Stacking car driven by mini-tiller

A technology of stacking trucks and micro tillage machines, applied in the direction of lifting devices, etc., can solve the problems of high price, high maintenance and repair costs, unsafety, etc., and achieve the effect of low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below with reference to the accompanying drawings and embodiments.

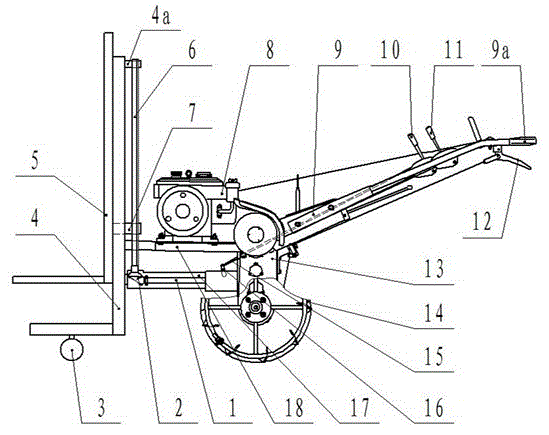

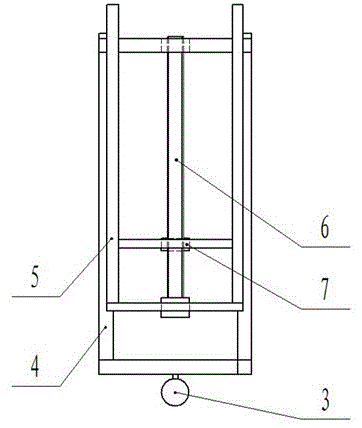

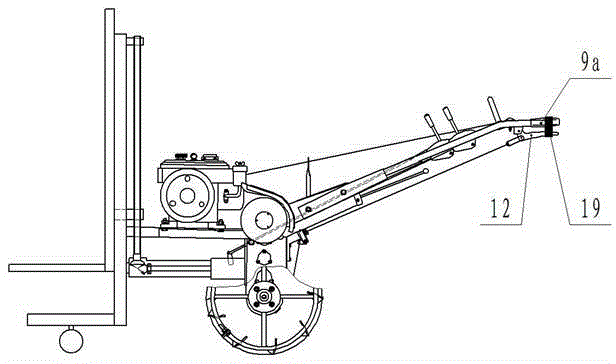

[0012] As shown in the figure: A stacker driven by a micro-tiller, including a power take-off shaft, a bevel gear pair, a frame, a bracket, a screw rod, a screw nut, an engine, a handrail frame, a steering handle, a main gearbox, a hanger Gear lever and auxiliary gearbox; the frame 4 is fixedly connected with the auxiliary gearbox 17 and the frame 18; the auxiliary gearbox 17 is provided with a power output shaft 1 and a bevel gear pair 2; the bevel gear pair 2. One end is connected with the power output shaft 1, and the other end is connected with the lead screw 6; the screw nut 7 is fixedly connected with the bracket 5; One end is connected with the bevel gear pair 2;

[0013] The present invention is powered by a micro-tiller, and is driven by the micro-tiller to carry out transportation operations; load the goods into the bracket 5, close the power clut

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap