Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

33 results about "Thin-film transistor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A thin-film transistor (TFT) is a special kind of MOSFET (metal-oxide-semiconductor field-effect transistor) made by depositing thin films of an active semiconductor layer as well as the dielectric layer and metallic contacts over a supporting (but non-conducting) substrate. A common substrate is glass, because the primary application of TFTs is in liquid-crystal displays (LCDs). This differs from the conventional bulk MOSFET transistor, where the semiconductor material typically is the substrate, such as a silicon wafer.

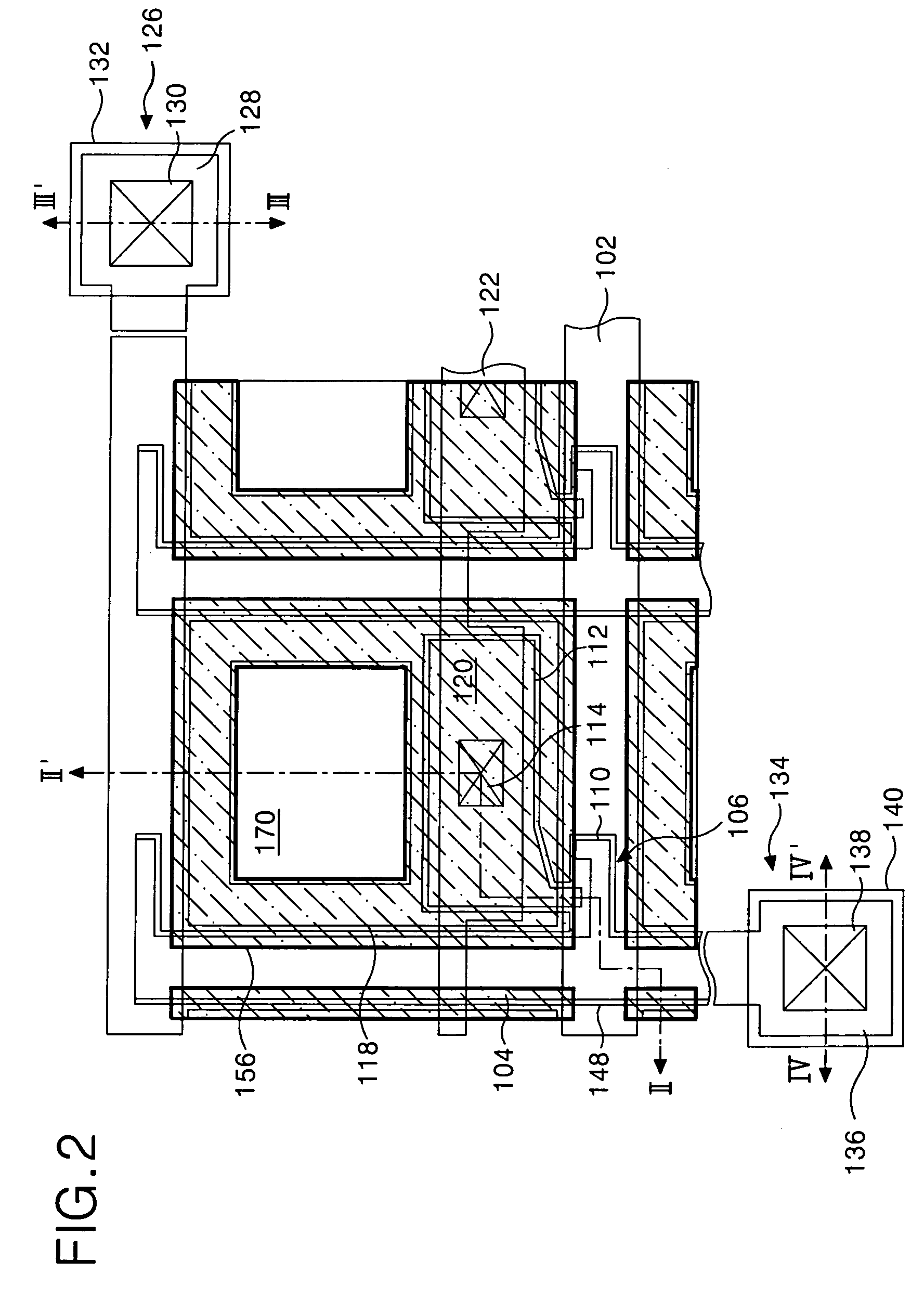

Method of fabricating a semiconductor device

Owner:SEMICON ENERGY LAB CO LTD

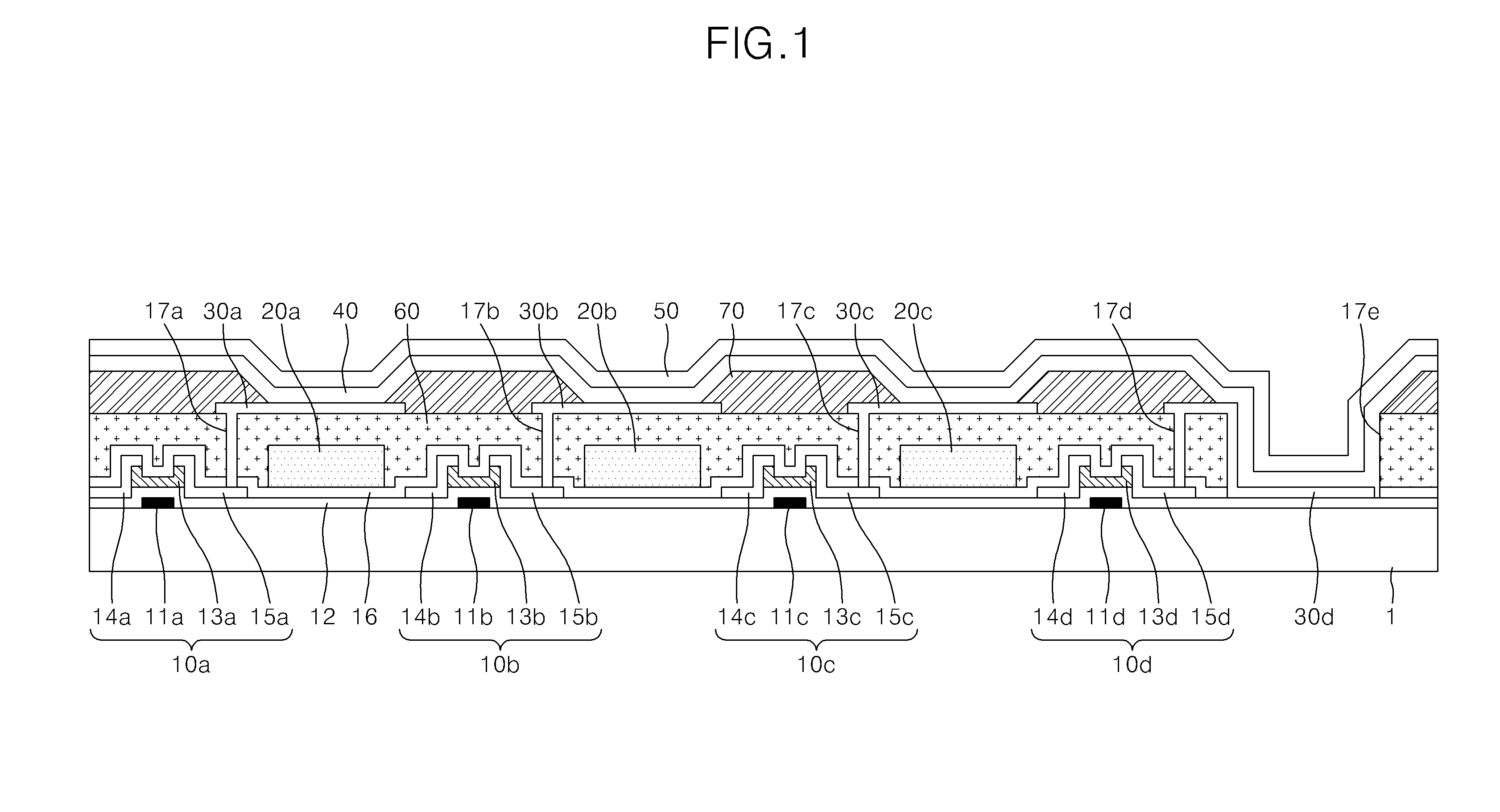

Display device and method for fabricating the same

ActiveUS20080030833A1High light transmittanceIncrease brightnessSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceColor structure

Owner:SAMSUNG DISPLAY CO LTD

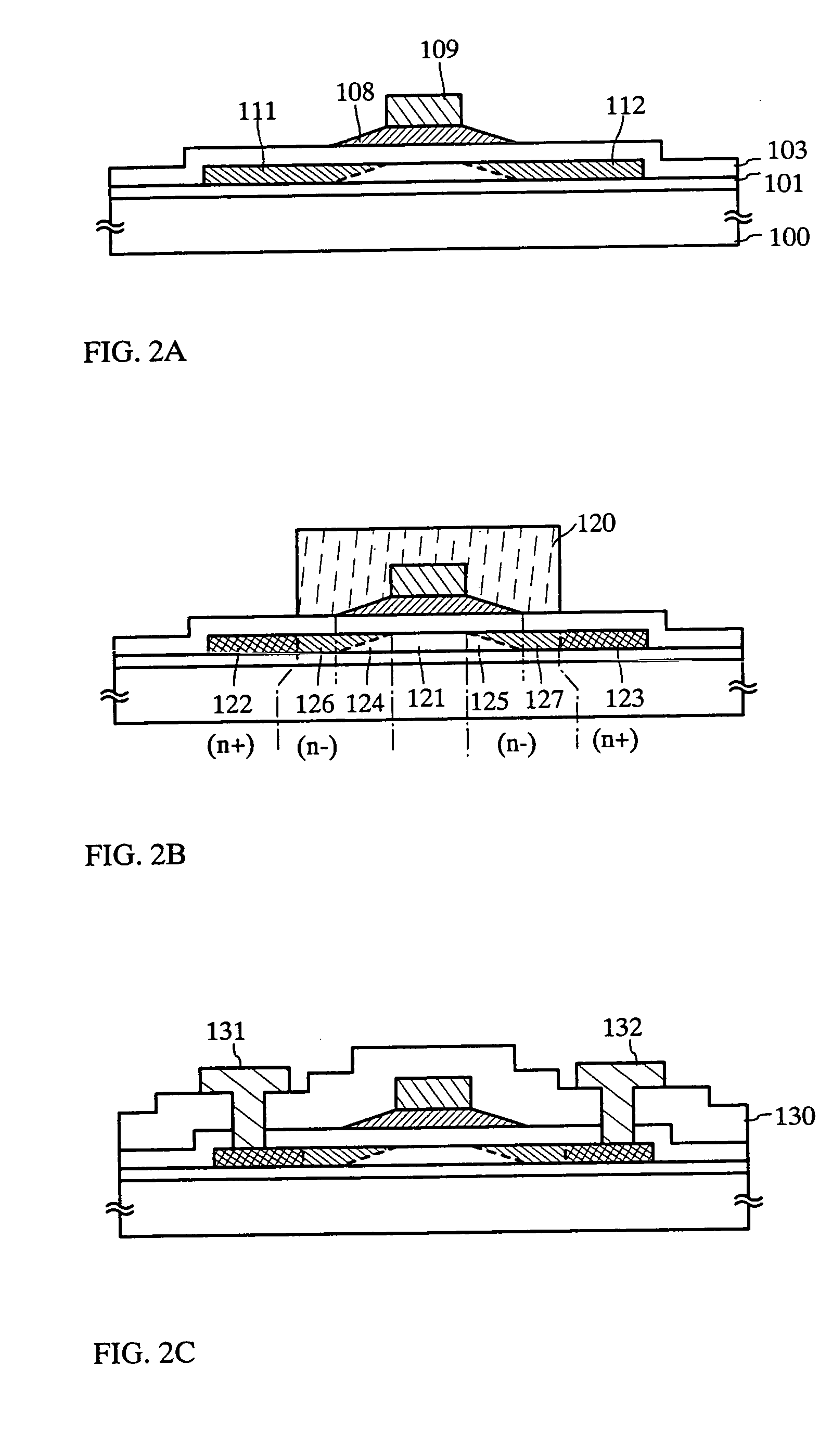

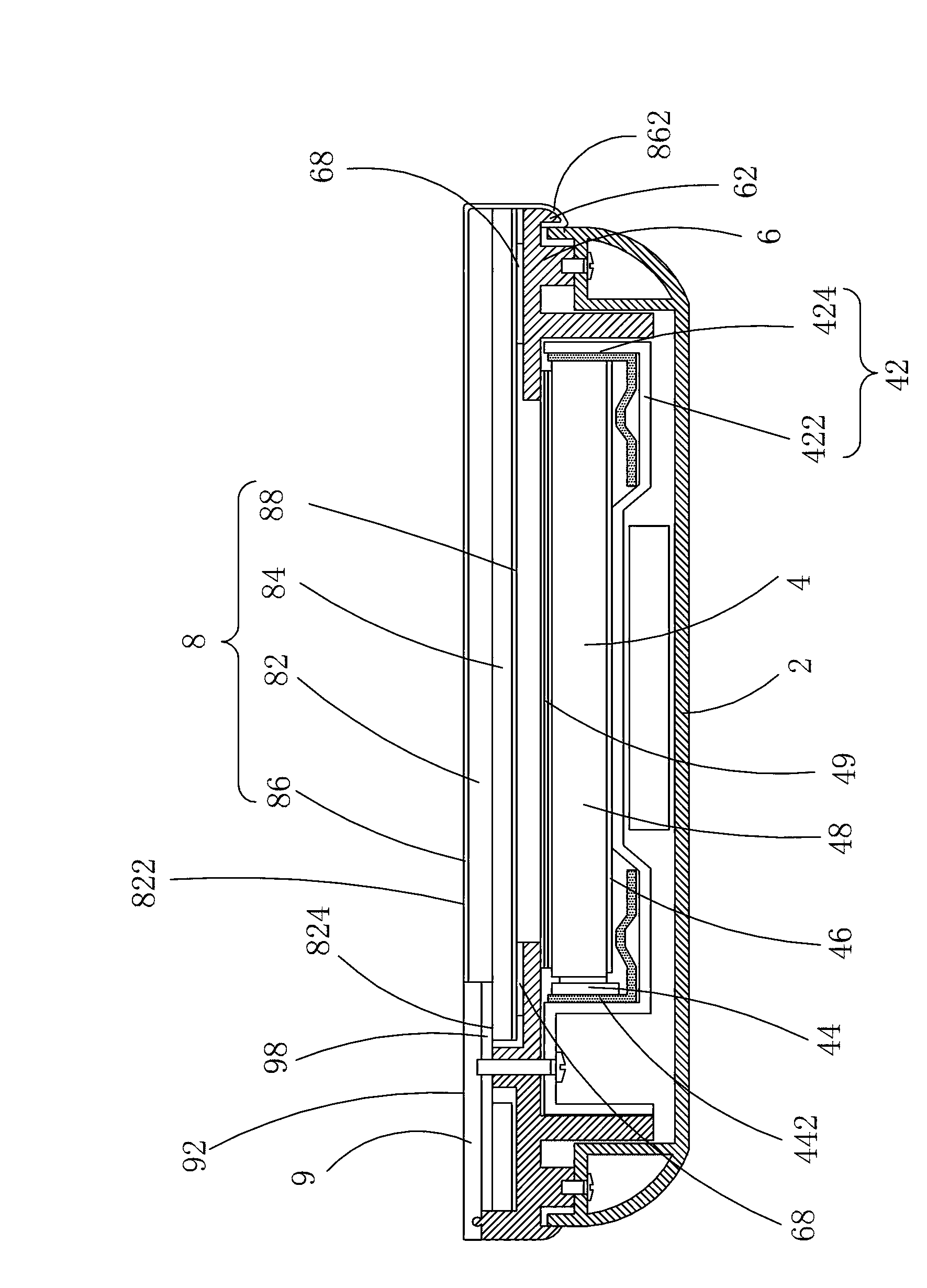

Thin film transistor and method of fabricating the same

ActiveUS20060033107A1Improve featuresRemain very smallTransistorSemiconductor/solid-state device manufacturingSemiconductorTransistor

Owner:SAMSUNG DISPLAY CO LTD

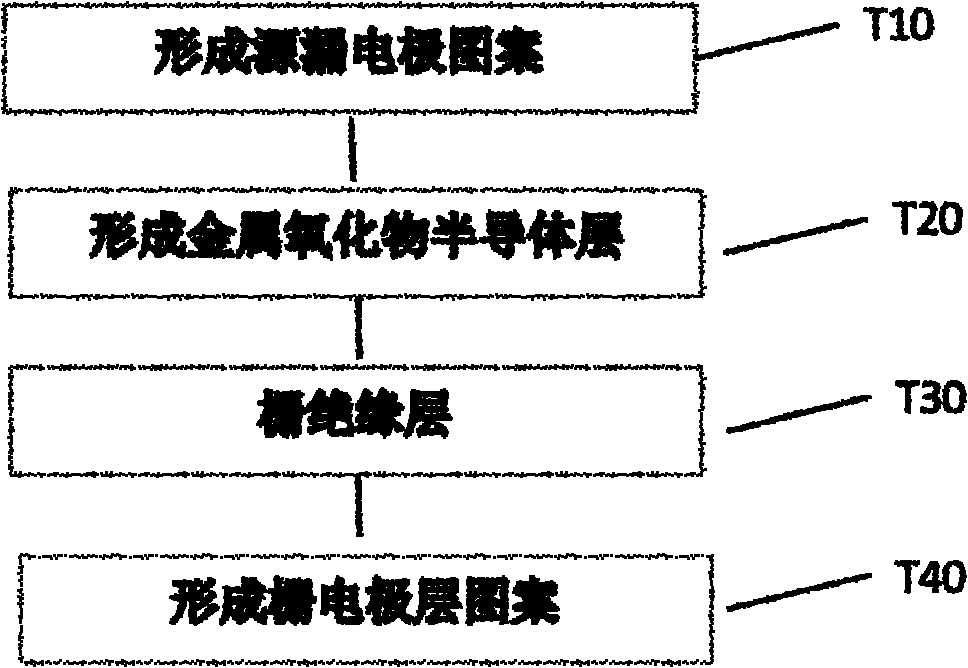

Preparation method of top gate metal oxide thin film transistor (TFT)

InactiveCN102157564ASolve the technical problem of insufficient chargingIncrease the on-state currentTransistorSemiconductor/solid-state device manufacturingEtchingElectrical conductor

Owner:SHANGHAI JIAO TONG UNIV

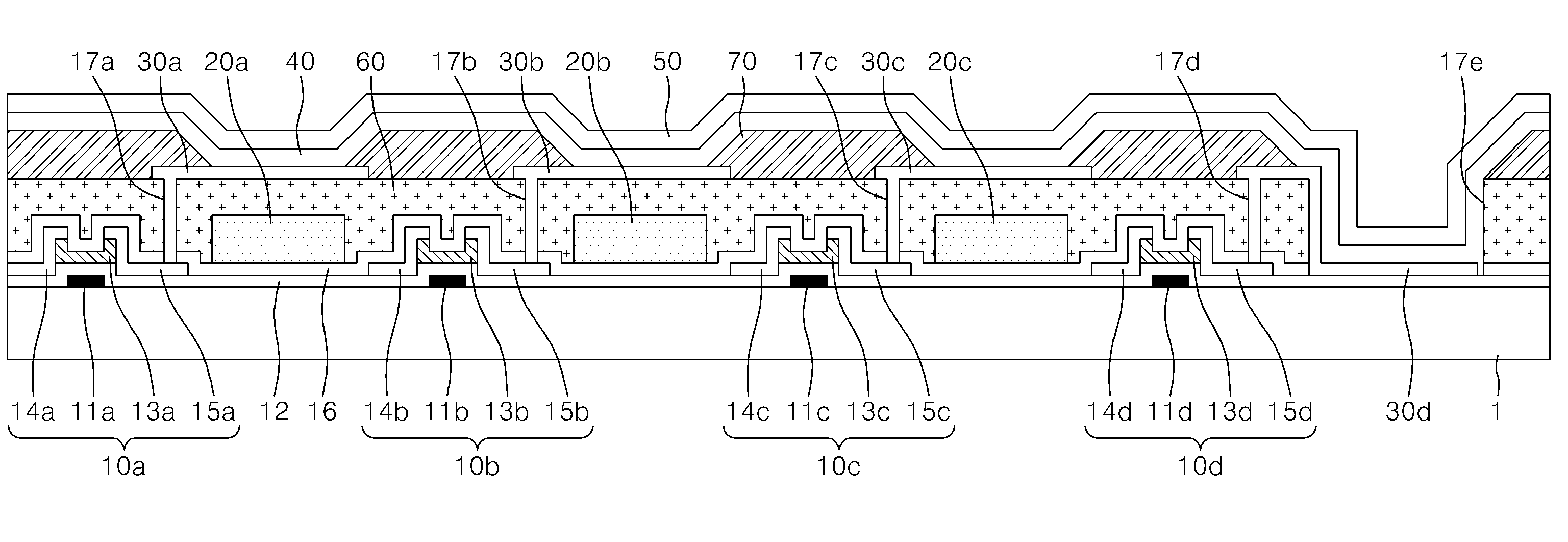

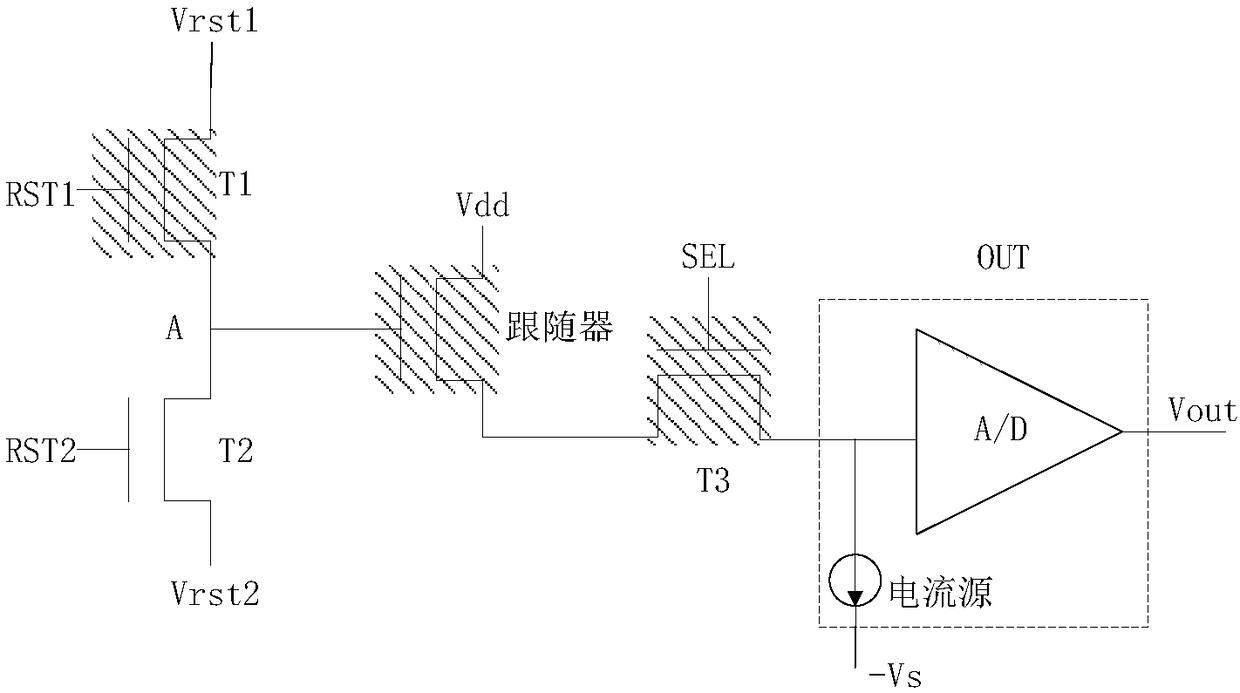

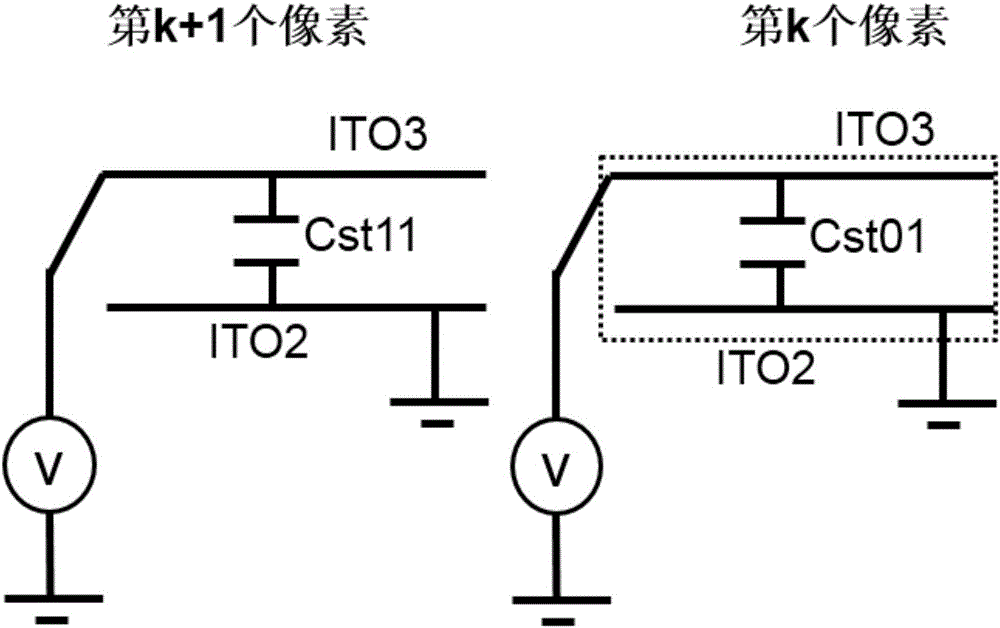

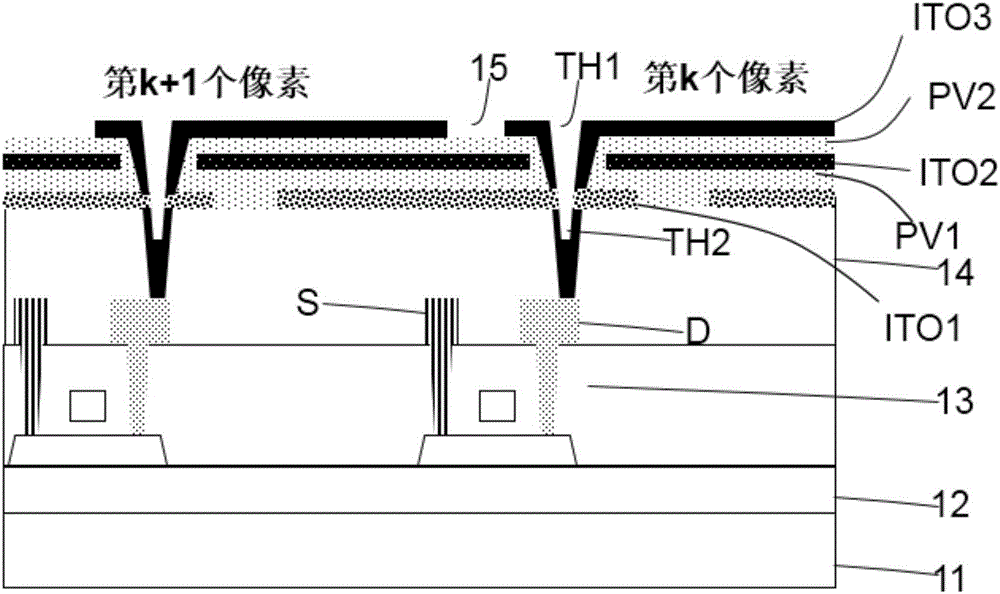

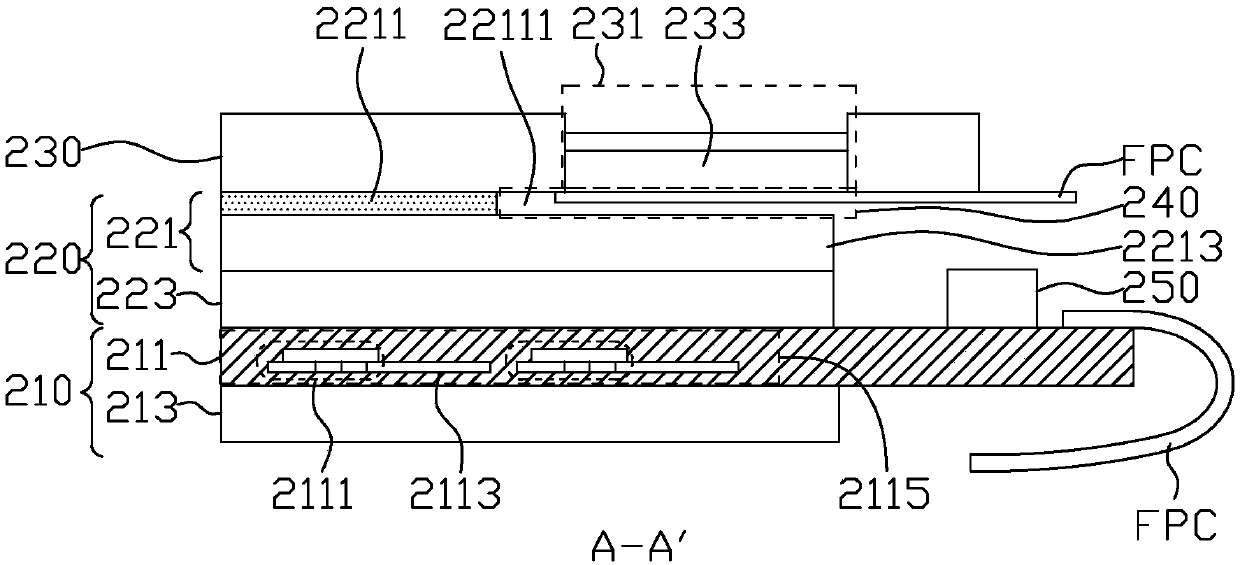

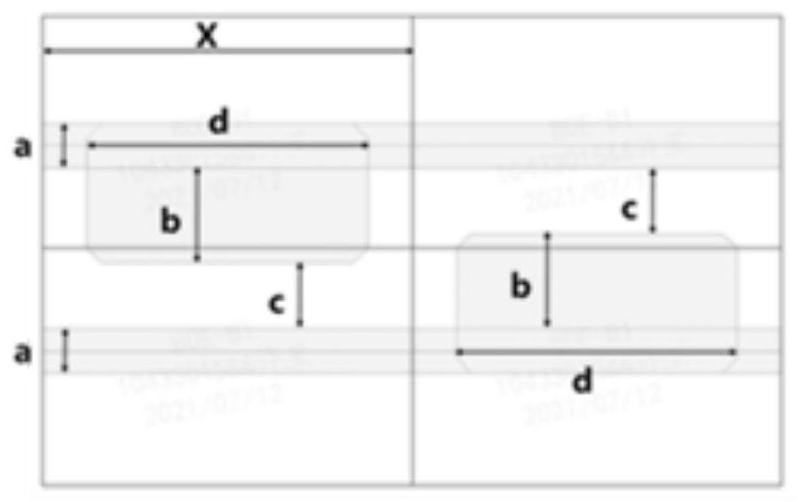

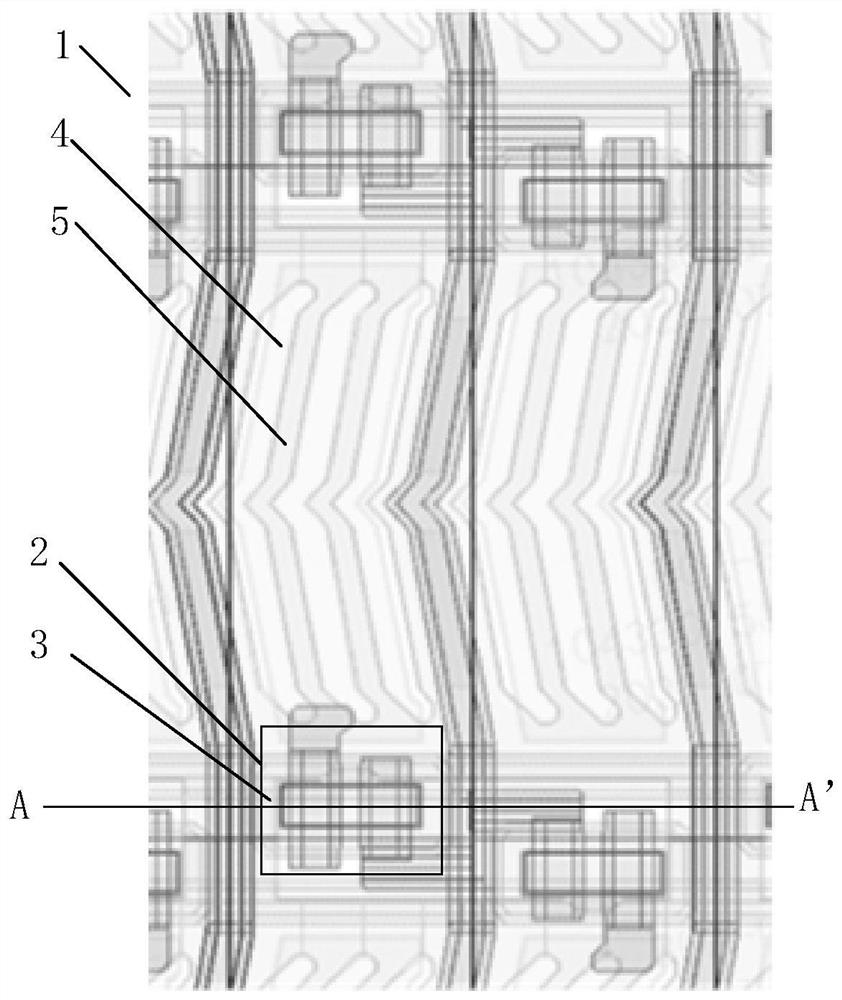

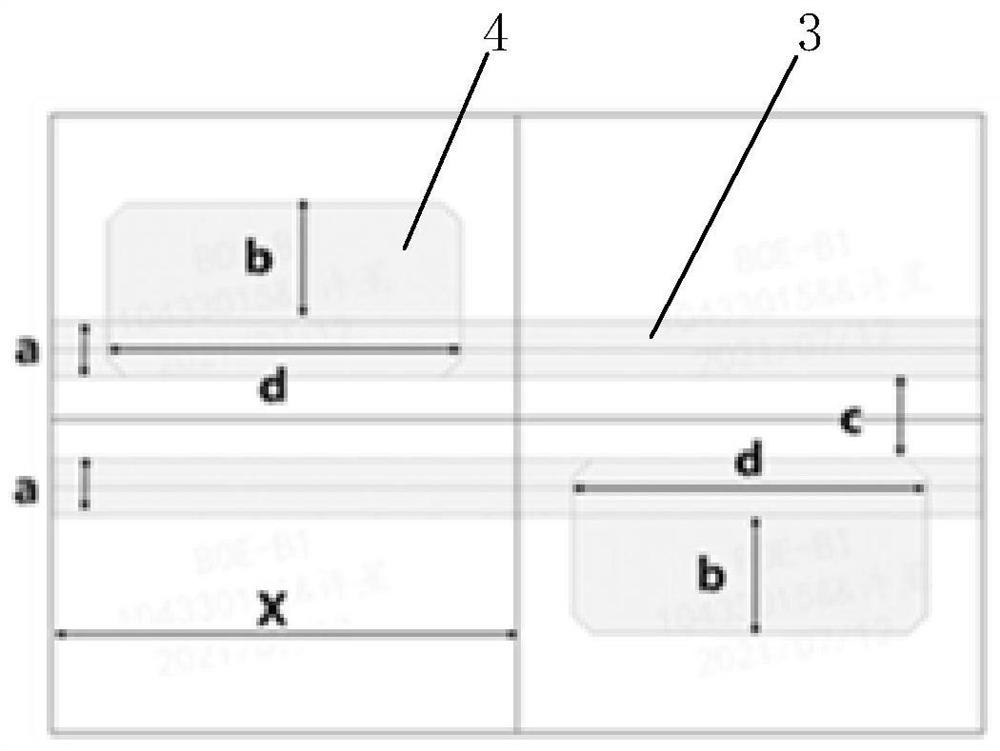

Amorphous silicon image sensor with storage capacitor structure

ActiveCN102157533AIncreased charge storage capacityImprove signal dynamic rangeRadiation controlled devicesCapacitanceDynamic range

Owner:CARERAY DIGITAL MEDICAL TECH CO LTD

TFT array substrate manufacture method

ActiveCN105702623AReduce sizeNo short circuit problemSolid-state devicesSemiconductor/solid-state device manufacturingPixel densitySlope angle

The invention provides a TFT (Thin Film Transistor) array substrate manufacture method which comprises the following steps: coating and forming a flat layer on source electrodes and drain electrodes; instead of processing via holes, depositing and patterning a common electrode layer and a passivated protection layer; forming via holes in the passivated protection layer so as to expose the flat layer, and then ashing the flat layer so as to expose the drain electrodes. Compared with a conventional method by which the common electrode layer is deposited and patterned after the via holes are formed in the flat layer, the TFT array substrate manufacture method described in the invention is advantageous in that no electrically conductive material will be left in the via holes of the flat layer when the common electrode layer is patterned, and therefore no short circuit problem will occur in the via holes of the flat layer; the via holes are formed in the flat layer in a pixel region by a means of dry etching through ashing operation, the formed via holes are allowed to have large slope angles, and therefore the size of a TFT can be reduced to a certain extent and and pixel density can be improved.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

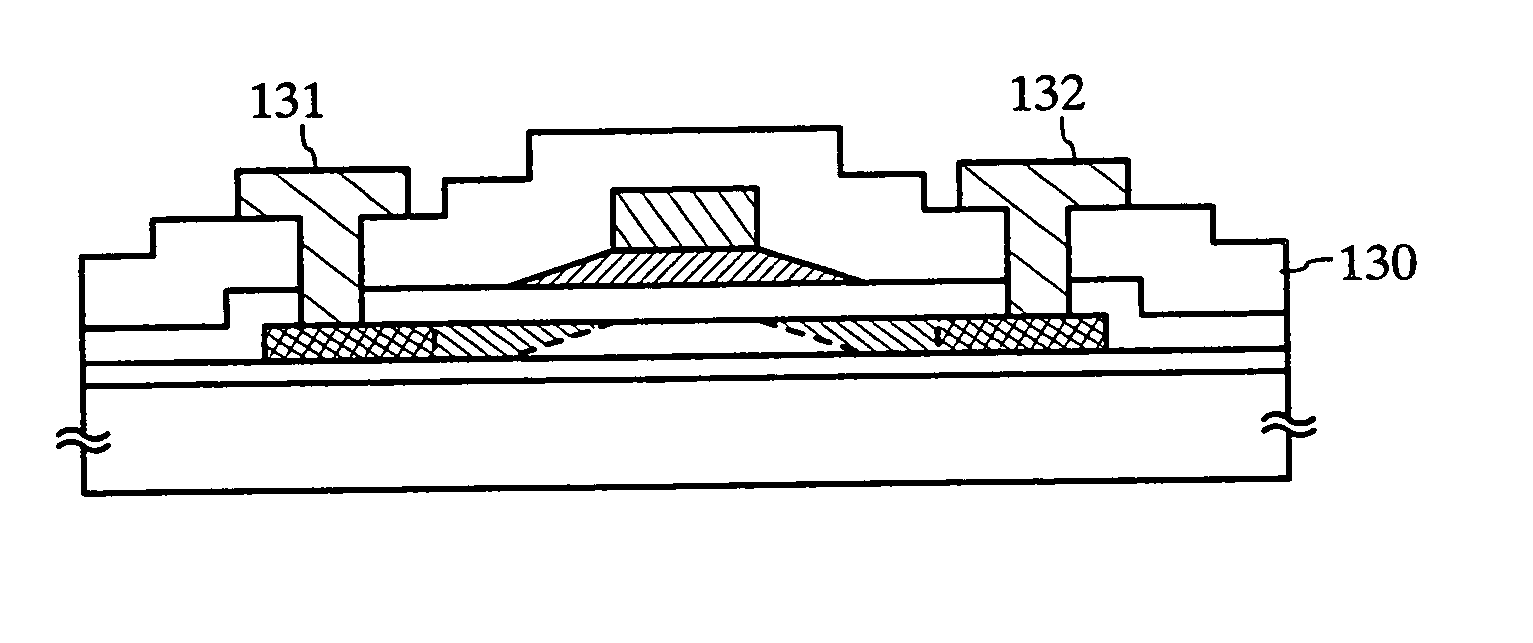

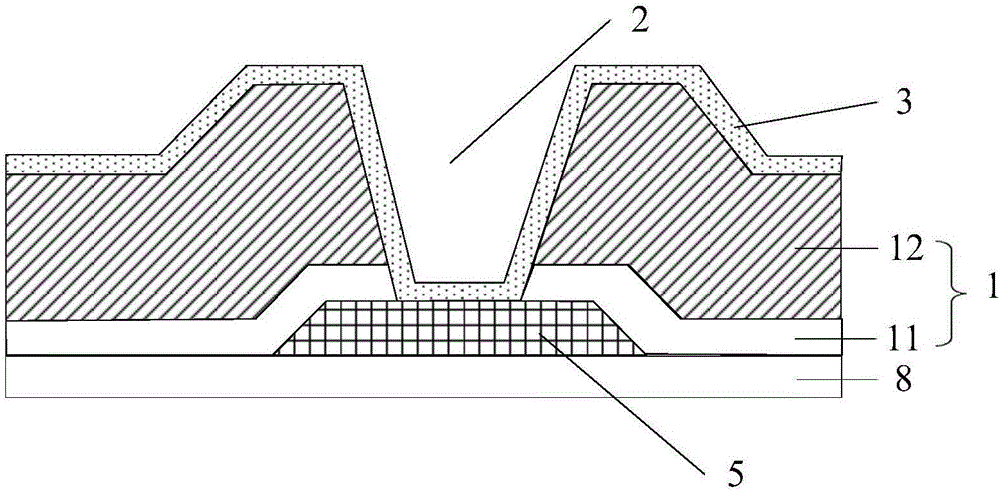

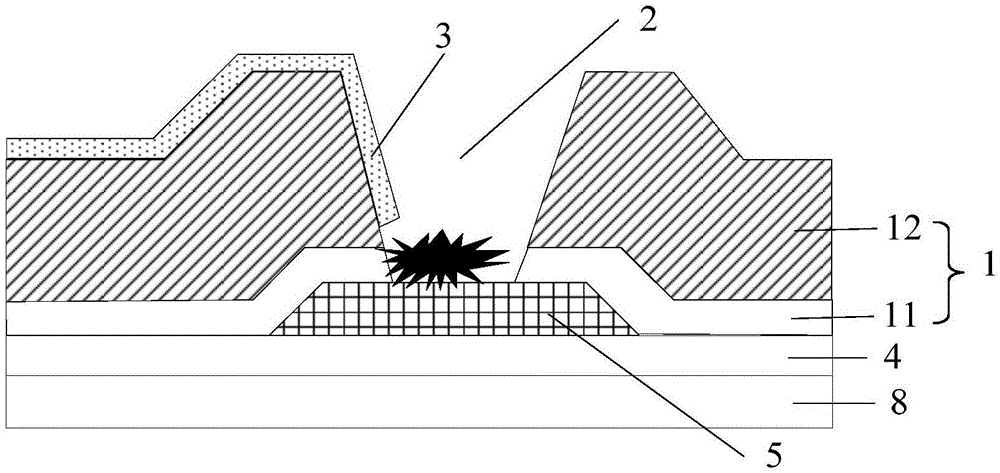

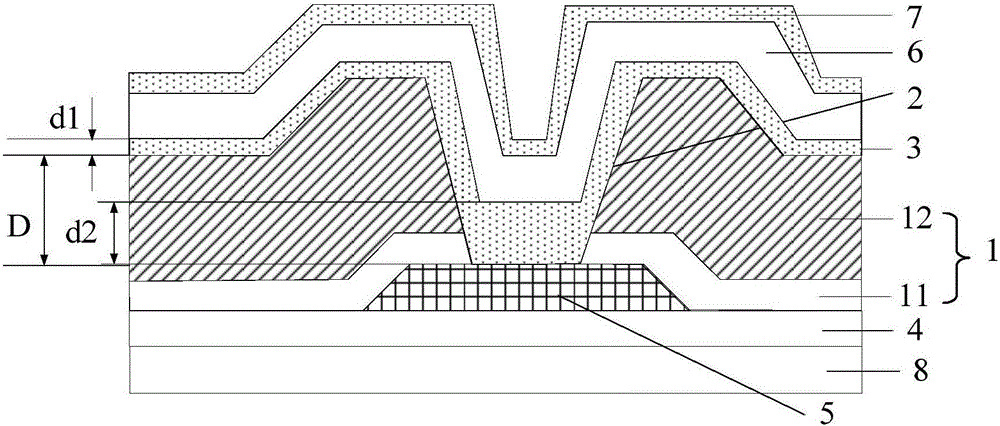

Polysilicon thin film transistor and method of fabricating the same

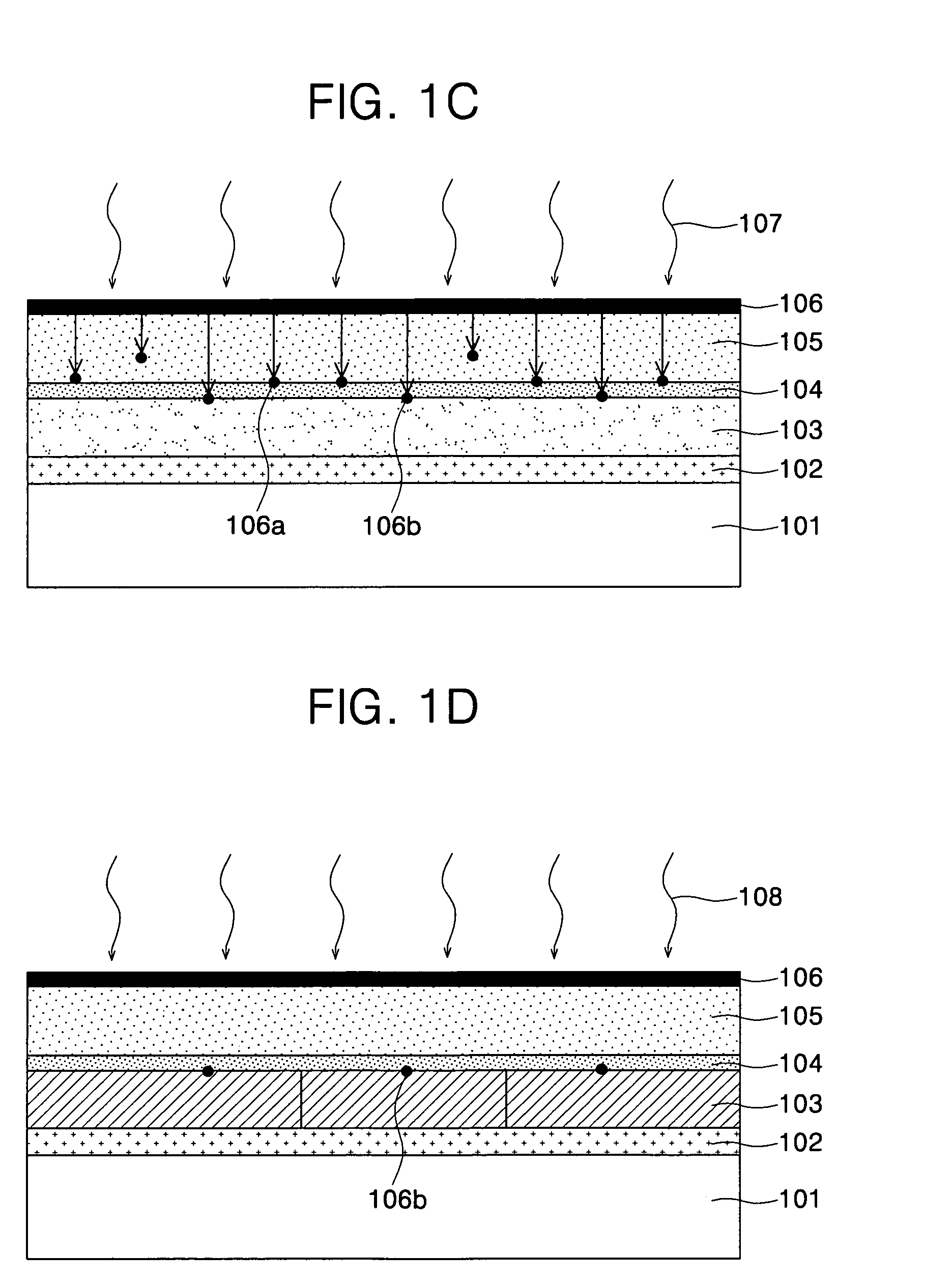

A method of fabricating a polycrystalline silicon thin film transistor is disclosed. One embodiment of the method includes: forming an amorphous silicon layer on a panel; scanning a continuous wave laser beam having a wavelength range of about 600 to about 900 nm between a visible light range of a red color and a near infrared range onto the amorphous silicon layer to preheat the amorphous silicon layer; overlappingly scanning a pulse laser beam having a wavelength range of about 100 to about 550 nm between a visible light range and an ultraviolet range in addition to the continuous wave laser beam on the panel to melt the preheated amorphous silicon layer; and stopping scanning the pulse laser beam to crystallize the molten silicon layer.

Owner:SAMSUNG MOBILE DISPLAY CO LTD

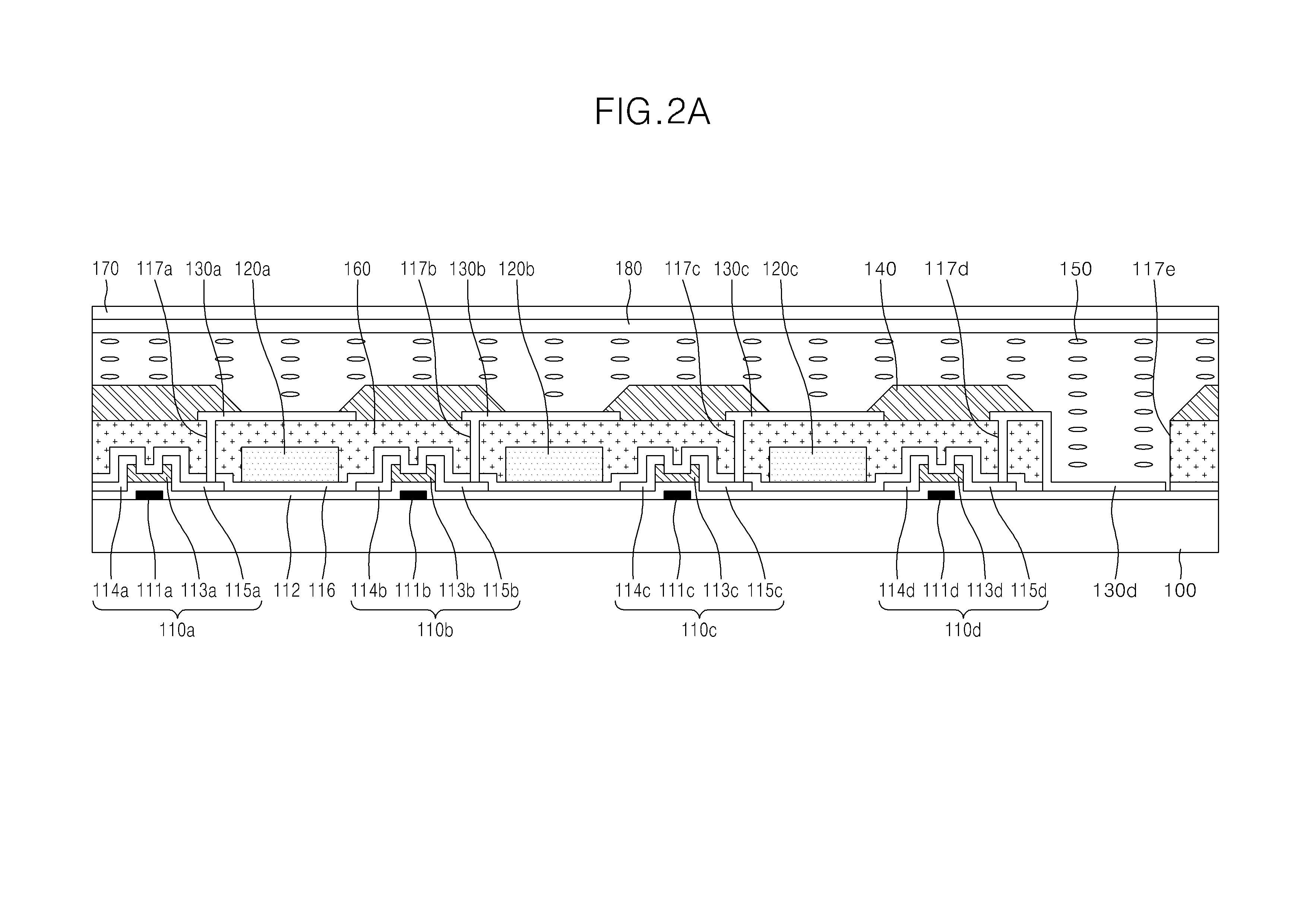

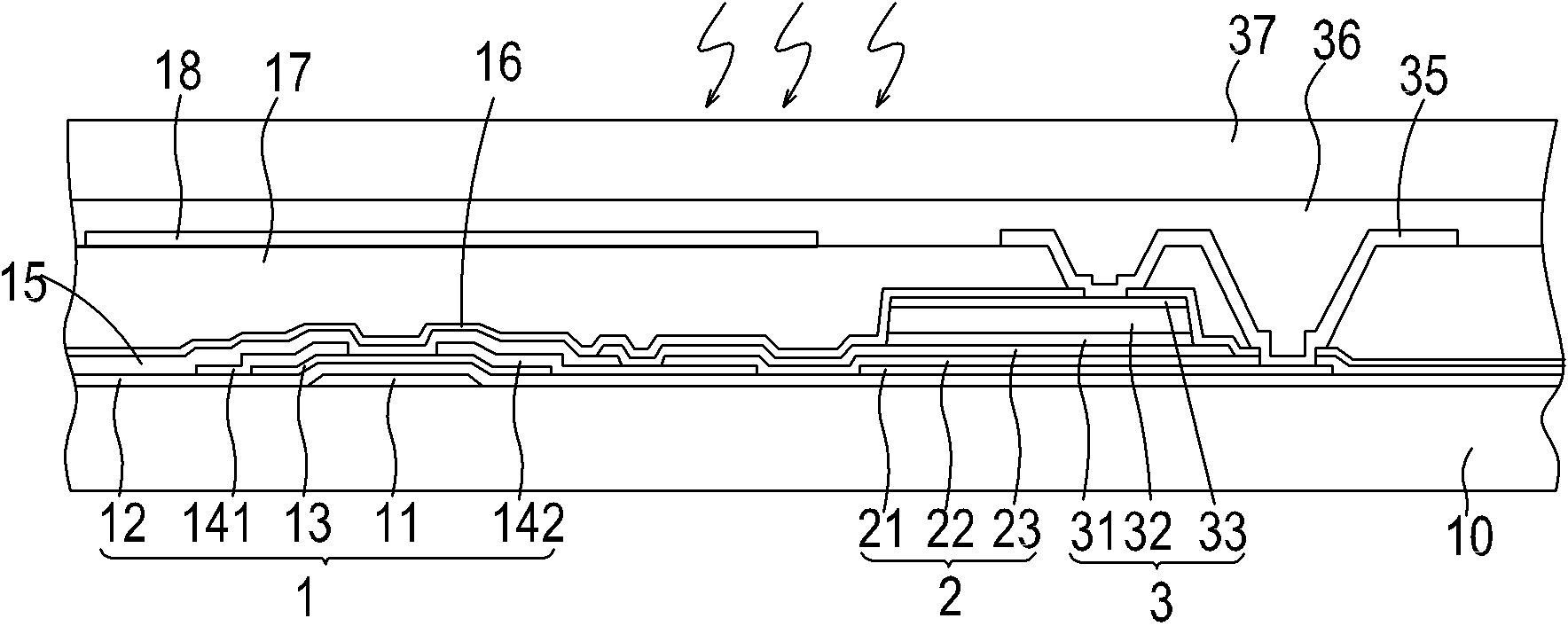

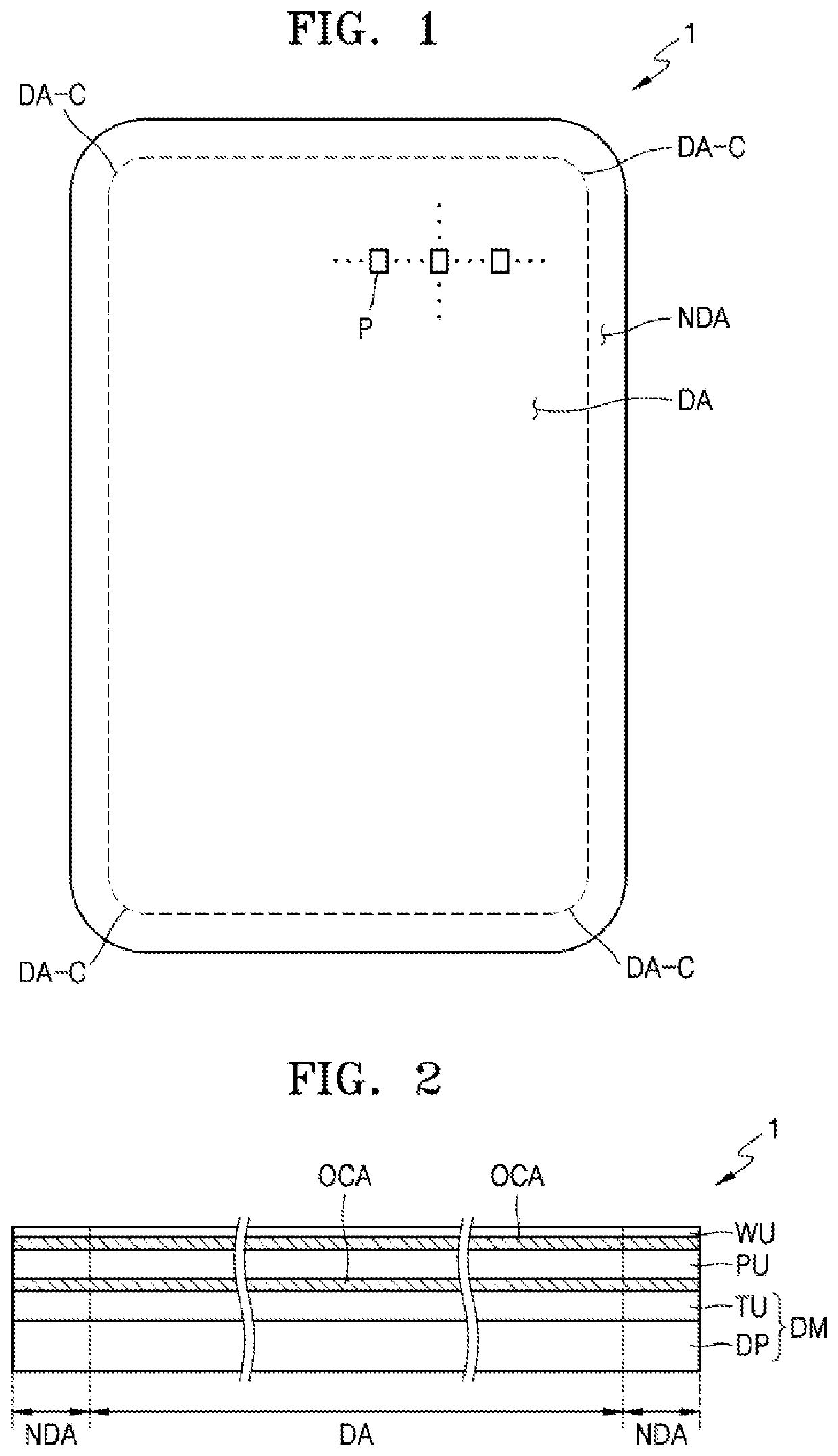

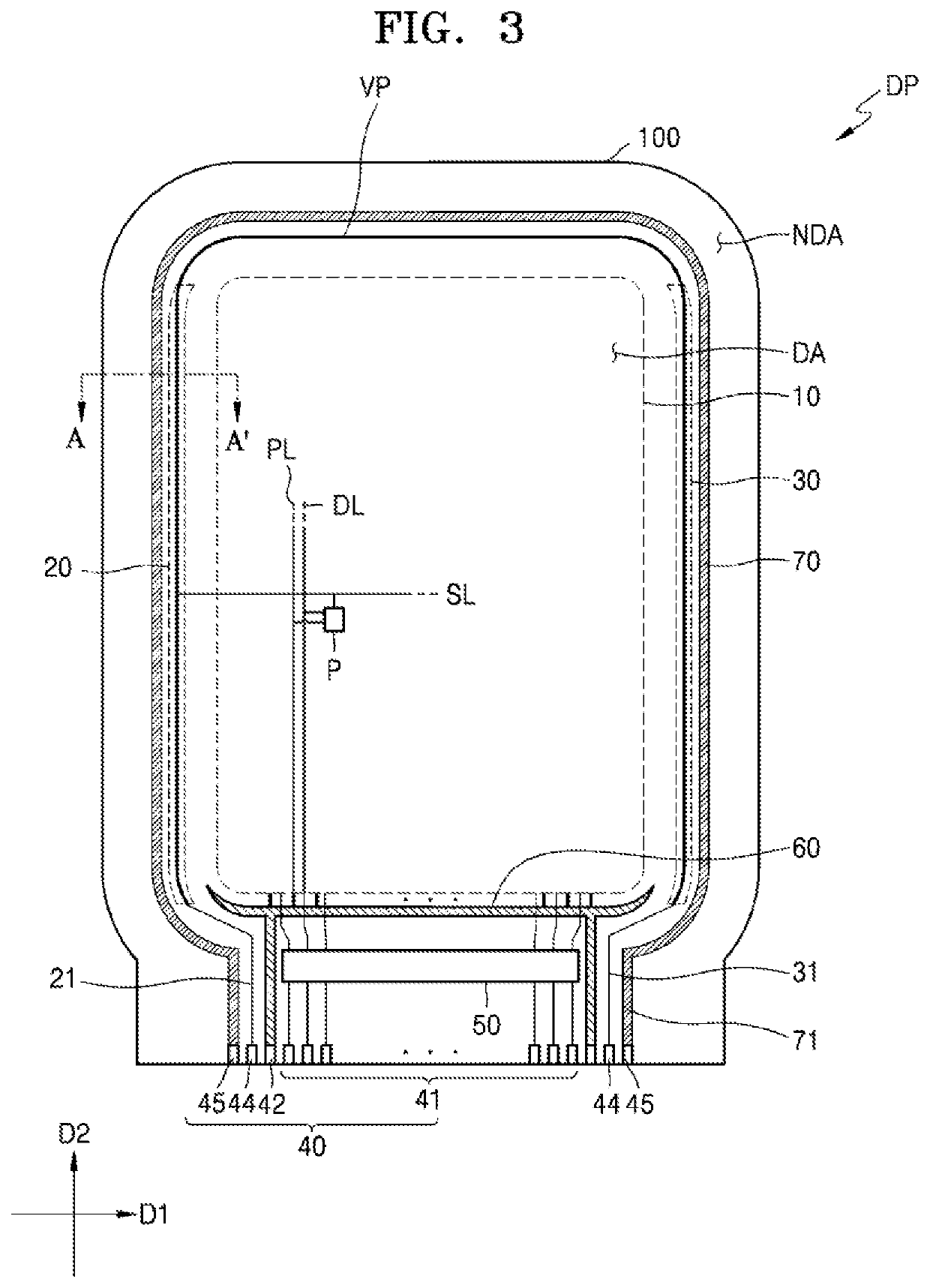

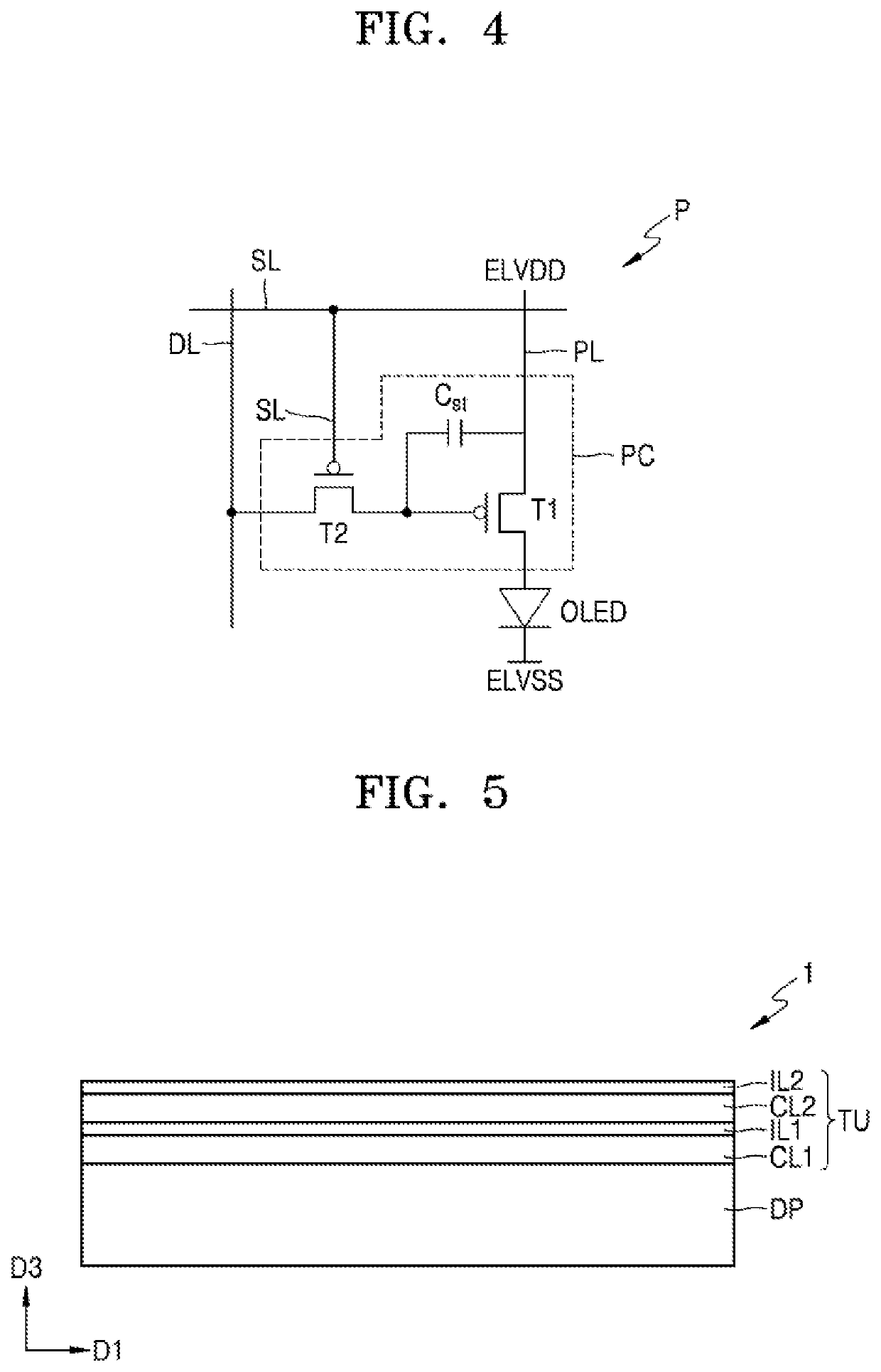

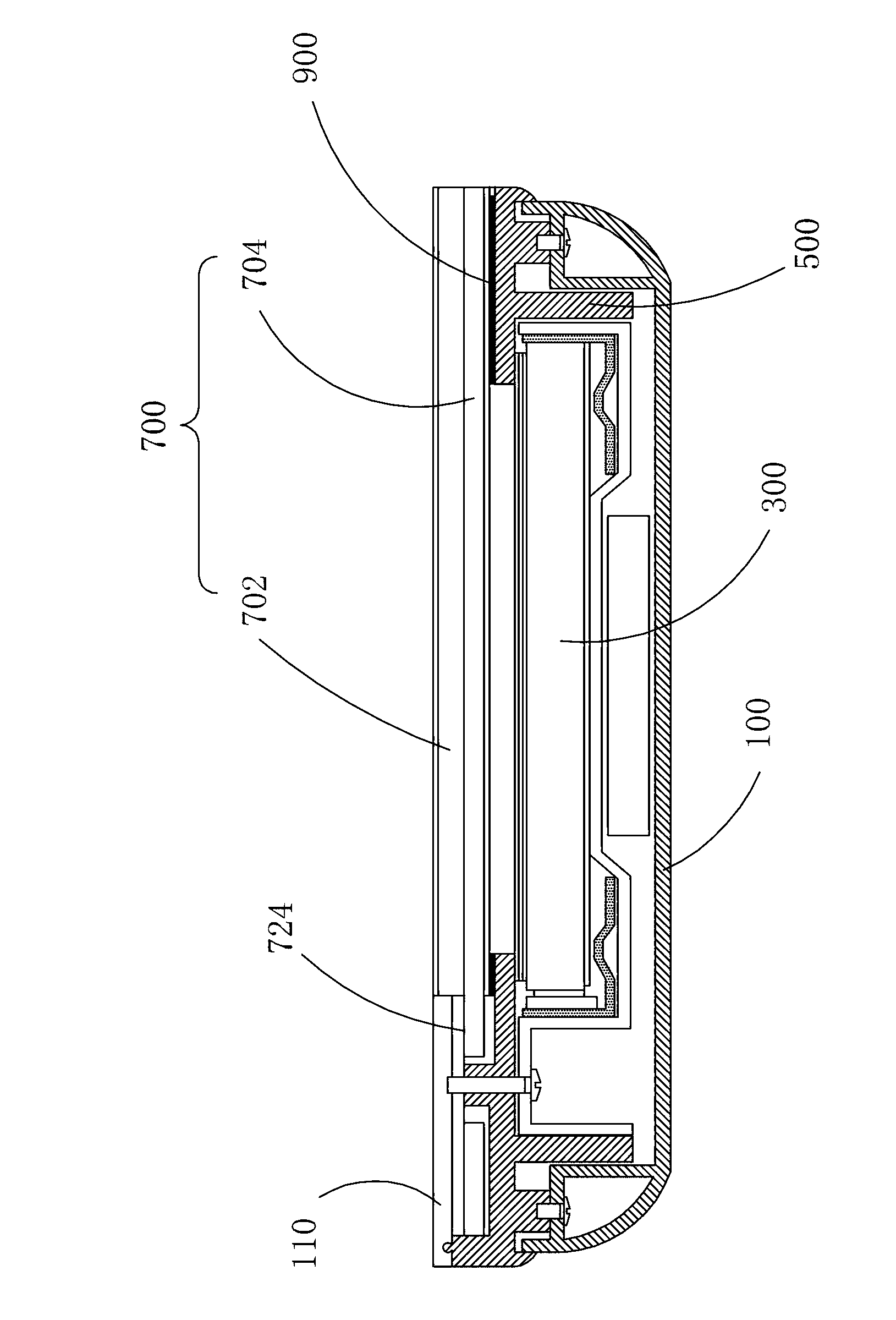

Display device

ActiveUS20200212115A1Reduce reflectivitySolid-state devicesSemiconductor/solid-state device manufacturingLight reflectionDisplay device

Owner:SAMSUNG DISPLAY CO LTD

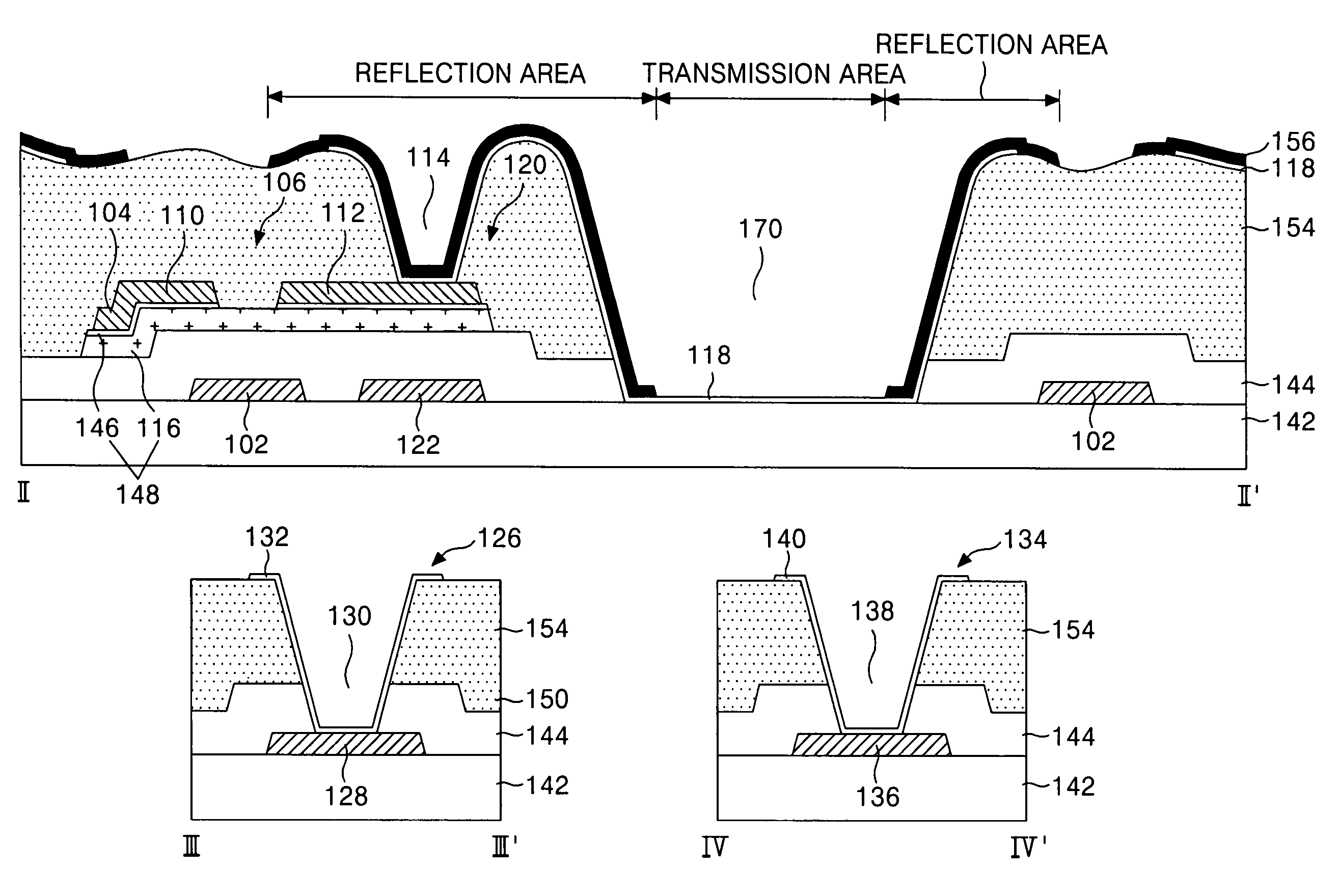

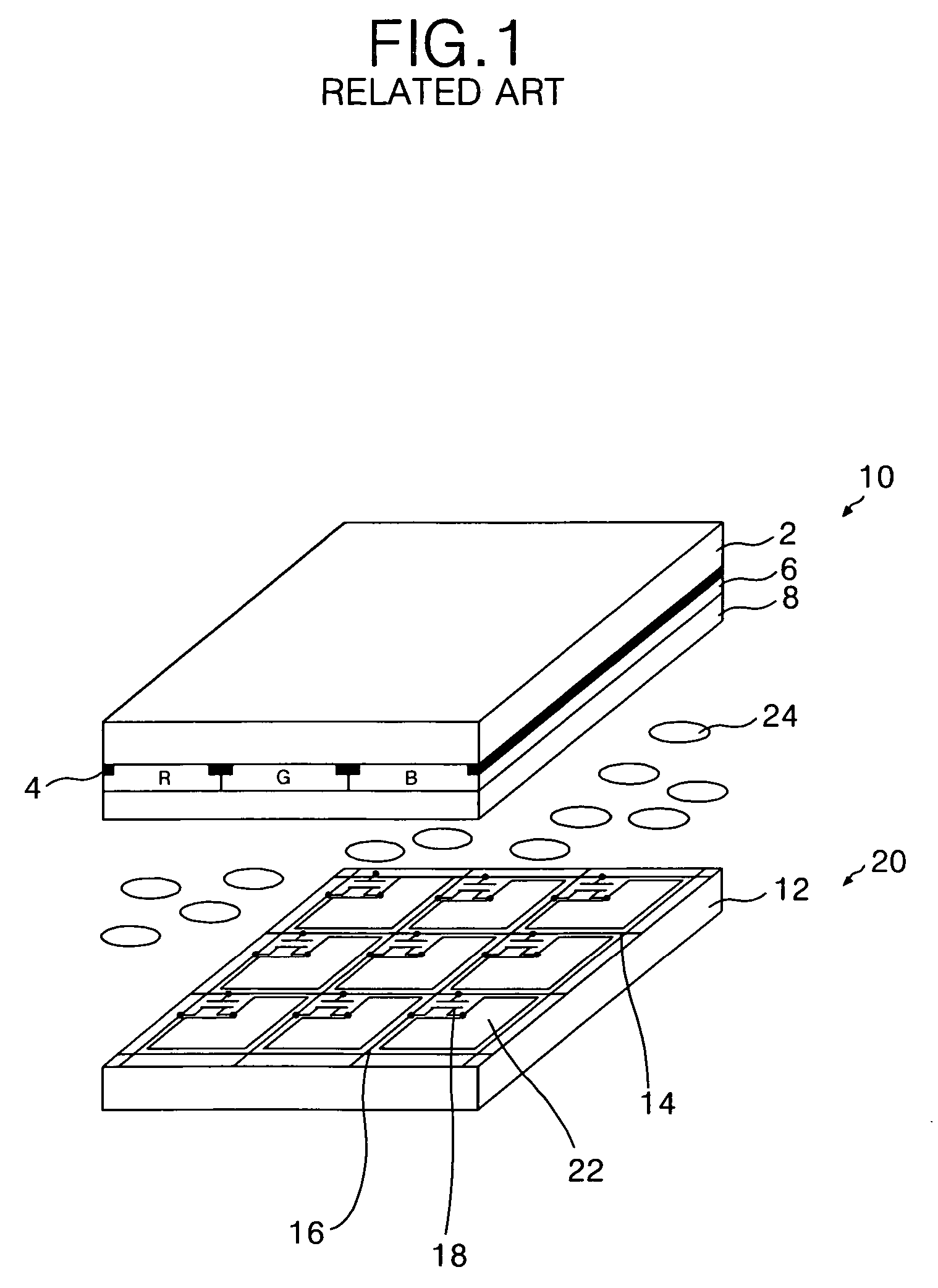

Liquid crystal display device and fabricating method thereof

Owner:LG DISPLAY CO LTD

Liquid crystal display device without frame

ActiveCN102841458AAchieve fixationEasy to disassembleNon-linear opticsLiquid-crystal displayEngineering

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

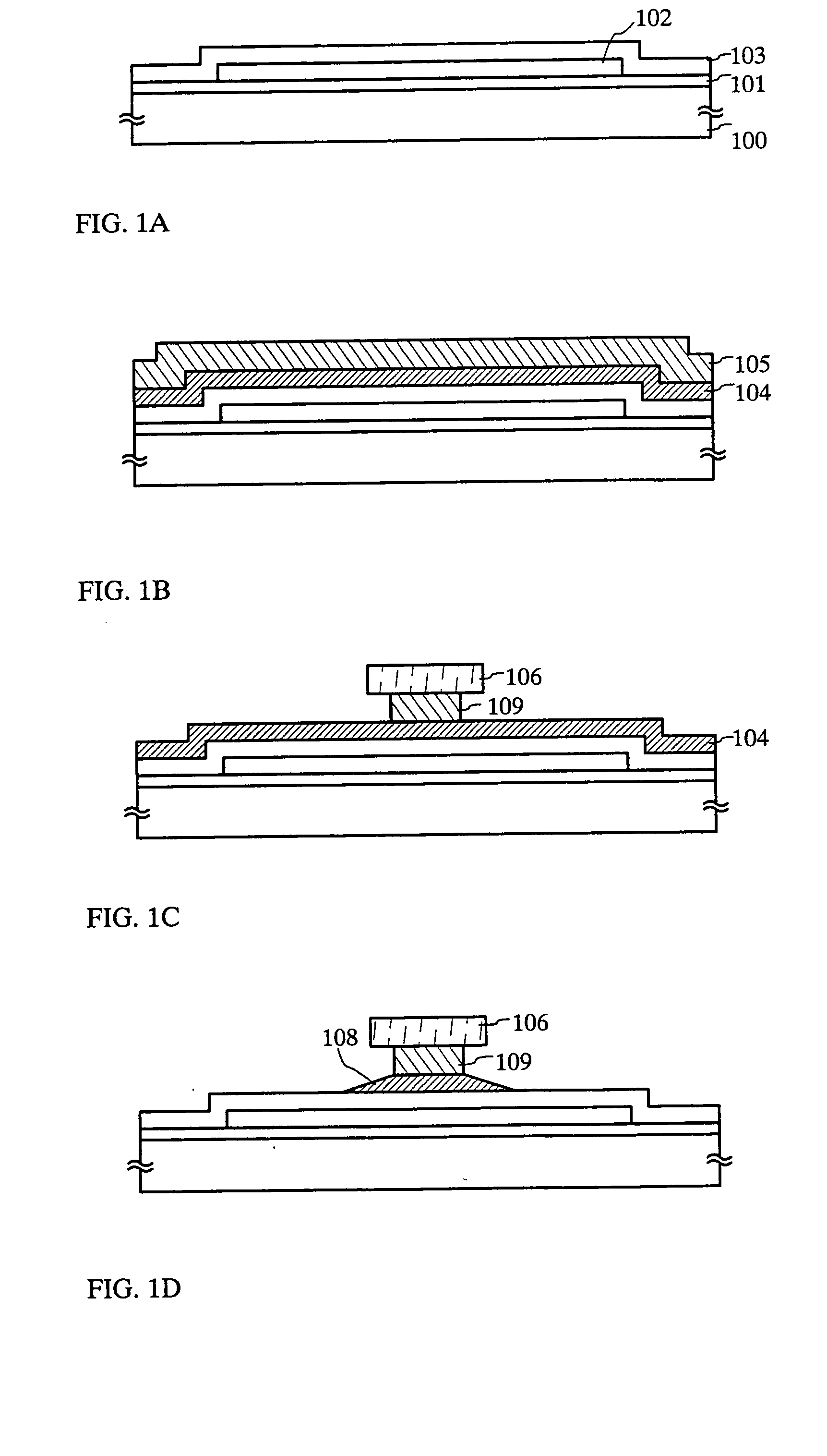

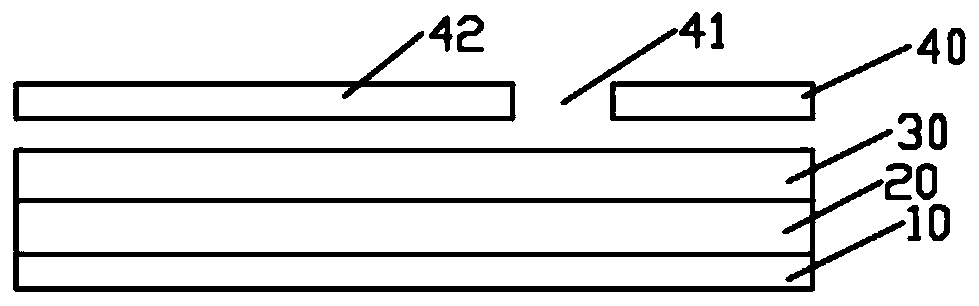

Method for manufacturing self-aligned thin-film transistor and structure thereof

InactiveUS20110001135A1Made preciselyImprove featuresTransistorSemiconductor/solid-state device manufacturingUltraviolet lightsOptoelectronics

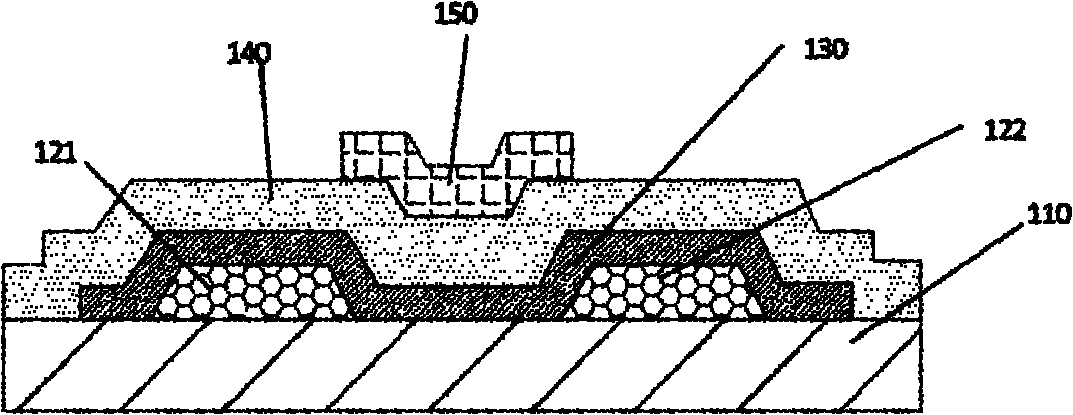

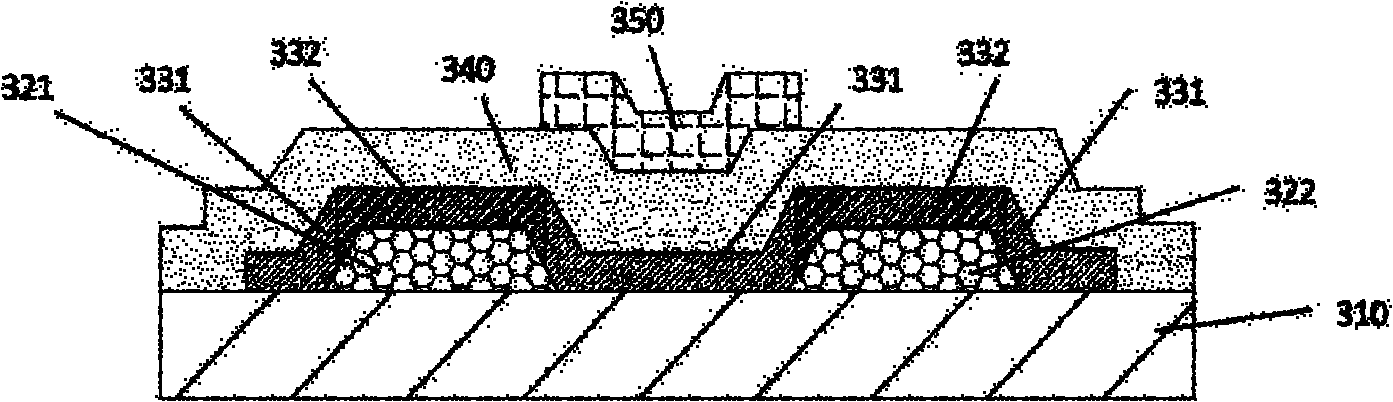

A method for manufacturing a self-aligned thin-film transistor (TFT) is described. Firstly, an oxide gate, a dielectric layer, and a photoresist layer are deposited on a first surface of a transparent substrate in sequence. Then, an ultraviolet light is irradiated on a second surface of the substrate opposite to the first surface to expose the photoresist layer, in which a gate manufactured by the oxide gate serves as a mask, and absorbs the ultraviolet light irradiated on the photoresist layer corresponding to the oxide gate. Then, the exposed photoresist layer is removed, and a transparent conductive layer is deposited on the unexposed photoresist layer and the dielectric layer. Then, a patterning process is executed on the transparent conductive layer to form a source and a drain, and an active layer is formed to cover the source, the drain, and the dielectric layer, so as to finish a self-aligned TFT structure.

Owner:NAT CHIAO TUNG UNIV

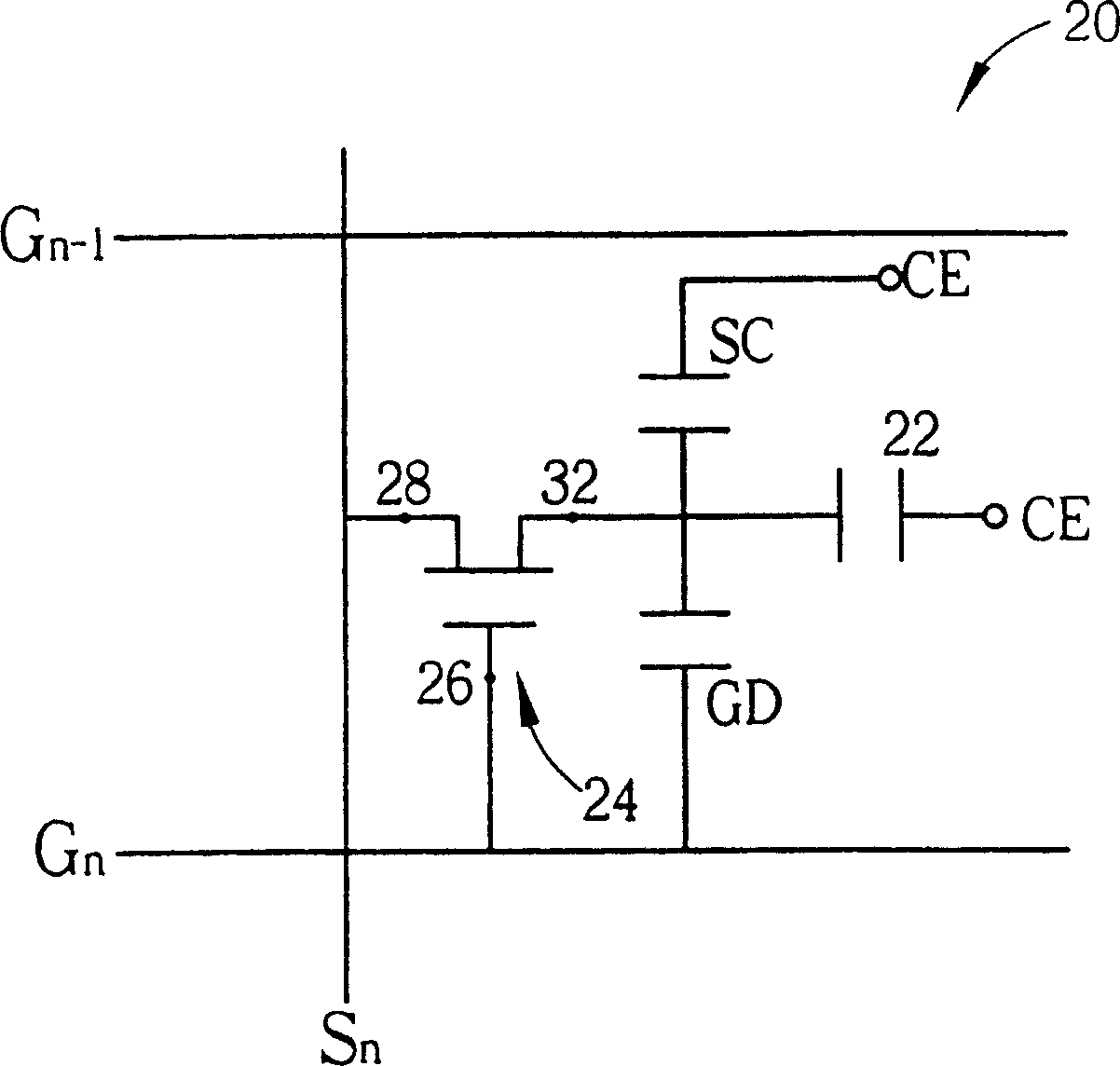

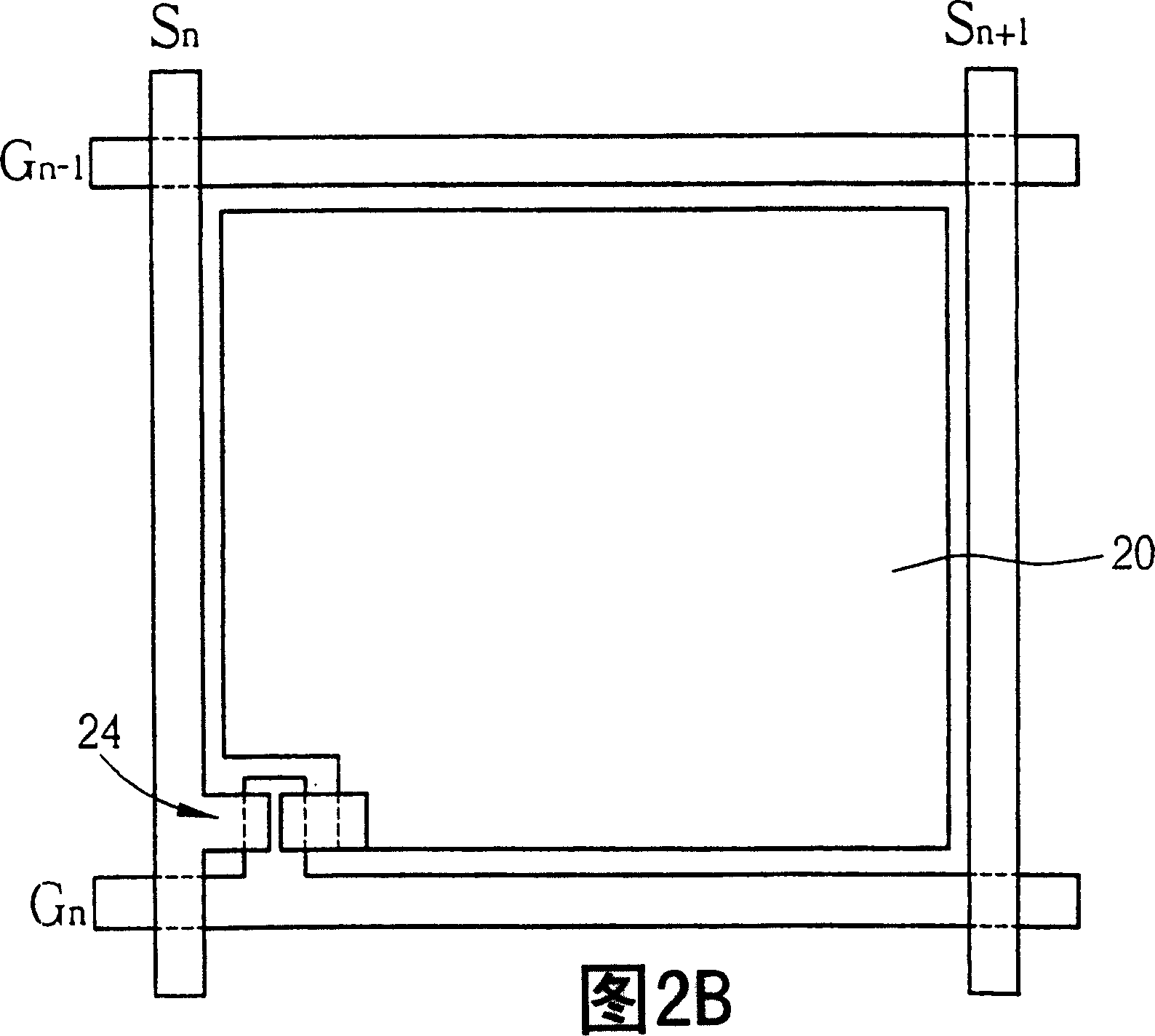

Liquid crystal display with double-film transister pixel structure

InactiveCN1536415AImage quality will not be affectedHigh resolutionTransistorNon-linear opticsLiquid-crystal displayWidth ratio

Owner:AU OPTRONICS CORP

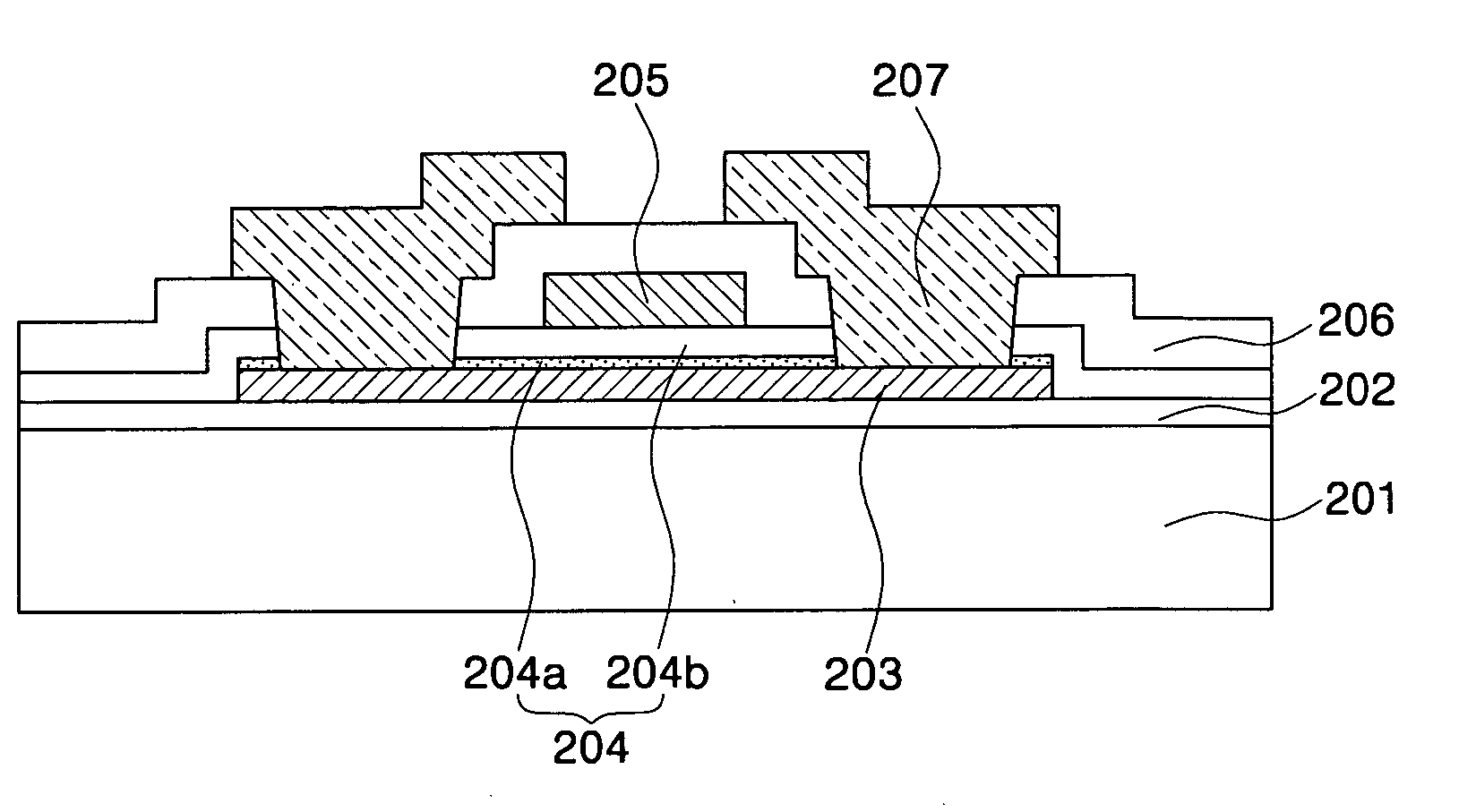

Method of manufacturing thin film transistor

InactiveUS20020072158A1Good precisionImprove directivitySolid-state devicesSemiconductor/solid-state device manufacturingMass numberEngineering

In a thin film transistor, a first insulating film on a silicon layer formed in an island on a substrate is smaller in thickness than the silicon layer so that the stepped island edges is gentle in slope to facilitate covering the island with a second insulating film. This reduces occurrence of gate leak considerably. Since the peripheral region of the stepped island is smaller in thickness than the central region above the channel, it is possible to minimize occurrence of gate electrode breakage. The silicon layer contains two or more inert gas atoms, and the atoms smaller in mass number (e.g., He) are contained in and near an interface with a silicon active layer while the atoms larger in mass number (e.g., Ar) than those smaller in mass number are contained in and near a second interface with a gate electrode.

Owner:GOLD CHARM LTD

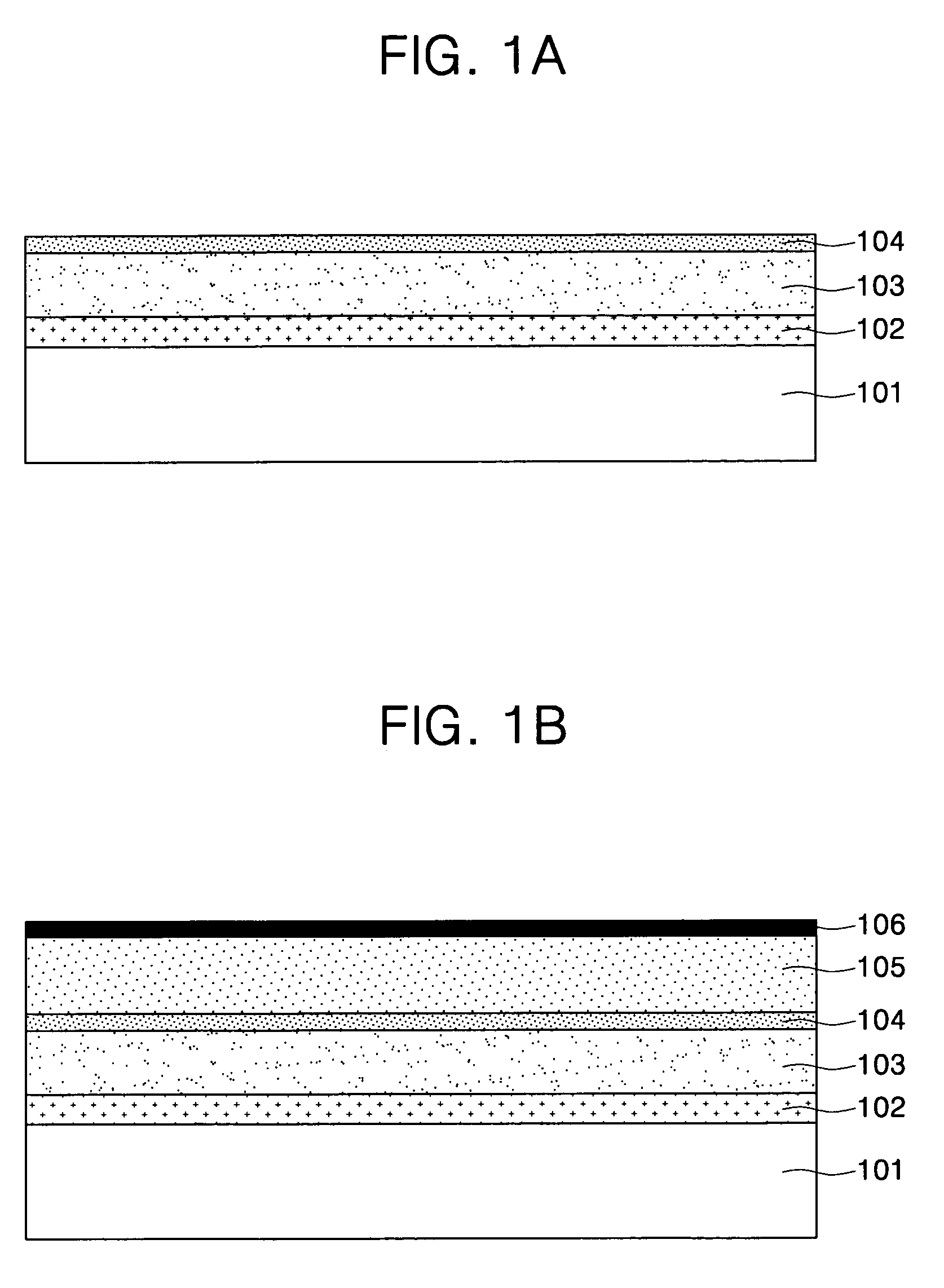

Method for preparing polysilicon

InactiveCN1727525AReduce the temperatureLower threshold voltagePolycrystalline material growthSemiconductor/solid-state device manufacturingFine lineSemiconductor materials

A process for preparing polycrystal silicon includes preparing non-crystal silicon film on glass substrate, preparing a thin Ni layer, photoetching the Ni layer to become fine lines, laser annealing, removing excessive Ni, and laser annealing again for crystallizing the silicon film. Its advantages are short time and low substrate temp.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

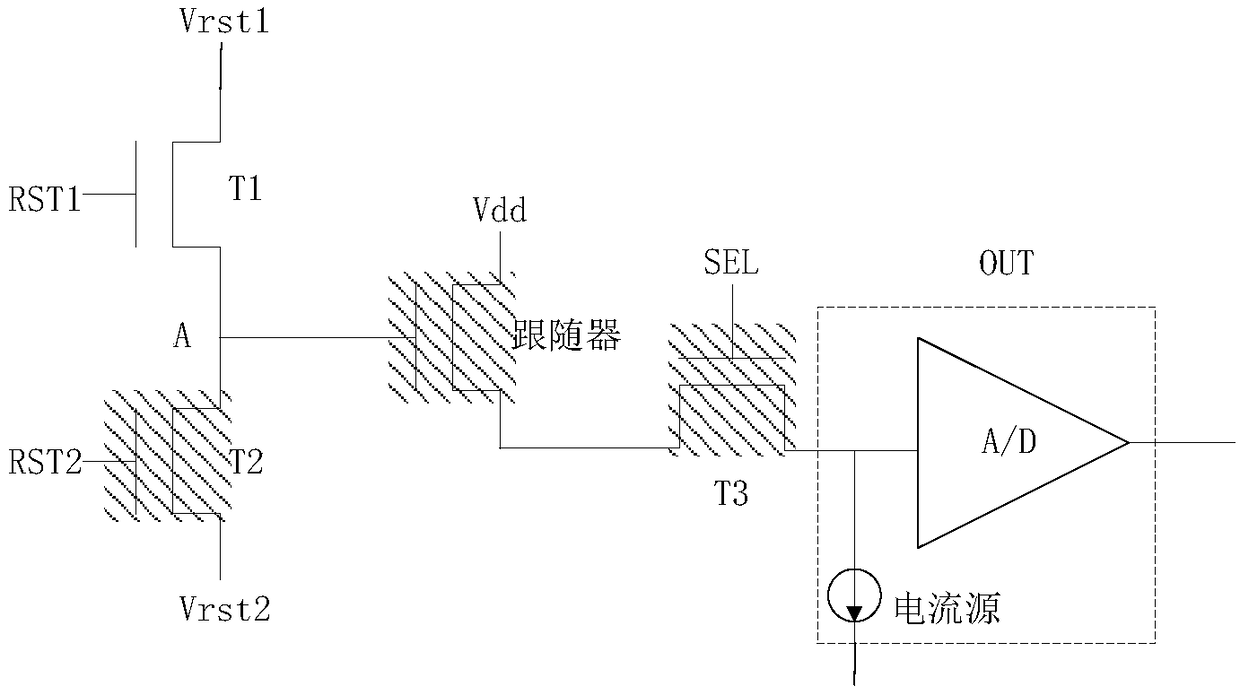

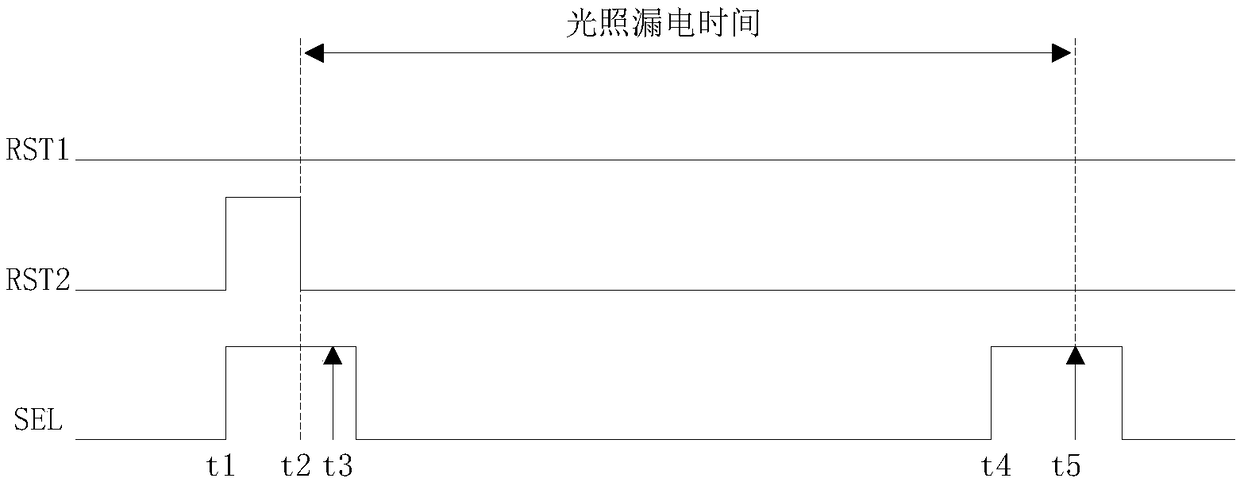

Light sensor, light detecting method and display device

ActiveCN108303176AImprove test accuracyTransistorPhotometry using reference valueSignal-to-noise ratio (imaging)Control signal

Owner:BOE TECH GRP CO LTD

Black frame voltage compensation method for data driver of OLED display

ActiveCN105225640AImprove toleranceExpand the scope of operationStatic indicating devicesVoltage compensationSet point

The invention discloses a black frame voltage compensation method for a data driver of an OLED display, and the method comprises the following steps: giving out a plurality of set point voltages which at least comprise a highest-order voltage, a lowest-order voltage, and at least one-order voltage between the highest-order voltage and the lowest-order voltage; building a voltage curve of a data driver based on the set point voltages; enabling the highest-order voltage to be set independent of the voltage curve; and independently pulling up the highest-order voltage. Through the independent giving of a black frame voltage, the method enables the black frame voltage to be independent for adjustment, thereby enlarging range of circuit operation and exerting no impact on the setting of gray scale voltages. Through the setting of the independent black frame voltage, the method can increase the difference between the black frame voltage and the voltage of one gray scale which is one gray scale less, improves the tolerance for current leakage of a thin film transistor (TFT) assembly, and can solve a problem that the current leakage of the assembly causes the slight lighting of the frame which affects comparison.

Owner:EVERDISPLAY OPTRONICS (SHANGHAI) CO LTD

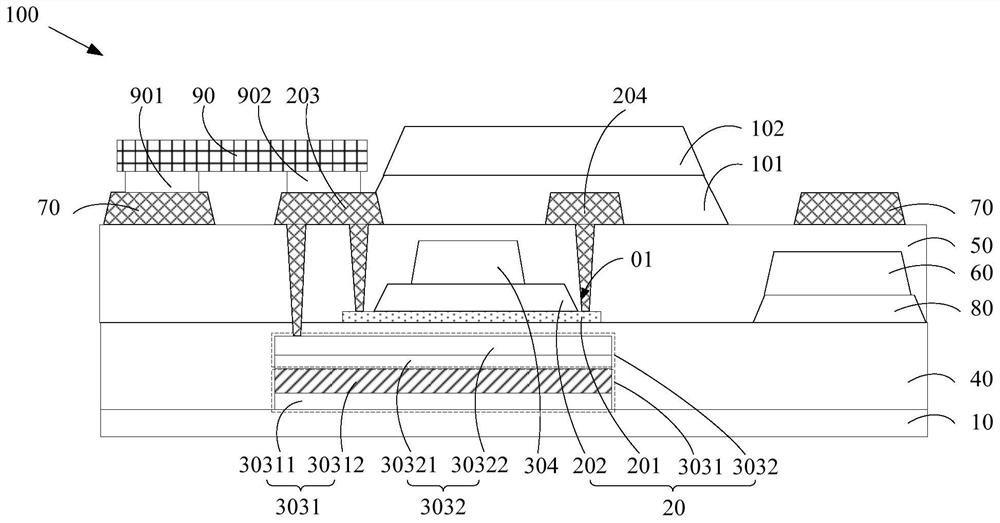

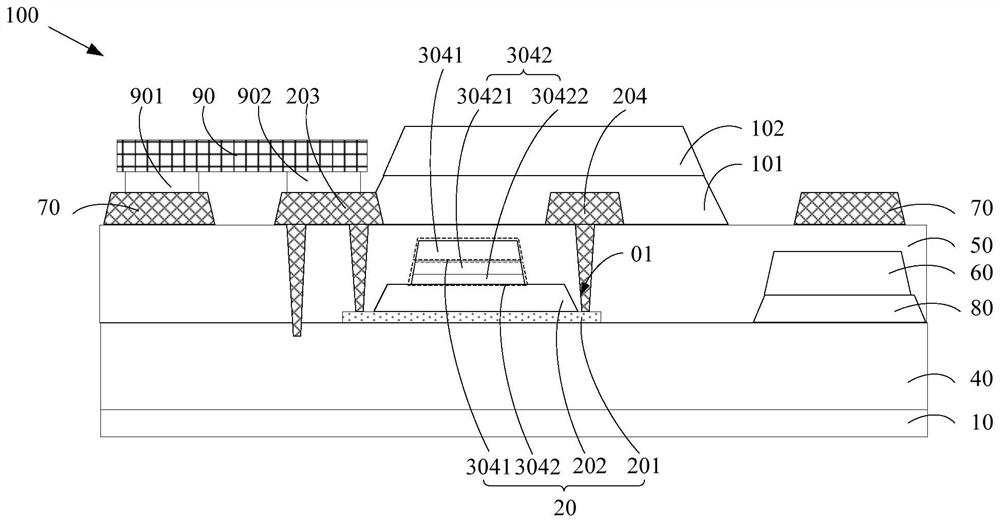

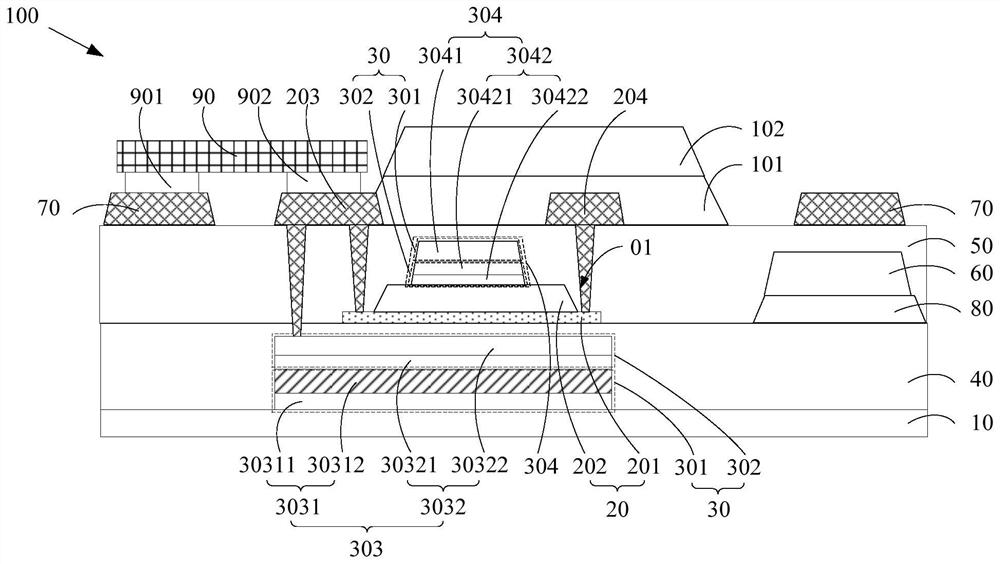

Array substrate, display panel and preparation method of array substrate

ActiveCN106711156AIncreasing the thicknessReduce the differenceSolid-state devicesSemiconductor/solid-state device manufacturingPhysicsThin-film transistor

The invention provides an array substrate, a display panel and a preparation method of the array substrate. The array substrate comprises a protective layer and a through hole and also comprises a first conducting layer, wherein the protective layer is formed on the substrate; the through hole penetrates through the protective layer; the first conducting layer is positioned on one side, far away from the substrate, of the protective layer with the through hole. The thickness of the first conducting layer at the bottom part of the through hole is more than that of the first conducting layer at the area beyond the through hole, namely, the thickness of the first conducting layer at the bottom part of the through hole is increased, and the section difference between the bottom of a middle hole and the top of the hole can be reduced, so that the risk of dropping of the first conducting film layer in the through hole is reduced, further the signal interruption of the electrodes is avoided and the electric connection performance of a TFT (Thin Film Transistor) is improved.

Owner:BOE TECH GRP CO LTD +1

Visible light and ultraviolet selectivity photoelectric detector

The present invention provides a visible light and ultraviolet selectivity photoelectric detector. The detector comprises an ultraviolet detection portion, a thin film transistor and a transverse visible light detection portion which are arranged on an insulation substrate. The structure of the detector is reasonably designed, the ultraviolet detection portion, the thin film transistor and the transverse visible light detection portion are integrated on one substrate, and an ultraviolet detection function layer is taken as the channel layer of the thin film transistor so as to shorten the size of the device and optimize the structure of the device, the thin film transistor is employed to realize selection of visible light and ultraviolet detection and improve the detection efficiency.

Owner:BEIJING EAST GOOD TECH DEV CO LTD

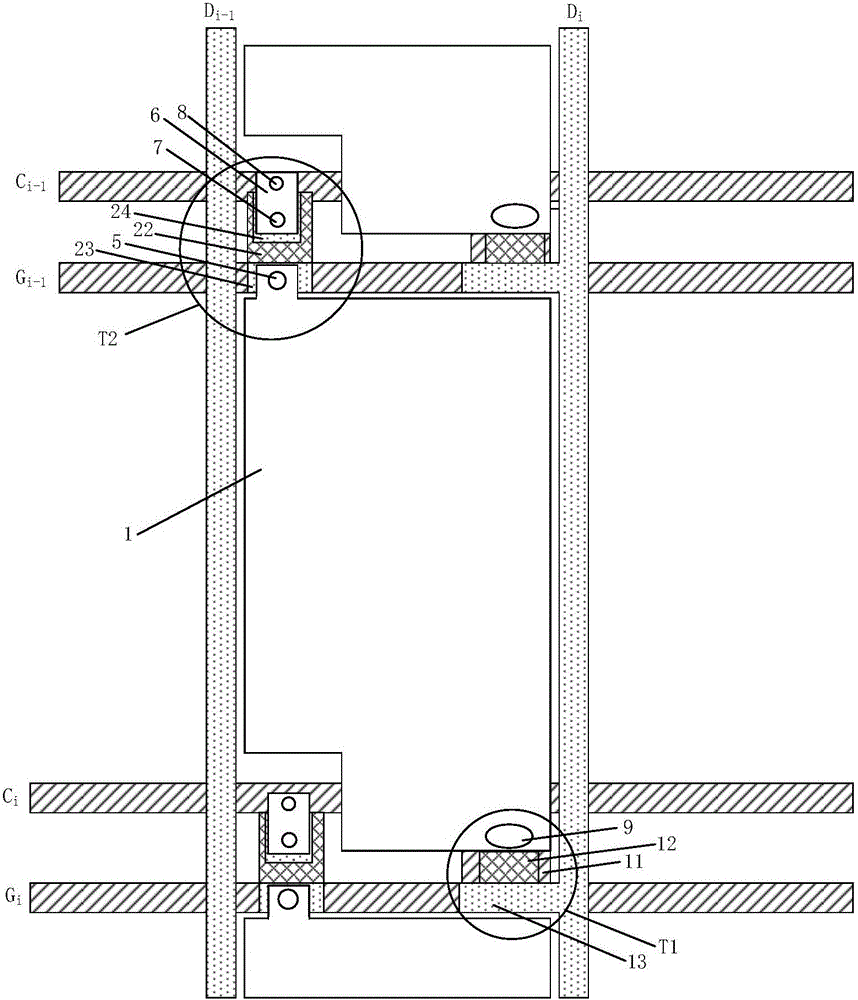

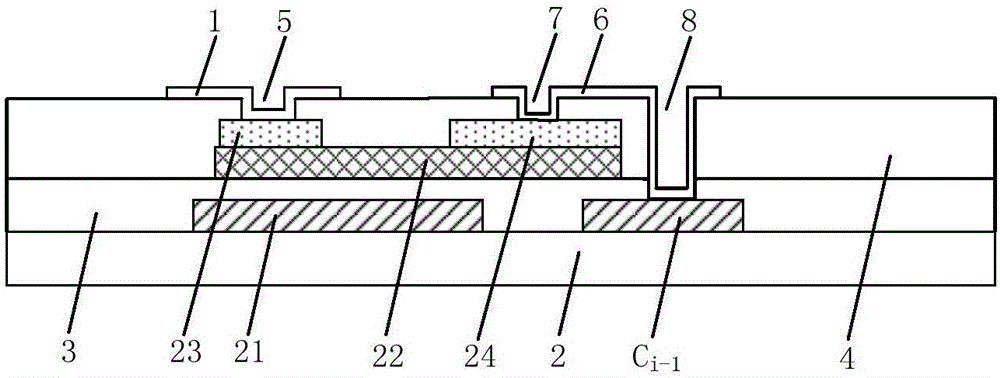

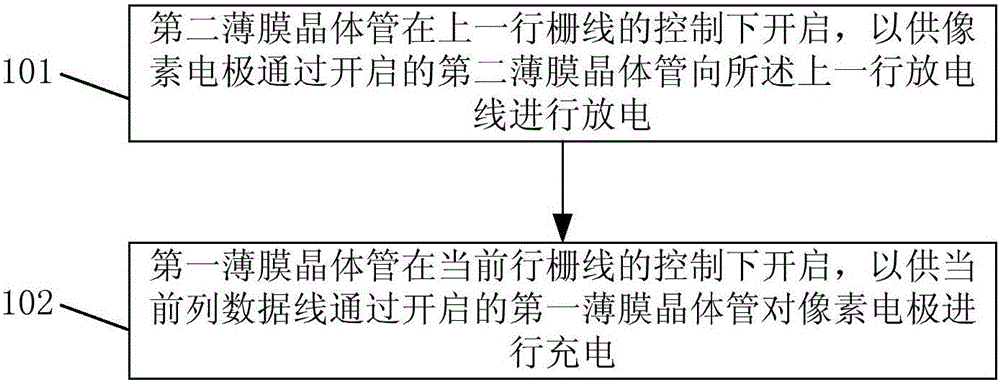

Pixel structure, method for driving pixel structure, display substrate and display panel

InactiveCN105974704AShorten the timeImprove charge and discharge efficiencyNon-linear opticsEngineeringCharge and discharge

Owner:BOE TECH GRP CO LTD +1

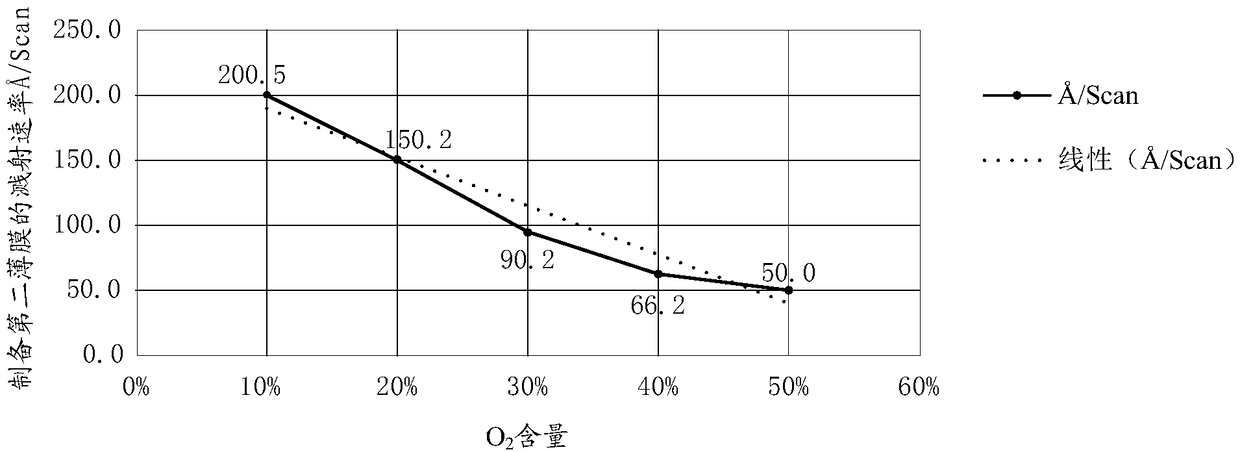

Thin film transistor and manufacturing method thereof and display substrate

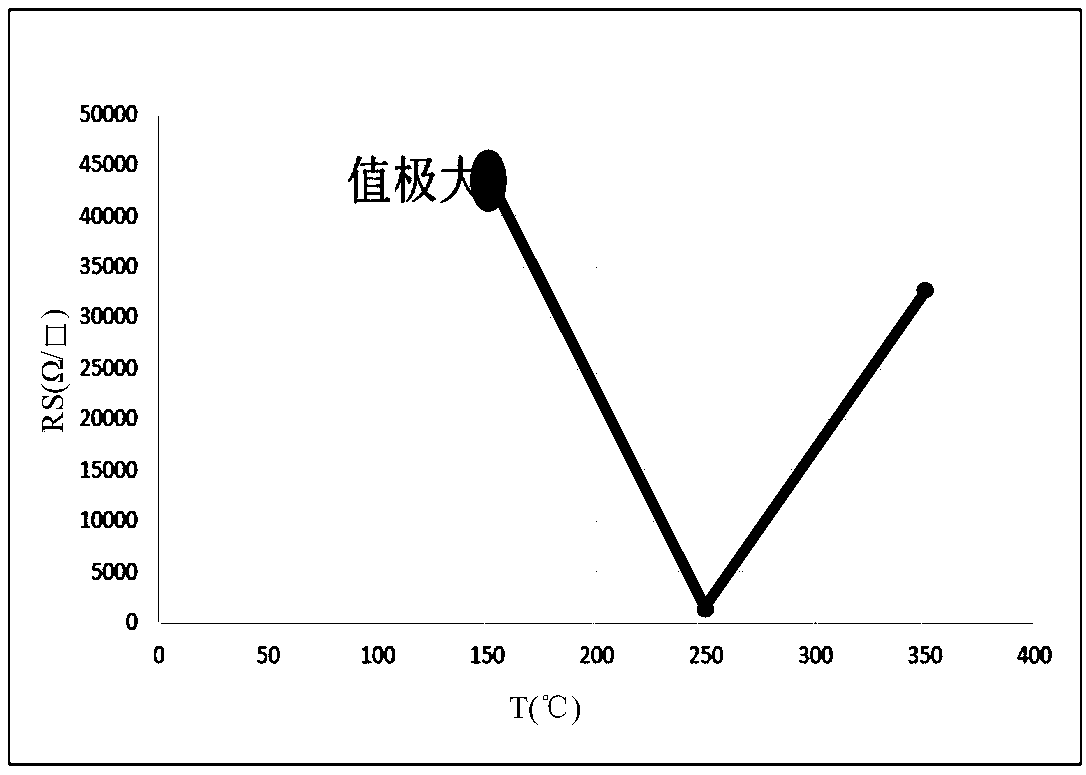

ActiveCN108766972AReduce oxygen contentReduce sheet resistivityTransistorSolid-state devicesOptoelectronicsConductive materials

Owner:BOE TECH GRP CO LTD

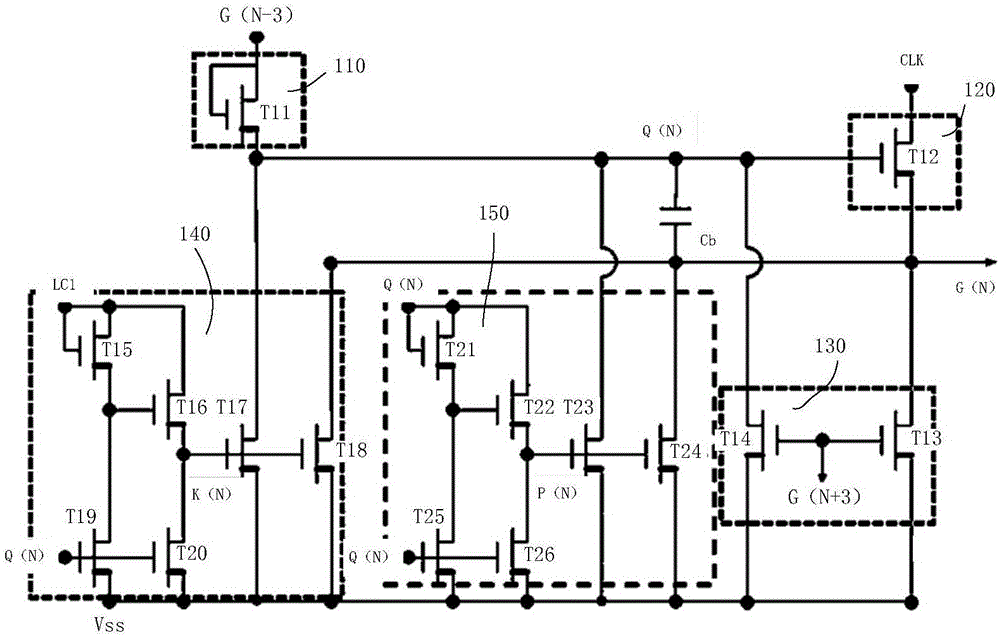

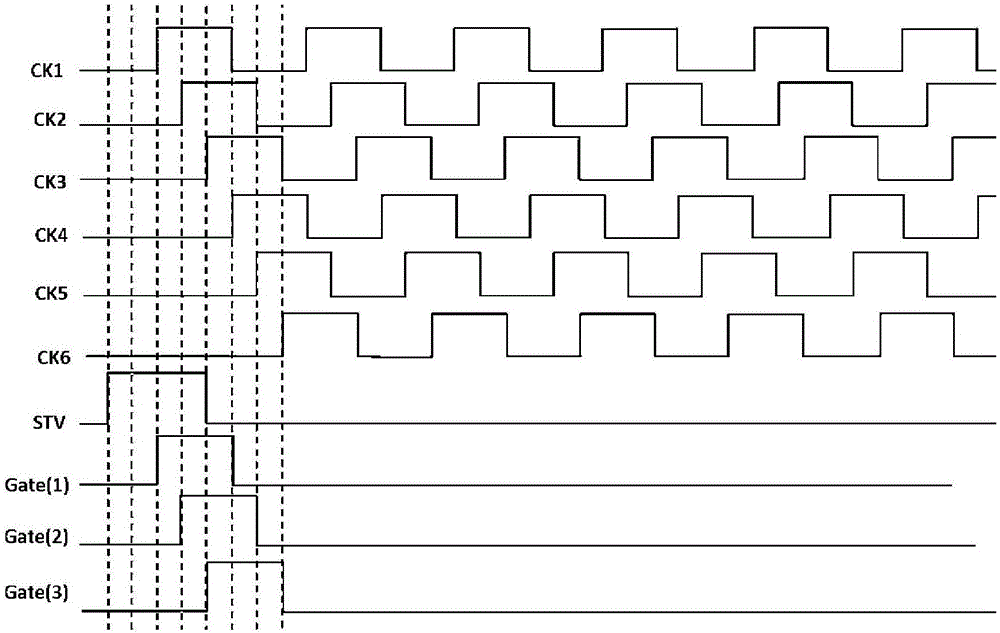

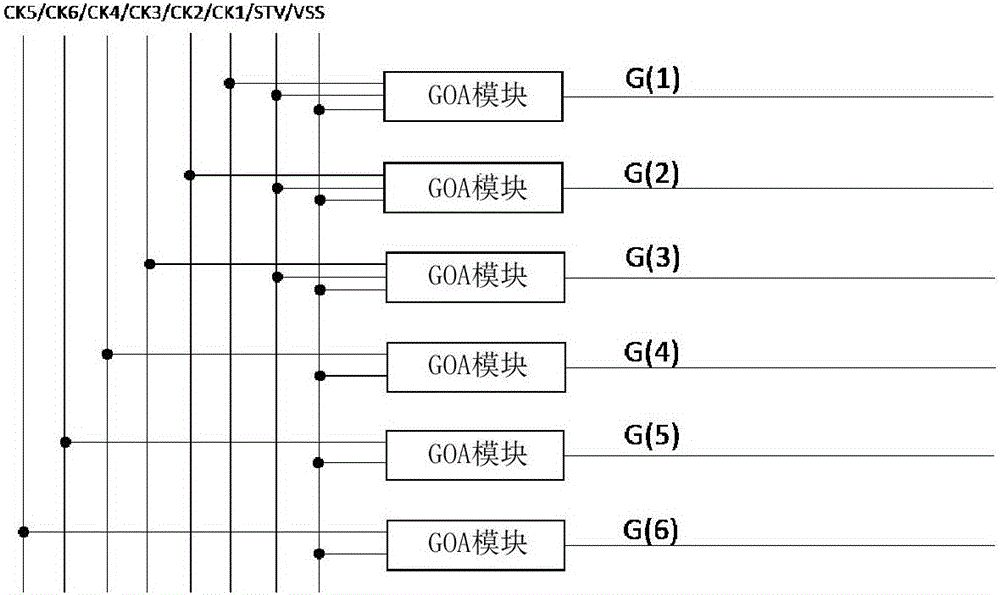

Array substrate row drive circuit and drive method thereof

ActiveCN106782391AEasy to useAvoid overlappingStatic indicating devicesLiquid-crystal displayControl signal

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

Method for repairing thin-film transistor array substrate and thin film removing method

ActiveCN1976009AAvoid abnormal conductionGuaranteed normal operationSemiconductor/solid-state device detailsSolid-state devicesOptoelectronicsPellicle membrane

Owner:AU OPTRONICS CORP

Niobium alloy sputtering target material and preparation method thereof

ActiveCN113584366AFine grainImprove matchVacuum evaporation coatingSputtering coatingActivated carbonLiquid-crystal display

Owner:丰联科光电(洛阳)股份有限公司

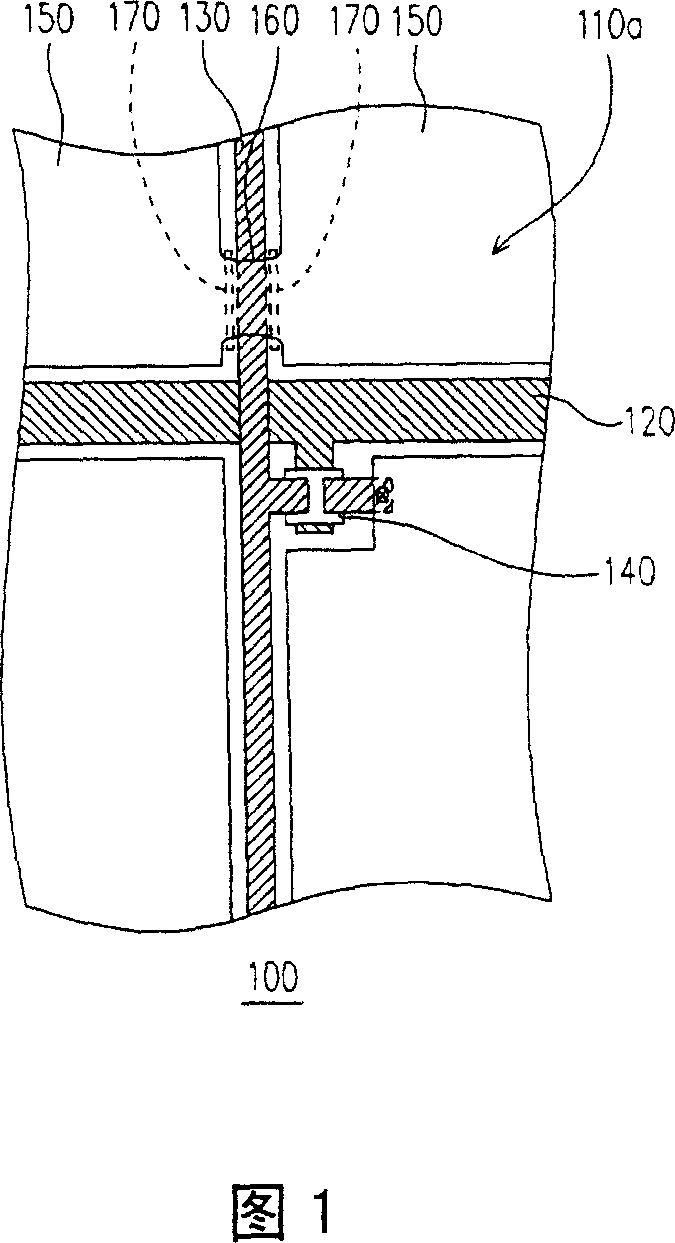

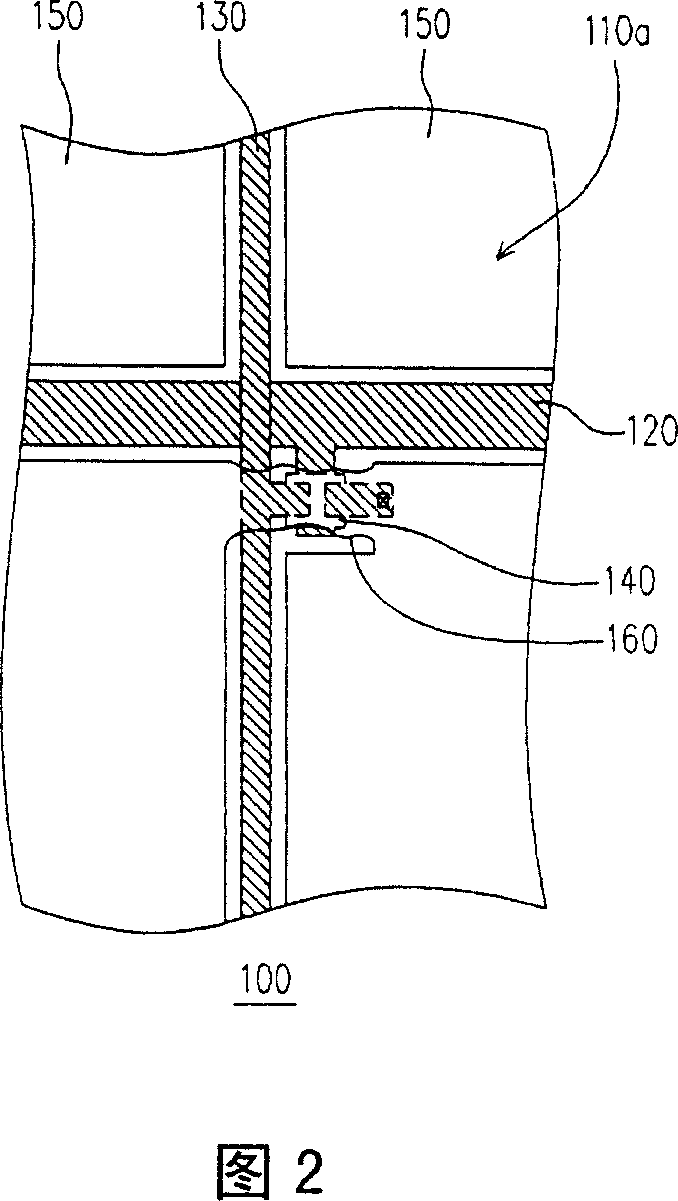

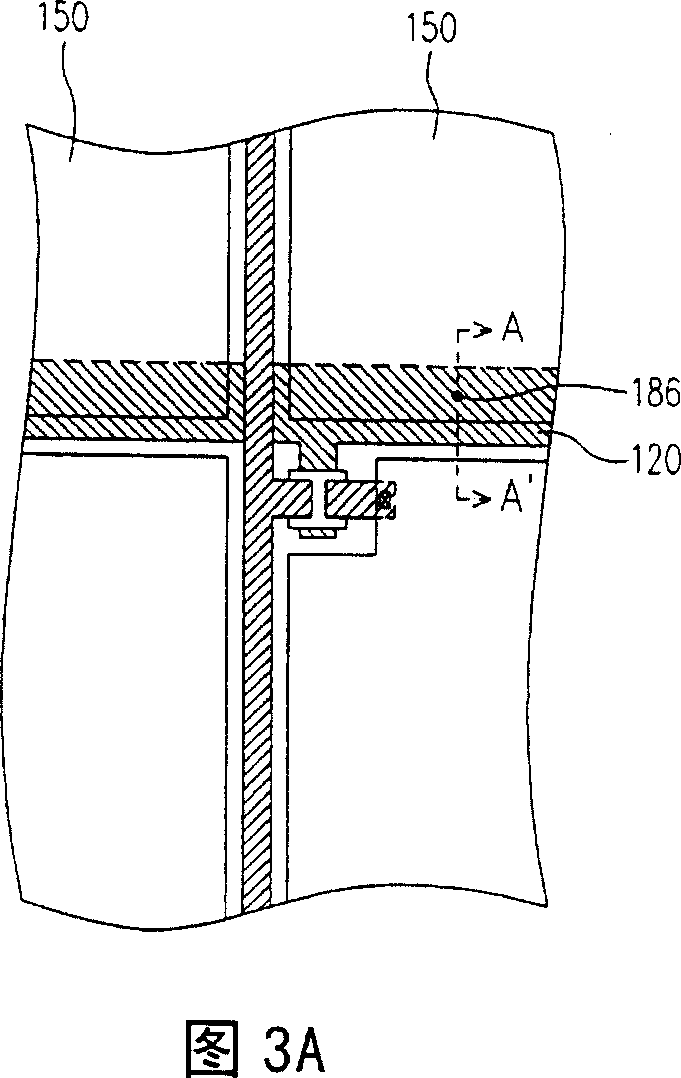

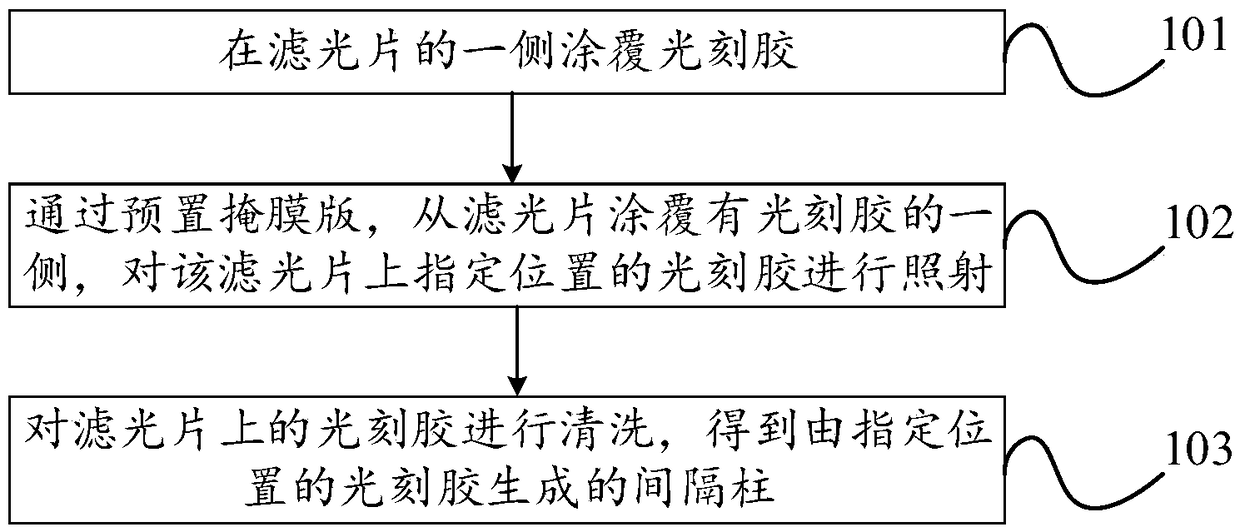

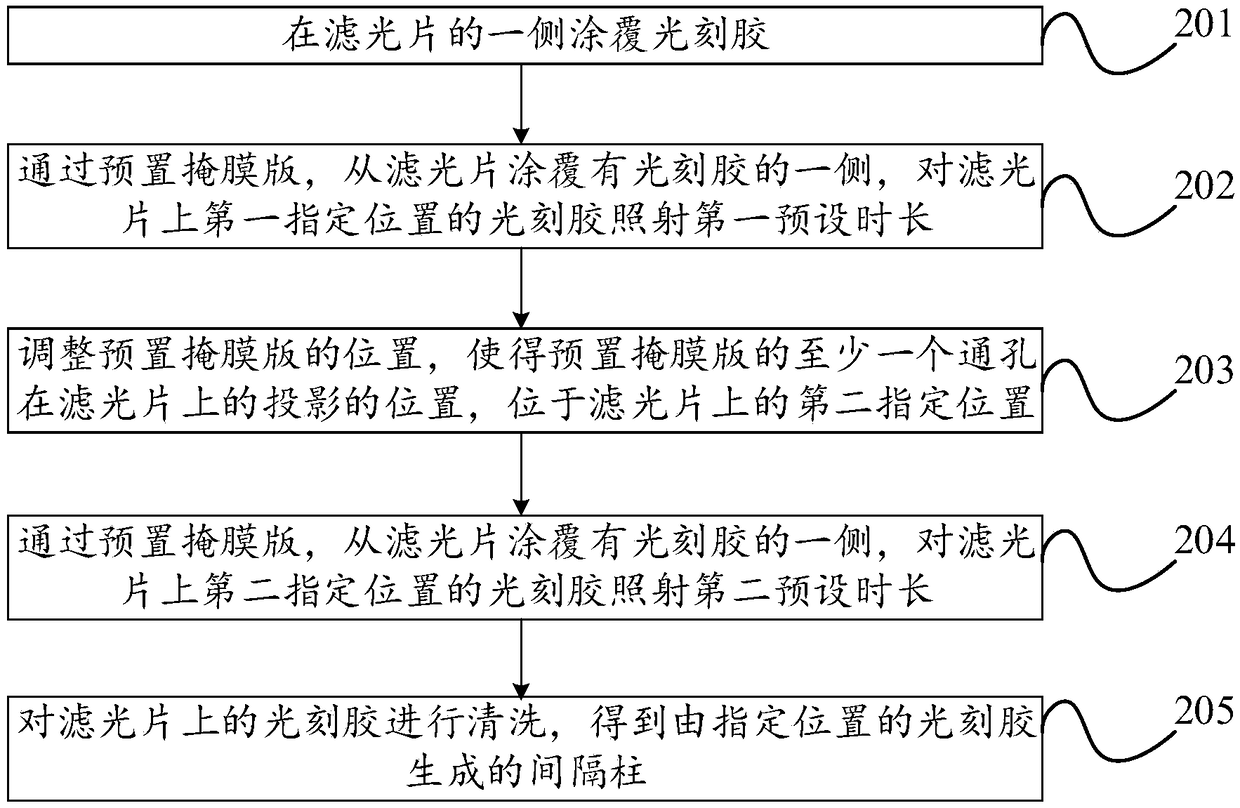

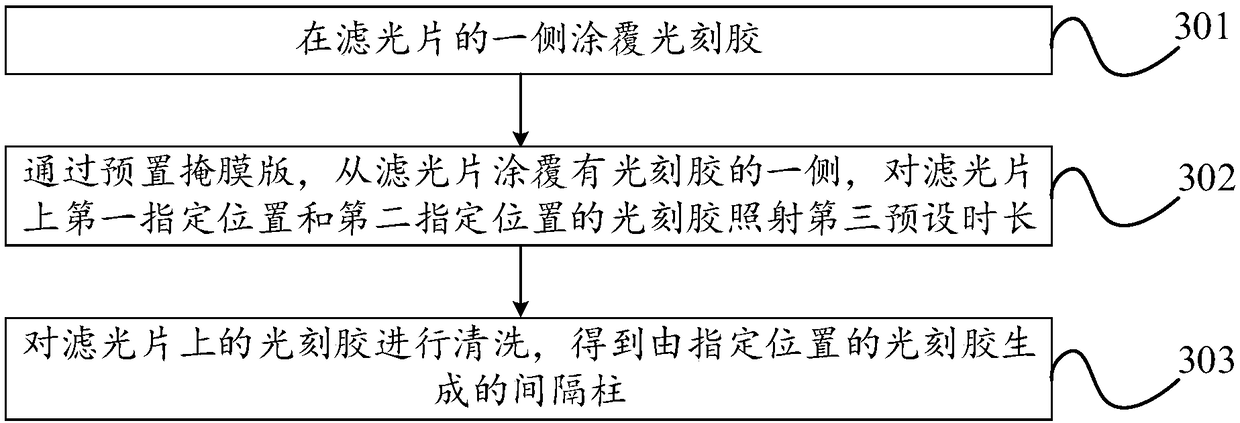

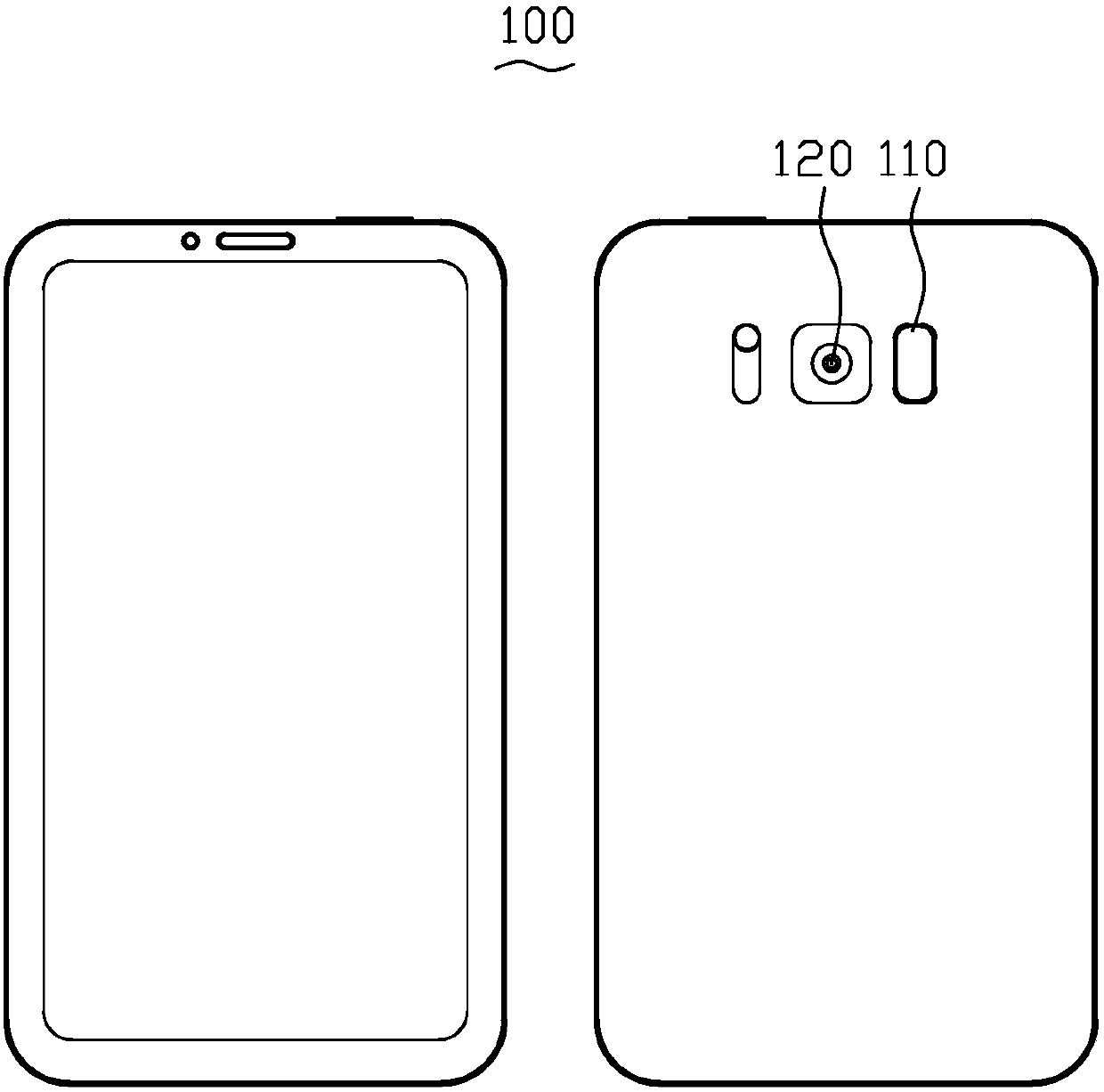

Generation method for spacer supports and liquid crystal box structure

InactiveCN108845464AAvoid the problem of height errorHigh precisionPhotomechanical apparatusNon-linear opticsPhotoresistForming processes

Owner:TRULY SEMICON

Array substrate, display panel and manufacturing method of array substrate

Owner:XIAMEN TIANMA MICRO ELECTRONICS +1

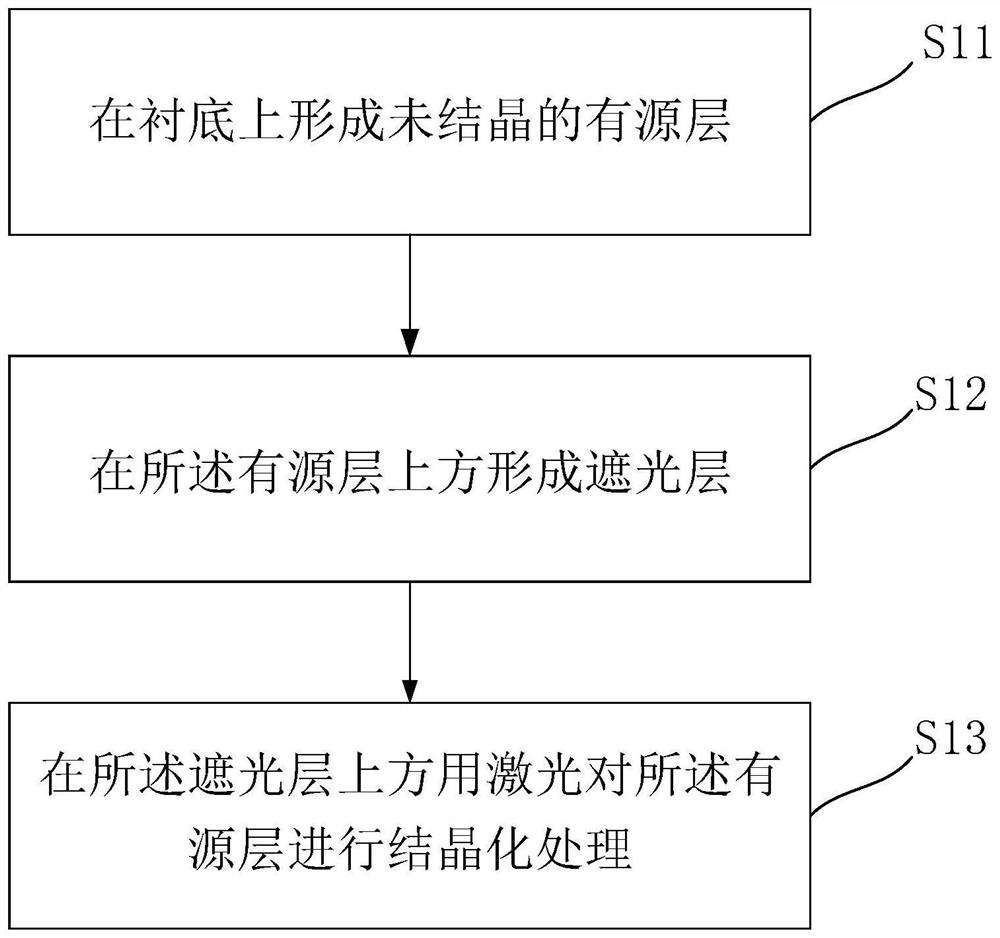

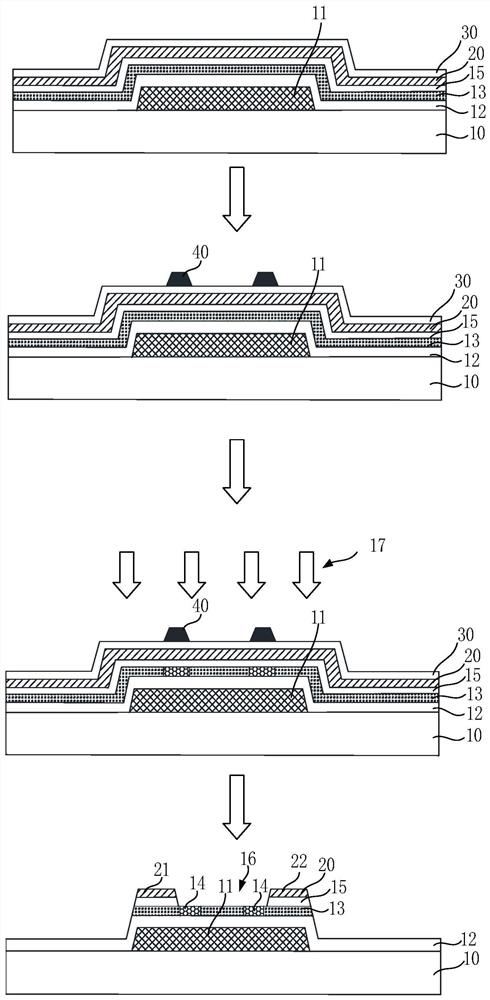

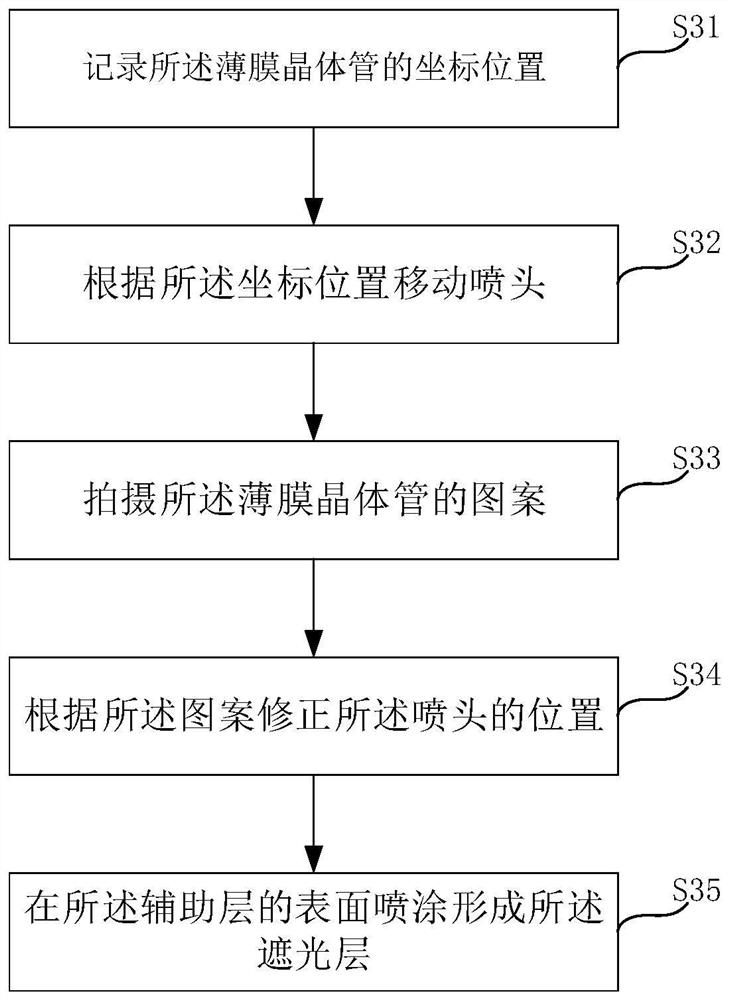

Manufacturing methods and manufacturing apparatuses of display panel and thin film transistor

ActiveCN112542386AImprove mobilityLow mobilitySolid-state devicesSemiconductor/solid-state device manufacturingThin membraneEngineering

Owner:BEIHAI HKC OPTOELECTRONICS TECH CO LTD +1

Manufacturing method of display panel

ActiveCN110634794AImprove reliabilitySolve the problems that easily cause the performance of TFT devices to decline sharply or even failSolid-state devicesSemiconductor/solid-state device manufacturingUltravioletEngineering

Owner:HEFEI XINSHENG OPTOELECTRONICS TECH CO LTD +1

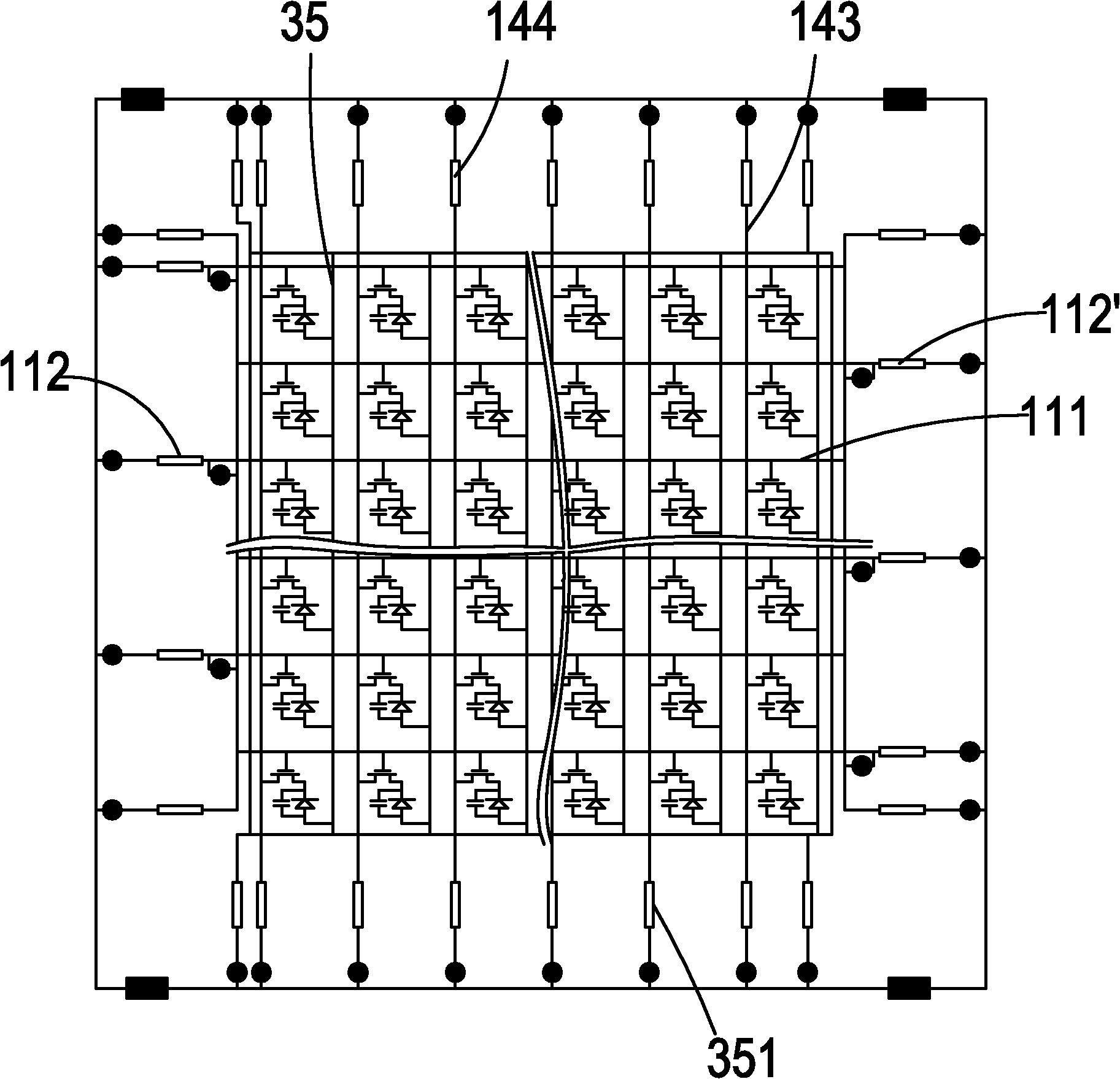

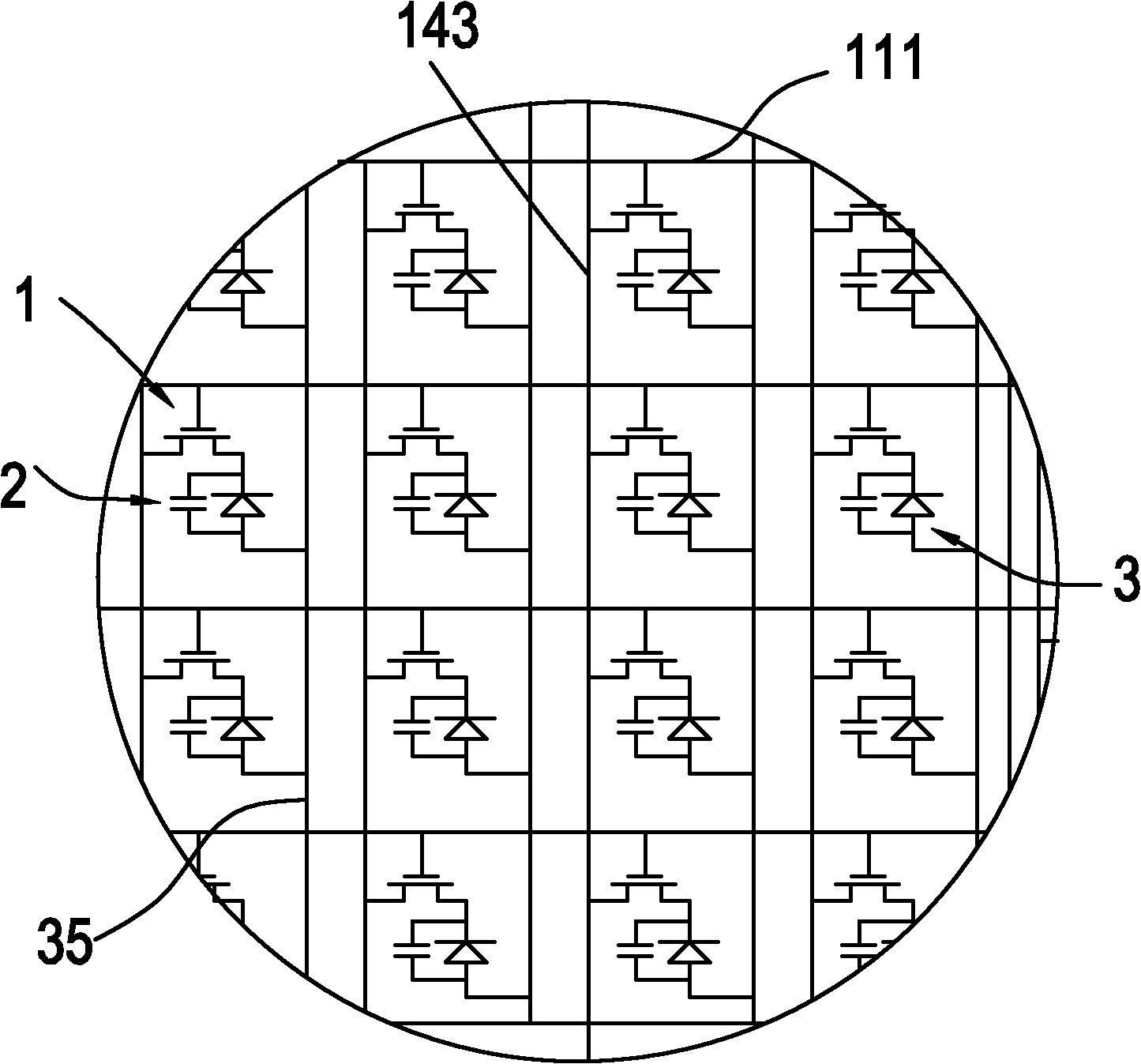

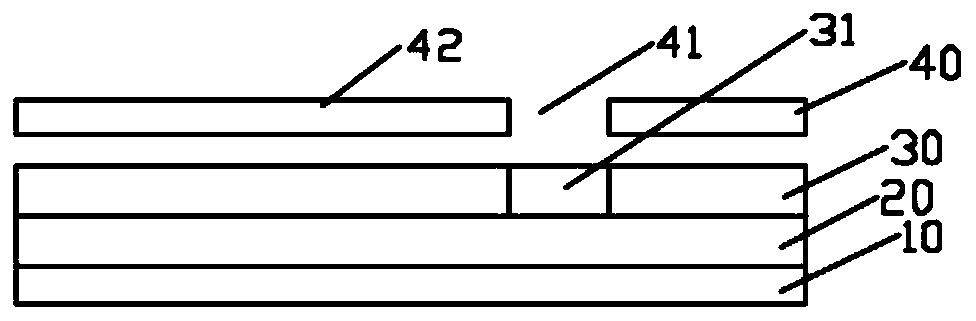

High-screen duty cycle display device with fingerprint identification

ActiveCN109255281AWith pressure sensing functionRaise the ratioDigital data processing detailsPrint image acquisitionTransistor arrayArray data structure

Owner:FOCALTECH ELECTRONICS

Display structure of double-gate driving equipment and display device

PendingCN113937110AAddress riskIncrease storage capacitySolid-state devicesIdentification meansCapacitanceDisplay device

Owner:BOE TECH GRP CO LTD +1

Display panel, preparation method thereof and display device

InactiveCN112802905AReduce the risk of failureImprove stabilityTransistorSolid-state devicesDisplay deviceThin membrane

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap