Electronic device installed in an engine room

A technology for engine rooms and electronic equipment, applied to circuits, printed circuits, electrical components, etc., can solve problems without any consideration, and achieve the effect of increasing the service life, extending the connection life, and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

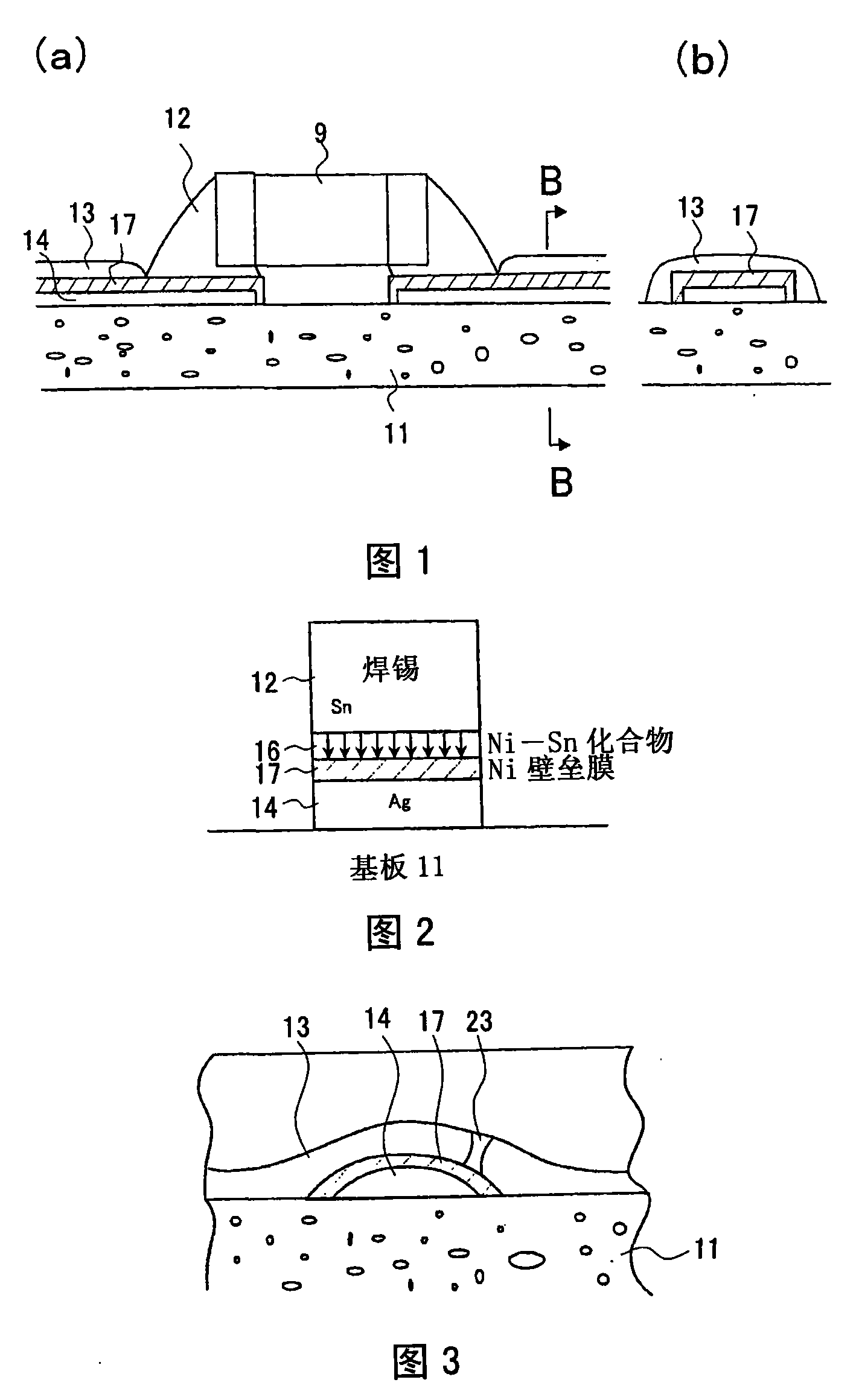

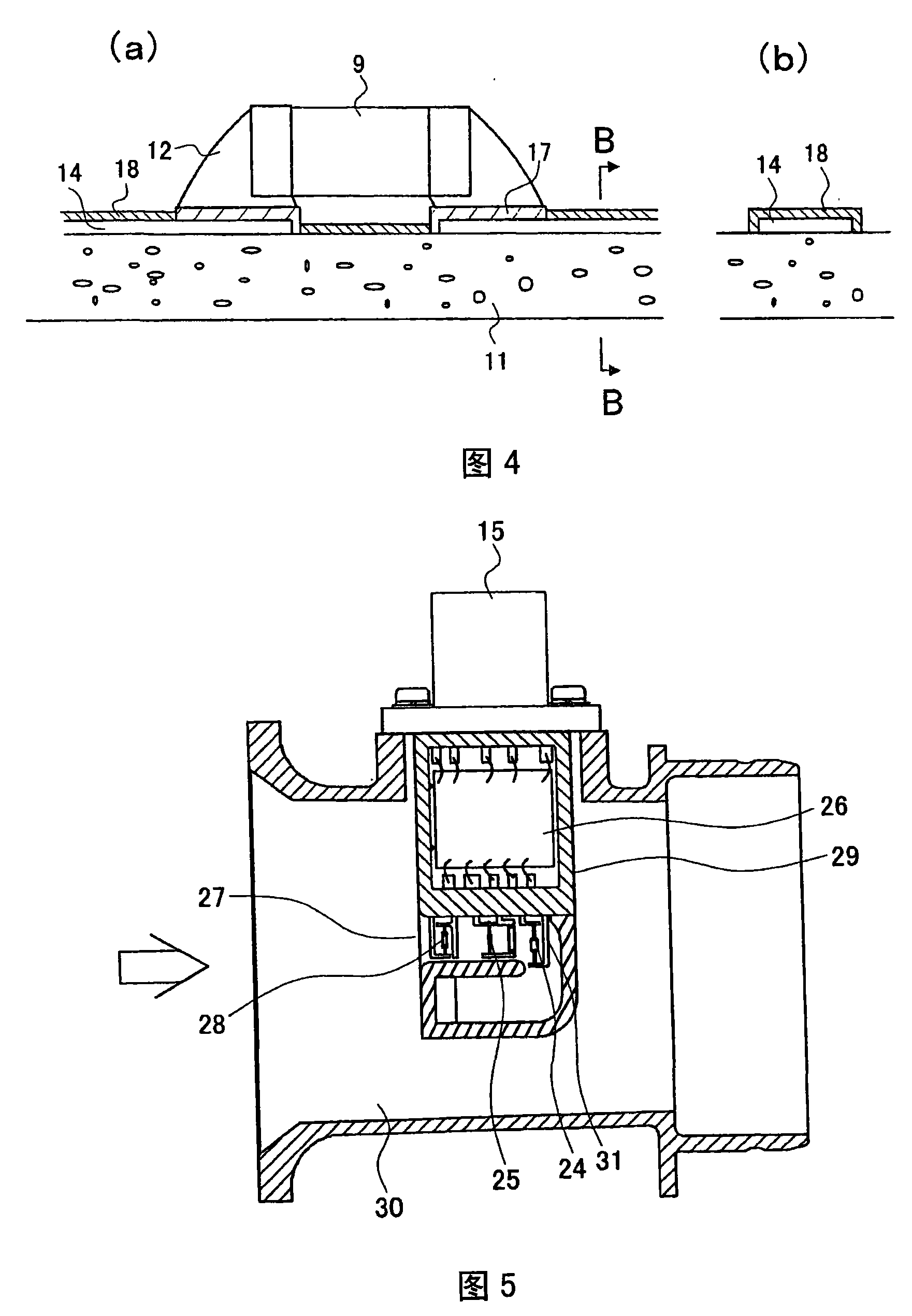

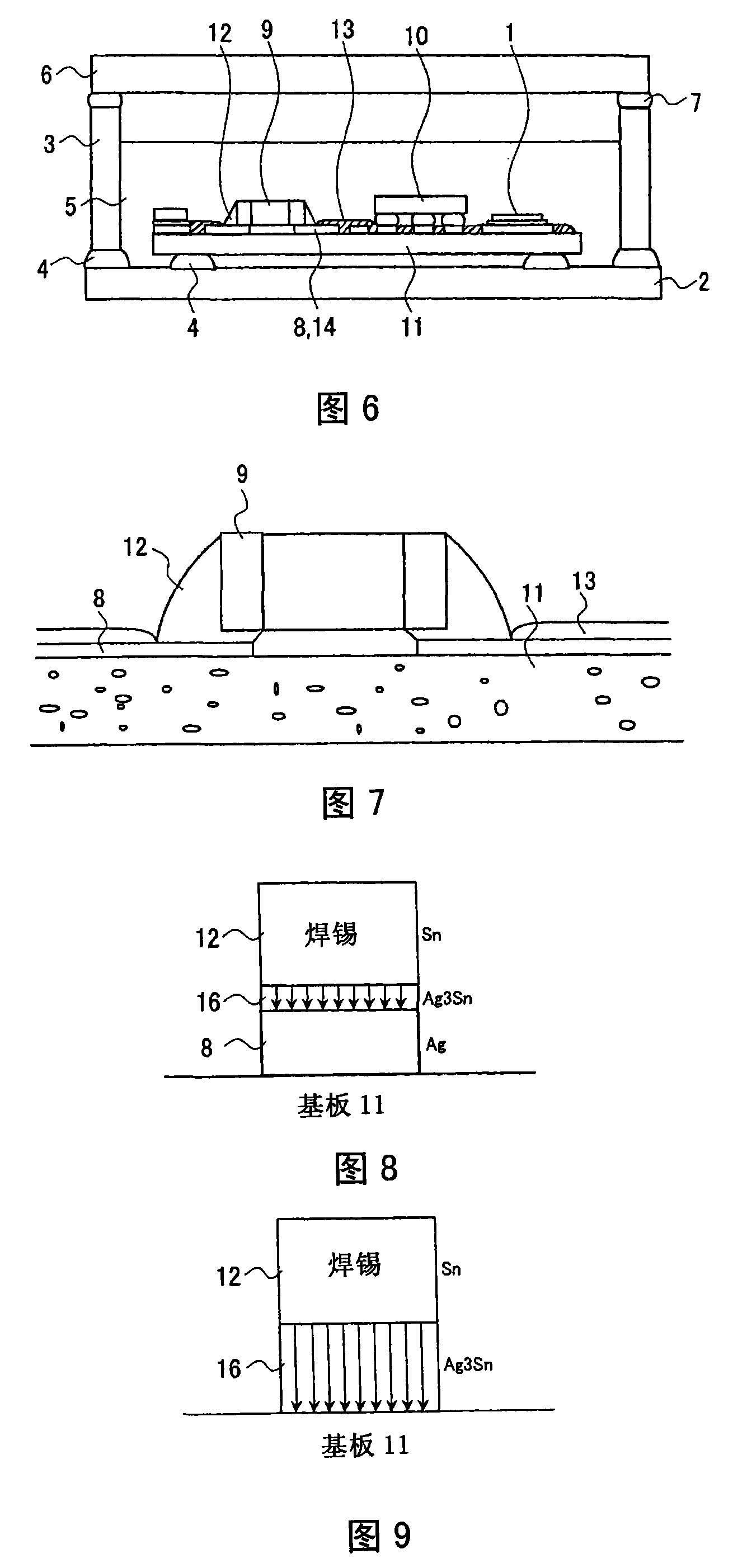

[0055] The main part of the electronic equipment installed in the engine room of this invention is demonstrated based on drawing. FIG. 1 is an enlarged view of a main part of this embodiment, and FIG. 2 is a schematic diagram showing the principle of extending the connection life by soldering of electronic equipment.

[0056] On the surface of the ceramic substrate 11, silver is printed, transferred, or plated to form a conductor pattern from the silver conductor wiring (conductor member) 14, and the entire surface of the conductor wiring 14 is formed by interdiffusion with solder. Nickel, which is a metal member other than the conductor wiring 14 , forms a barrier metal film 17 to cover the periphery of the conductor wiring 14 . Then, after coating the solder 12 on the barrier metal film 17, the chip component 9, which is an electronic component, is mounted, passed through a curing furnace (reflow furnace), thereby melting the solder 12, and connecting the chip component 9 to th

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap