Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

6 results about "Thermal load" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thermal load is demand for heat energy. The heat may be needed for space heating, hot water heating, or some industrial process. The thermal load can be served by the boiler, by a generator from which waste heat can be recovered, or by surplus electricity.

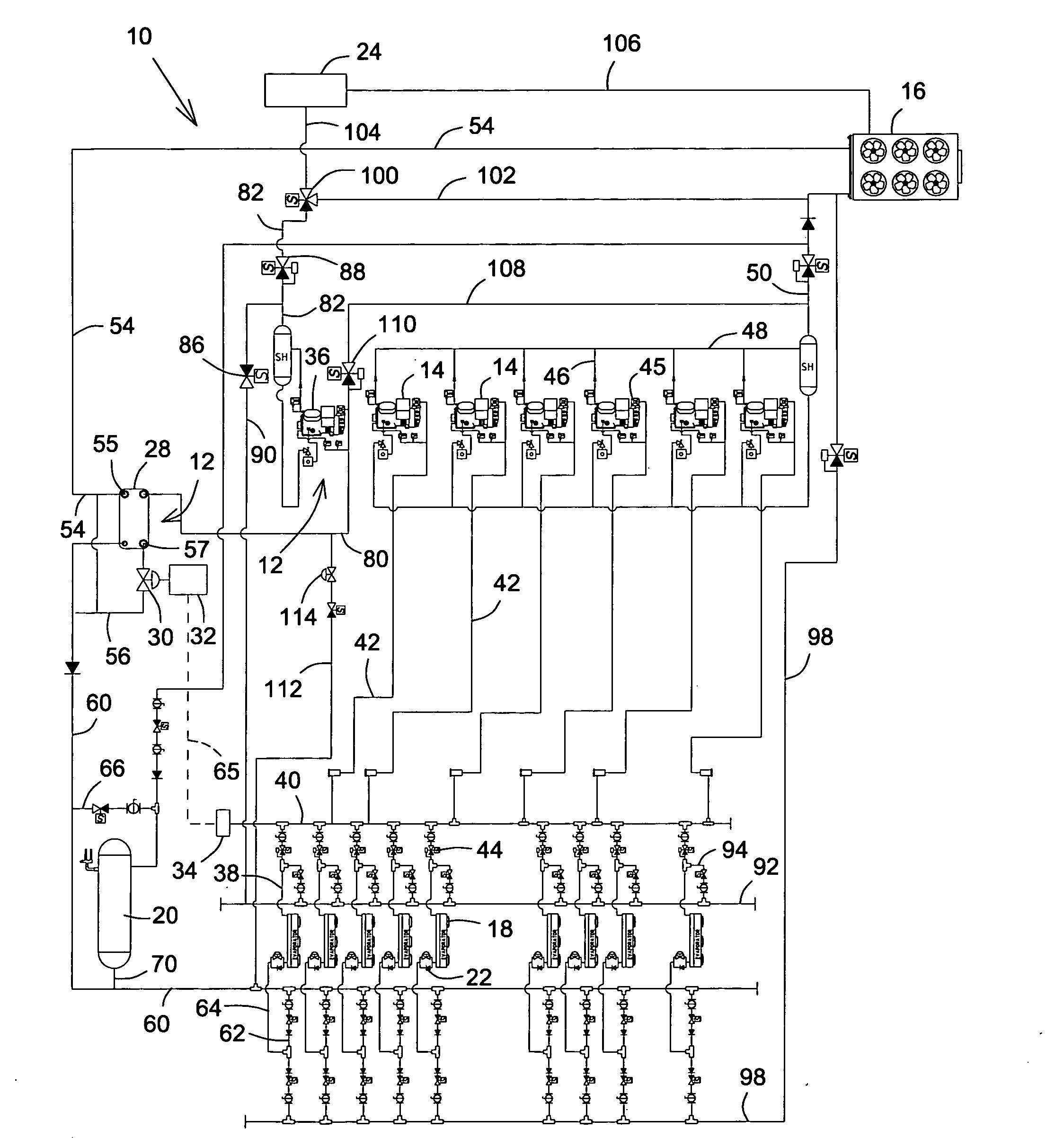

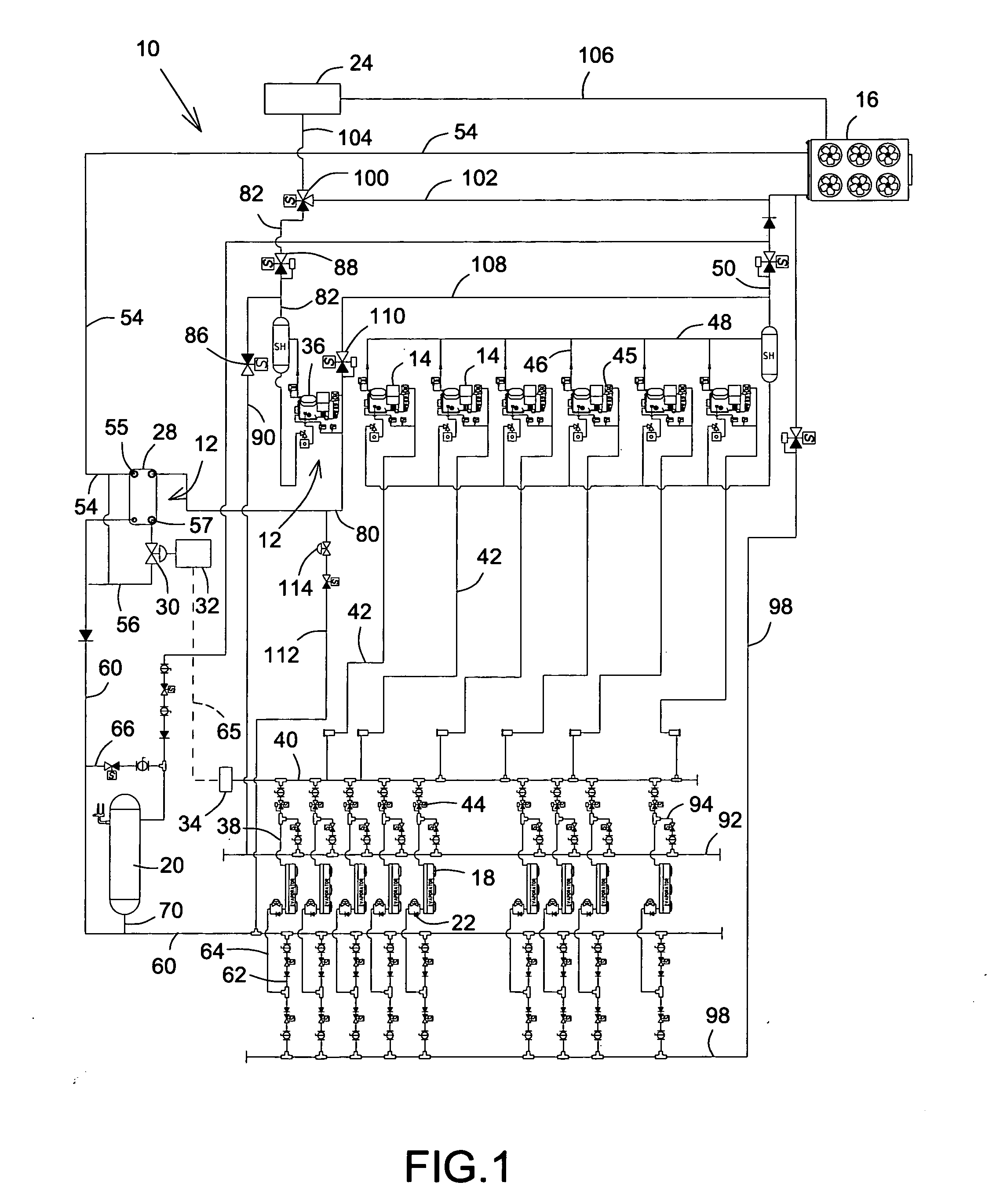

Refrigeration system having adjustable refrigeration capacity

InactiveUS20080011004A1Adjustable quantityMechanical apparatusCompression machines with non-reversible cycleRefrigeration compressorEngineering

Owner:LESAGE GAETAN +1

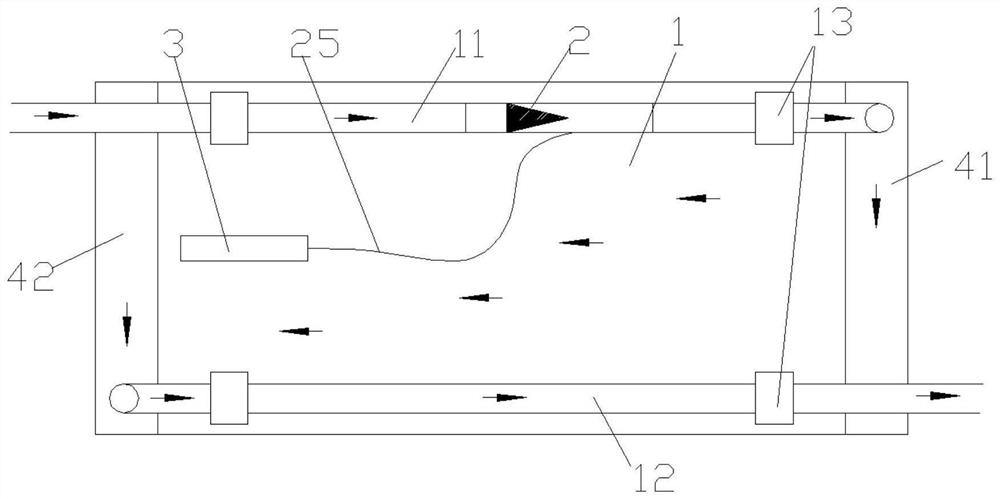

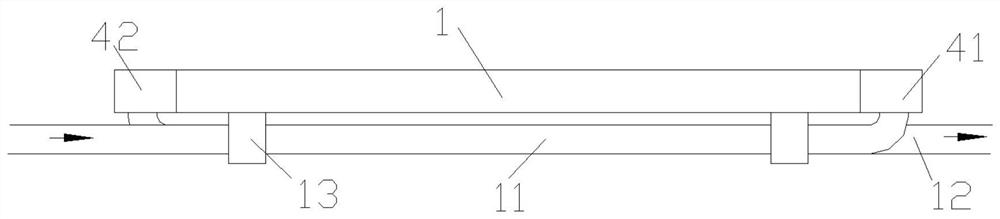

Dual-air-duct air conditioner and dehumidification method and system thereof

ActiveCN110736144AEnsure normal dehumidificationExpand coverage areaMechanical apparatusLighting and heating apparatusAir cycleEngineering

The invention relates to the field of refrigeration equipment, and discloses a dual-air-duct air conditioner and a dehumidification method and system thereof. By obtaining target temperature Ts and target relative humidity [phi]s set by a user and obtaining indoor ambient temperature Tin, outdoor ambient temperature Tout and indoor relative humidity phi in real time, whether the air conditioner meets parameter conditions for entering into an ultralow-sensible-heat high-latent-heat load area dehumidification mode, a low-sensible-heat high-latent-heat load area dehumidification mode and a medium-high-sensible-heat load area dehumidification mode or not is judged, the rotating speed of an upper fan and the rotating speed of a lower fan are controlled under certain dehumidification mode, thusthe three dehumidification modes can be switched, especially when the dual-air-duct air conditioner operates in the ultralow-sensible-heat high-latent-heat load area dehumidification mode, the upper fan is controlled to operate in a low-air gear to be mainly used for promoting air circulation, the lower fan is controlled to operate at the lowest reliable fan rotating speed to be mainly used for dehumidification, latent heat output of a compressor during low-frequency operation is improved while sensible heat output is lowered, and constant-temperature dehumidification is achieved.

Owner:HISENSE (SHANDONG) AIR CONDITIONING CO LTD

Method for calculating thermoelectric peak shaving capacity of solar gas combined cycle unit

PendingCN112234650ALower heating costsReduce consumptionFrom solar energySingle network parallel feeding arrangementsThermodynamicsProcess engineering

The invention discloses a method for calculating the peak shaving capacity of a solar gas-steam combined cycle combined heat and power generation system. The method comprises the following steps of: adding solar energy into a gas-steam combined cycle unit; determining the flow of heat conduction oil supplied to a gas unit by a solar loop and determining the minimum peak regulation output conditionand the maximum peak regulation output improvement of a heat supply unit under the same heat supply load requirement. The method can be applied to calculation and evaluation of the peak regulation maximum and minimum output conditions of a new system after the solar loop is added to the gas-steam combined cycle unit for transformation, and therefore important reference data are provided for the unit peak regulation capacity change conditions and the transformation scheme after solar energy is applied to the gas combined cycle combined heat and power generation unit.

Owner:CECEP GUOJI UNITED POWER (NINGXIA) CO LTD

Method for adjusting metal wall temperature deviation of high-temperature reheater of opposed firing coal boiler

ActiveCN113339782AReduce unevennessAccurate adjustment effectSuperheating controlIndirect carbon-dioxide mitigationHearthComponents of crude oil

The invention provides a method for adjusting metal wall temperature deviation of a high-temperature reheater of an opposed firing coal boiler. The method comprises the following steps that flue gas components of an inlet flue section of an SCR system and metal wall temperature data of the high-temperature reheater are collected; the flue gas components of the inlet flue section of the SCR system are tested, and if opposed firing combustors in opposed firing combustion sets at the corresponding positions of low O2 content and high CO content are insufficient combustion positions in a hearth, the opening degree of secondary air doors outside the opposed firing combustors is turned up; if the opposed firing combustors in the opposed firing combustion sets at the corresponding positions of high O2 content and low CO content are sufficient combustion positions in the hearth, the opening degree of the secondary air doors outside the opposed firing combustors is turned down; and opposed firing over-fire air combustors in opposed firing over-fire air sets corresponding to the overtemperature point or the high point of the metal wall temperature of the high-temperature reheater are obtained, the opening degree of secondary air doors in the opposed firing over-fire air combustors are turned up, and the opening degree of central air of the opposed firing over-fire air combustors is turned up. According to the adjusting method, the positions of the overtemperature point and the high point of the metal wall temperature of the heating surface of the high-temperature reheater are adjusted and controlled, the thermal load deviation of the heating surface is reduced, and the reheating steam temperature is increased.

Owner:SUZHOU XIRE ENERGY SAVING ENVIRONMENTAL PROTECTION TECH CO LTD +1

Heat exchange substrate assembly, heat exchange module, controller and air conditioner

PendingCN112185913AAvoid condensationThermometer detailsLighting and heating apparatusThermodynamicsEngineering

Owner:GREE ELECTRIC APPLIANCES INC

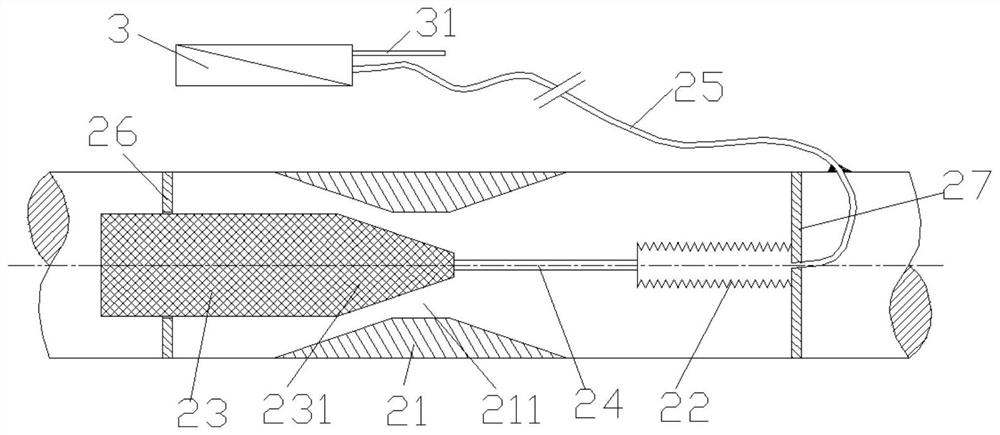

Modal test structure temperature compensator in vacuum environment

ActiveCN111071501ALess radiant heatFirmly connectedCosmonautic condition simulationsEngineeringTest chamber

The embodiment of the invention relates to a modal test structure temperature compensator in a vacuum environment. The modal test structure temperature compensator comprises a thermal vacuum test boxbody, an upper compensation plate and a lower compensation plate, the upper compensation plate and the lower compensation plate jointly form the temperature compensator, a test piece is fixed on the inner rear wall of the thermal vacuum test box body, and the upper compensation plate and the lower compensation plate are respectively positioned on the upper side and the lower side of the test piece, are made of the same material, have the same thermal load as the test piece, and cover most circumferential positions of the test piece to effectively reduce the radiation heat of the test piece tothe surrounding space; and an annular base is used for fixedly connecting the upper compensation plate and the lower compensation plate to the inner rear wall of the thermal vacuum test box body, threaded holes are used in cooperation with screws, and the annular base is fixed to the rear wall of the interior of the thermal vacuum test box body through the screws, so the upper compensation plate and the lower compensation plate are stably connected through the connecting mode, thereby vibration caused by external force is avoided, and the test piece is prevented from being affected.

Owner:INST OF MECHANICS CHINESE ACAD OF SCI

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap