Double-layer composite board leveling machine

A composite board and leveling machine technology, which is applied in the field of leveling machine equipment, can solve the problems of low production efficiency, increased production cost, laborious labor, etc., and achieve the effects of improving production efficiency, prolonging the life of the guide surface, and increasing the number of bending times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

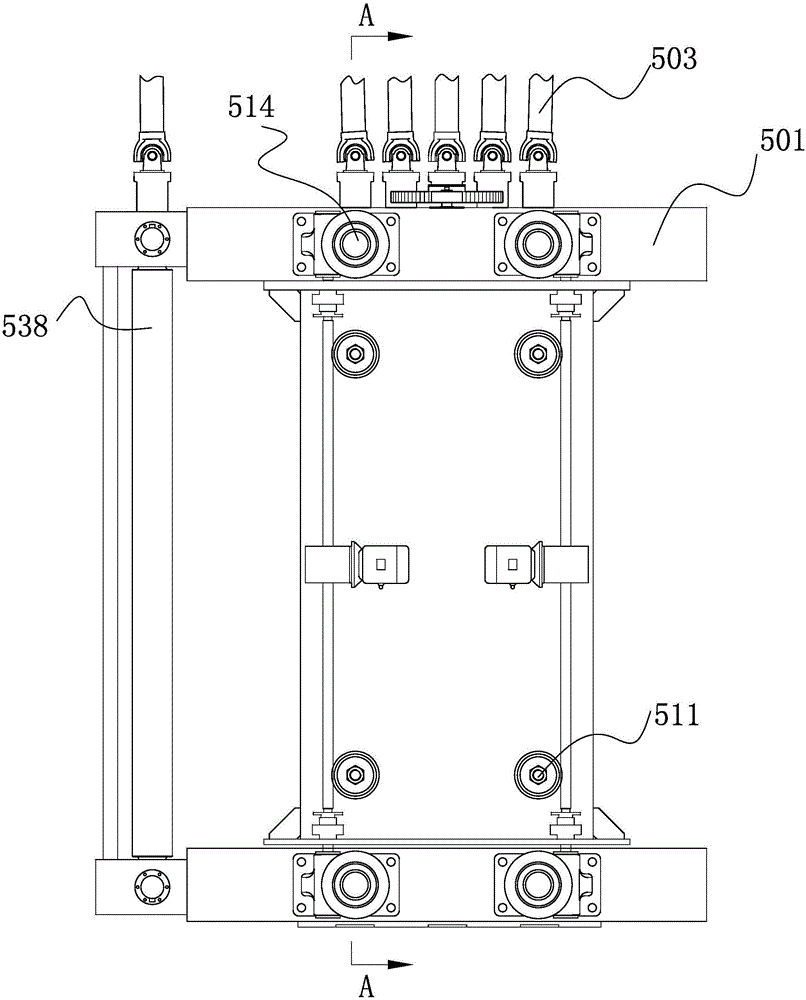

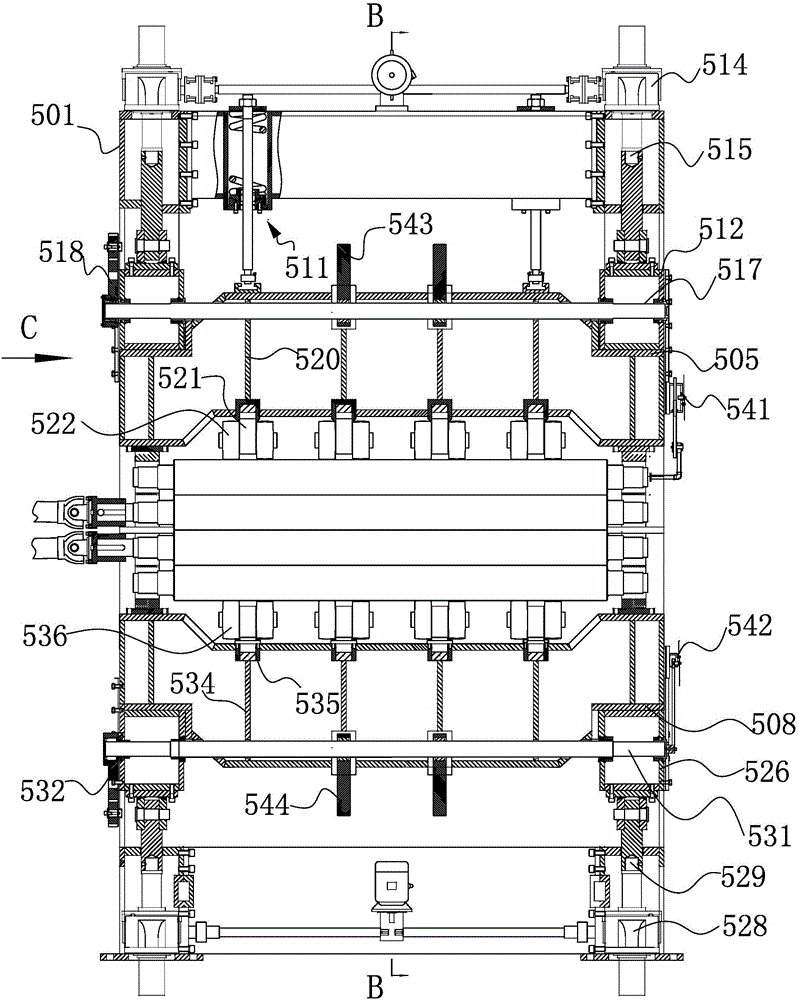

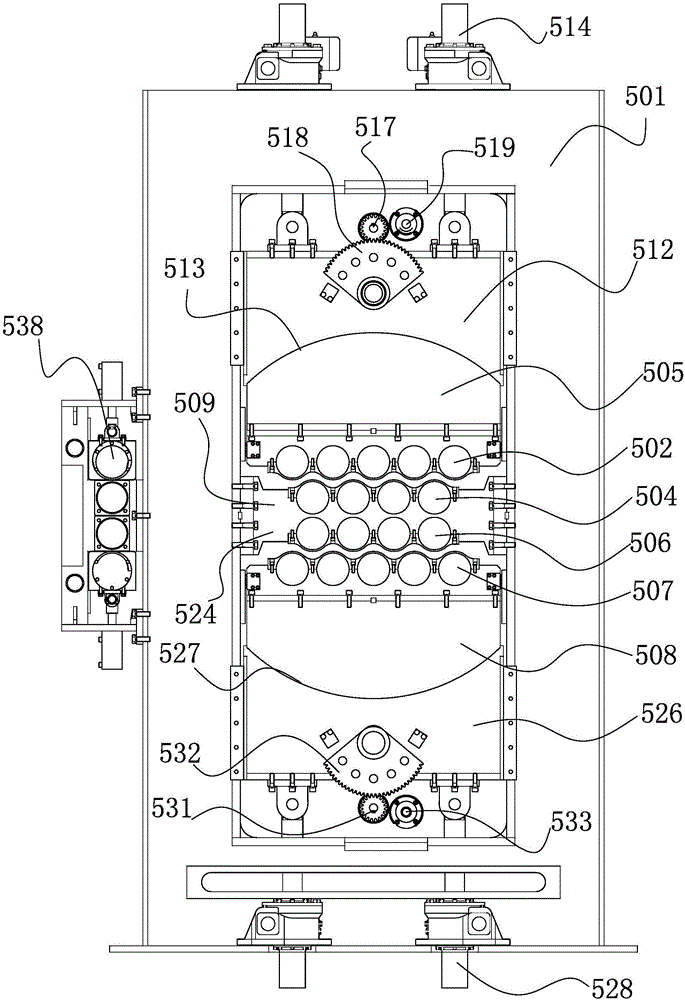

[0027] Such as figure 1 , figure 2 with image 3Commonly shown, a double-layer composite plate leveling machine, a gantry frame 501, an upper leveling roller system and a lower leveling roller system; The driven upper roller is the lower leveling roller 504, the upper roller is the upper leveling roller 502, which is rotatably installed on the upper movable beam 505, and the upper movable beam 505 is connected to the gantry frame 501 through the balance device 511; the upper roller is the lower leveling roller 504 Rotate and install on the upper fixed crossbeam 509, and the upper fixed crossbeam 509 is fixedly connected with the gantry frame 501; The contact surface is an arc-shaped upper guide surface 513; an upper lifting adjustment mechanism for controlling the lifting of the upper force frame 512 is arranged between the gantry frame 501 and the upp

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap