Parallel flow evaporator partition plate assembling and riveting tool and using method

A technology for riveting tooling and evaporators, applied in heat exchange equipment, etc., can solve problems such as low work efficiency, internal leakage of evaporators, waste of working hours, etc., and achieve the effects of saving working hours, improving work efficiency, and flexible and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments.

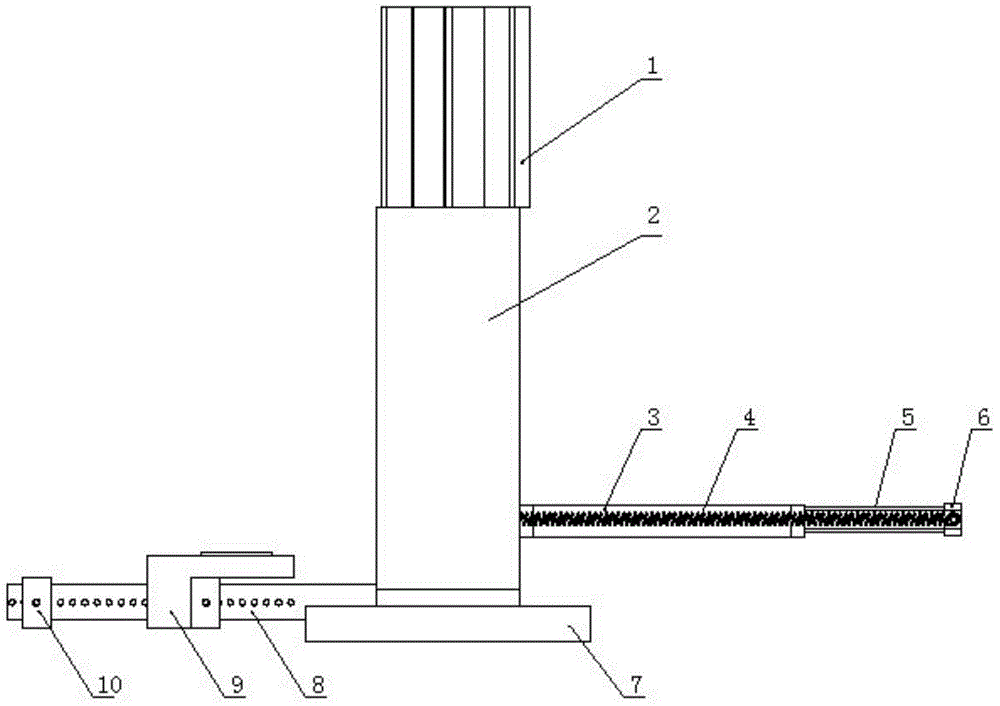

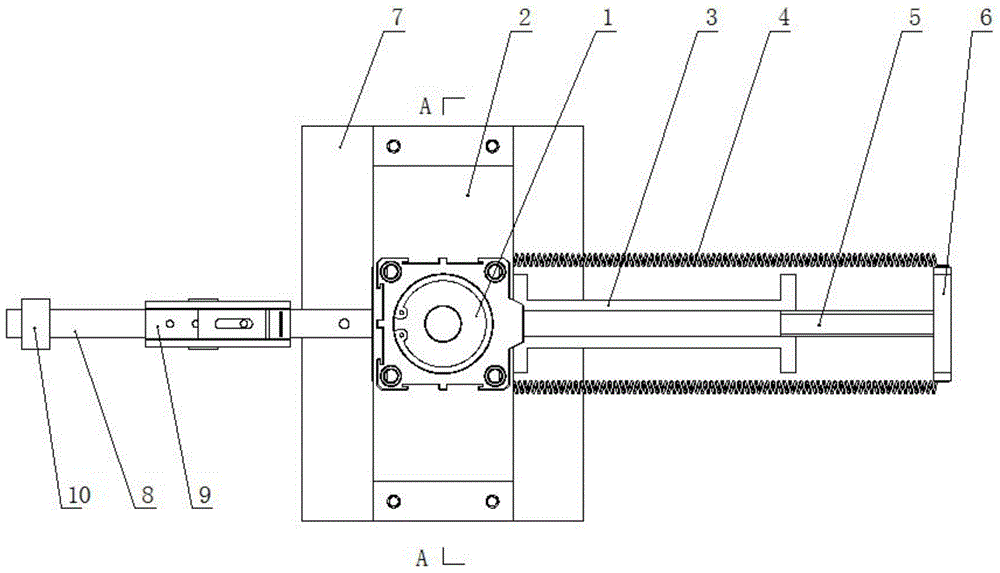

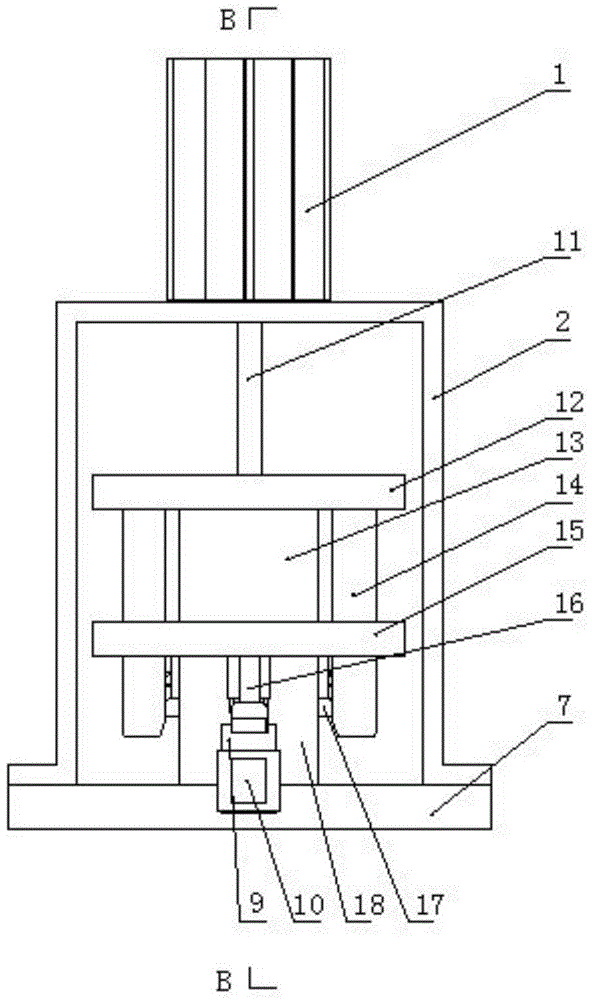

[0021] A parallel flow evaporator partition assembly riveting tooling, such as Figures 1 to 3 As shown, it includes a base plate 7, a gantry frame 2, a cylinder 1, a partition pressing rod assembly, a workpiece adjustment assembly, and a material storage assembly. The clapboard pressing bar assembly located in the gantry frame corresponds to installing a clapboard guiding block 18 on the bottom plate of the clapboard pressing bar assembly, and the right side of the clapboard guiding block is connected to a material storage assembly with a clapboard 22 installed horizontally. The left side of the base of the material storage assembly is horizontally installed to place the workpiece adjustment assembly of the collector (not shown in the figure).

[0022] In this embodiment, the partition pressing rod assembly includes a partition

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap