Energy-saving water treatment system and method for gasified concentrated water

A technology of water treatment system and concentrated water, applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. Removal of organic matter, impossibility of industrial application, etc., to avoid impact, improve efficiency, and prevent system blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment

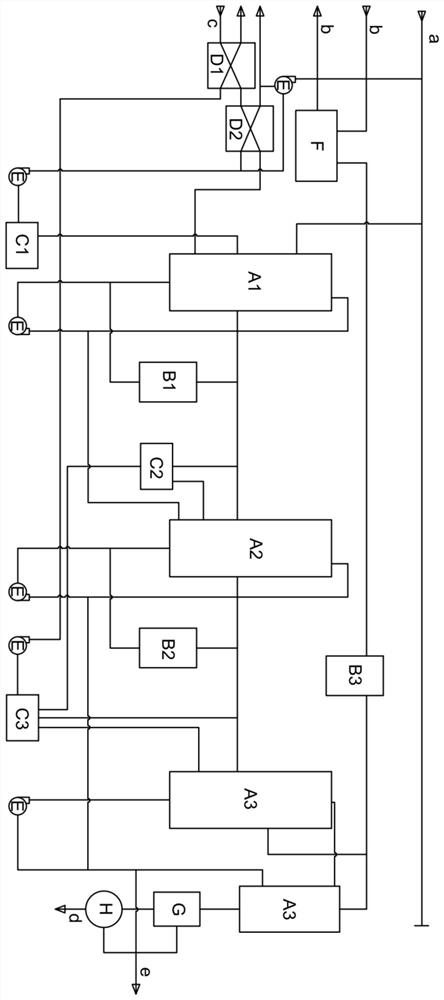

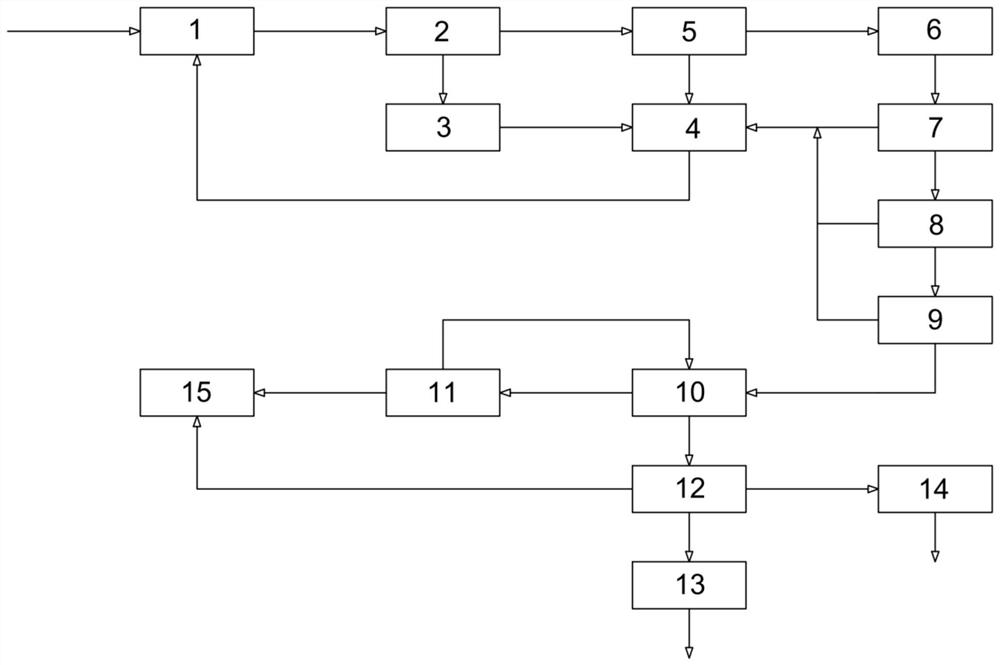

[0028] The present application relates to an energy-saving water treatment system for gasified concentrated water, comprising at least an evaporation and crystallization unit located downstream of a membrane concentration unit, and the membrane concentration unit is configured as: a first-stage membrane concentration device, a second-stage membrane concentration device and / Or at least the first-grade concentrated water with the salt concentration above the operating index of the evaporative crystallization unit can be obtained by reusing the two.

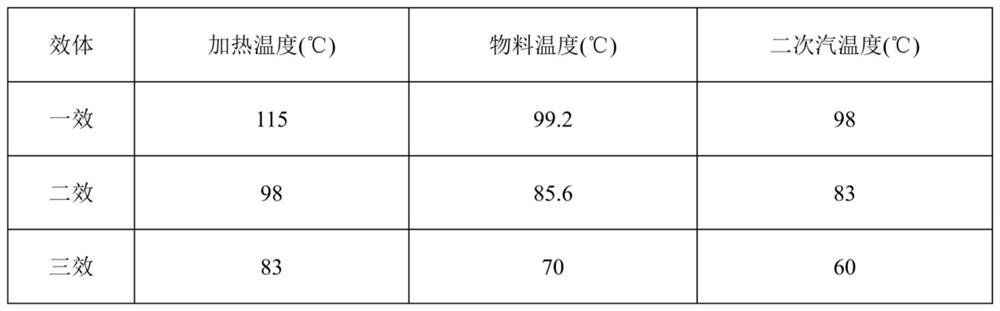

[0029] The first-grade concentrated water is lifted by the feed pump and sent to the evaporation and crystallization unit, and three-effect vacuum evaporation is used. The temperature estimates the material composition and the liquid phase concentration analysis during the evaporation process. The boiling point rise of the liquid phase materials for each effect is 1.21°C / 2.58°C / 9.15°C. Considering that the feed concentration of t

Embodiment approach

[0053] According to a preferred embodiment, the method further includes: when the first-stage concentrated water enters the second-effect falling-film circulating evaporator, limiting the evaporation temperature of the second-effect falling-film circulating evaporator to be gas-phase secondary steam The second saturated steam temperature corresponding to the pressure forms a second pressure different from the first saturated steam temperature, and the boiling point temperature of the primary concentrated water is changed based on the difference of the evaporator pressure to separate the liquid foam and generate secondary The steam is heated as a three-effect heat source; when the first-level concentrated water enters the three-effect forced circulation evaporator, the evaporation temperature of the three-effect forced circulation evaporator is limited to the third saturated steam temperature corresponding to the pressure of the secondary steam in the gas phase. A third pressure di

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap