Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

21 results about "Injection moulding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Injection moulding is a manufacturing process for producing parts by injecting molten material into a mould. Injection moulding can be performed with a host of materials mainly including metals (for which the process is called die-casting), glasses, elastomers, confections, and most commonly thermoplastic and thermosetting polymers. Material for the part is fed into a heated barrel, mixed (Using a helical shaped screw), and injected (Forced) into a mould cavity, where it cools and hardens to the configuration of the cavity. After a product is designed, usually by an industrial designer or an engineer, moulds are made by a mould-maker (or toolmaker) from metal, usually either steel or aluminium, and precision-machined to form the features of the desired part. Injection moulding is widely used for manufacturing a variety of parts, from the smallest components to entire body panels of cars. Advances in 3D printing technology, using photopolymers which do not melt during the injection moulding of some lower temperature thermoplastics, can be used for some simple injection moulds.

Fine die cast metallic parts

InactiveUS20050087320A1Minimize amount of gasGreat dimensionPorosityDie casting

A finished molded metal part is produced by an injection molding system includes a feeder in which a metal is melted and a first chamber into which a desired amount of melted metal is introduced. The molded metal parts can have extremely fine dimensions, small thicknesses, and indented or protruding surface features that are molded with such low porosity that no further milling / finishing operation is required before the part is used in its finished state.

Owner:TAKATA CORPORATION

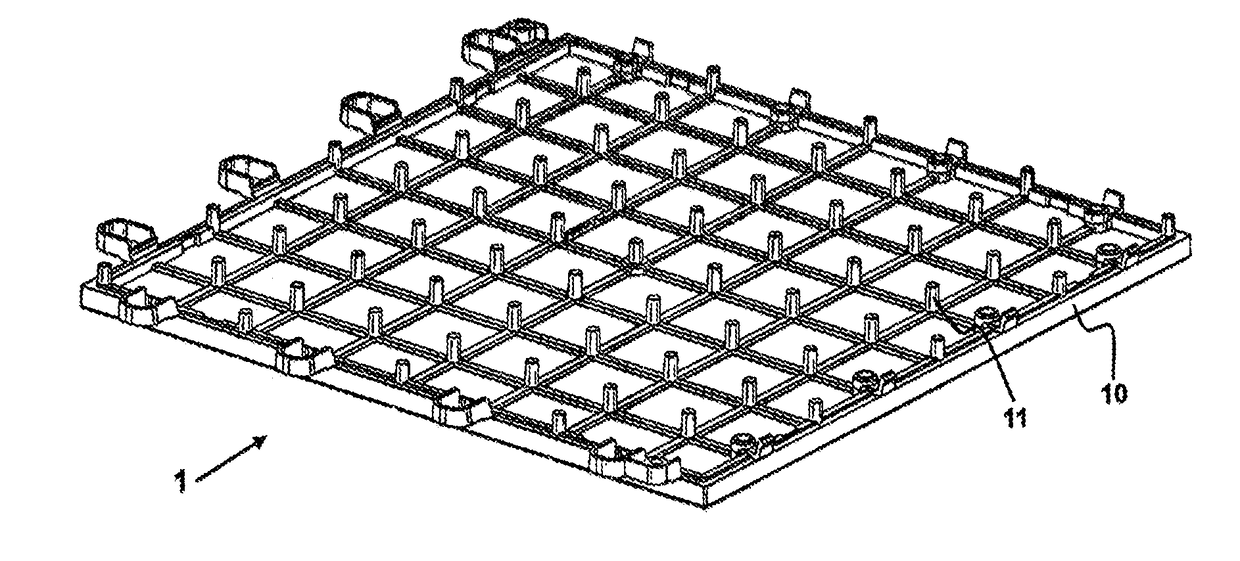

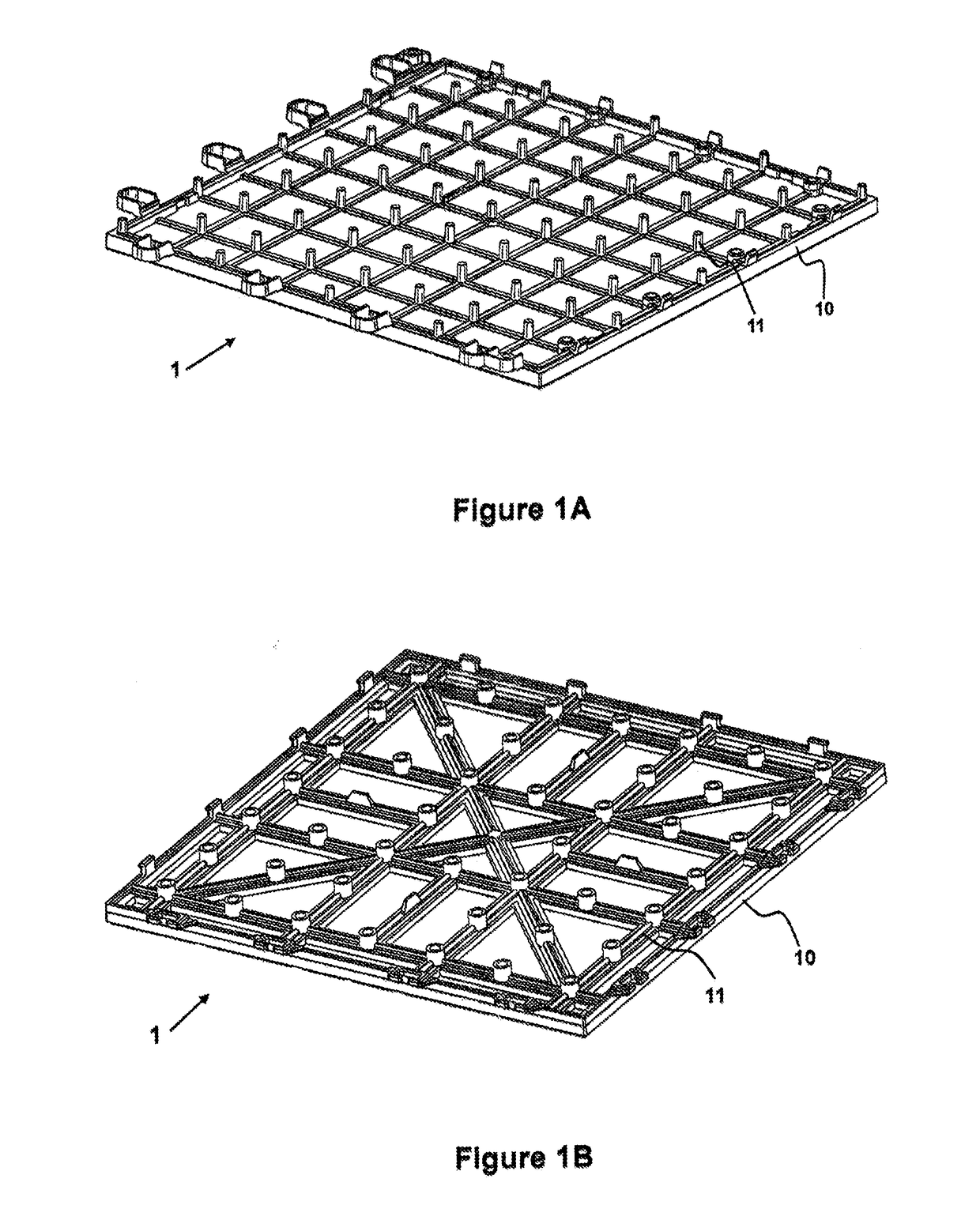

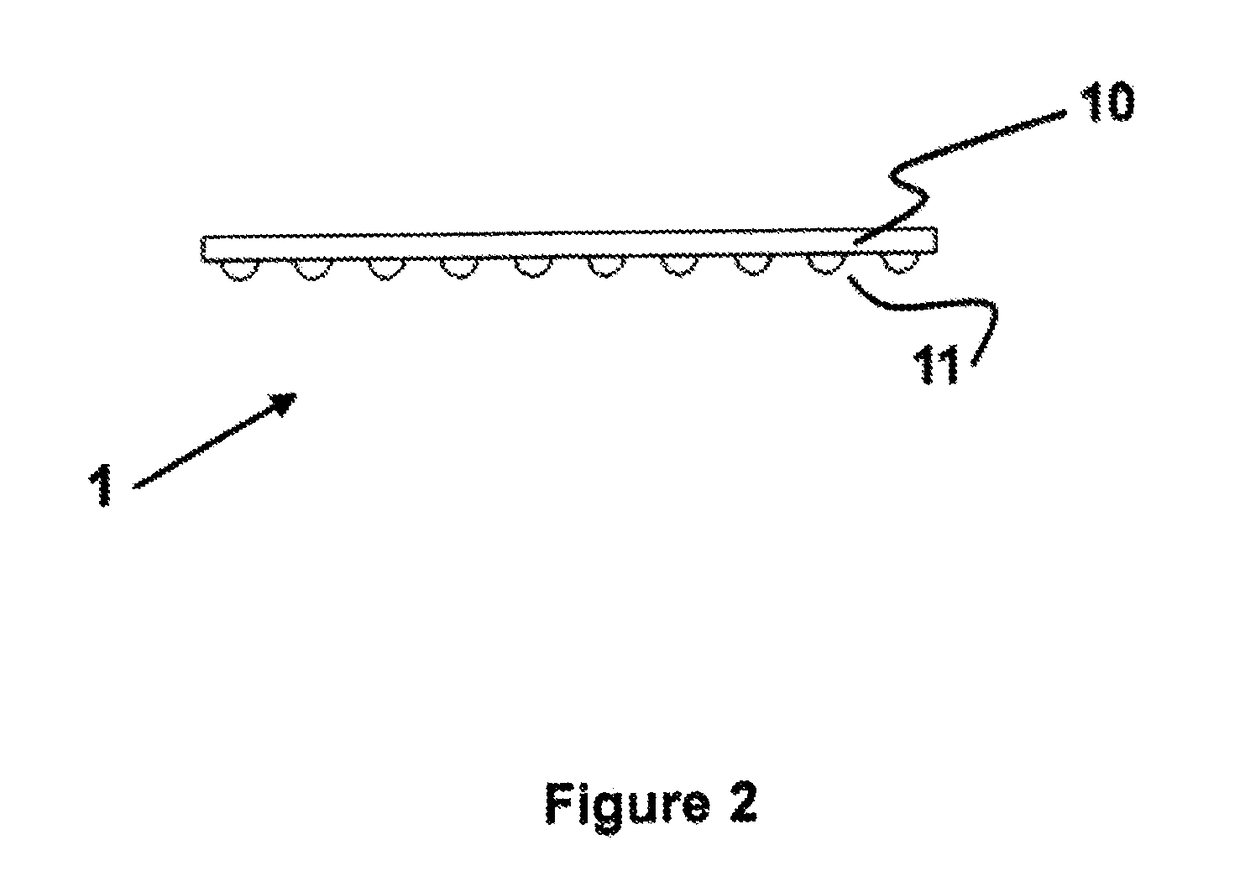

Production of two-layer composite deck tile by injection molding method

InactiveUS20170081862A1Eliminate disadvantagesEnhanced advantageSingle unit pavingsSynthetic resin layered productsOutdoor areaInjection moulding

Owner:SEMA PLASTIK KALIP VE MAKINE SANAYI VE TICARET LTD STI

Injection moulding process of polyethylene (PE) material pieces for infusion apparatus

Owner:江西科伦医疗器械制造有限公司

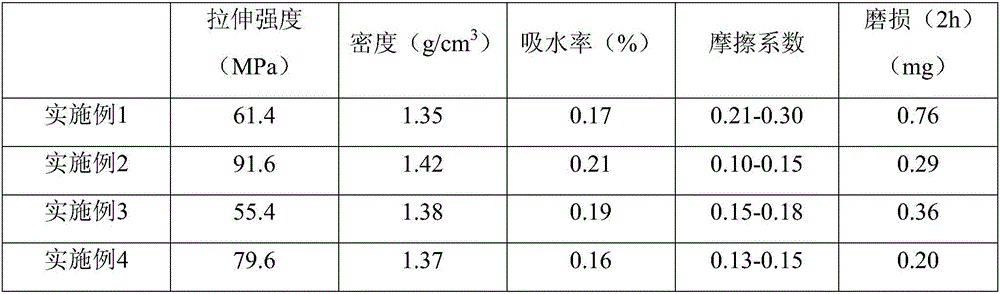

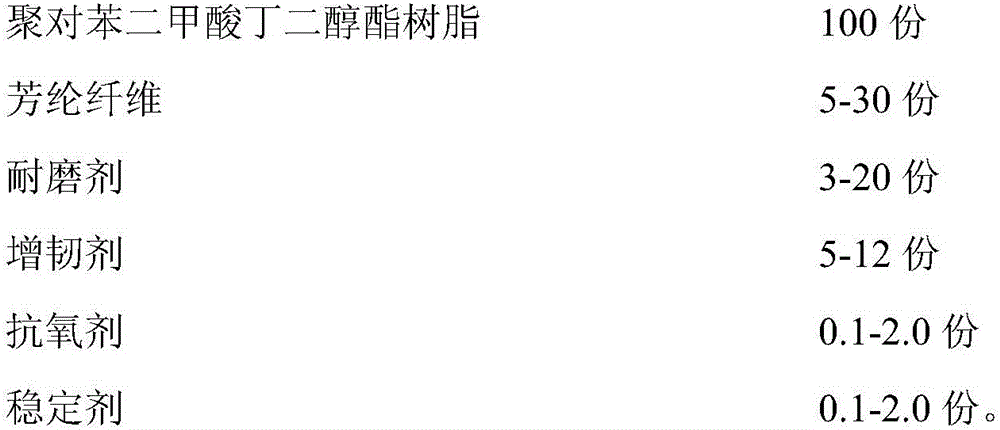

High-molecular self-lubricating material, preparation method of high-molecular self-lubricating material, and plate spring flanged bushing made of high-molecular self-lubricating material

InactiveCN106633695AWith wear resistanceGood dimensional stabilityResilient suspensionsVehicle springsPolytetramethylene terephthalateAntioxidant

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

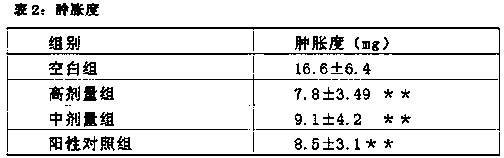

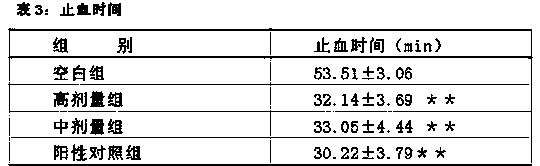

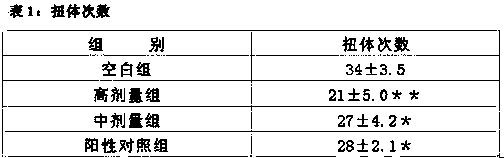

Suppository for treating haemorrhoids

InactiveCN103830405ALess medicinalEasy to makeAnthropod material medical ingredientsSuppositories deliveryInjection mouldingConstipation

Owner:GUIYANG UNIV

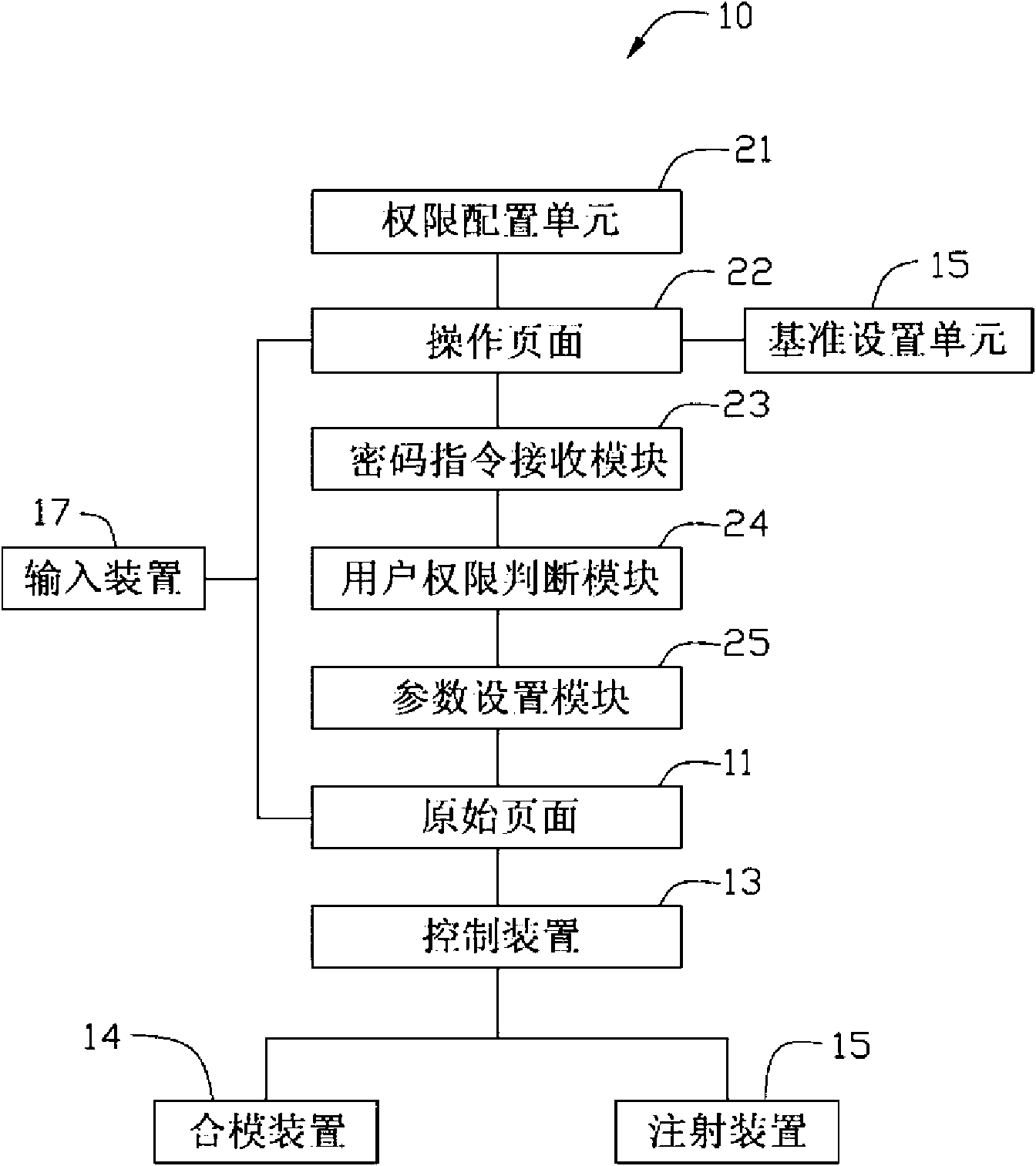

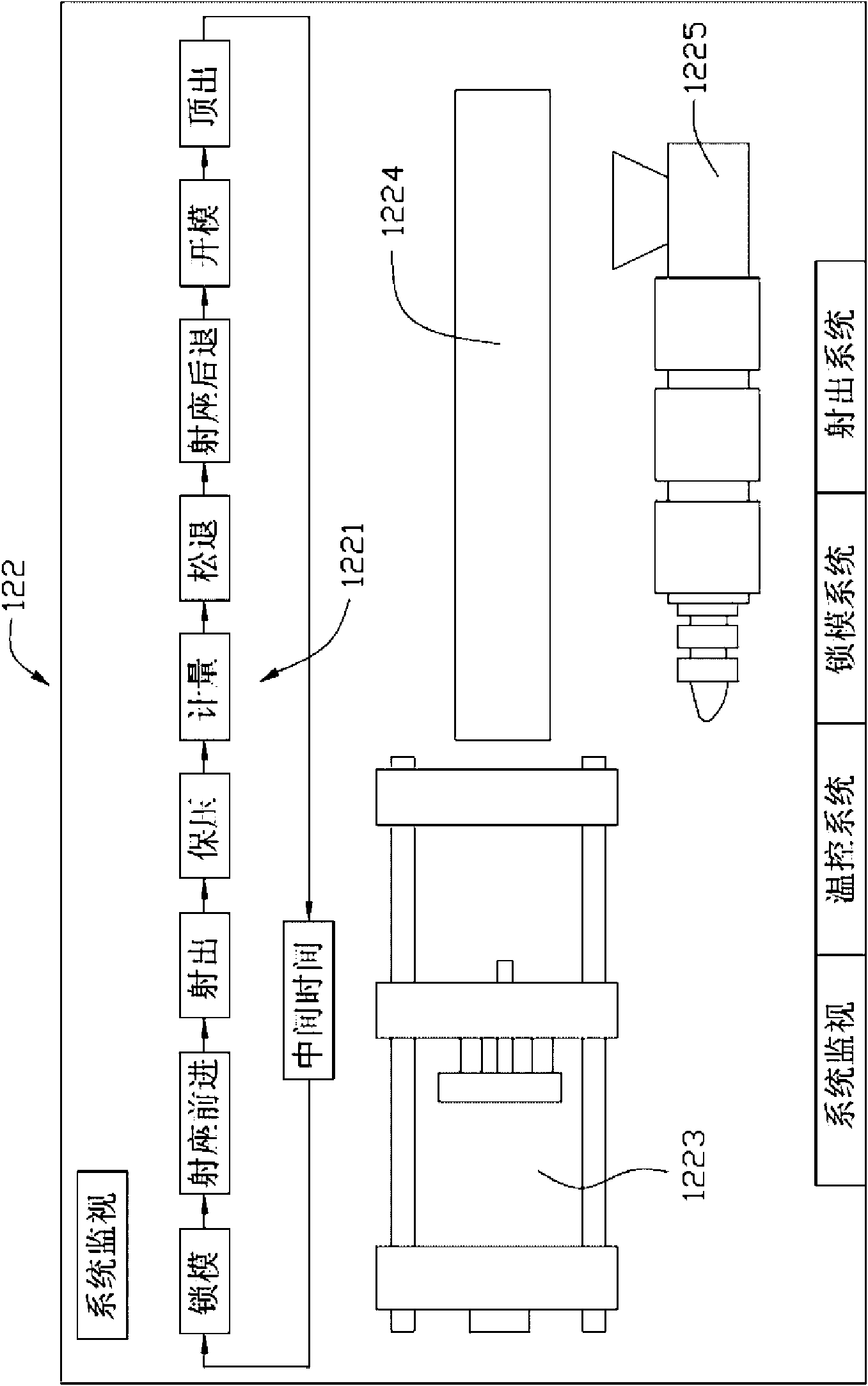

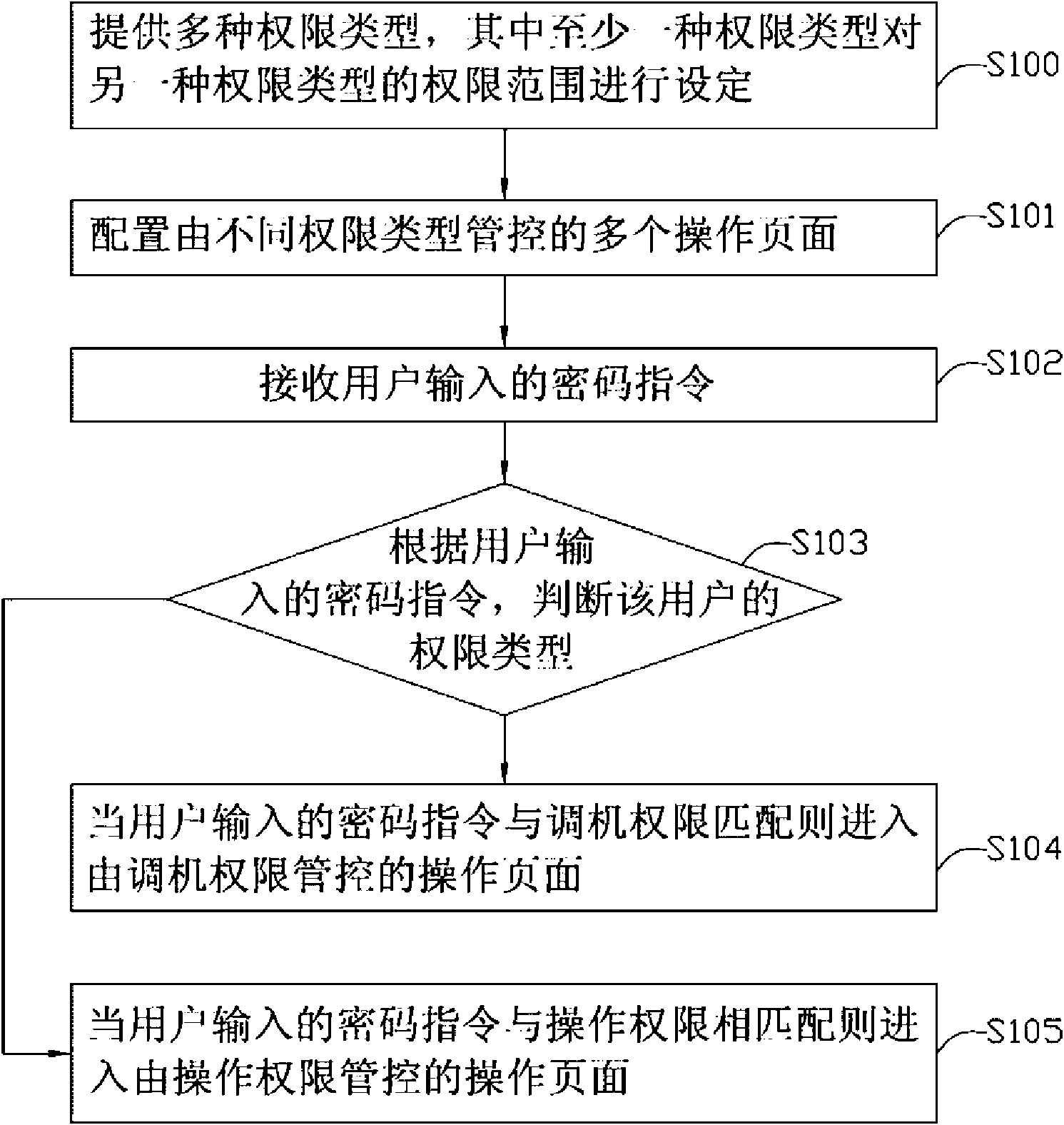

Method for setting control parameters of injection molding machine and injection molding machine

InactiveCN101941278AEasy to controlMeet needsNumerical controlInjection mouldingInjection molding machine

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

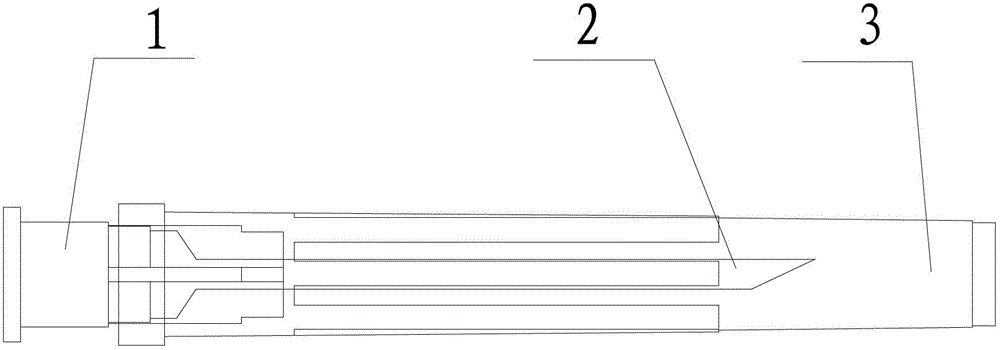

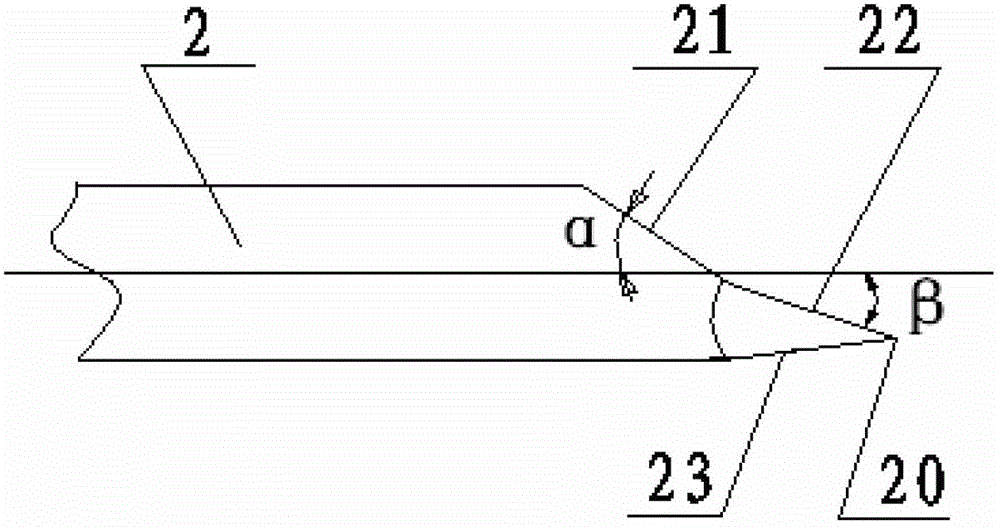

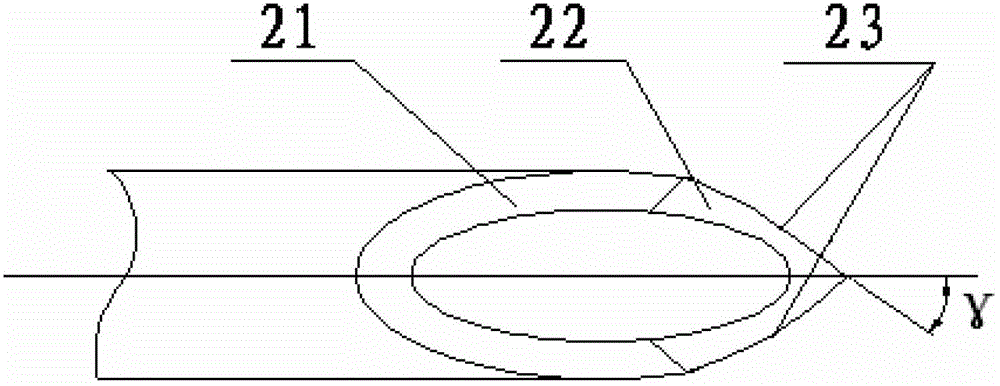

Disposable medical syringe needle

InactiveCN102716531AMeet production requirementsEasy to processInfusion needlesDiseaseInjection moulding

Owner:侯李明

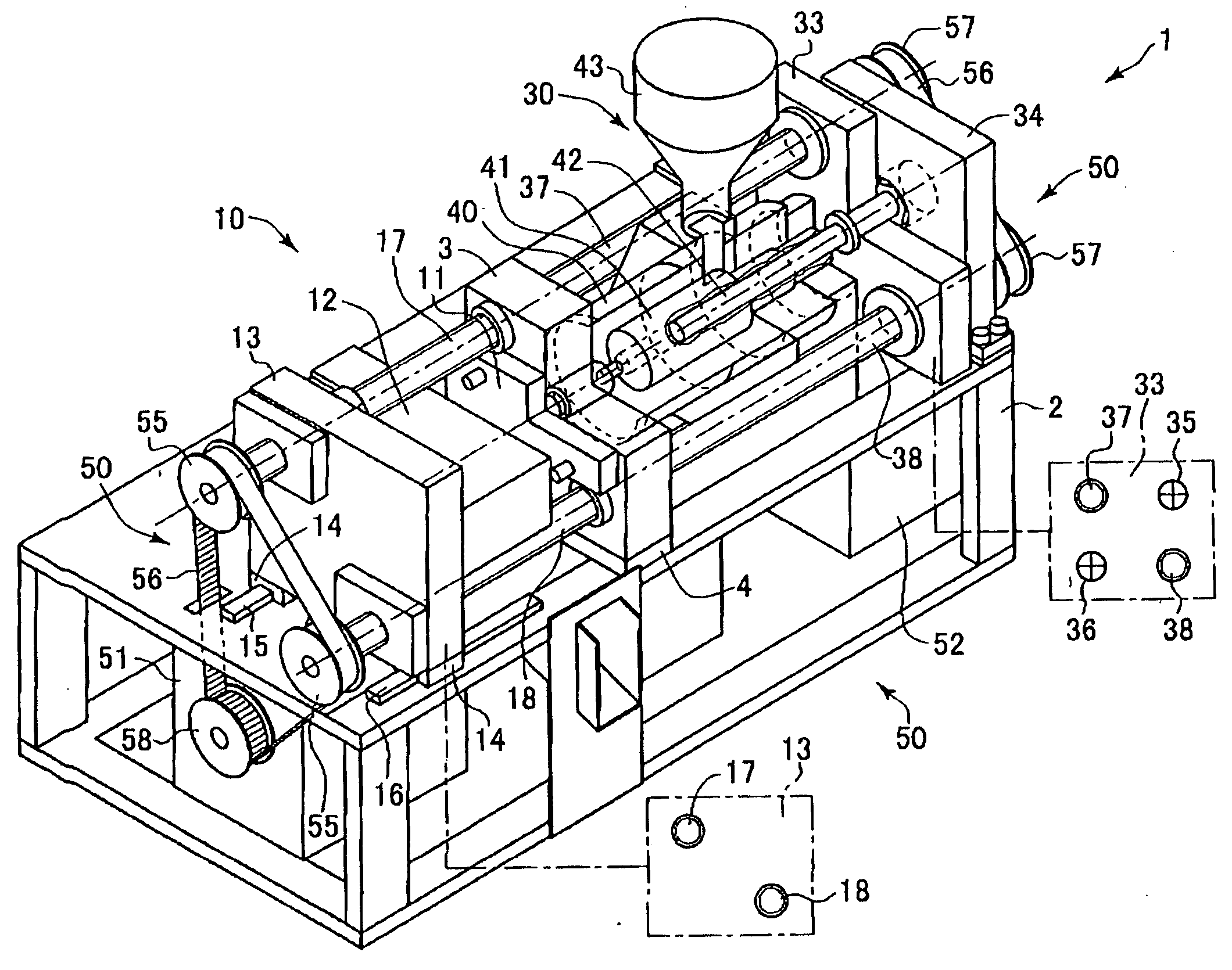

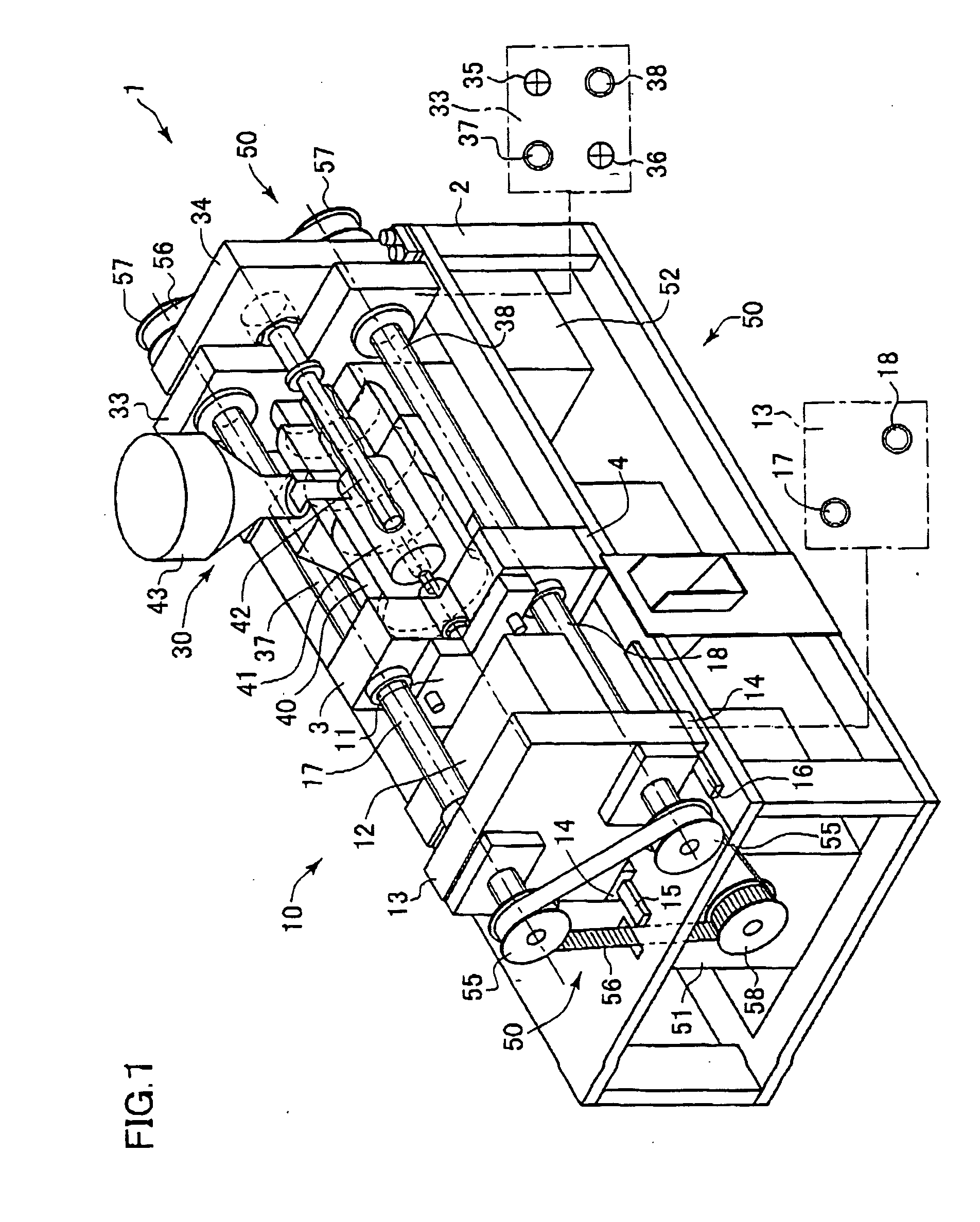

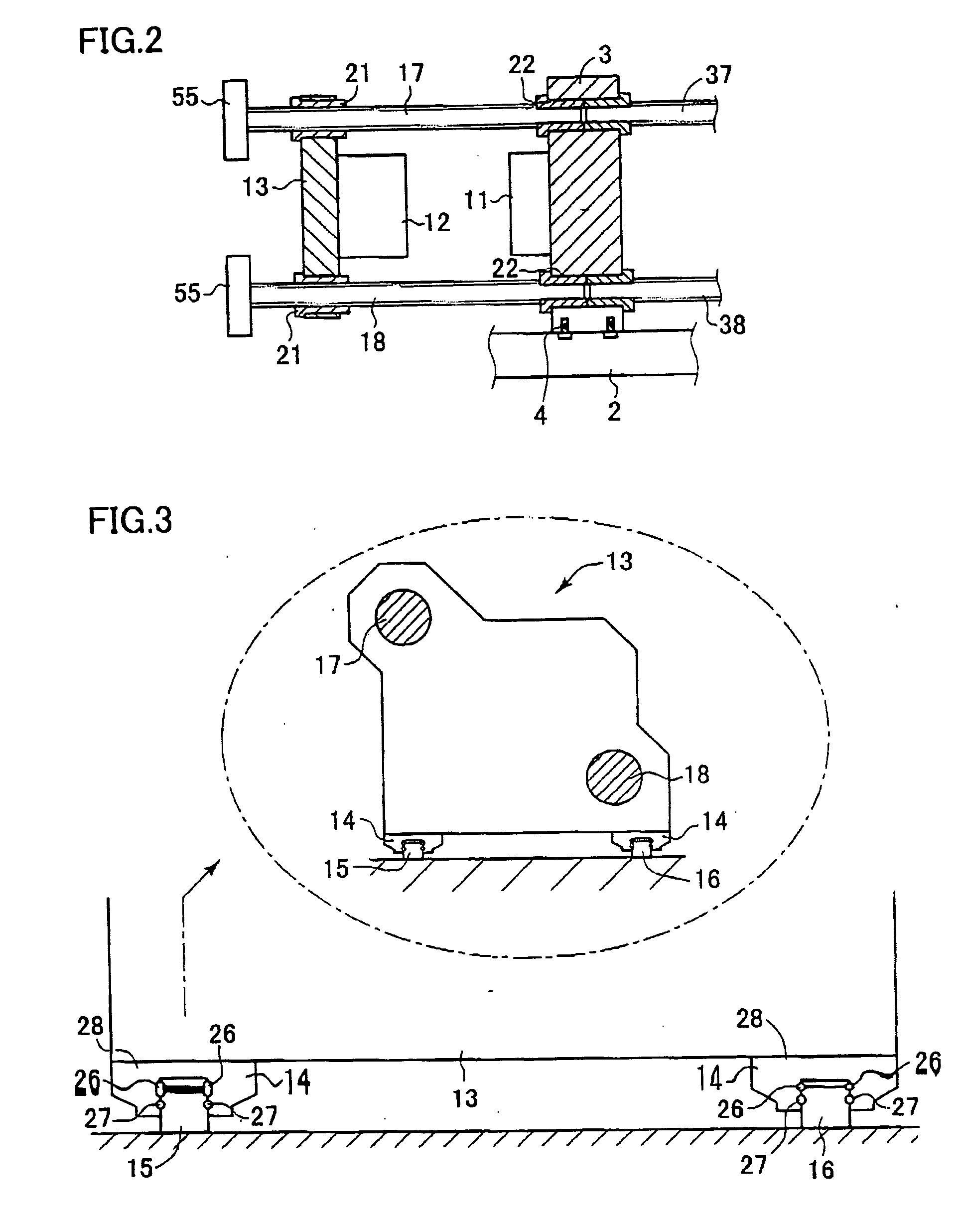

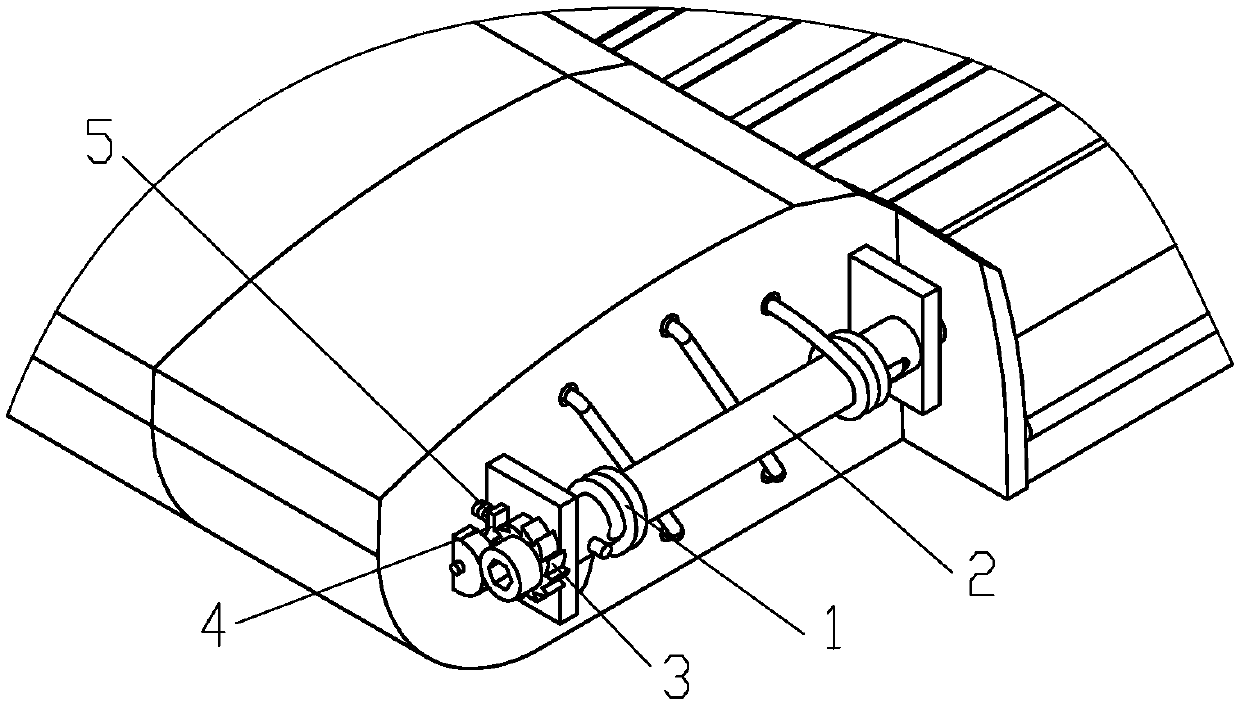

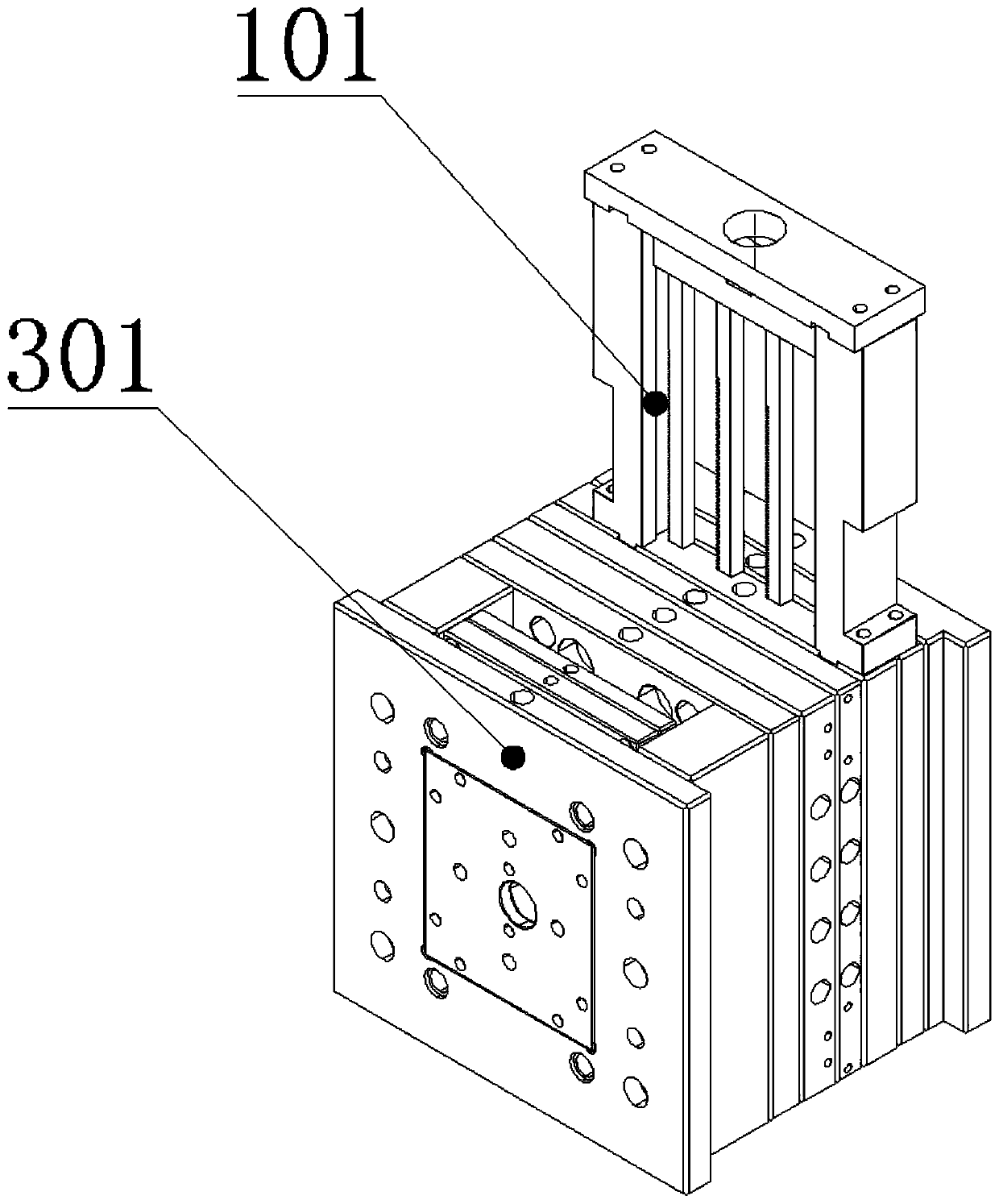

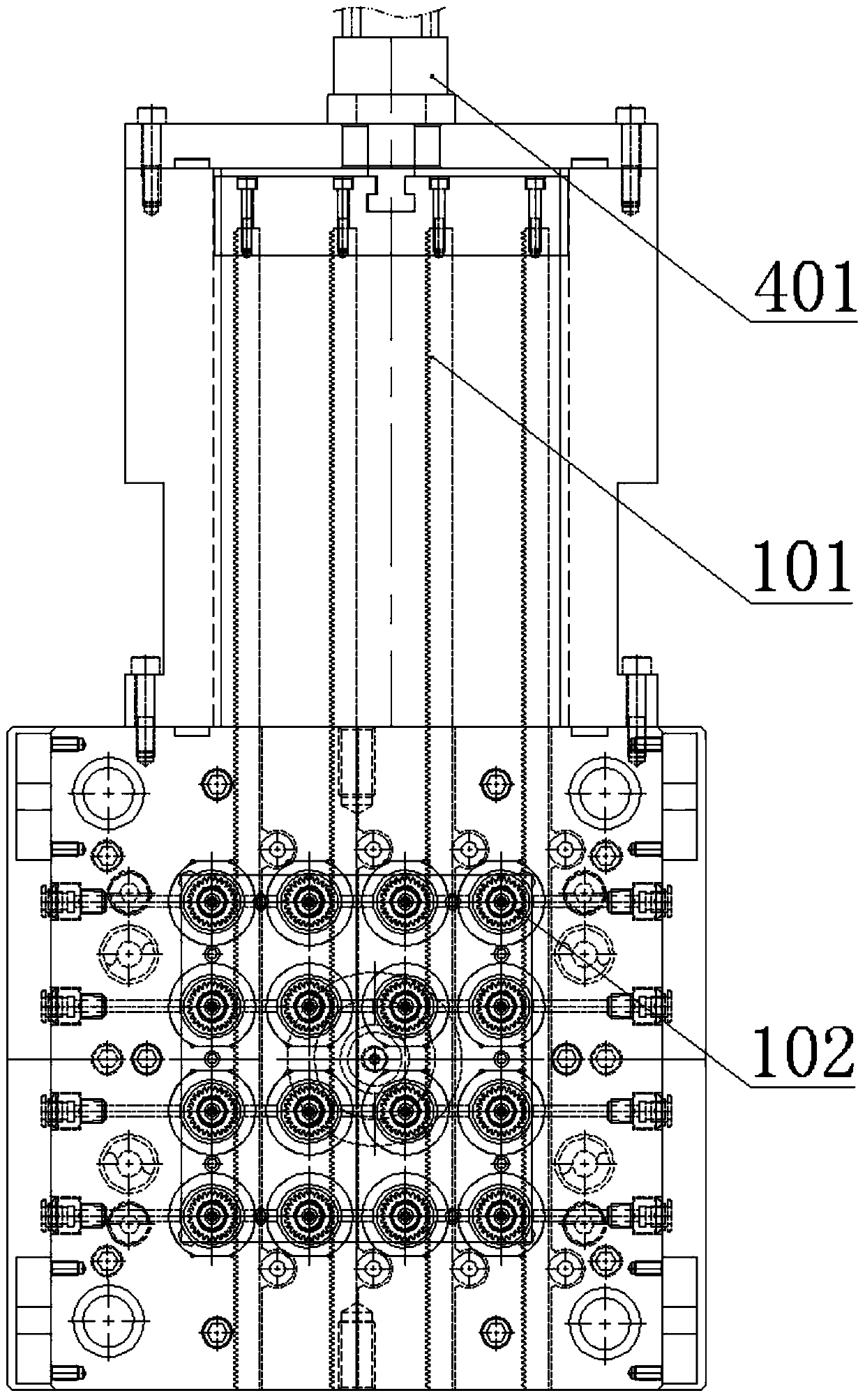

Motor-driven injection molding apparatus

InactiveUS20050074517A1Reduce the number of partsSimple structureCeramic shaping apparatusFood shapingTiming beltBall screw

Owner:DAIWA KASEI IND CO LTD

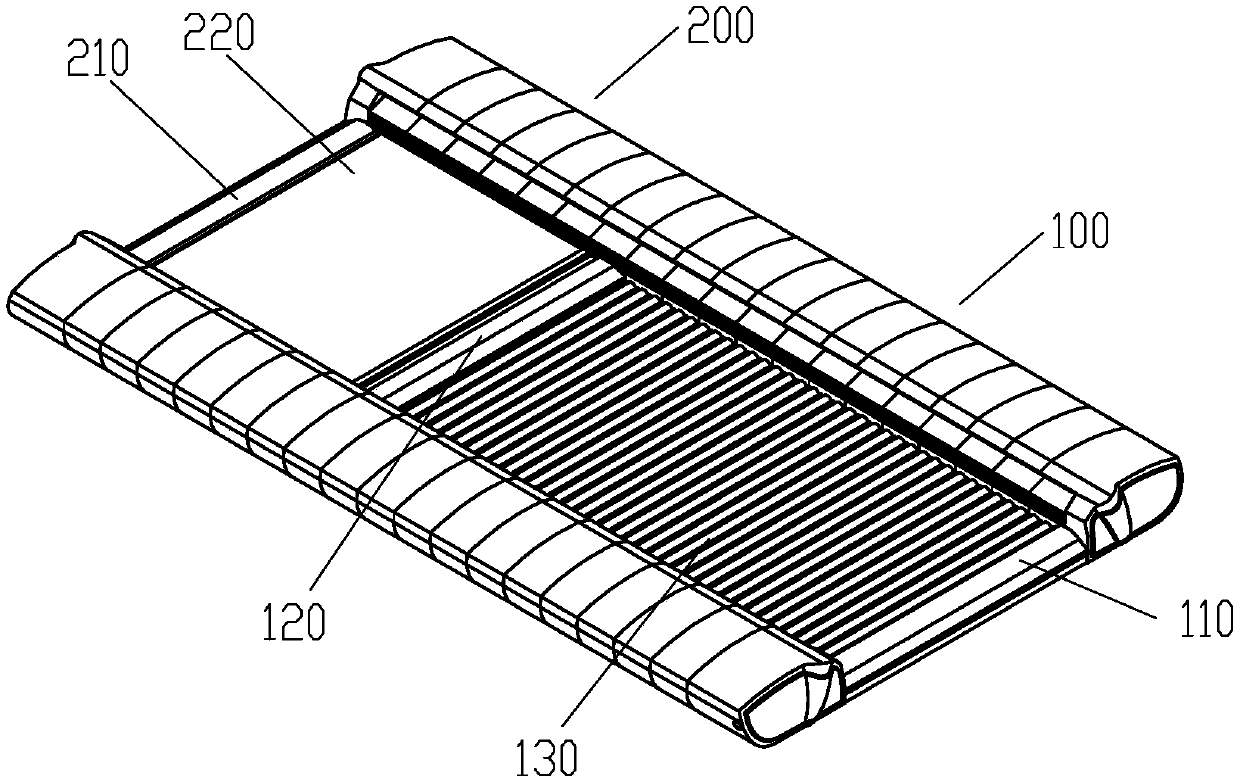

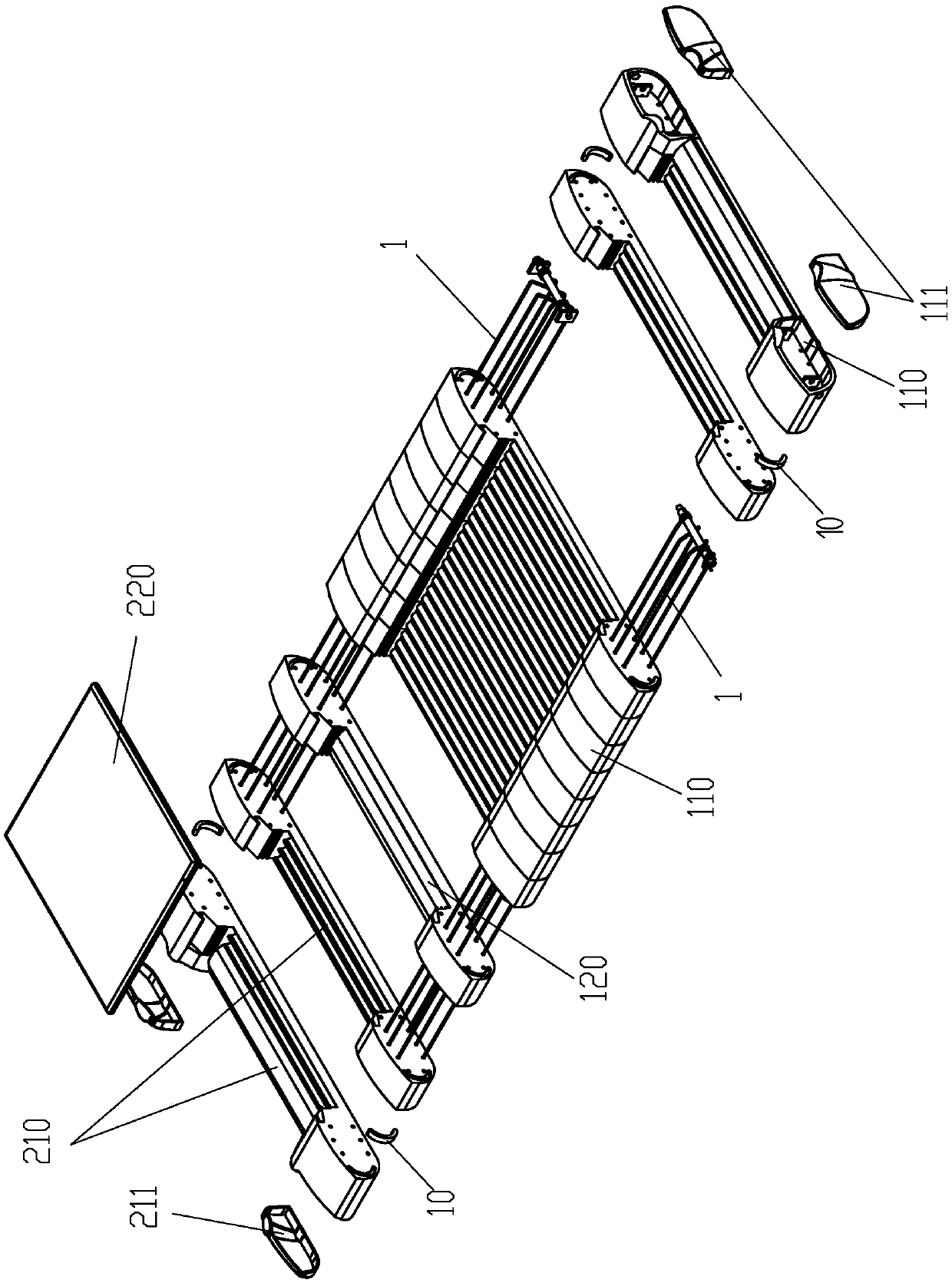

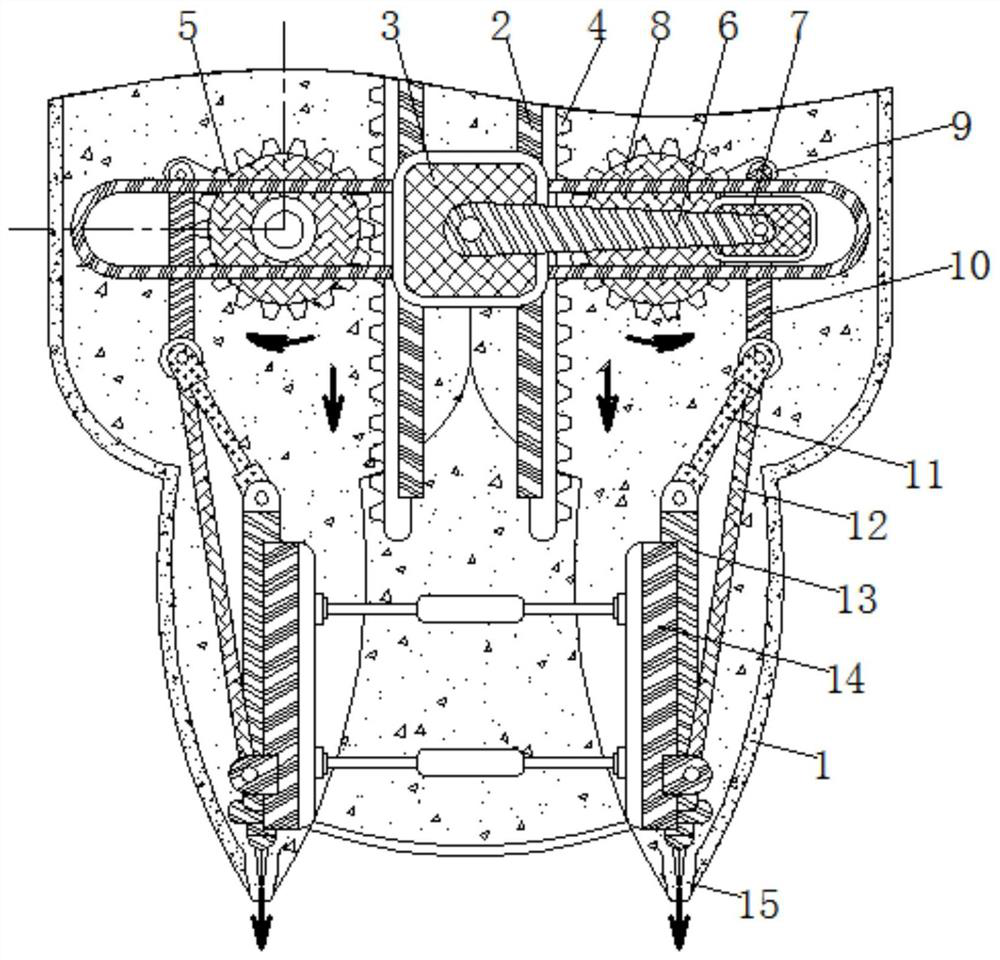

Butting splicing type shoe sole cleaning machine fixed by aid of stays

PendingCN108670168AConducive to addingSimple cavity shapeFootwear cleanersEngineeringInjection moulding

Owner:CHONGQING JIEBANG ELECTRIC CO LTD

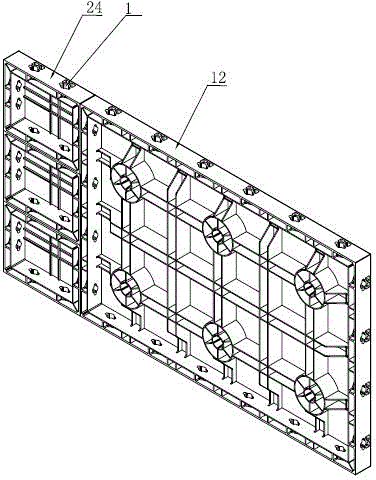

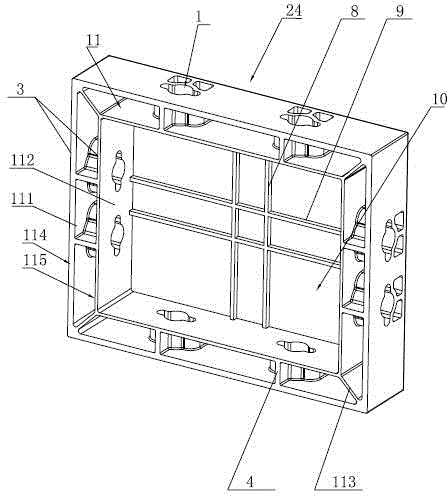

Combined type plane building template structure

InactiveCN104790654AHigh strengthSimple structureForming/stuttering elementsPolypropylene compositesEngineering

Owner:江苏程禾乡创建设发展有限公司

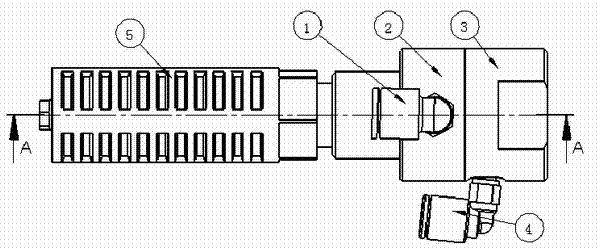

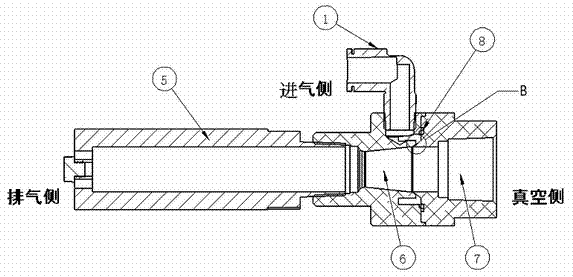

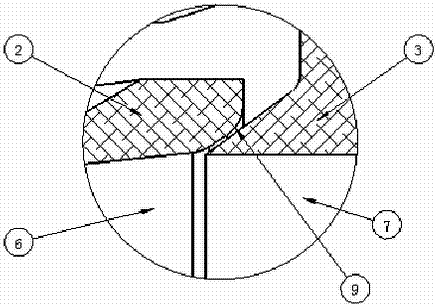

High-flow vacuum generator

InactiveCN104512012AIncrease the size of the acceleration zoneIncrease profitJet pumpsMachines/enginesLow noiseIndustrial equipment

Owner:STAR SEIKI XIANGYANG

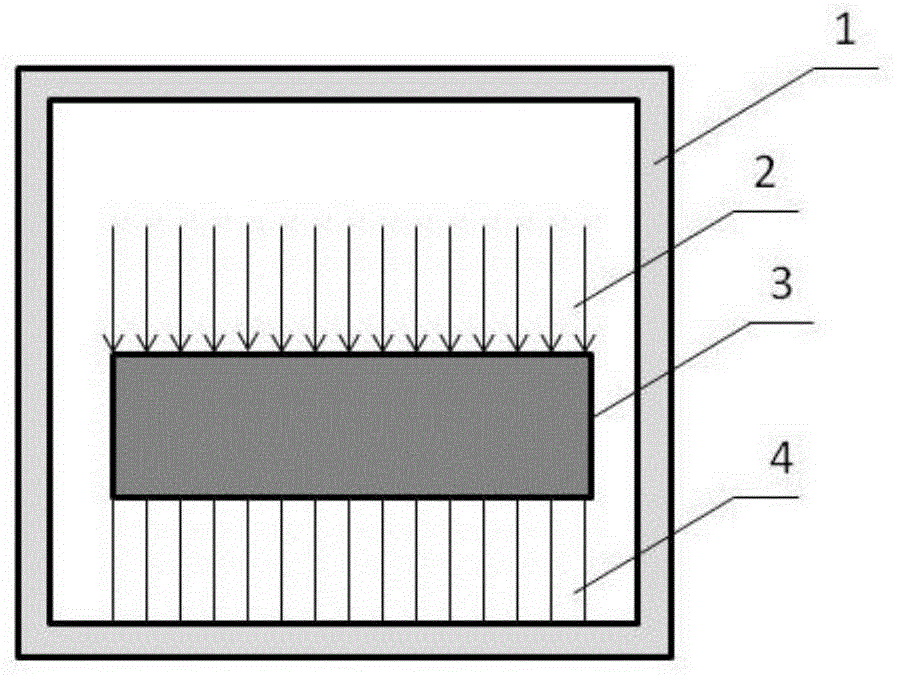

Preparation method for composite polymer film with high thermal conductivity

ActiveCN105128372AHigh thermal conductivityWide variety of sourcesFlat articlesFiberCompression molding

Owner:TSINGHUA UNIV

Device for injection molding

The present disclosure relates to a device for the injection molding of an item including at least one face, a protruding peripheral part provided with an edge for the connection with another face, said device including mold elements movable with respect to each other and jointly cooperating by delimiting therebetween joint planes as well as a cavity intended to be filled with liquid plastic material through injection channels to form said item after the ejection from the mold, characterized in that it includes a mold element to form the protruding part of the item, whose joint plane with the immediately adjacent front mold element is angularly oriented from said edge and on at least a portion of the length thereof, according to the direction of ejection.

Owner:AURAY PLAST

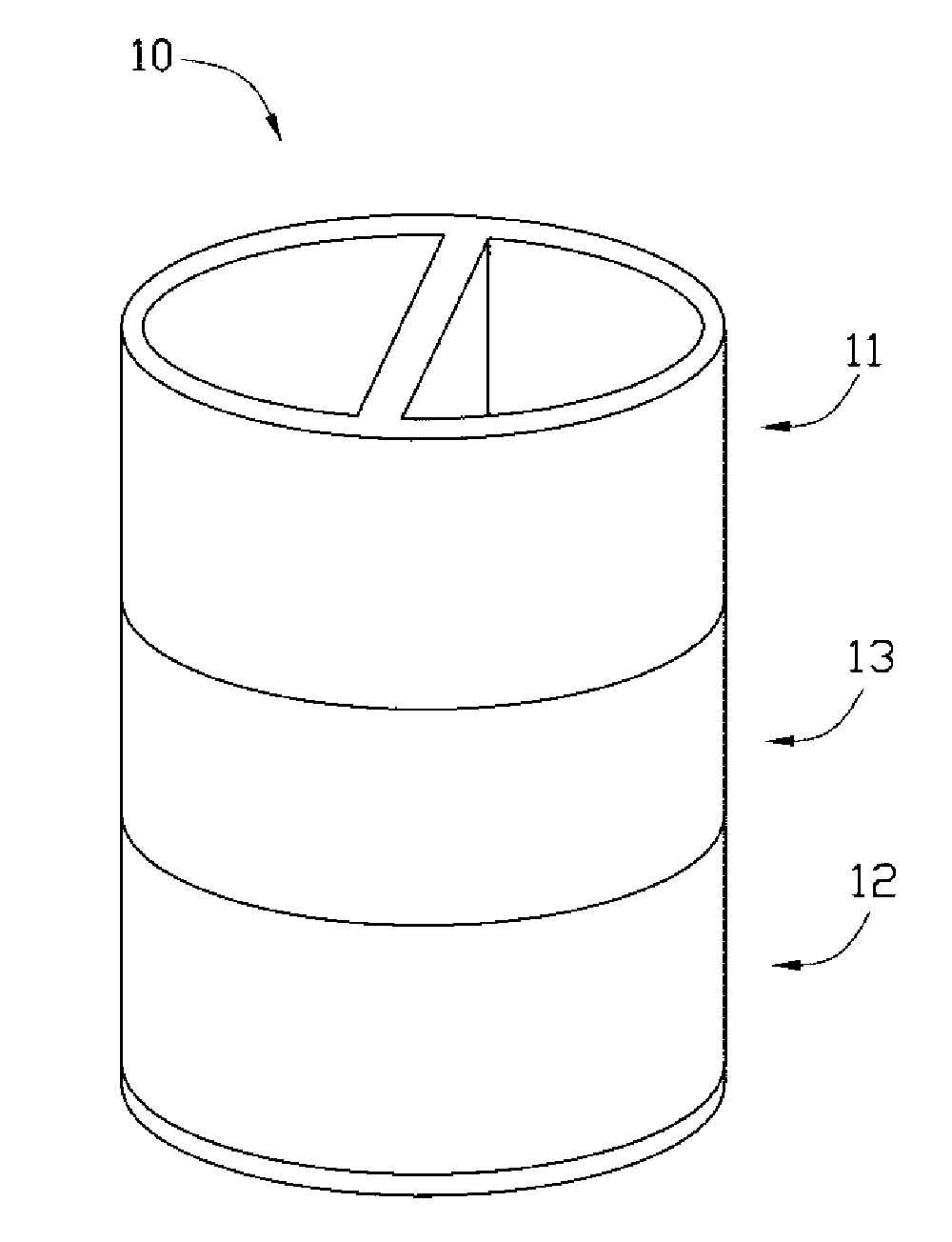

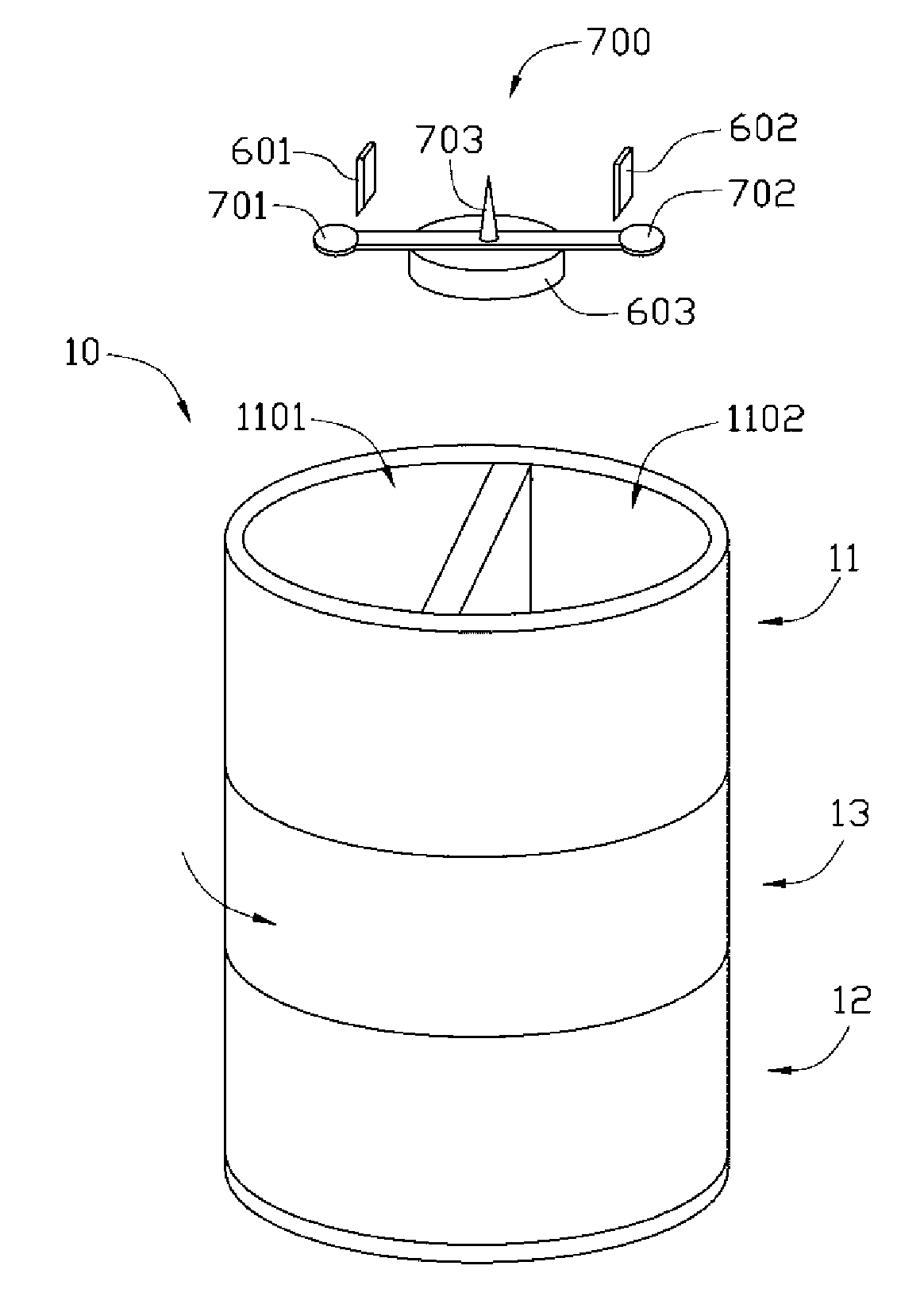

Accommodation device

InactiveCN101554935AEasy to checkEasy to classifyRigid containersInternal fittingsInjection mouldingComputer science

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

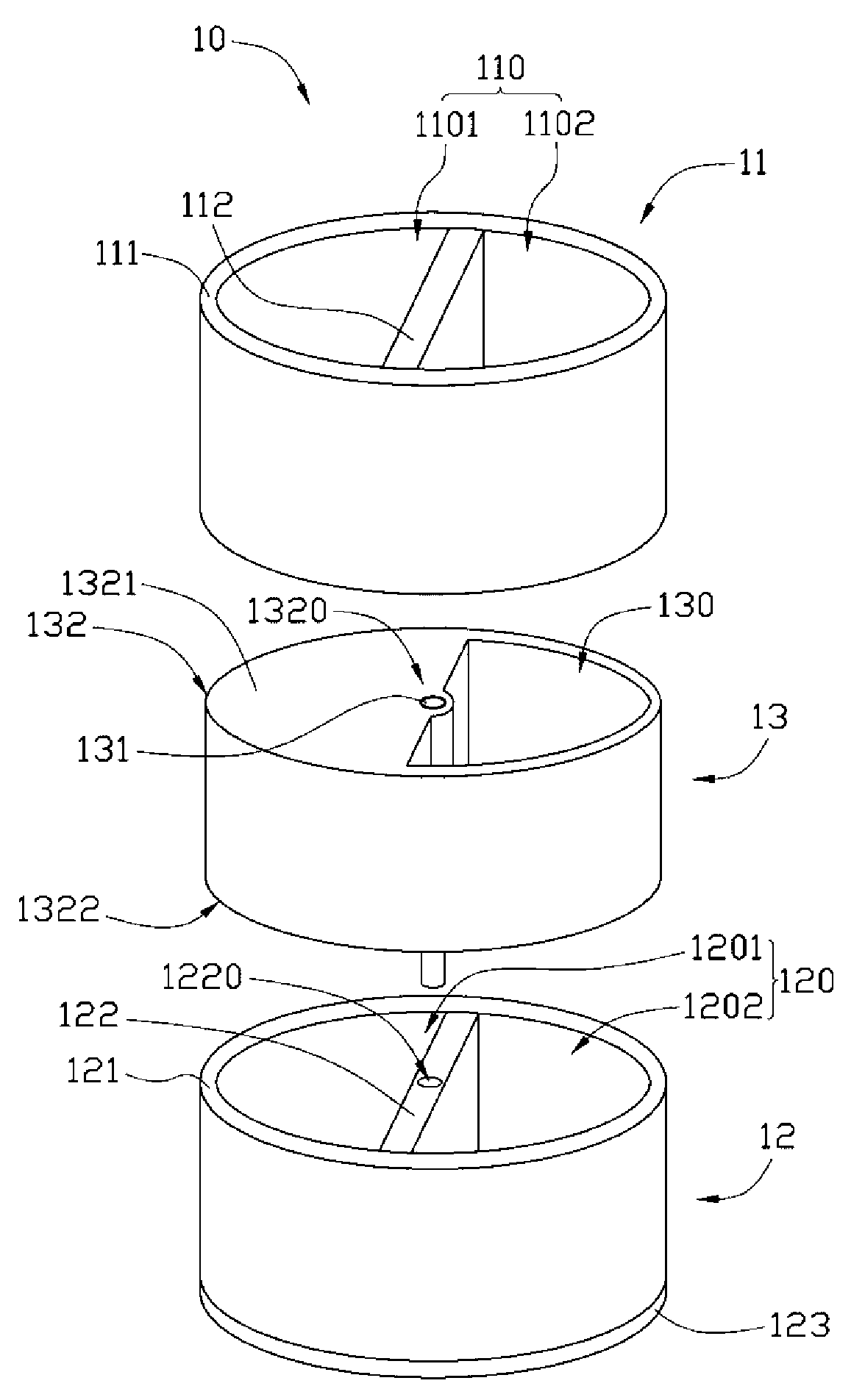

Screw tooth core-returning mechanism and die

Owner:广州莱汇科技有限公司

Efficient injection molding device for automobile bumper production

Owner:WUHU ECHOM SCI & TECH

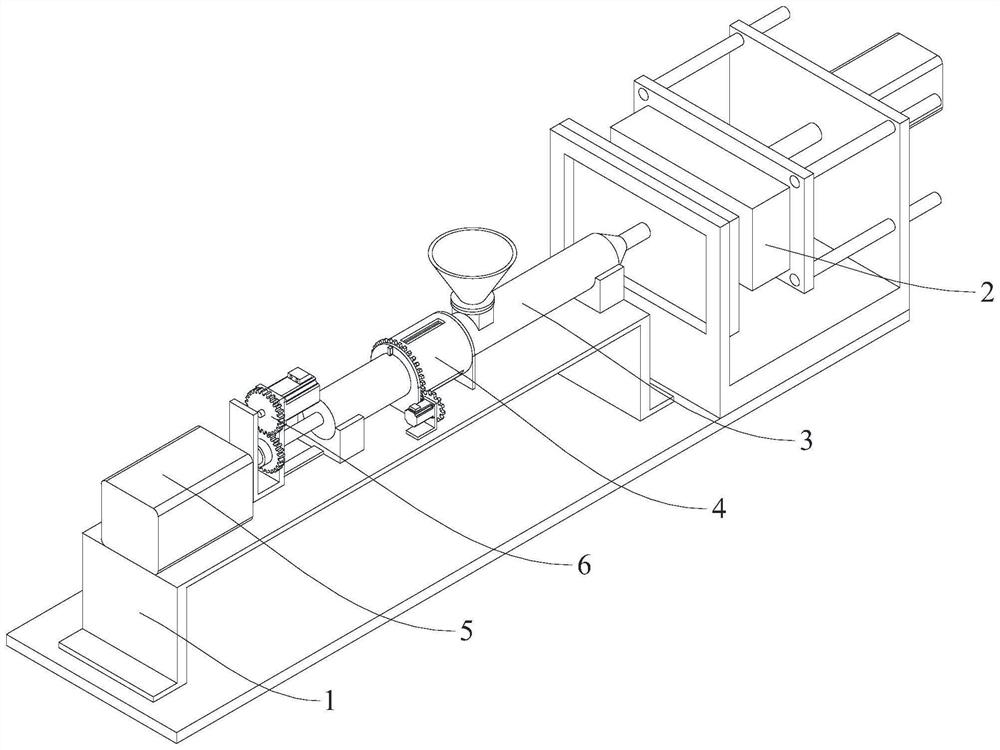

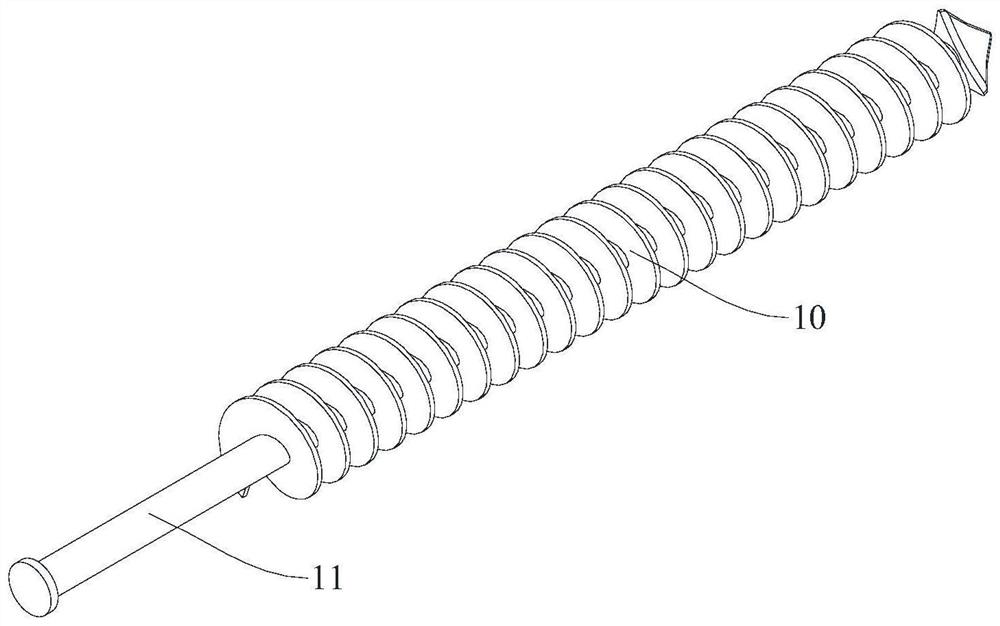

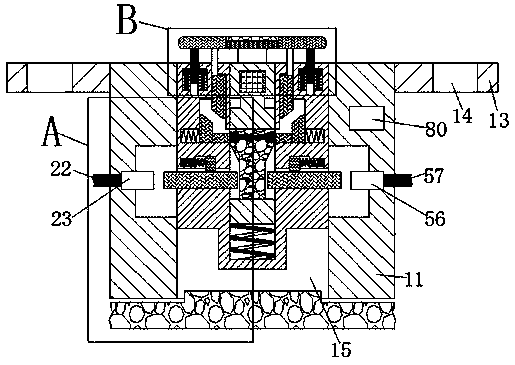

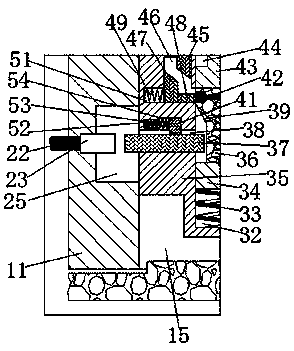

Injection moulding equipment

InactiveCN108527801ASimple structureEasy to operateContact operating partsElectricityInjection moulding

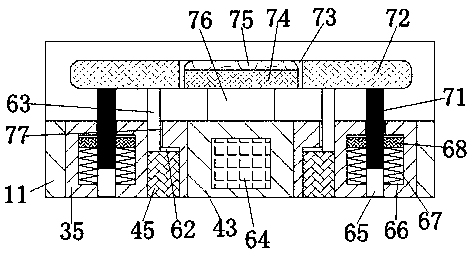

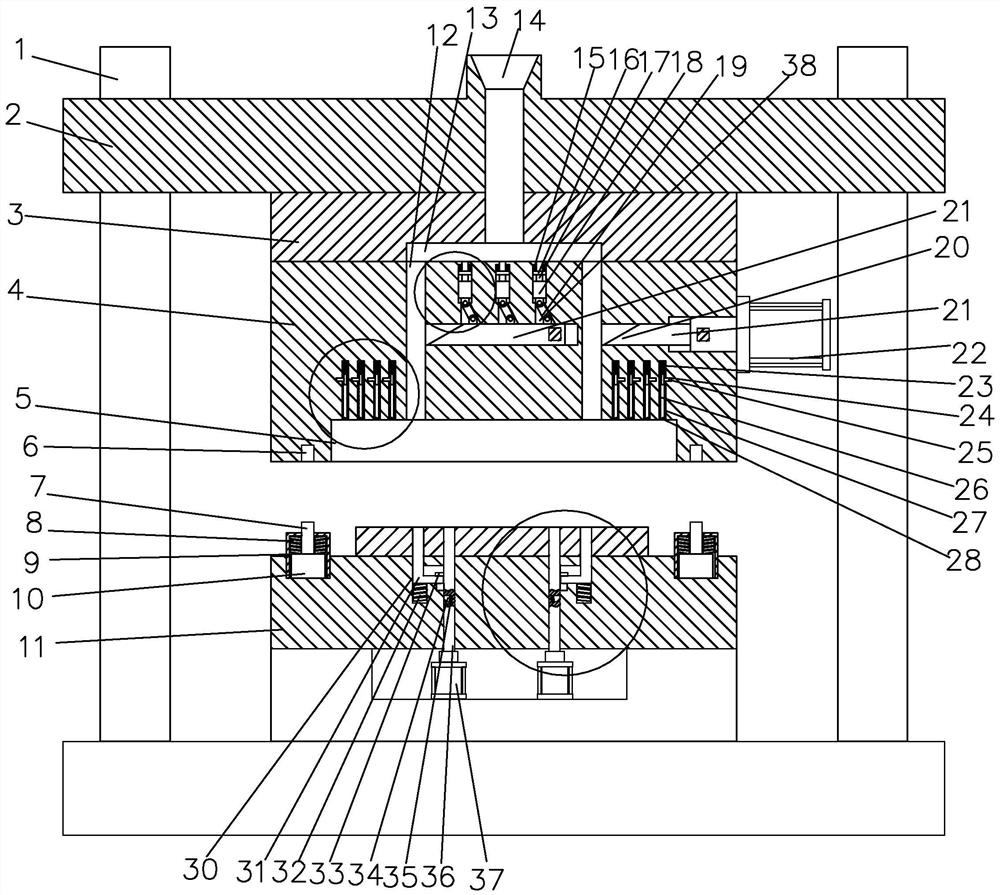

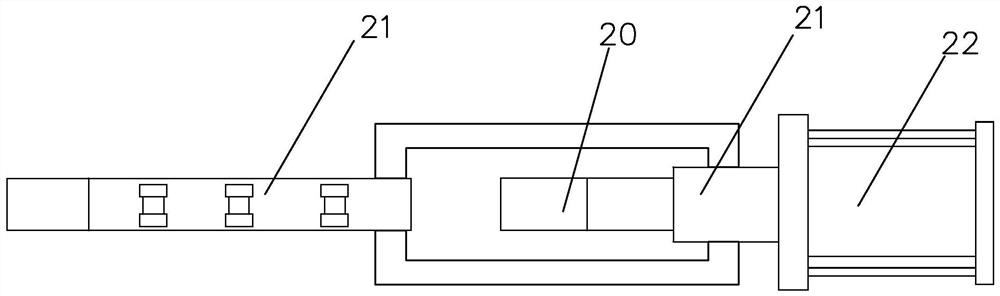

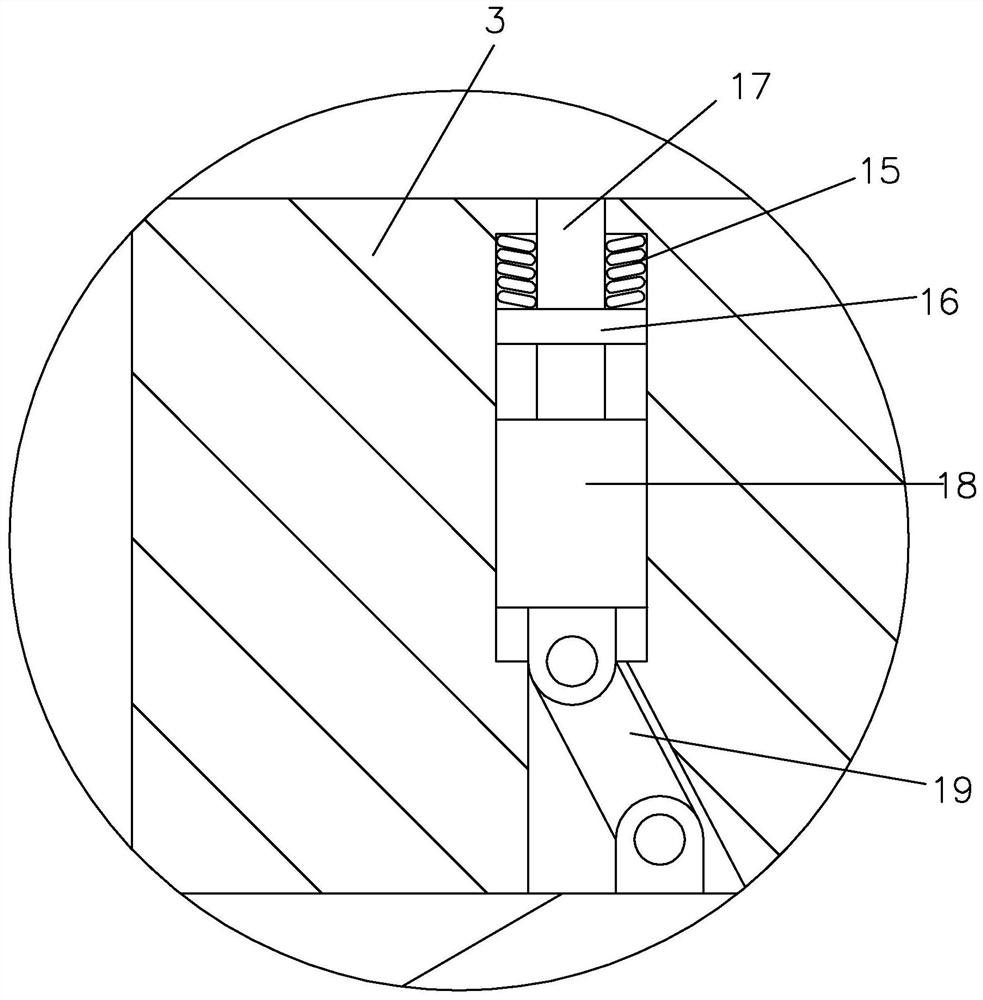

The present invention discloses injection moulding equipment, which includes a base, an electricity feeding device arranged in the base and an interlocking device arranged in the base. The electricityfeeding device includes a loading chamber running through the base up and down, sink ports located in the loading chamber and communicated with the loading chamber are disposed on the left and rightof the loading chamber symmetrically, a first electricity feeding block is fixedly disposed on the left inner wall of the left sink port, the left end of the first electricity feeding block is fixedlyconnected to a first lead that is located in the base and has one end extending out of the left end face of the base, a second electricity feeding block is fixedly disposed on the right inner wall ofthe right sink port, and the right end of the second electricity feeding block is fixedly connected to a second lead that is located in the base and has one end extending out of the right end face ofthe base.

Owner:广州市灵汐科技有限公司

Novel injection mold

ActiveCN112848101AEase of ejectionIncrease productivityVibration suppression adjustmentsEngineeringInjection moulding

Owner:苏州吉雄精密机械有限公司

Wheatstrawplant fibersynthetic resin and preparation process thereof

Owner:安徽科邦树脂科技有限公司

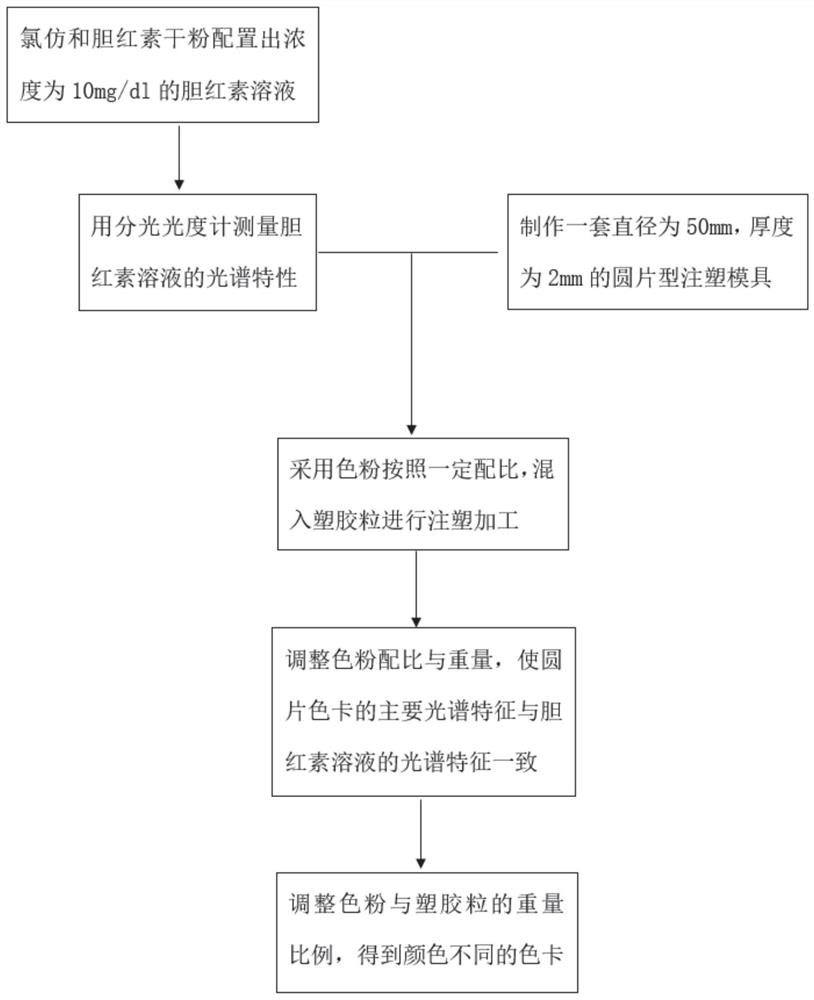

Method for manufacturing calibration color card of newborn percutaneous jaundice instrument

PendingCN114454416AAchieve traceabilityImprove consistencySensorsDiagnostic recording/measuringSpectrum analyzerInjection moulding

Owner:深圳丹娃科技有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap