Pixel structure, method for driving pixel structure, display substrate and display panel

A pixel structure and pixel electrode technology, applied in nonlinear optics, instruments, optics, etc., can solve the problems of reducing the charging and discharging efficiency of the pixel electrode, increasing the charging time of the pixel electrode, etc., so as to improve the charging and discharging efficiency and shorten the charging time. effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order for those skilled in the art to better understand the technical solution of the present invention, the pixel structure and its driving method, display substrate and display panel provided by the present invention will be described in detail below with reference to the accompanying drawings.

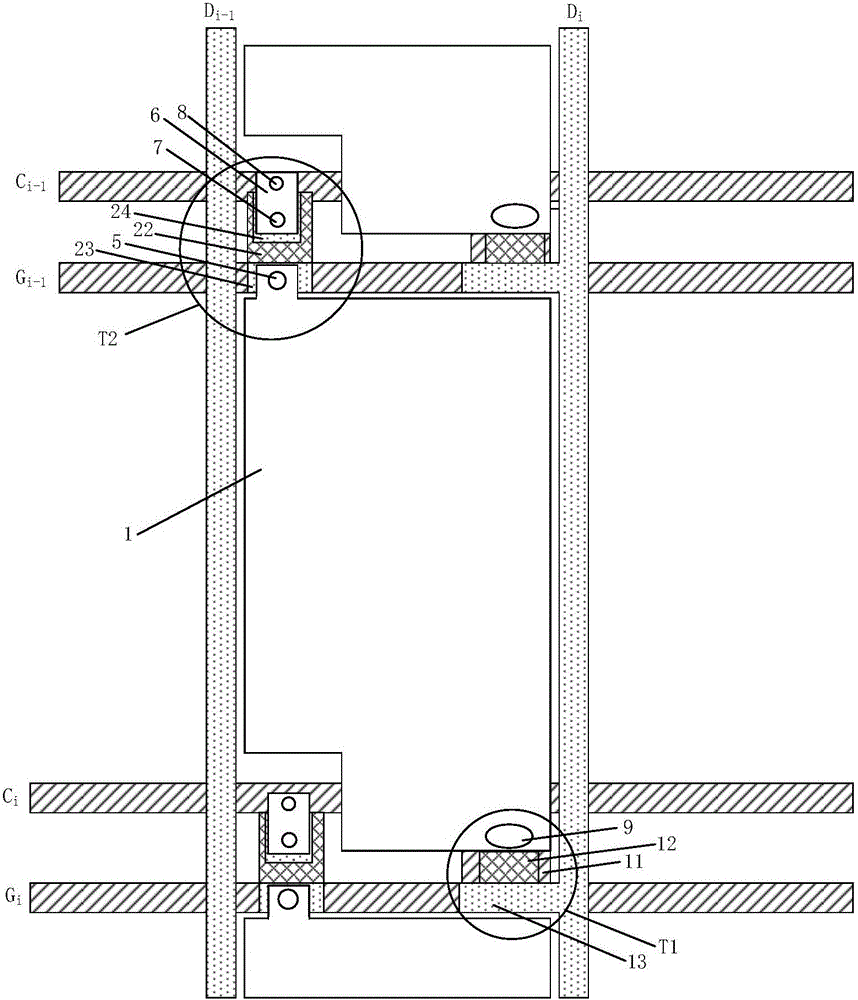

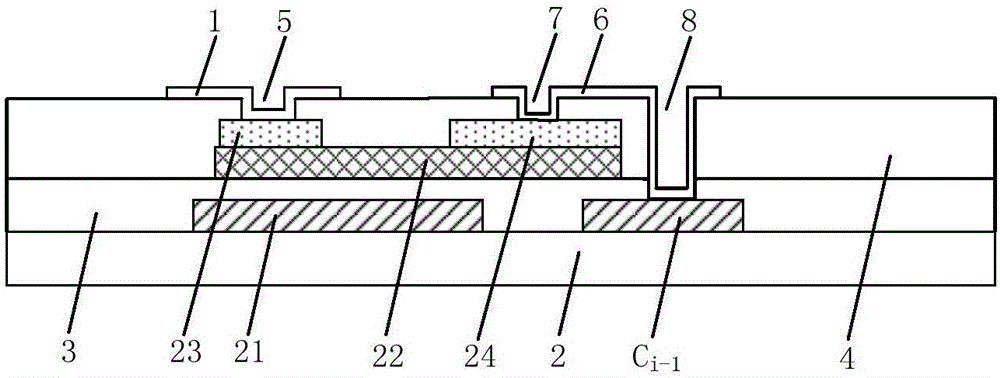

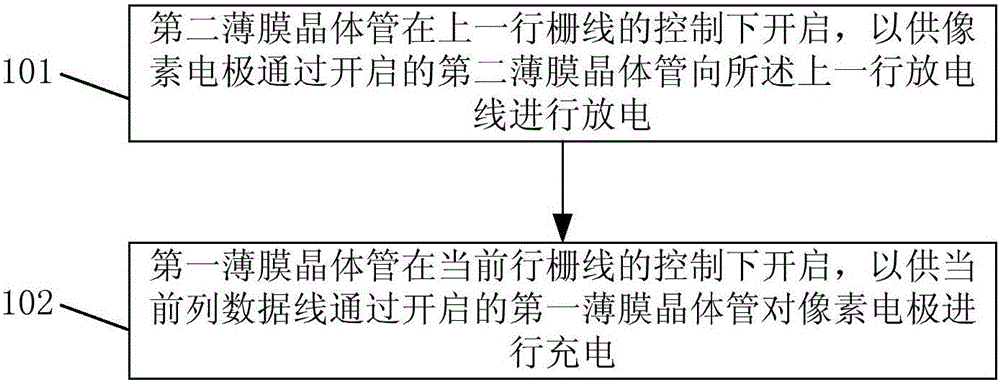

[0027] figure 1 A schematic structural diagram of a pixel structure provided in Embodiment 1 of the present invention, as shown in figure 1 As shown, the pixel structure includes: a first thin film transistor T1, a second thin film transistor T2 and a pixel electrode 1, and the first thin film transistor T1 is connected to the current row gate line G i , the current column data line D i and the pixel electrode 1, the second thin film transistor T2 is connected to the gate line G of the last row i-1 , the last line of discharge line C i-1 and pixel electrode 1. The second thin film transistor T2 is used in the upper row of gate line G i-1 It is turned on under the control

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap