Black radix aconiti carmichaeli processing technology as well as product and application thereof

A technology for processing Heishun tablets, which is applied in the processing technology of Heishun tablets and its products and applications. It can solve the problems of water addition, feeding temperature, and time without detailed standards, alkaloids are prone to hydrolysis, and effective ingredients are lost. , to achieve the effect of improving appearance and internal quality, ensuring stability and reproducibility, and reducing toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

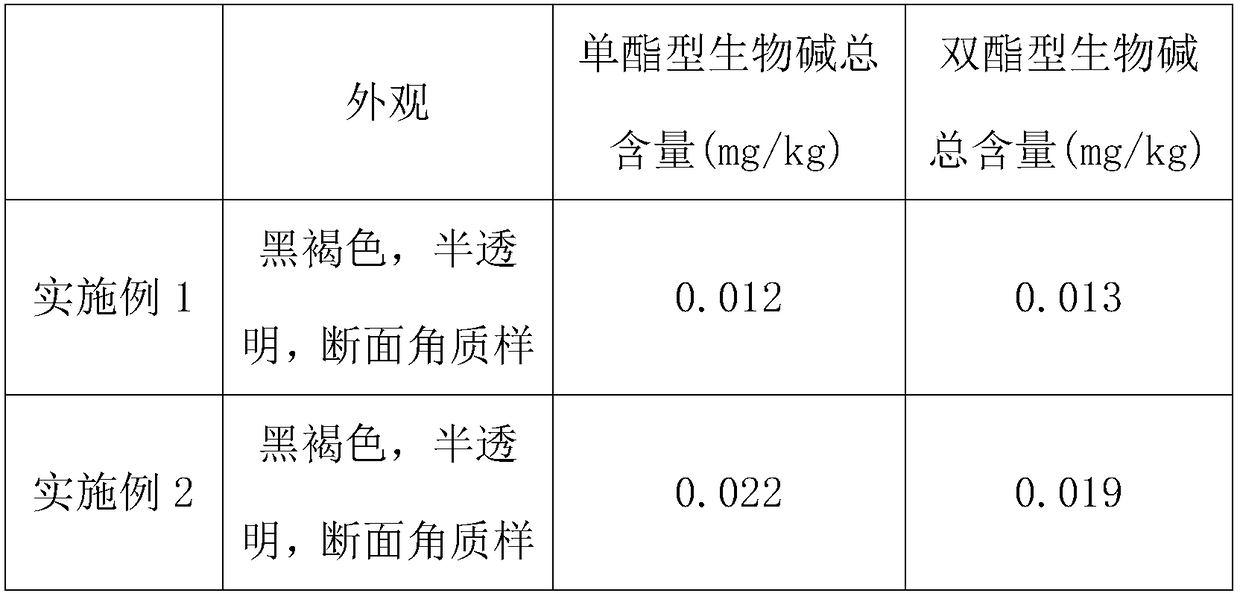

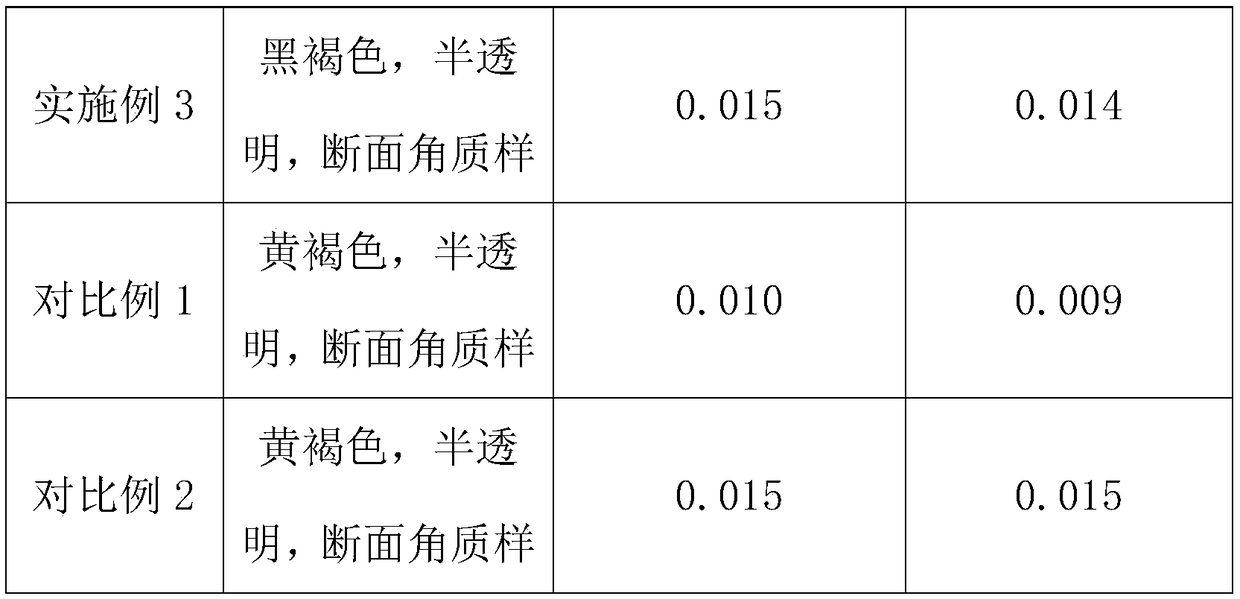

Embodiment 1

[0039] A process for processing black smooth film, comprising the steps of:

[0040] The step of slicing: cut the aconite into thin slices with a thickness of 0.4cm;

[0041] Steps of toning: use the toning solution to dye the aconite slices into a strong brown color; the toning solution is prepared from brown sugar and rapeseed oil at a mass ratio of 1:1;

[0042] Steps for steaming with moisture retention and heating: put the aconite slices in the boiler, and use the gradual heating method to steam for 8 minutes at a temperature of 90 °C and a steam pressure of 0.02 Mpa; at a temperature of 105 °C and a steam pressure of 0.04 Steamed under the condition of 20min; steamed under the condition of temperature of 120°C and steam pressure of 0.1Mpa for 20min; and controlled the humidity in the boiler to 60%, and steamed in water;

[0043] The step of co-decocting ginger and licorice: putting the steamed aconite slices in the decoction of ginger and licorice and co-decocting until the

Embodiment 2

[0046] A process for processing black smooth film, comprising the steps of:

[0047] The step of slicing: cut the aconite into thin slices with a thickness of 0.5cm;

[0048] Steps of toning: use the toning solution to dye the aconite slices into a strong brown color; the toning solution is prepared from brown sugar and rapeseed oil at a mass ratio of 1:1;

[0049] Steps for steaming with moisture retention and heating: put the aconite slices in the boiler, and use the gradual heating method to steam for 10 minutes at a temperature of 105°C and a steam pressure of 0.02Mpa; Steam for 30 minutes under the same conditions; steam for 30 minutes at a temperature of 120°C and a steam pressure of 0.1Mpa; and control the humidity in the boiler to 65% for steaming;

[0050] The step of co-decocting ginger and licorice: putting the steamed aconite slices in the decoction of ginger and licorice and co-decocting until the juice is collected; wherein, the preparation of the decoction of ging

Embodiment 3

[0053] A process for processing black smooth film, comprising the steps of:

[0054] Slicing steps: cut the aconite into thin slices with a thickness of 0.6cm;

[0055] Steps of toning: use the toning solution to dye the aconite slices into a strong brown color; the toning solution is prepared from brown sugar and rapeseed oil at a mass ratio of 1:1;

[0056] Steps for steaming with moisture retention and heating: put the aconite slices in the boiler, and use the gradual heating method to steam for 12 minutes at a temperature of 105°C and a steam pressure of 0.02Mpa; Steam for 40 minutes under the same conditions; steam for 40 minutes at a temperature of 130°C and a steam pressure of 0.1Mpa; and control the humidity in the boiler to 70% for steaming;

[0057] The step of co-decocting ginger and licorice: the steamed aconite slices are placed in the decoction of ginger and licorice and co-decocted until the juice is collected; wherein, the preparation of the decoction of ginger a

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap