Refrigeration system having adjustable refrigeration capacity

a refrigeration system and refrigeration capacity technology, applied in the direction of compression machines with several evaporators, compression machines with non-reversible cycles, lighting and heating apparatus, etc., can solve the problems of insufficient refrigeration of thermal loads, unwanted freezing of thermal loads, and insufficient refrigerating of thermal loads, so as to reduce the starting and stopping of refrigerating compressors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

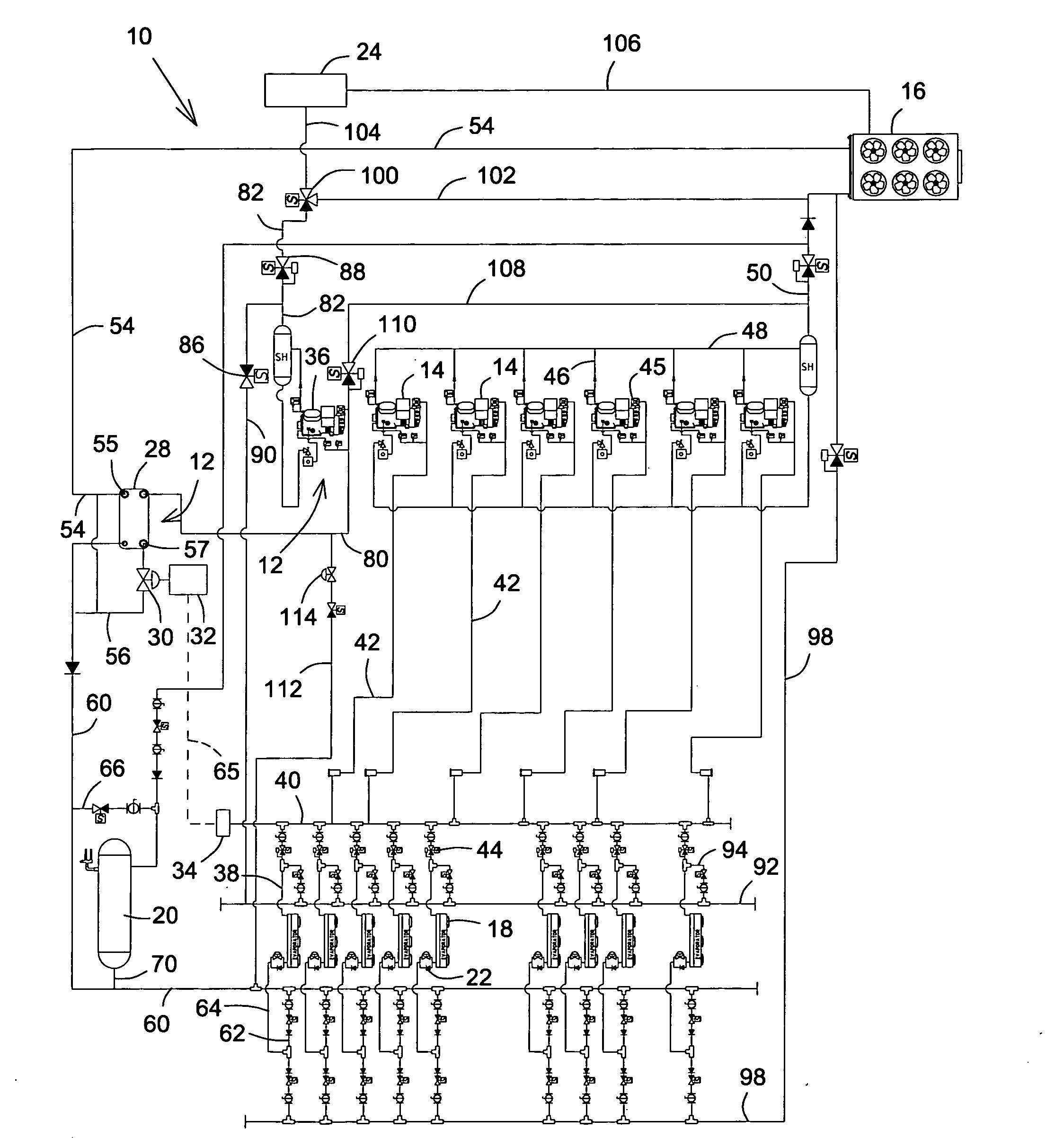

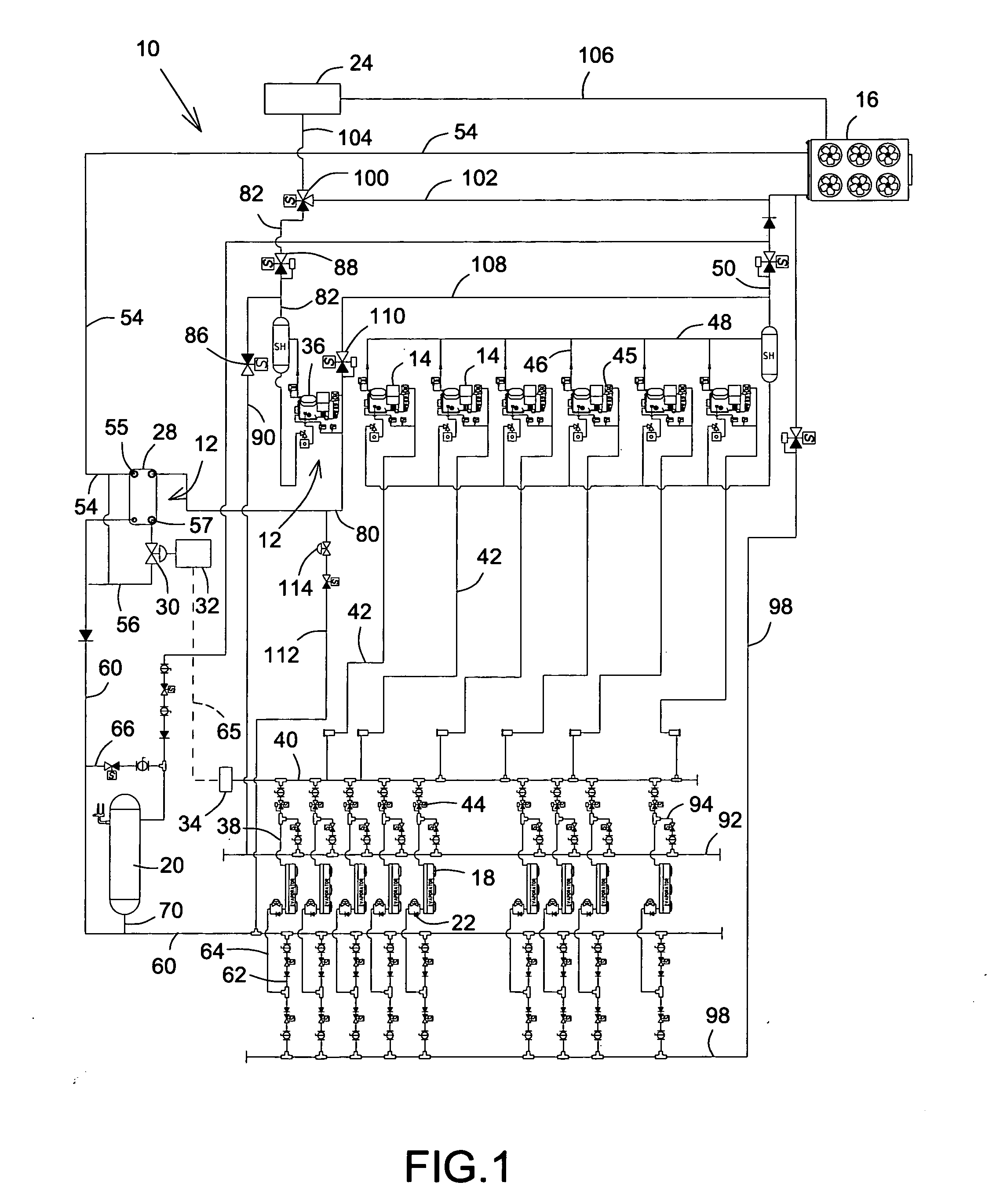

[0025]FIG. 1 is a schematic diagram of a refrigeration system, shown generally as 10, having an adjustment system, shown generally as 12, for adjusting refrigeration capacity thereof. Broadly speaking, the system 10 includes at least one, but preferably two or more, refrigerating compressors 14, adjustment system 12, an outdoor air-cooled condenser 16 as a refrigerant condensing means, at least one evaporator 18, a refrigerant liquid receiver 20, one or more refrigeration expansion valves 22, and optionally, heat reclaim means 24. System 10 also includes a plurality of conduits, also referred to as lines and manifolds, through which refrigerant is circulated in system 10 for refrigerating therewith a thermal load between refrigerating compressors 14, adjustment system 12, refrigerant condensing means 16, evaporator 18, refrigerant liquid receiver 20, refrigeration expansion valves 22, and heat reclaim means 24, all of which are connected in fluid communication for refrigerant by condui

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap