Array substrate row drive circuit and drive method thereof

A technology of array substrate row and drive circuit, applied in instruments, static indicators, etc., can solve problems such as affecting the potential of Q point, abnormal panel display, abnormal output waveform, etc., and achieve the effect of avoiding overlapping in time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0035] In the prior art, the input terminals of the array substrate row drive modules with a set number of stages receive the same pull-up control signal. Since there is a time overlap between the high potential signal output by the gate and the high potential of the pull-up control signal, the array substrate row drive circuit Under the environment of high temperature operation, the potential of the Q node will be affected, resulting in the abnormal output waveform of the set number of stages and the abnormal panel display.

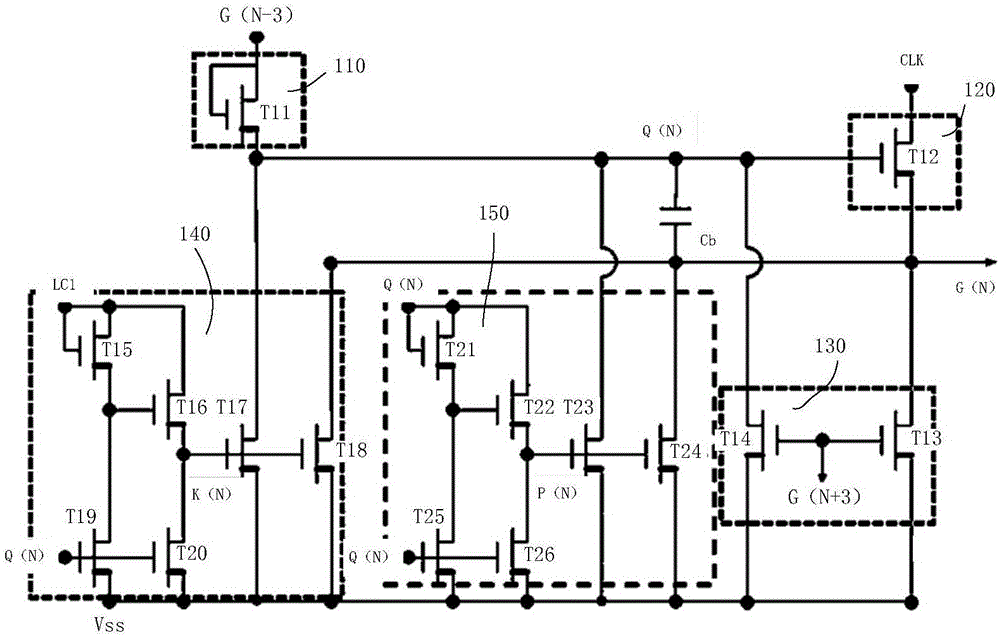

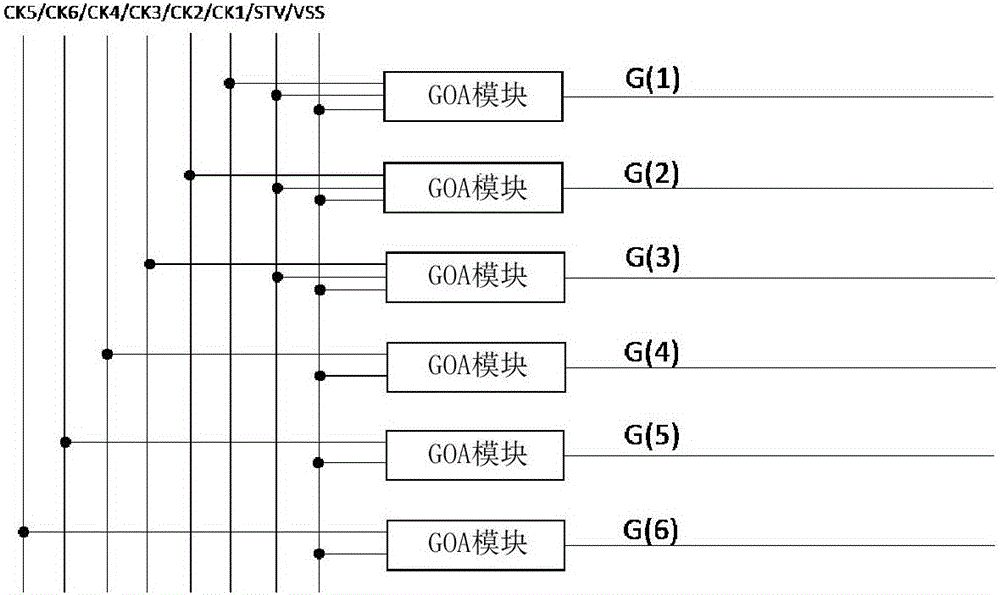

[0036] Based on this, this embodiment provides an array substrate row driving circuit, including: a multi-stage array substrate row driving module and a plurality of thin film transistors. Receive different pull-up control signals and output corresponding gate signals;

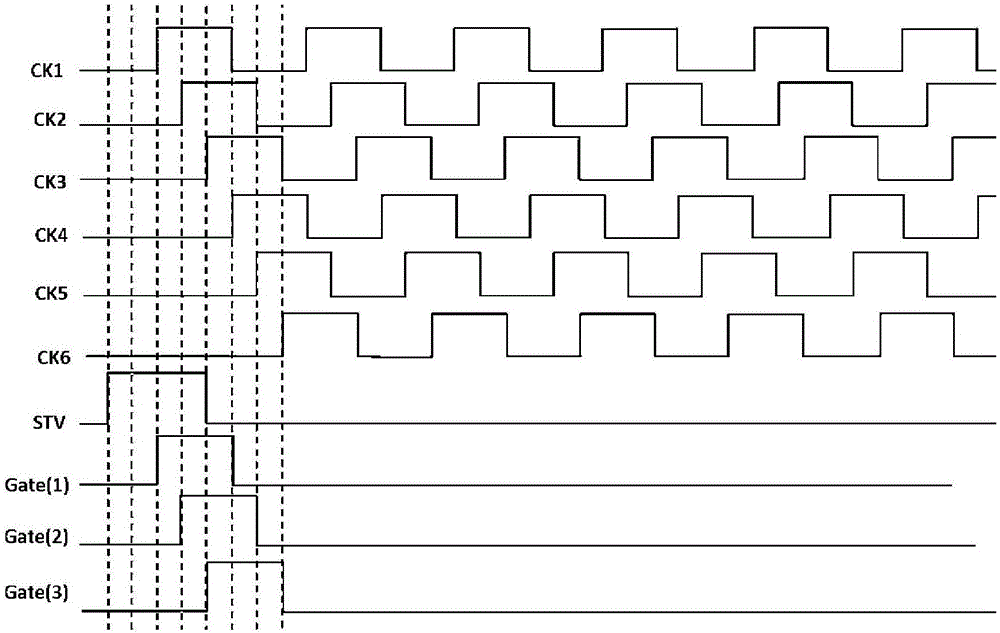

[0037] For each array substrate row driving module with a set number of stages, the falling edge of the pull-up control signal received at its input terminal is aligned with the rising edge

no. 2 example

[0051] Figure 7 It is a schematic diagram of the implementation flow of the driving method of the row driving circuit of the array substrate according to the second embodiment of the present invention. As shown in the figure, it may include the following steps:

[0052] S710. Determine the different pull-up control signals corresponding to the array substrate row driving modules of the set number of stages. For each array substrate row driving module of the set number of stages, the falling edge of the corresponding pull-up control signal is connected The rising edge of the pole signal is aligned.

[0053] Taking the array substrate row driving modules with the set number of stages as the first two-stage array substrate row driving modules as an example, the first two-stage array substrate row driving modules include a first-stage array substrate row driver module and a second-stage array substrate row driver module. module, the first pull-up control signal corresponding to the

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap