Hearth ash blowing method

A furnace and furnace structure technology, applied in the combustion method, combustion product treatment, removal of solid residue, etc., can solve the problems of improving heat transfer efficiency, decreasing heat transfer efficiency of the heating surface, and inability to blow the ash on the heating surface.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

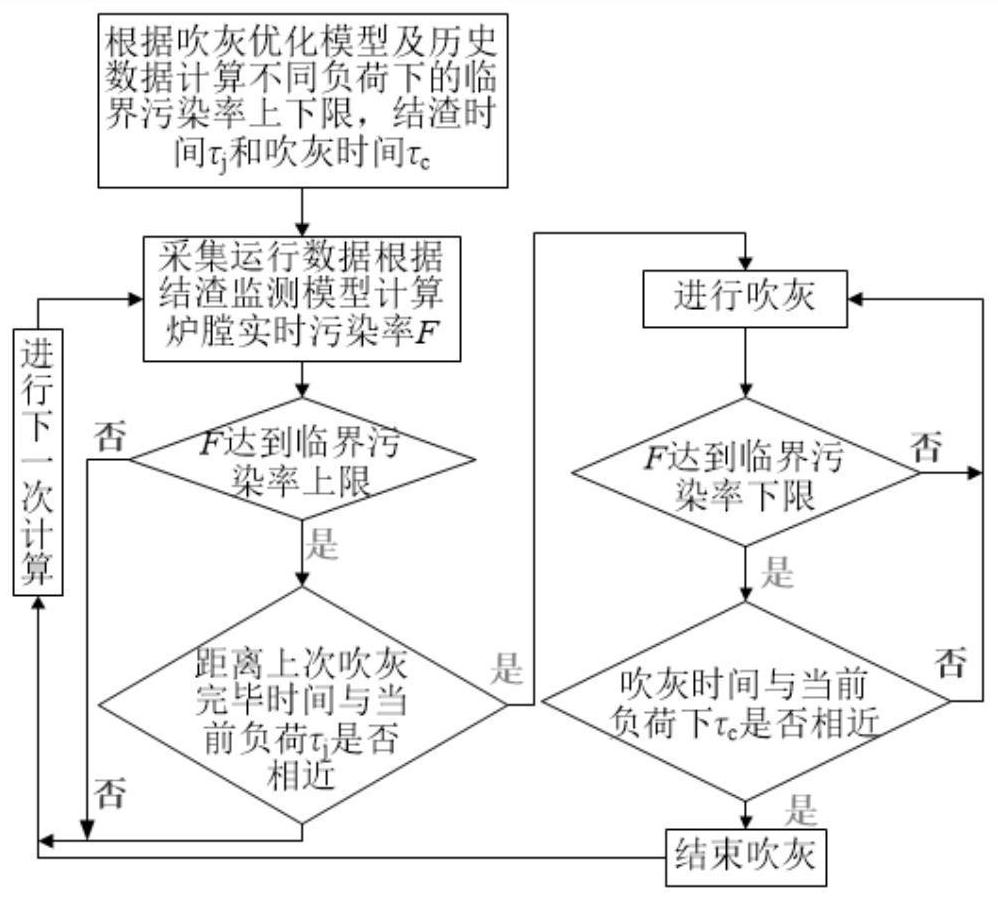

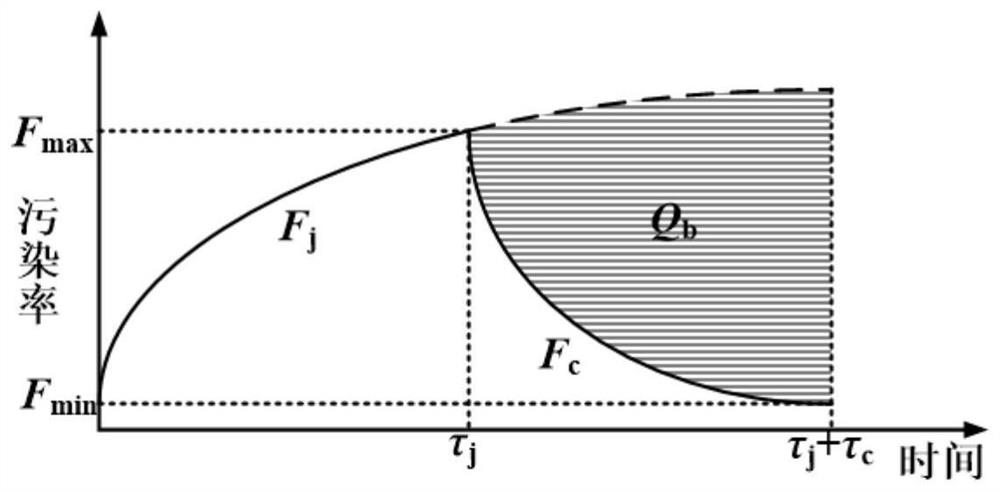

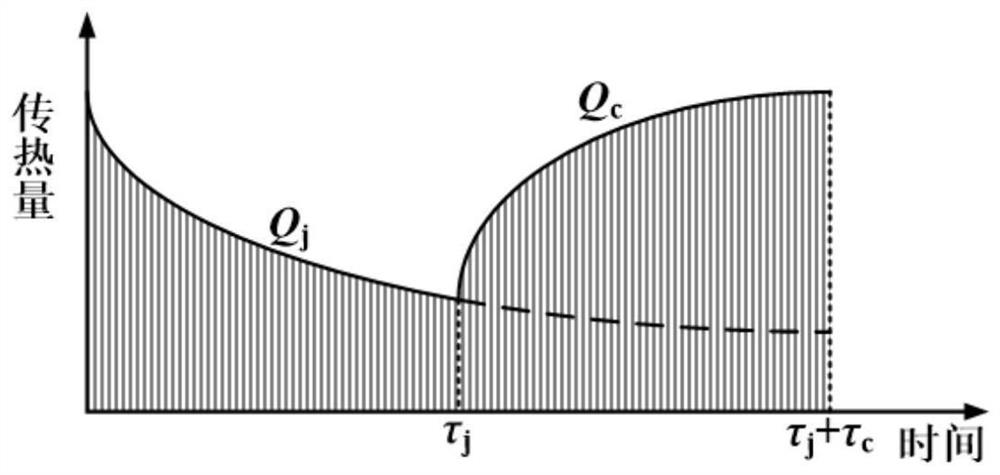

[0037] now combined with Figure 1-4 The present invention is described in further detail.

[0038] It should be noted that terms such as "upper", "lower", "left", "right", "front", and "rear" quoted in the invention are only for clarity of description, not for Limiting the practicable scope of the present invention, and the change or adjustment of the relative relationship shall also be regarded as the practicable scope of the present invention without substantive changes in the technical content.

[0039] Such as figure 1 and Figure 4 As shown, in one of the embodiments of the present invention, the selected boiler is a 600MW supercritical once-through boiler, the boiler model is HG-1956 / 25.4-YM5 type, which is an intermediate reheating, supercritical pressure variable pressure operation with built-in A once-through boiler with a recirculation pump starting system. This boiler adopts Π-shaped layout, single furnace, balanced ventilation, solid slag discharge, swirl burne

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap