High-flow vacuum generator

A vacuum generator and large flow technology, which is applied in the direction of machines/engines, non-volume pumps, mechanical equipment, etc., can solve the problem of inconvenient removal of small and small products, and achieve improved gas source utilization, fast speed, and large flow Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

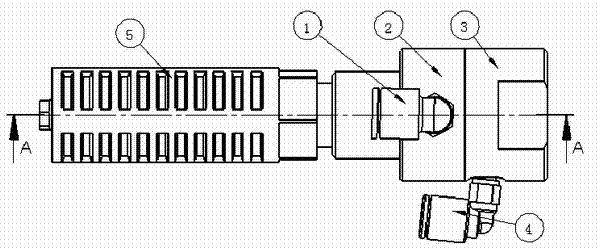

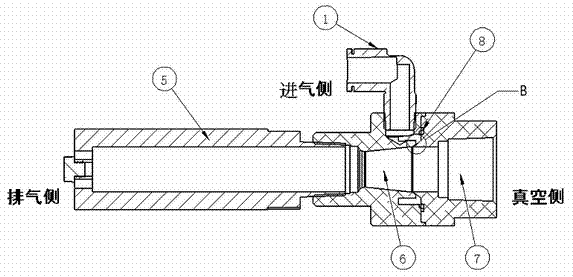

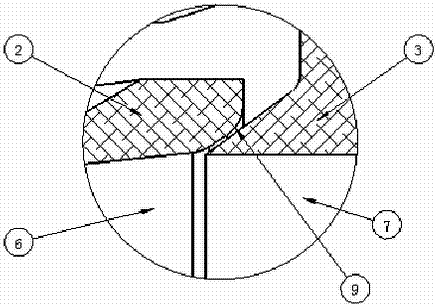

[0016] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, the diffusion side bracket 2 and the vacuum side bracket 3 are made of super duralumin material, and are anodized; the two ends of the diffusion side bracket 2 are respectively connected with the vacuum side bracket 3 and the muffler 5; There is a diffusion chamber 6, and the vacuum side bracket 3 has an adsorption chamber 7, one end of the diffusion chamber 6 communicates with the adsorption chamber 7, and the other end of the diffusion chamber 6 is connected to the muffler 5; The side support 3 is equipped with a trachea joint 2 4, the trachea joint 1 communicates with the diffusion chamber 6, and the trachea joint 2 4 communicates with the adsorption chamber 7; the gap formed between the diffusion side support 2 and the vacuum side support 3 is a high-speed The nozzle 9 of the jet; the sealing ring 8 is arranged between the diffuser side bracket 2 and the vacuum side bracket 3 .

[0017] Whe

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap