Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

5 results about "Steam temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

ANSWER; The basic steam point of water is when it is heated to a temperature of 212 degrees Fahrenheit, 100 degrees Celsius or 373 degrees Kelvin.

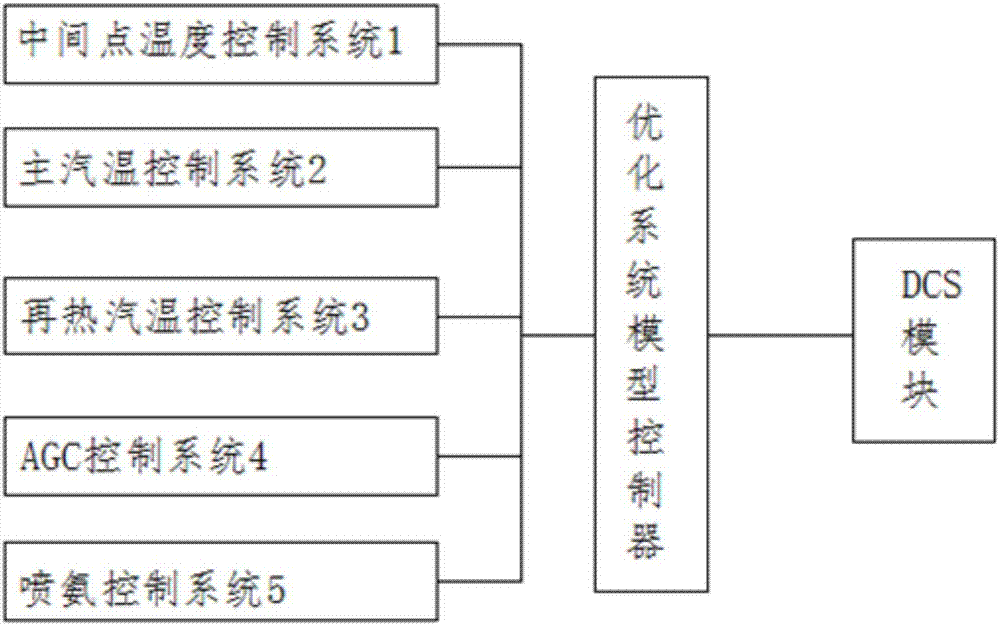

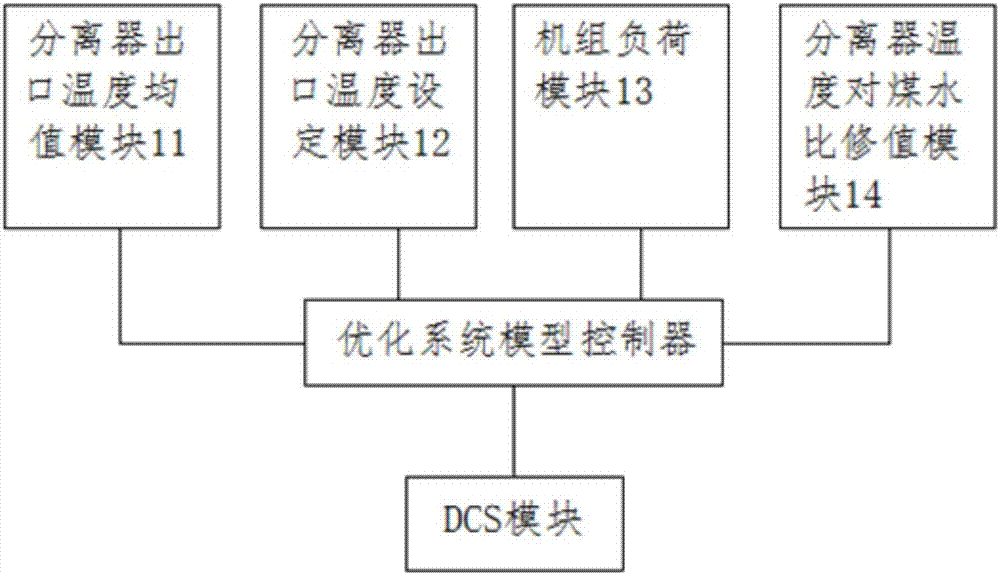

Ultra-supercritical thermal generator set coordinated control system

Owner:JIANGSU DATANG INT LUSIGANG POWER GENERATION

Method for adjusting metal wall temperature deviation of high-temperature reheater of opposed firing coal boiler

ActiveCN113339782AReduce unevennessAccurate adjustment effectSuperheating controlIndirect carbon-dioxide mitigationHearthComponents of crude oil

The invention provides a method for adjusting metal wall temperature deviation of a high-temperature reheater of an opposed firing coal boiler. The method comprises the following steps that flue gas components of an inlet flue section of an SCR system and metal wall temperature data of the high-temperature reheater are collected; the flue gas components of the inlet flue section of the SCR system are tested, and if opposed firing combustors in opposed firing combustion sets at the corresponding positions of low O2 content and high CO content are insufficient combustion positions in a hearth, the opening degree of secondary air doors outside the opposed firing combustors is turned up; if the opposed firing combustors in the opposed firing combustion sets at the corresponding positions of high O2 content and low CO content are sufficient combustion positions in the hearth, the opening degree of the secondary air doors outside the opposed firing combustors is turned down; and opposed firing over-fire air combustors in opposed firing over-fire air sets corresponding to the overtemperature point or the high point of the metal wall temperature of the high-temperature reheater are obtained, the opening degree of secondary air doors in the opposed firing over-fire air combustors are turned up, and the opening degree of central air of the opposed firing over-fire air combustors is turned up. According to the adjusting method, the positions of the overtemperature point and the high point of the metal wall temperature of the heating surface of the high-temperature reheater are adjusted and controlled, the thermal load deviation of the heating surface is reduced, and the reheating steam temperature is increased.

Owner:SUZHOU XIRE ENERGY SAVING ENVIRONMENTAL PROTECTION TECH CO LTD +1

Off-the-road tyre low-external-temperature vulcanization method

Owner:嘉兴市劼力机械科技有限公司

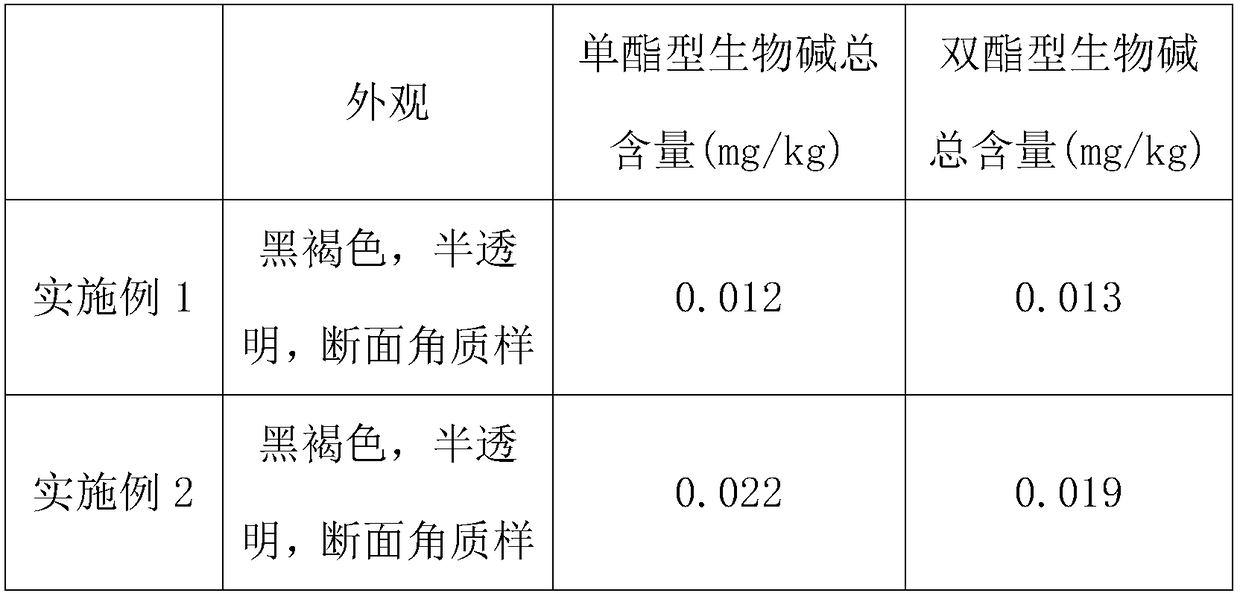

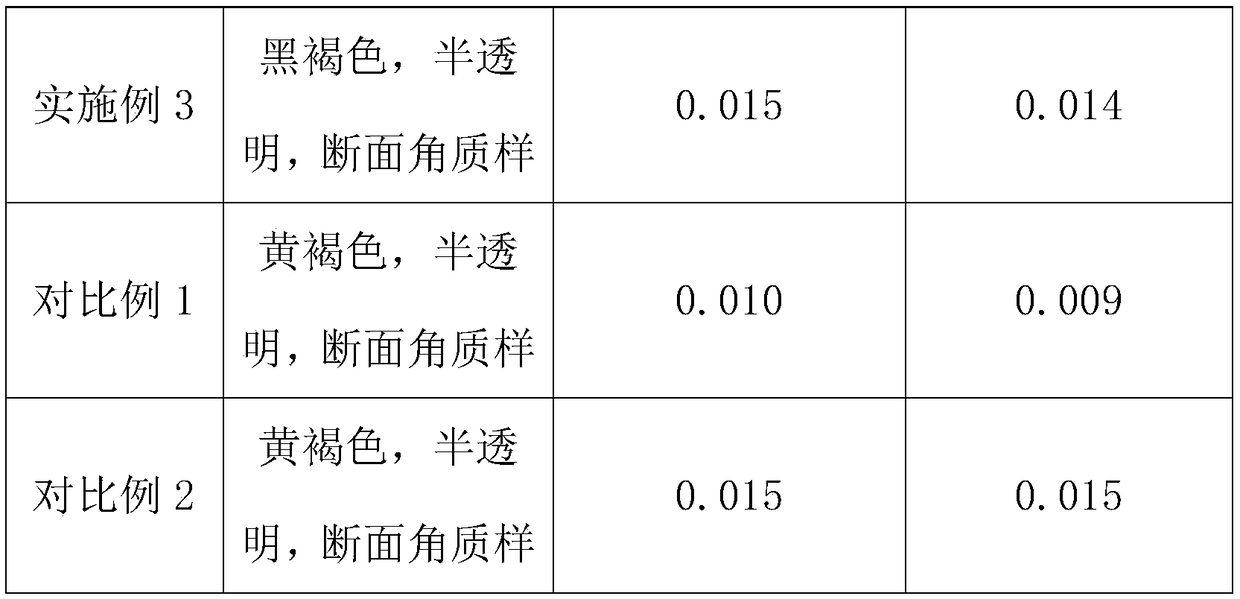

Black radix aconiti carmichaeli processing technology as well as product and application thereof

InactiveCN109045122ASimple production processGuaranteed stabilityDispersion deliveryAntipyreticRadix AconitiEngineering

Owner:KANGMEI TENGWANGGE (SICHUAN) PHARM CO LTD

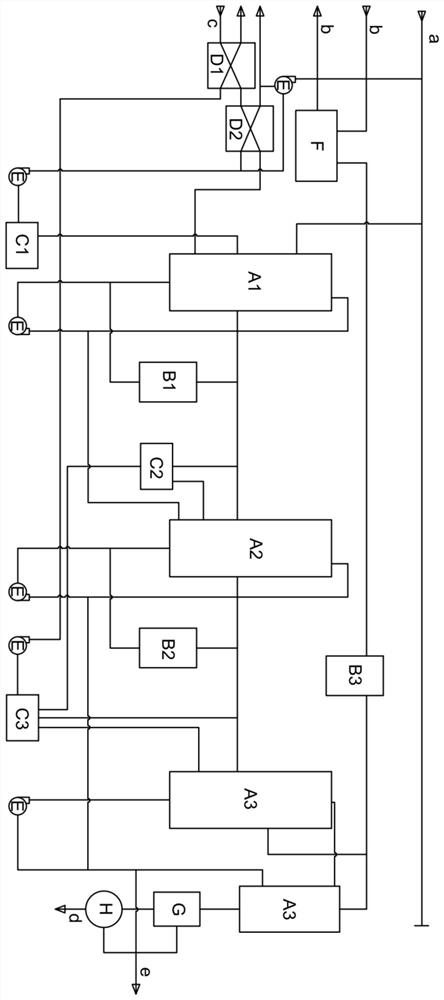

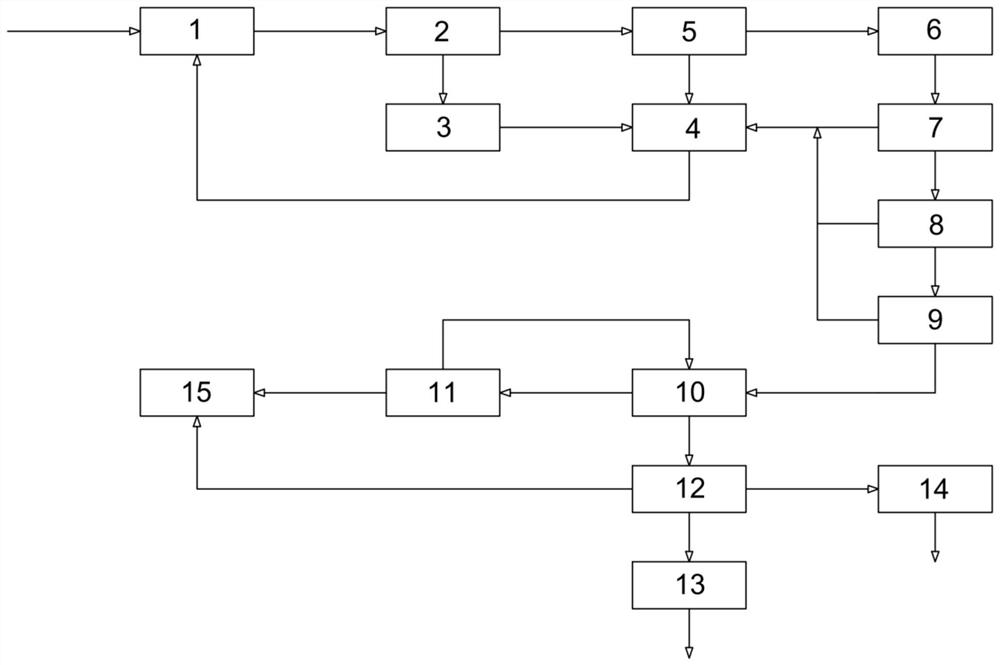

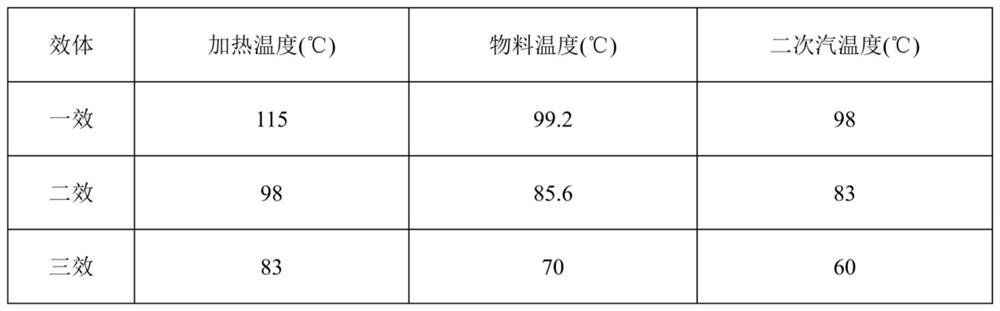

Energy-saving water treatment system and method for gasified concentrated water

PendingCN114804489AHigh recovery rateImprove crystallization efficiencyWater/sewage treatment by centrifugal separationTreatment involving filtrationSteam temperatureTreatment system

Owner:BGT GRP CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap