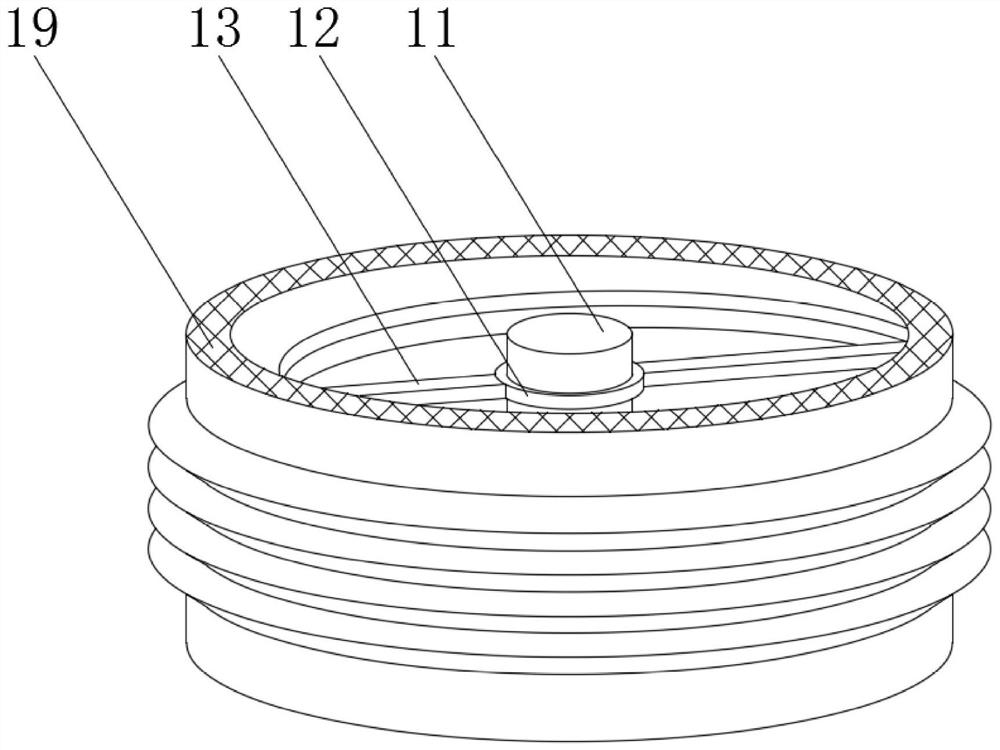

Swim ring-shaped side suction-type range hood

ActiveCN107726412ARealize side adsorptionUnique shapeDomestic stoves or rangesLighting and heating apparatusEngineeringSoot

Owner:FOSHAN VIOMI ELECTRICAL TECH +1

Method and device for recovering soot generated in preparation process of copper-phosphorus brazing filler metal

PendingCN110180292ADirect synthesisAvoid consumptionHuman health protectionGas treatmentWater vaporPhosphoric acid

Owner:ZHENGZHOU RES INST OF MECHANICAL ENG CO LTD +1

Boiler economizer

ActiveCN111981497AIncrease contact areaReduce accumulationRecuperative heat exchangersCombustion technology mitigationWater storageThermal insulation

Owner:甘肃富士特暖通科技有限公司

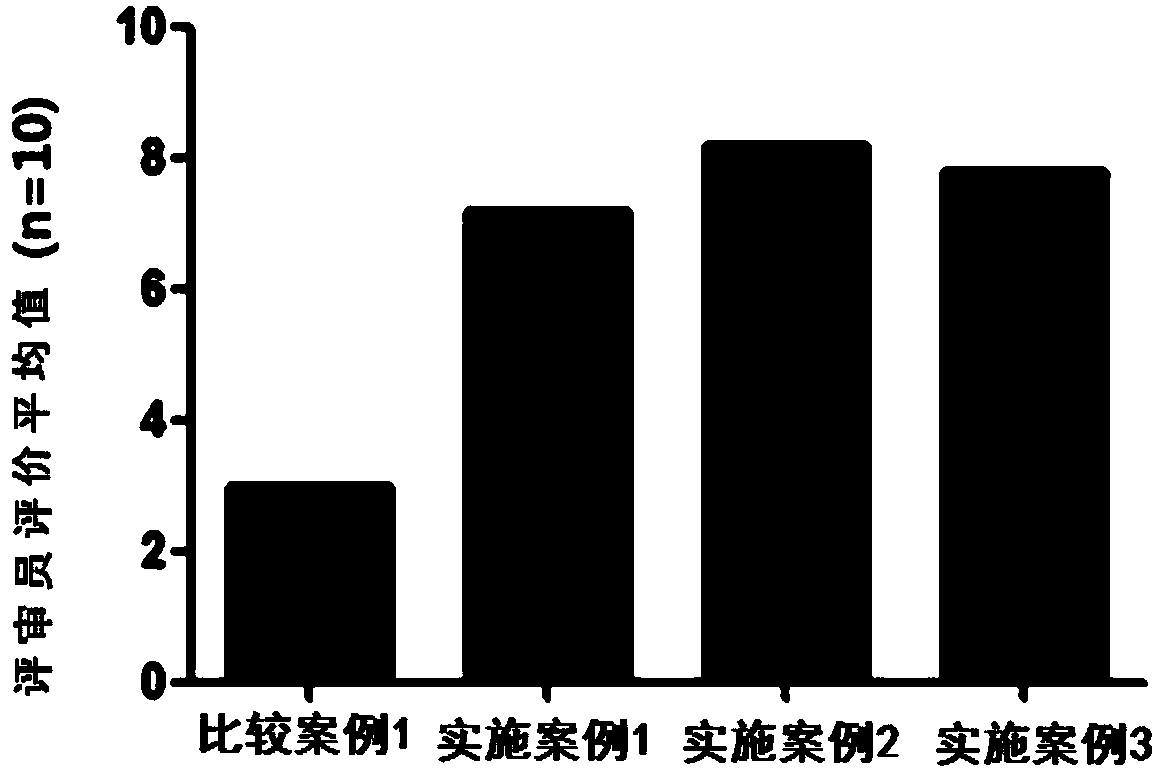

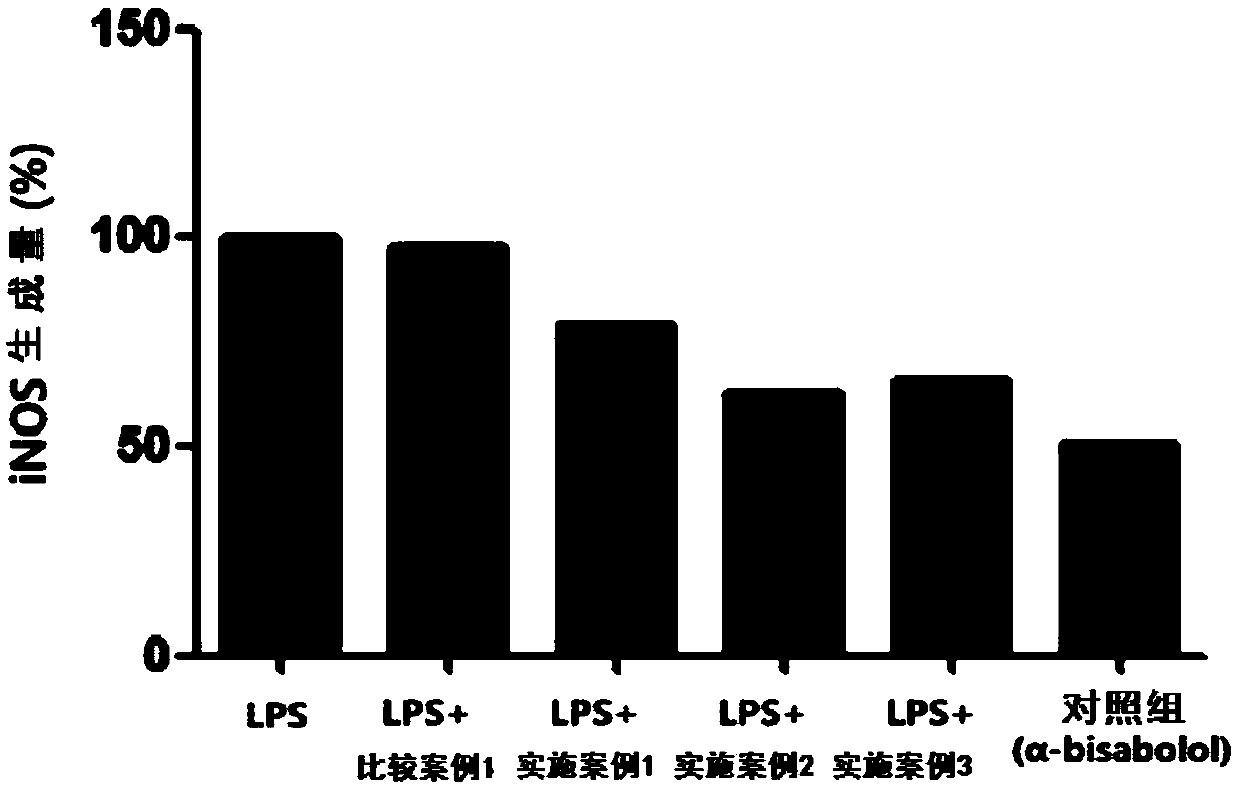

Anti-dust and anti-inflamatory cosmetic composition containing natural plant extracts

InactiveCN107837220APrevent intrusionGuaranteed cleanlinessCosmetic preparationsAntipyreticCosmetic ingredientAdditive ingredient

Owner:COSMAX INC

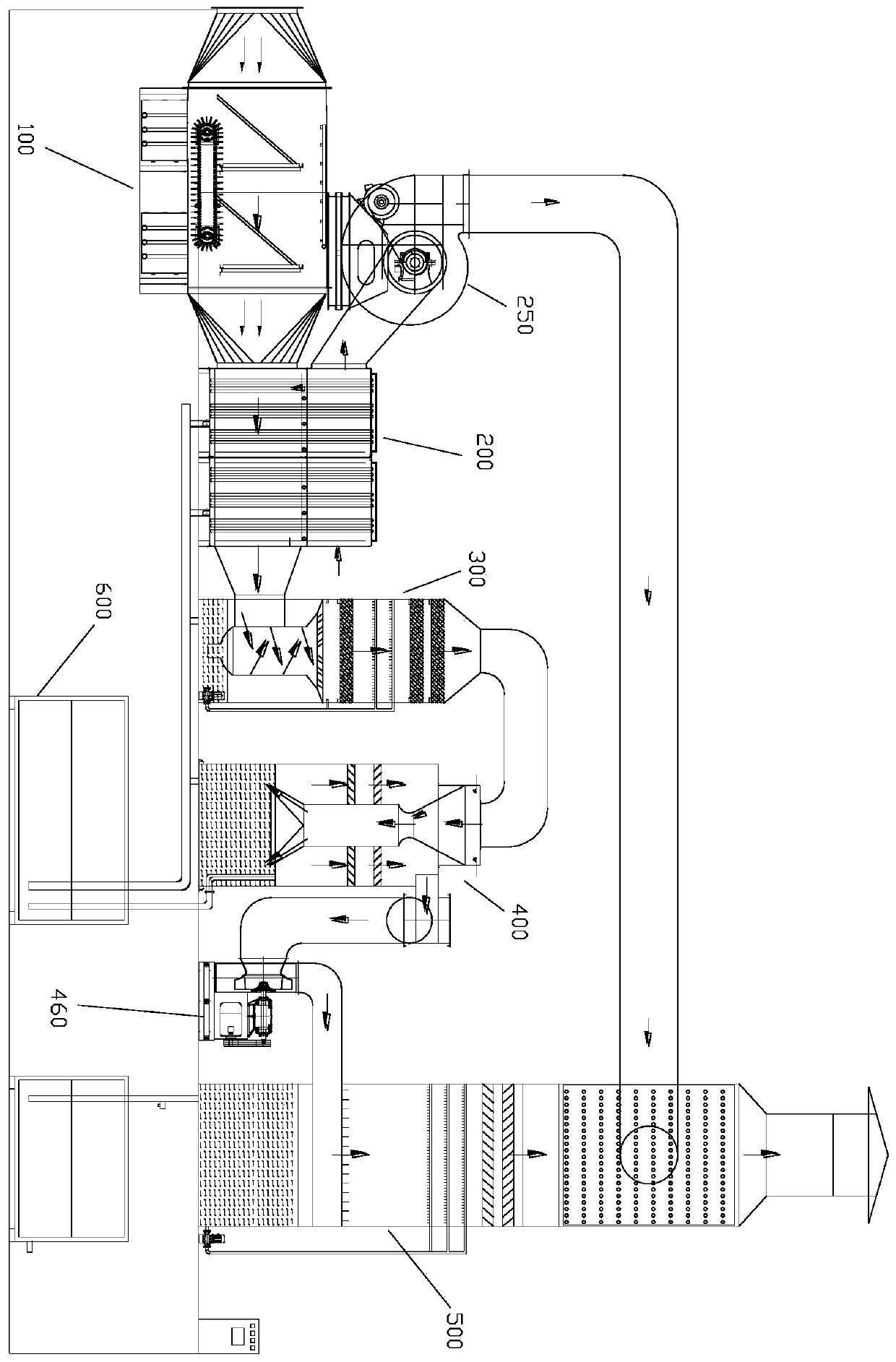

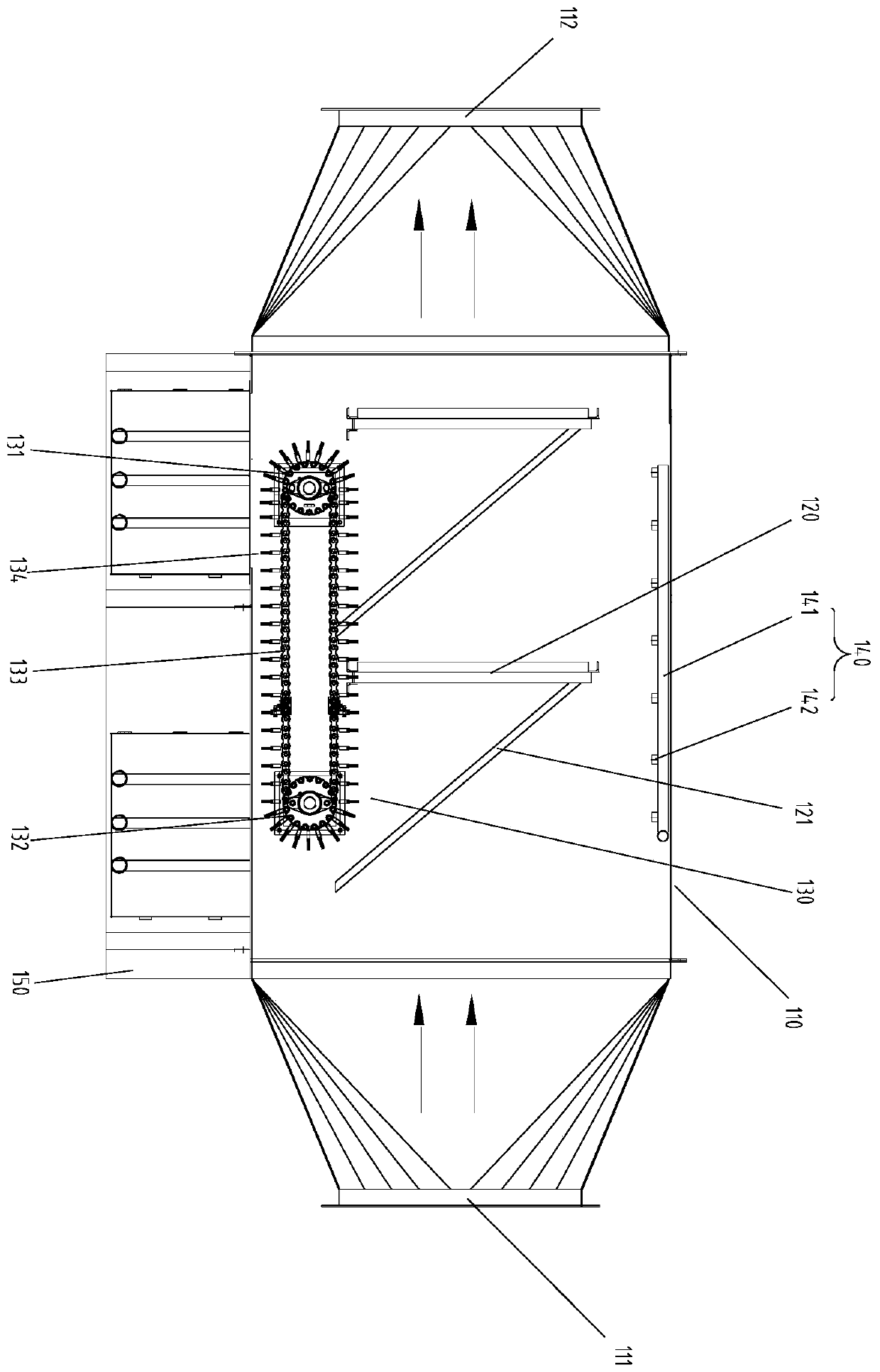

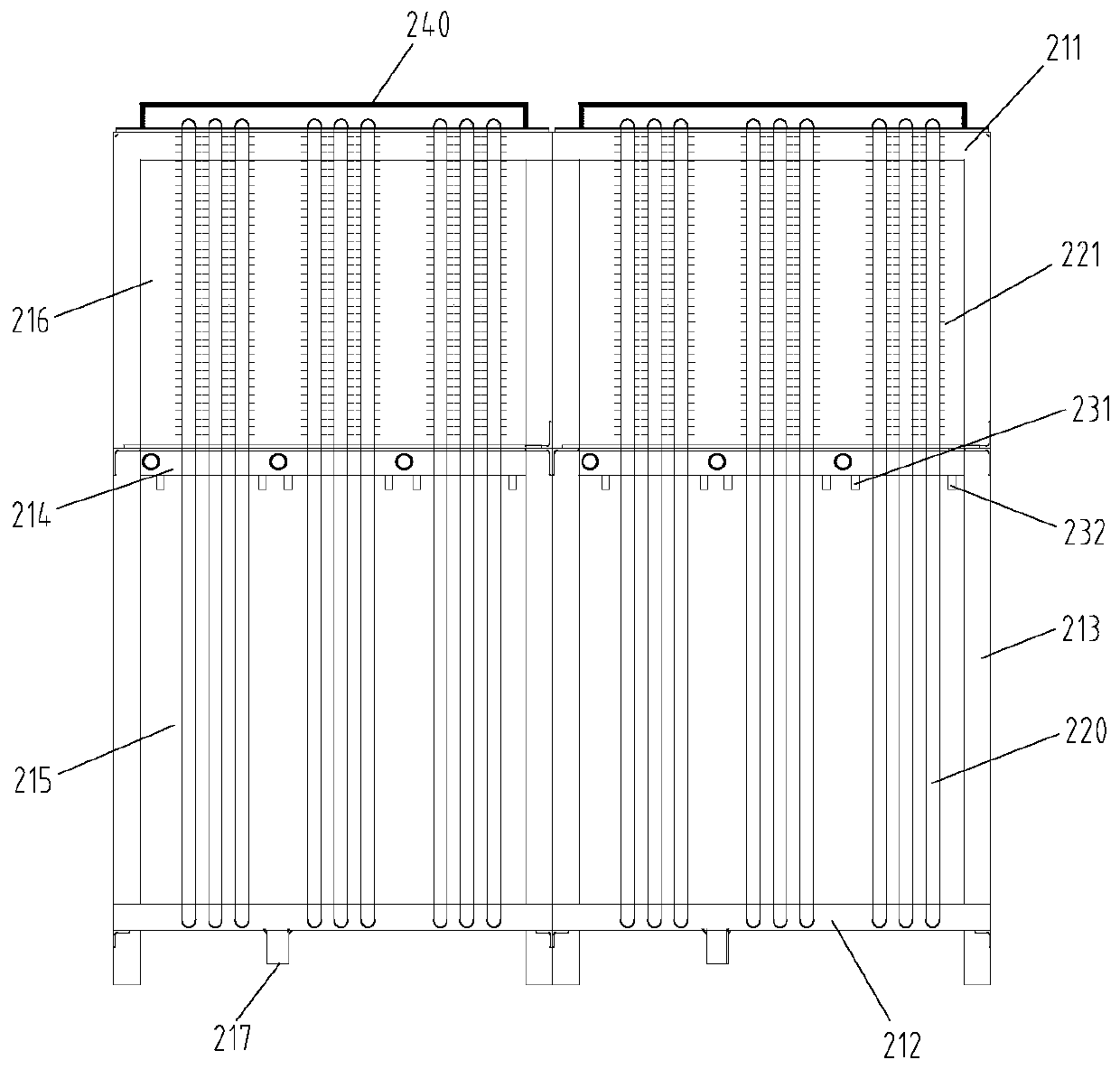

High-temperature printing and dyeing waste gas treatment equipment

PendingCN110270217AEmissions invisibleNo smellCombination devicesUsing liquid separation agentParticulatesMicrobubbles

Owner:SUZHOU BANGTIKE INTELLIGENT TECH CO LTD

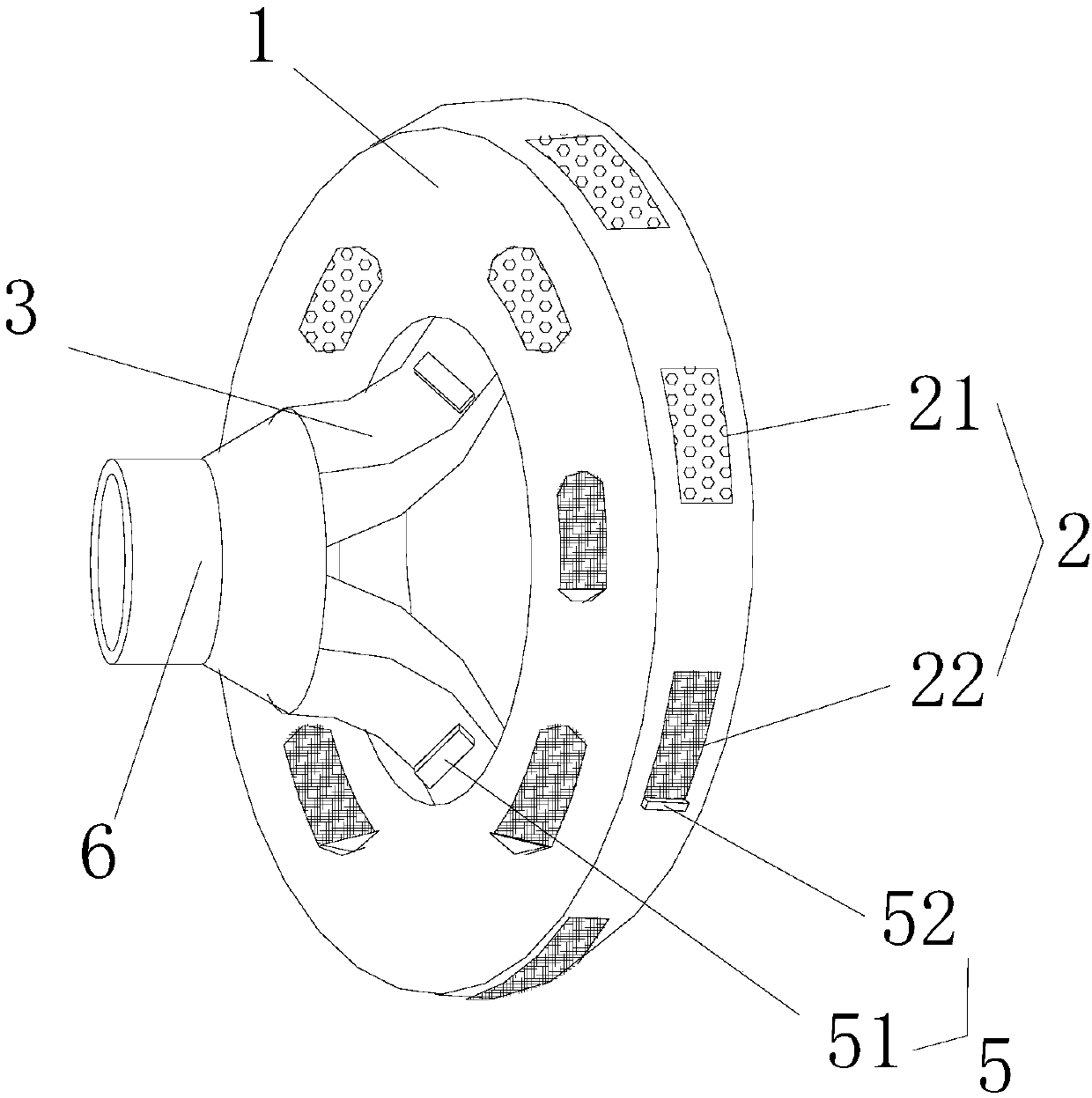

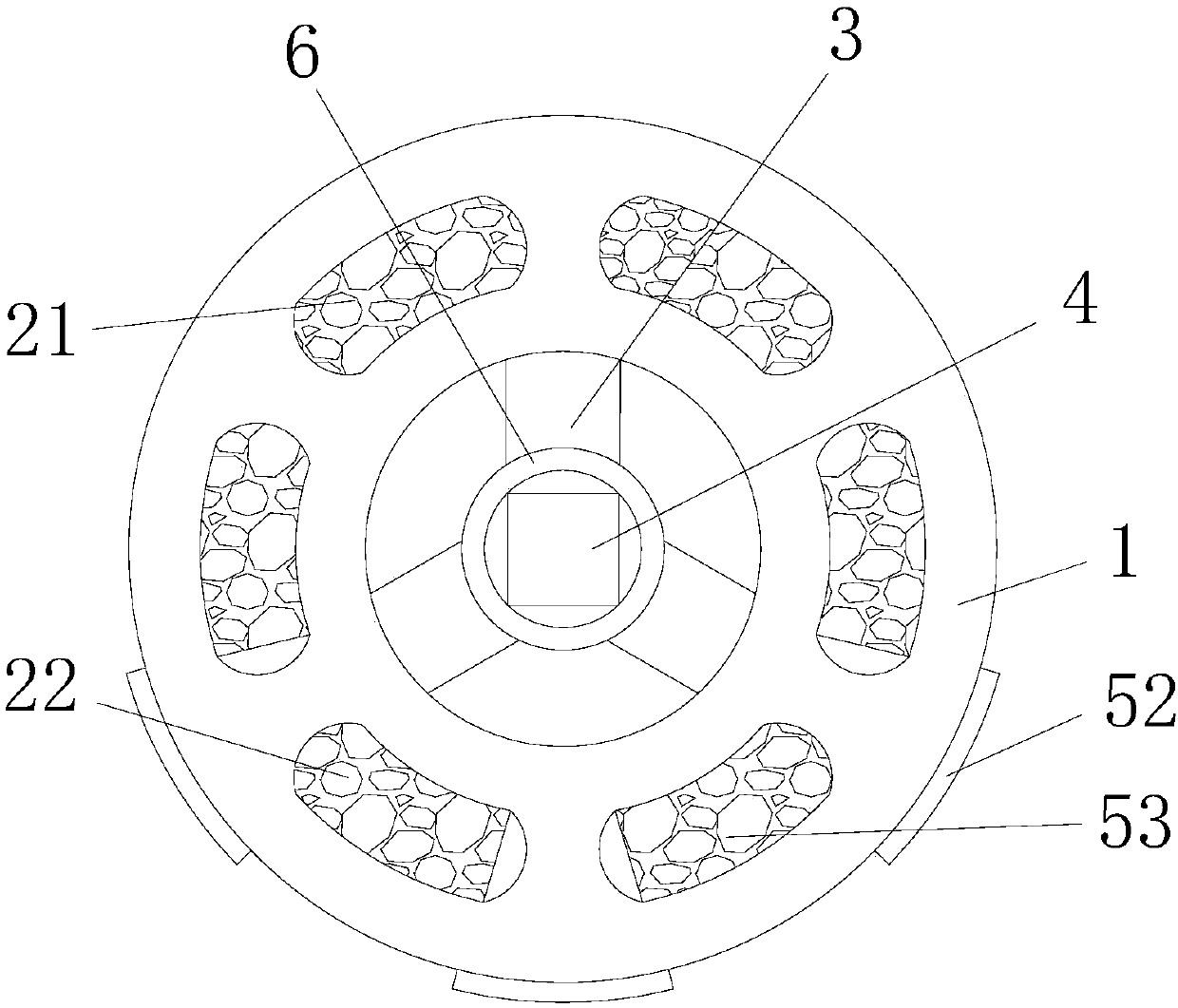

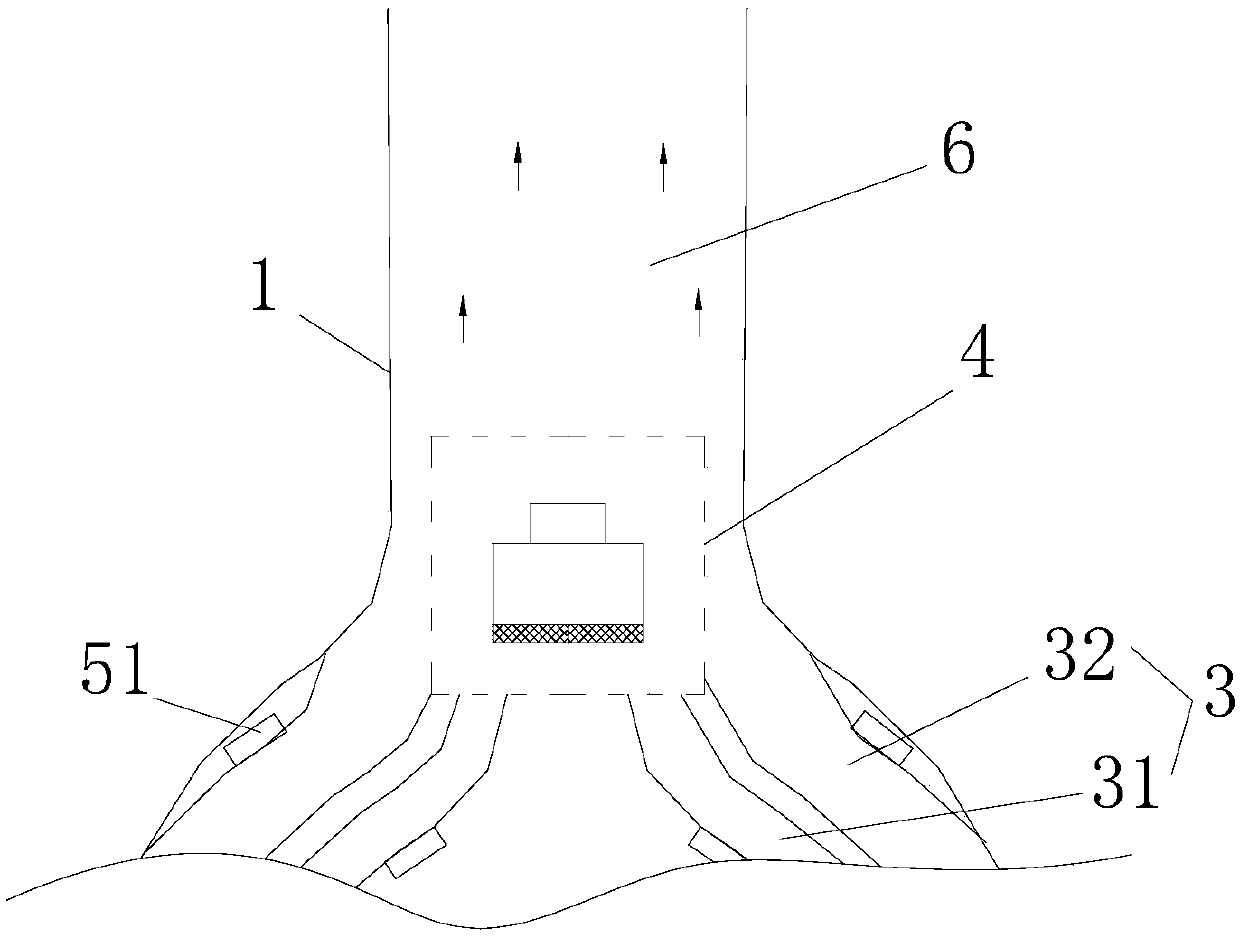

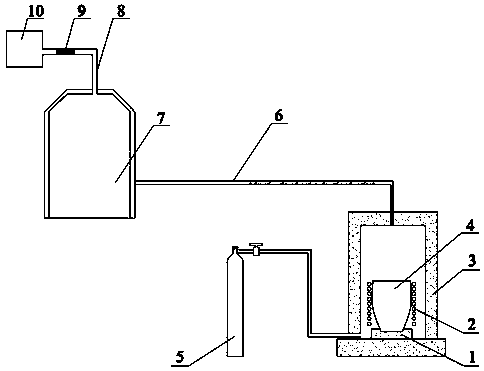

Dynamic fatigue testing machine for clutch cover assembly and testing method thereof

ActiveCN114152421AMeet testing needsImprove applicabilityMachine part testingTemperature controlControl system

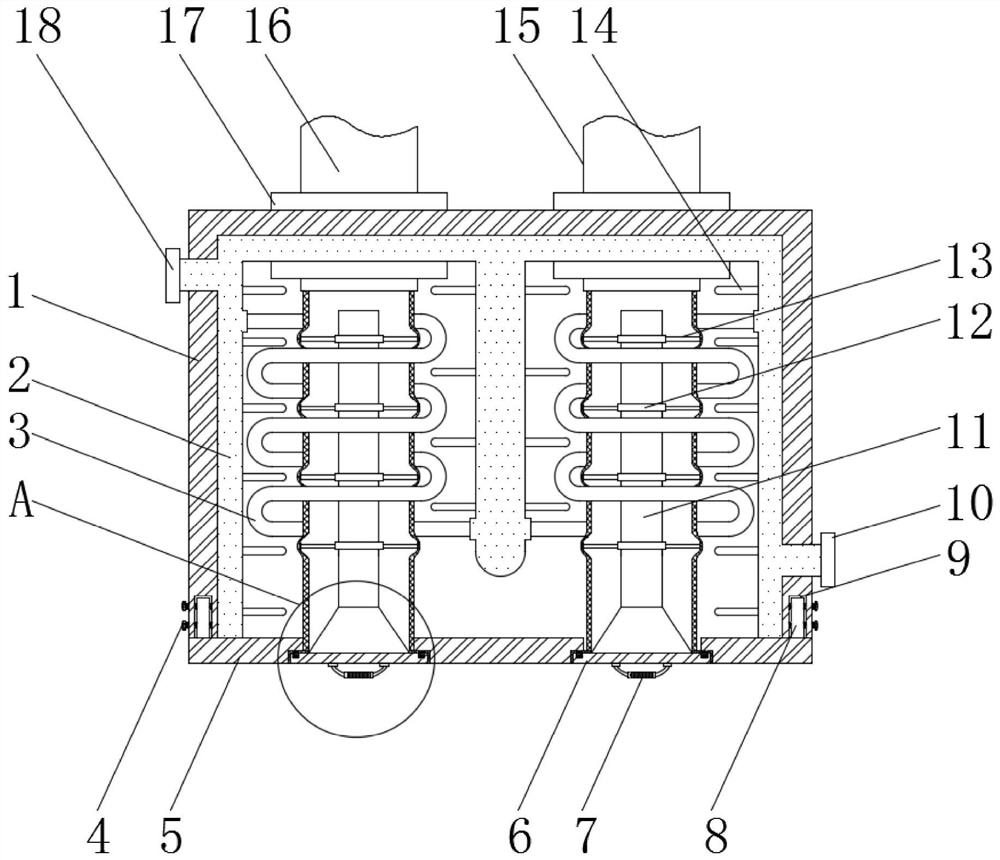

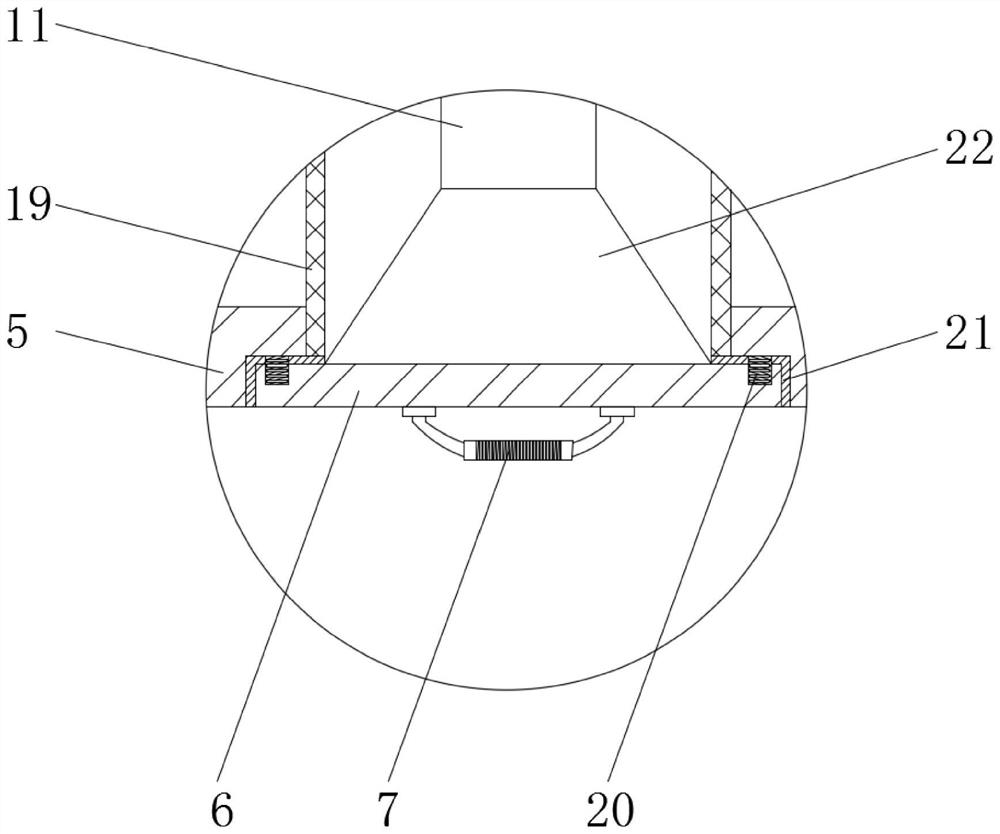

The invention discloses a clutch cover assembly dynamic fatigue testing machine and a testing method thereof.The clutch cover assembly dynamic fatigue testing machine comprises an operation control system, a rack, a main shaft driving mechanism, a main shaft box, a temperature control box and a sliding table, the main shaft driving mechanism, the main shaft box, the temperature control box and the sliding table are arranged on the upper plane of the rack, the main shaft driving mechanism is located on the left side of the main shaft box, and the temperature control box is located on the right side of the main shaft box; the sliding table is located on the right side of the temperature control box, and is characterized in that the spindle driving mechanism is directly connected to the spindle box through a coupler, a reciprocating separation driving mechanism is arranged on the sliding table, a soot blowing mechanism is arranged in the rack, and an outlet of the soot blowing mechanism is communicated with the temperature control box. Through the structural design, the test requirements of a push-type clutch cover assembly and a pull-type clutch cover assembly can be met, meanwhile, the dynamic separating force of the clutch cover assembly can be detected, the fatigue test can be monitored, various use working conditions can be simulated, and fatigue test data are more comprehensive and more accurate.

Owner:HUANGSHI SHENGDING AUTOMATION TECH CO LTD

Popular searches

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap