Heat exchange substrate assembly, heat exchange module, controller and air conditioner

A substrate and component technology that is applied in the fields of heat exchange substrate components, heat exchange modules, controllers, and air conditioners. It can solve problems such as built-in protection actions, small air-cooled heat dissipation capacity, and rise in module surface temperature to prevent shutdown protection. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

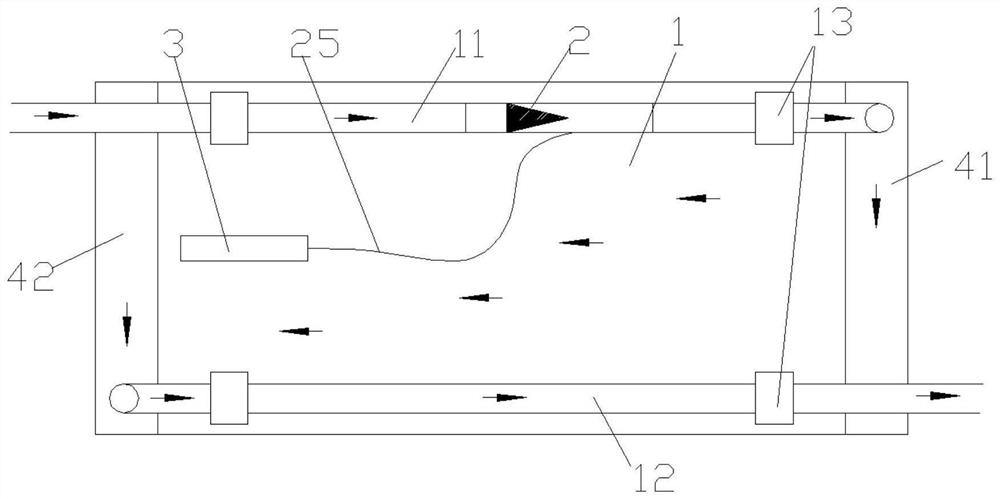

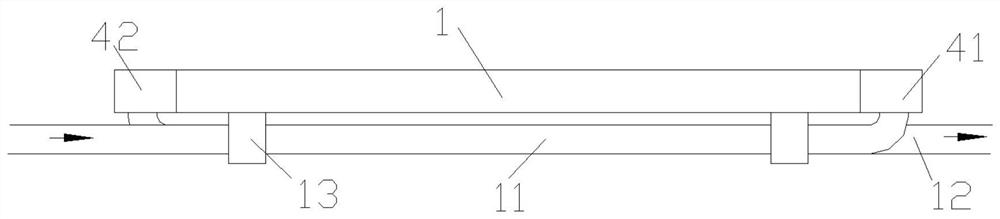

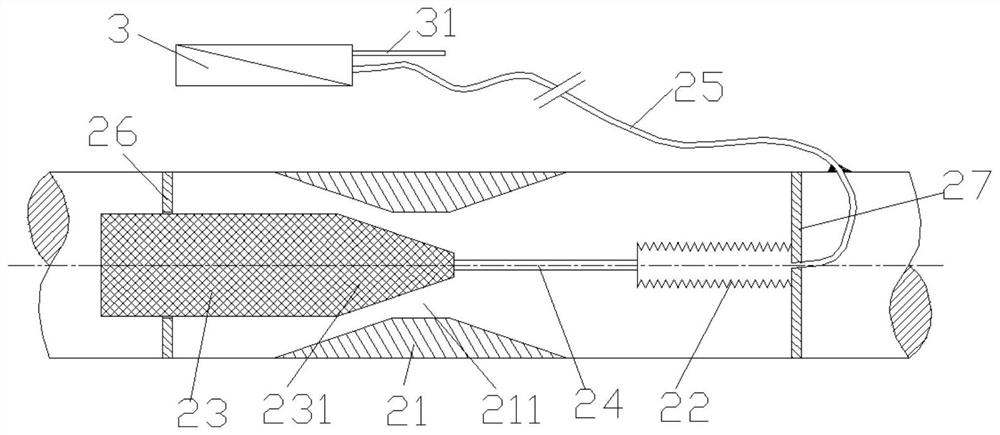

[0028] see in conjunction Figure 1 to Figure 7 As shown, according to an embodiment of the present invention, a heat exchange substrate assembly is provided, including a substrate body 1 and a temperature sensing package 3, a cooling flow channel is constructed in the substrate body 1, and the cooling flow channel has an inlet pipe 11, There is a flow regulating device 2 inside the inlet pipe 11, the temperature sensing package 3 communicates with the flow regulating device 2 and is filled with a thermal medium, and the thermal medium can follow the temperature of the preset area detected by the temperature sensing package 3 The temperature change and / or the temperature change of the cooling medium in the inlet pipeline 11 adjusts the flow rate of the cooling medium circulating in the flow regulating device 2 , such as the thermal medium such as R134a, R32, R22, R245fa and other refrigerants. In this technical solution, a flow regulating device is provided in the inlet pipe of

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap