Preparation method of single-sided high-glossiness 6061-H22 state aluminum alloy mirror plate

A 6061-H22, aluminum alloy technology, applied in the field of preparation of single-sided high-gloss 6061-H22 state aluminum alloy mirror panels, can solve the problems of few types of mirror aluminum alloys and the inability to prepare single-sided high-gloss mirror panels, etc. , to achieve the effect of improving the finish and cleaning quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

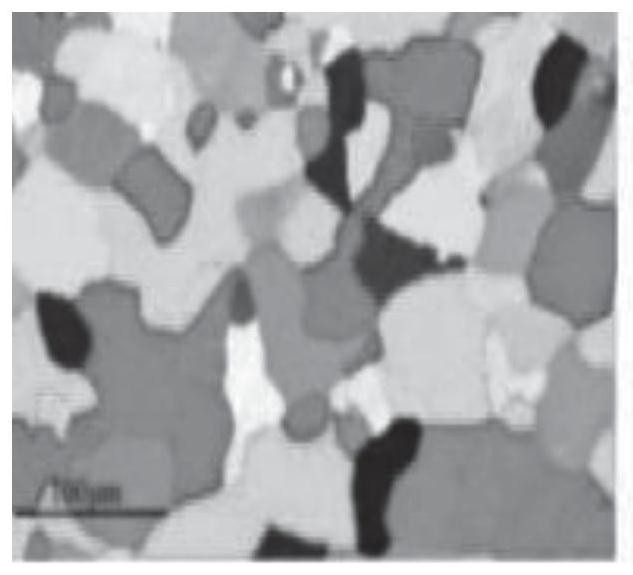

Image

Examples

preparation example Construction

[0036] A method for preparing a single-sided high-gloss 6061-H22 state aluminum alloy mirror panel, comprising the following preparation process:

[0037] S1. Put the weighed raw materials into a smelting furnace for smelting, after static refining, degassing, adding a grain refiner, filtering, and then casting by a semi-continuous casting method to obtain an ingot;

[0038] S2, heat the ingot prepared in step S1 at a temperature of 550°C-570°C for 15h-18h, and perform homogenization heat treatment;

[0039] S3. Carrying out surface milling treatment to the ingot after S2 treatment, during the surface milling treatment, ensure that the surface of the ingot after milling has no convex and concave feeling, and the roughness of the ingot surface is Ra<0.85 μm;

[0040] S4. Heating the ingot after the surface milling treatment in step S3 to 450°C-510°C, keeping it warm for more than 3 hours, and using the upper winding mode on the 1+4 type hot rolling unit to perform hot rolling into

Embodiment 1

[0056] A method for preparing a single-sided high-gloss 6061-H22 state aluminum alloy mirror panel, comprising the following preparation process:

[0057] S1. Weigh Si=0.55%-0.65%, Fe=0.10%-0.20%, Cu=0.23%-0.28%, Mn≤0.05%, Mg=1.0%-1.1%, Cr=0.18%-0.23%, Zn ≤0.05%, Ti=0.02%-0.03%, Al and other unavoidable elements, the other unavoidable individual elements ≤0.05% and ≤0.15% put into the melting furnace for smelting, after static refining and degassing , after adding a grain refiner, filter, and then use a semi-continuous casting method to cast to obtain an ingot, and the addition ratio of Mg to Si in the raw material of the aluminum alloy mirror panel is 1.73;

[0058] S2, heat the ingot prepared in step S1 at a temperature of 560° C. for 16 hours, and perform homogenization heat treatment;

[0059] S3. Carrying out surface milling treatment to the ingot after S2 treatment, during the surface milling treatment, ensure that the surface of the ingot after milling has no convex and c

Embodiment 2

[0074] A method for preparing a single-sided high-gloss 6061-H22 state aluminum alloy mirror panel, comprising the following preparation process:

[0075] S1. Weigh Si=0.55%-0.65%, Fe=0.10%-0.20%, Cu=0.23%-0.28%, Mn≤0.05%, Mg=1.0%-1.1%, Cr=0.18%-0.23%, Zn ≤0.05%, Ti=0.02%-0.03%, Al and other unavoidable elements, the other unavoidable individual elements ≤0.05% and ≤0.15% put into the melting furnace for smelting, after static refining and degassing , after adding a grain refiner, filter, and then use a semi-continuous casting method to cast to obtain an ingot, and the addition ratio of Mg to Si in the raw material of the aluminum alloy mirror panel is 1.73;

[0076] S2, heat the ingot prepared in step S1 at a temperature of 570° C. for 15 hours, and perform homogenization heat treatment;

[0077] S3. Carrying out surface milling treatment to the ingot after S2 treatment, during the surface milling treatment, ensure that the surface of the ingot after milling has no convex and c

PUM

| Property | Measurement | Unit |

|---|---|---|

| Roughness | aaaaa | aaaaa |

| Adhesion | aaaaa | aaaaa |

| Roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap