Sliding instrument and method for manufacturing same

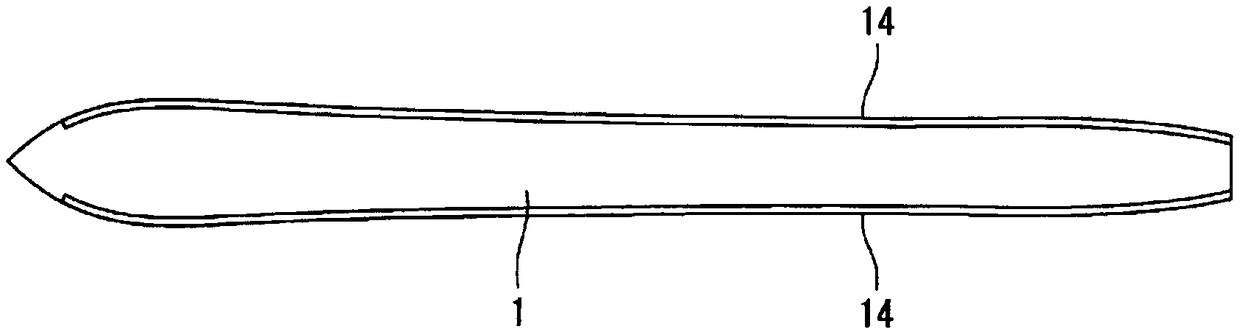

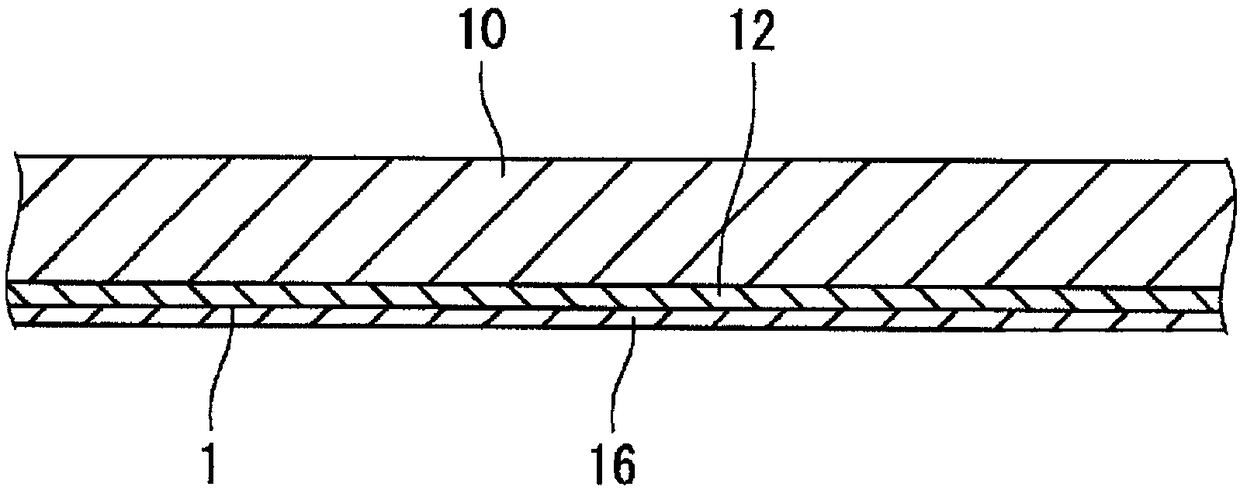

A technology for manufacturing methods and appliances, applied to chemical instruments and methods, skis, snowboards, etc., to achieve the effect of low frictional resistance and excellent gliding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] The slurry polishing composition used for polishing the test pieces of Examples 1 and 2 contained 20% by mass of silica having an average secondary particle diameter of 80 nm and 80% by mass of pure water (pH=10). The material of the polishing cloth used for polishing the test pieces of Examples 1 and 2 was suede. The slurry polishing composition used for polishing the test pieces of Examples 3 and 4 contained 18% by mass of alumina with an average secondary particle diameter of 3.0 μm and 82% by mass of pure water (pH=3). The material of the polishing cloth used for polishing the test piece of Example 3 and Example 4 was a nonwoven fabric. The slurry polishing composition used for polishing the test pieces of Comparative Example 1 and Comparative Example 2 contained 20% by mass of alumina with an average secondary particle diameter of 59.0 μm and 80% by mass of pure water (pH=6). The material of the polishing cloth used for polishing the test pieces of Comparative Exampl

Embodiment 5

[0070] The slurry polishing composition used for polishing the test piece of Example 5 contained 20% by mass of silica having an average secondary particle diameter of 80 nm and 80% by mass of pure water (pH=10). The material of the polishing cloth used for polishing the test piece of Example 5 was suede. The slurry polishing composition used for polishing the test piece of Example 6 contained 20% by mass of alumina having an average secondary particle diameter of 3.0 μm and 80% by mass of pure water (pH=6). The material of the polishing cloth used for polishing the test piece of Example 6 was a nonwoven fabric. The slurry polishing composition used for polishing the test piece of Example 7 contained 20% by mass of alumina with an average secondary particle diameter of 12.0 μm and 80% by mass of pure water (pH=6). The material of the polishing cloth used for polishing the test piece of Example 7 was non-woven fabric. The slurry polishing composition used for polishing the test

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap