Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

8 results about "High surface" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-surface-quality hot-galvanized transformation induced plasticity (TRIP) steel plate and manufacturing method thereof

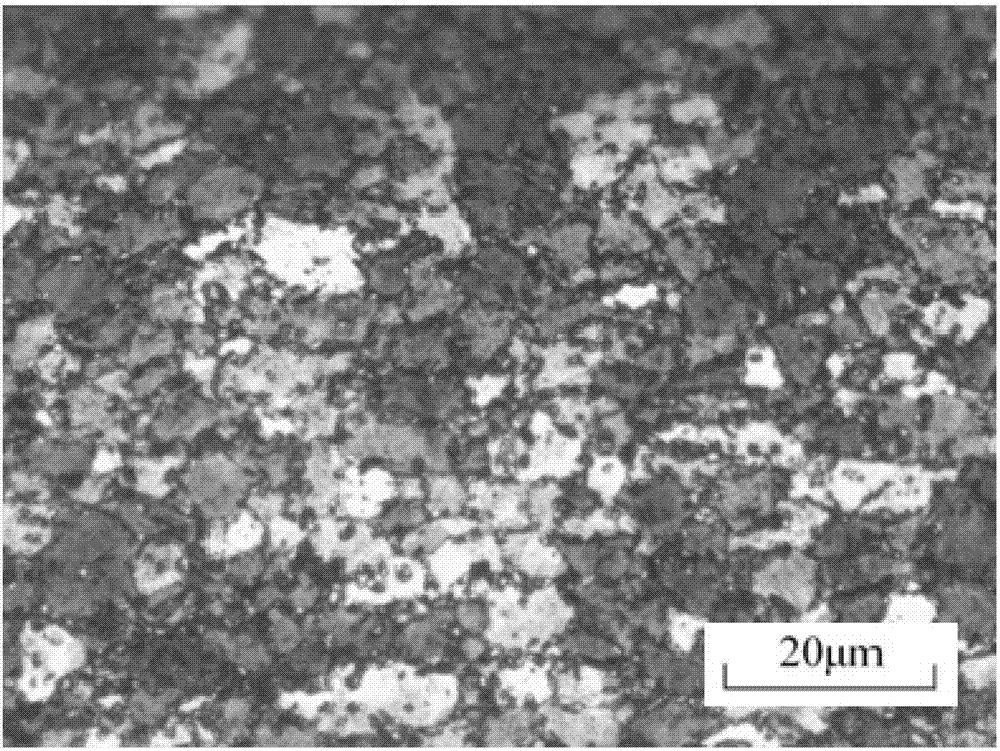

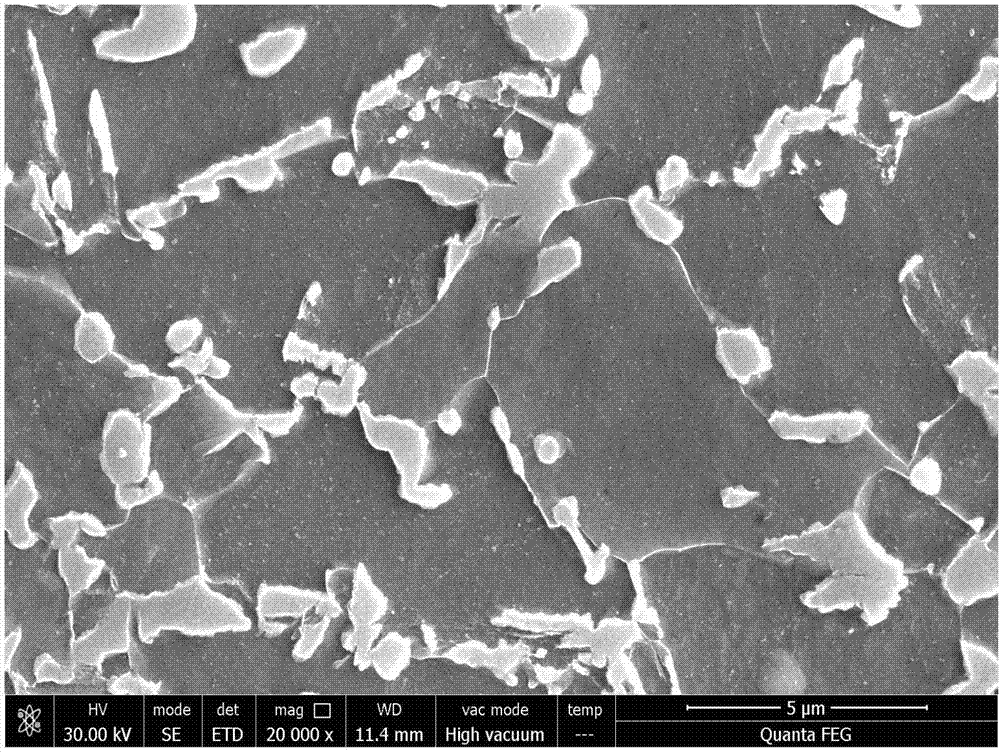

ActiveCN106868403AImprove performanceGood coating performanceHot-dipping/immersion processesFurnace typesSteelmakingHigh surface

Owner:MAGANG (GROUP) HOLDING CO LTD +1

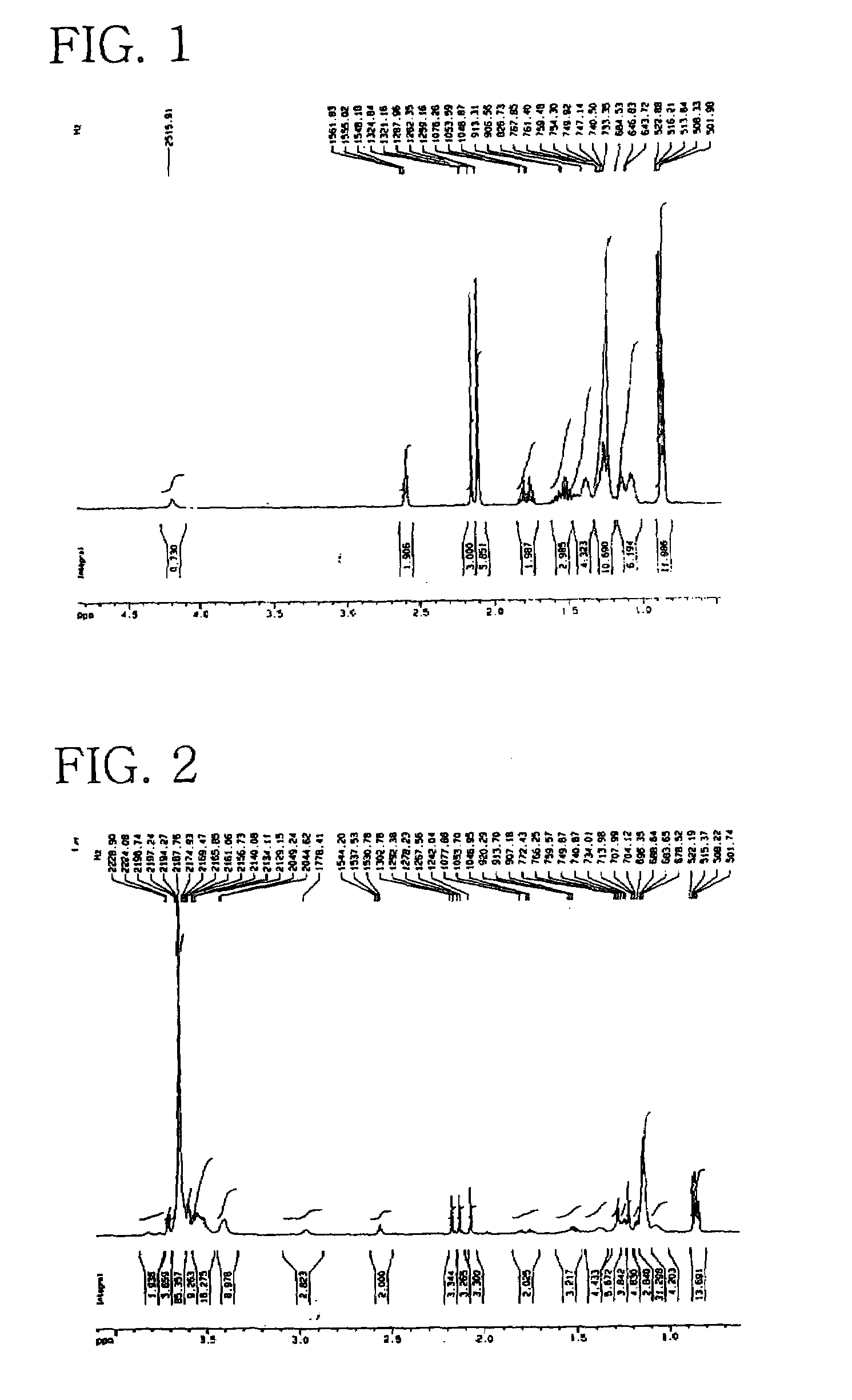

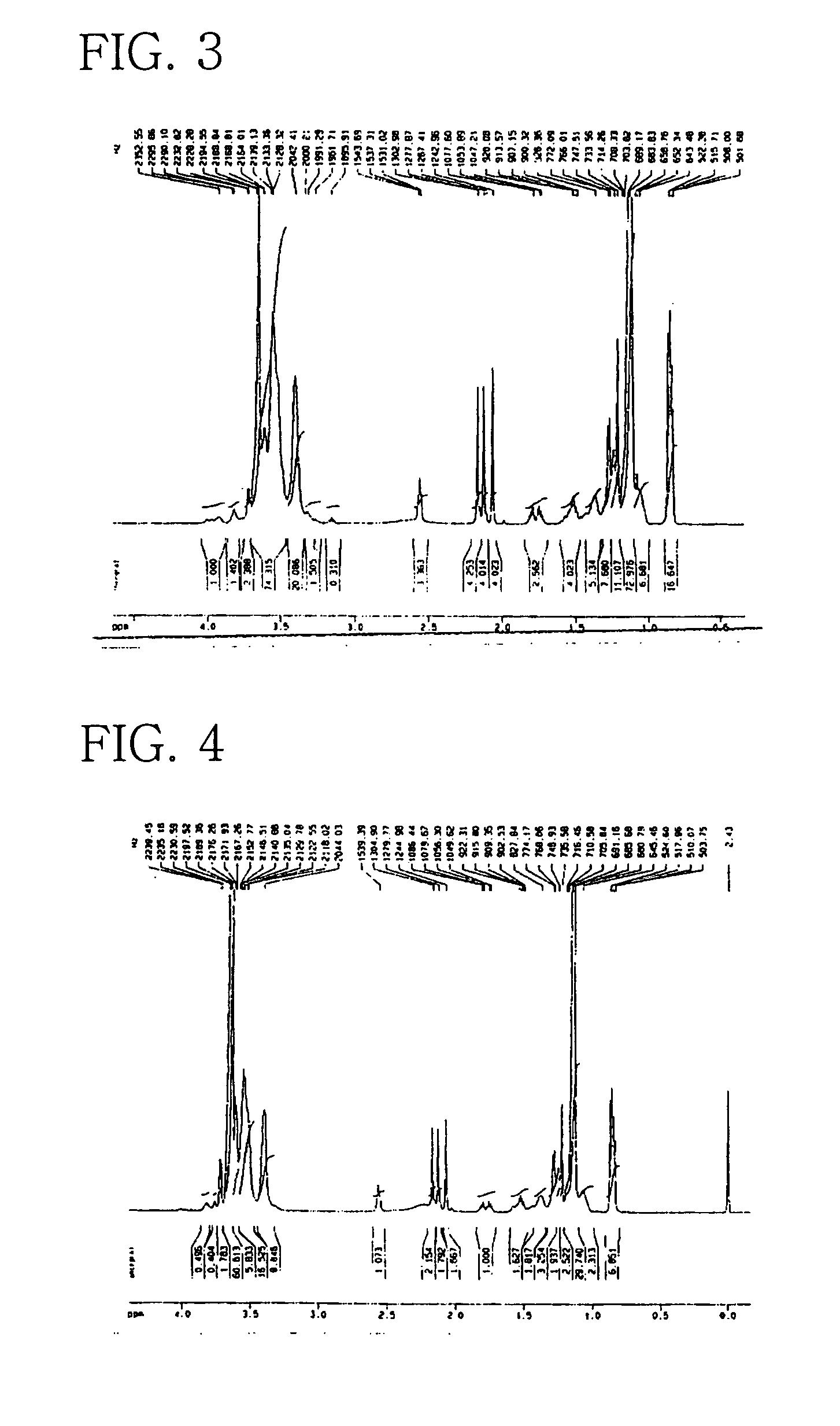

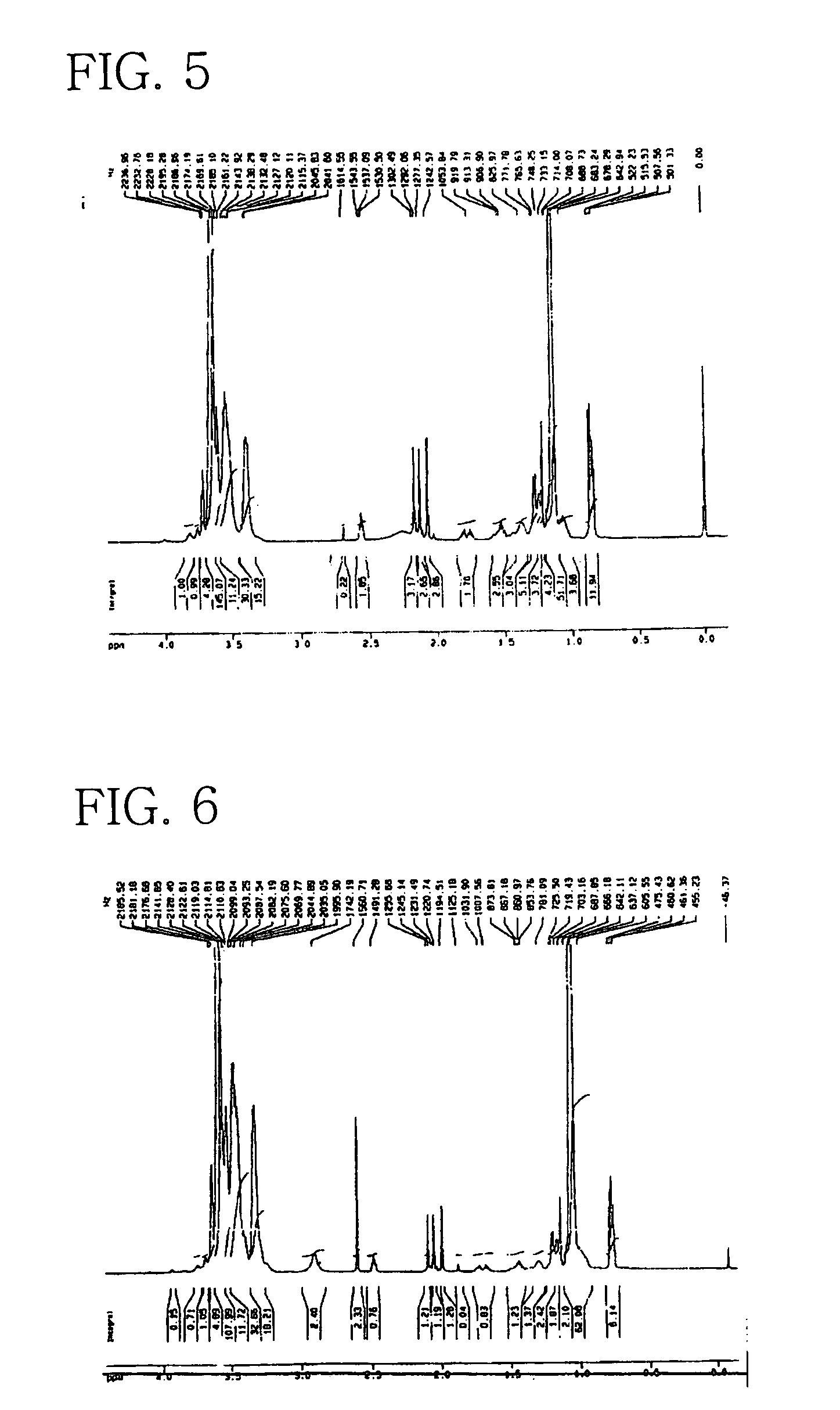

Polyoxyethylene-polyoxypropylene vitamin E and process for preparation thereof

InactiveUS7144919B1Increase the areaIncrease in sizeBiocideOrganic active ingredientsHigh surfaceCosmetic industry

Owner:KIM YOUNGDAE +3

Fluorine-carbon surfactant and method of producing the same

InactiveCN101279217AReduce surface tensionReduce manufacturing costTransportation and packagingMixingAdditive ingredientHigh surface

Owner:上海亚孚化工科技有限公司

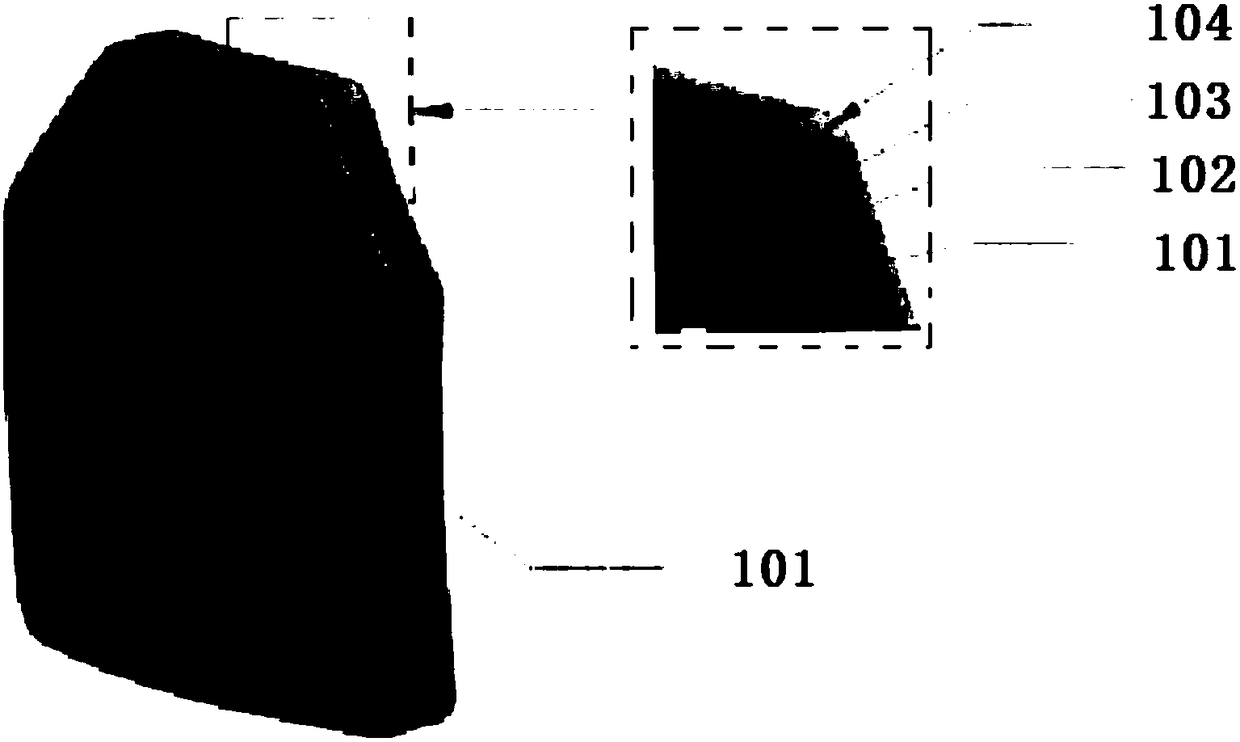

Packaging method of SMD type LED with lens

The invention relates to a packaging method of an SMD type LED with a lens. Slice arrangement is directly carried out an electroplated SMD type LED patch support; adhesive dispersing is carried out on a die bonder to fix a chip; a fixed chip support box is placed in an oven and a crystal bonding adhesive is baked, so that the fixed chip support box is solidified; and then the solidified chip support box is placed in a welding wire machine and a gold wire or an alloy wire are employed to enable a P / N junction of the chip to be bonded with the support; and the bonded support is directly discharged into a moulding die with a lens and a press machine is utilized to inject a silicon resin or a silica gel into the moulding die, so that one-time injection moulding of an SMD type LED with a lens is completed. According to the packaging method of the SMD type LED with a lens in the invention, an injection method is utilized to produce the SMD type LED with a lens; and the output is high and the consistency is high; besides, the LED has high surface smooth finish and is free of air bubbles; a bonding force between materials is good; and injection and moulding can be completed once.

Owner:HUBEI KUANGTONG ELECTRONICS

Cutter system for super-speed cutting of numerically-controlled machine tool

ActiveCN107020535AHigh cutting speedImprove machining accuracyDriving apparatusNumerical controlAviation

The invention discloses a cutter system for super-speed cutting of a numerically-controlled machine tool. The system comprises a main shaft, a housing, a locking sleeve and a cutter. The system is characterized in that the upper end of the main shaft is connected with the numerically-controlled machine tool; an input bearing is mounted at the lower end of the main shaft and positioned on the housing; the main shaft is connected with a rotating frame, and a crankshaft is mounted on the rotating frame; an epicycloidal wheel and a cycloidal wheel bearing are mounted in the middle part of the crankshaft, and a planet gear which is engaged with a sun gear is mounted at the lower end of the crankshaft; an output bearing is mounted on the sun gear and positioned on the housing; the sun gear is connected with the upper end of the locking sleeve, and the lower end of the locking sleeve is connected with the cutter. The system has the beneficial effects that the cutting rotation speed is extremely high during the processing of aviation and precision optical devices; the processing effect is good; the processing accuracy is high; extremely high surface roughness can be obtained; the actual engineering requirement of high-speed cutting can be met; the technological gaps can be filled; and moreover, the social benefit and the economic benefit are high.

Owner:TIANJIN POLYTECHNIC UNIV

Method for preparing nanometer copper powder by recycling copper from etching liquid

The invention discloses a method for preparing nanometer copper powder by recycling copper from etching liquid. The method is characterized by comprising the following steps of: step 1. extracting waste etching liquid; step 2. carrying out back extraction; step 3. preparing microemulsion; step 4. carrying out electro-deposition; step 5. collecting the nanometer copper powder; and step 6. drying and packaging. The invention also provides the nanometer copper powder prepared by the method. According to the method for preparing the nanometer copper powder by recycling the copper from the etching liquid, raw materials are wide in source and low in price, the process is short, and the equipment investment is low; and the product has the advantages of controllable morphology and particle size, high purity, high surface activity, a large specific surface area and good dispersity, and is suitable for continuous large-scale production.

Owner:江苏净源新材料有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap