Double-protein sausage and manufacture method thereof

A production method and double-protein technology, which are used in sausage casings, slaughtering, preservation of meat/fish with chemicals, etc., can solve the problems of weak meat, loose product structure, poor sliceability, etc., and achieve strong meat, compact structure, Good slicing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

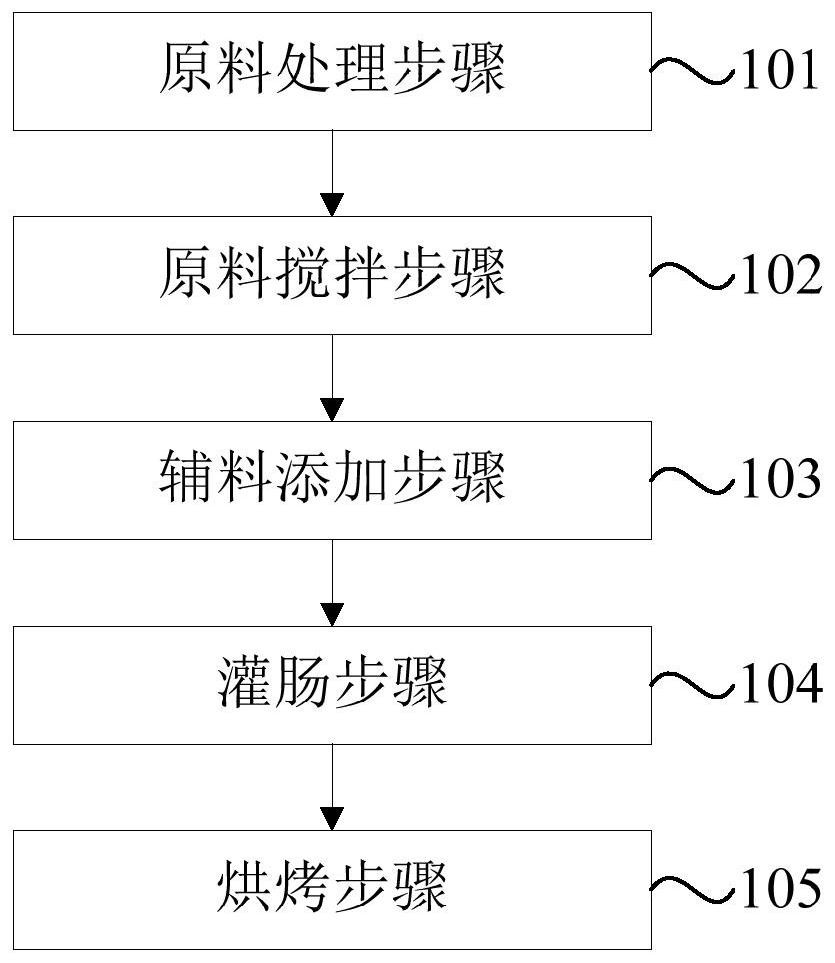

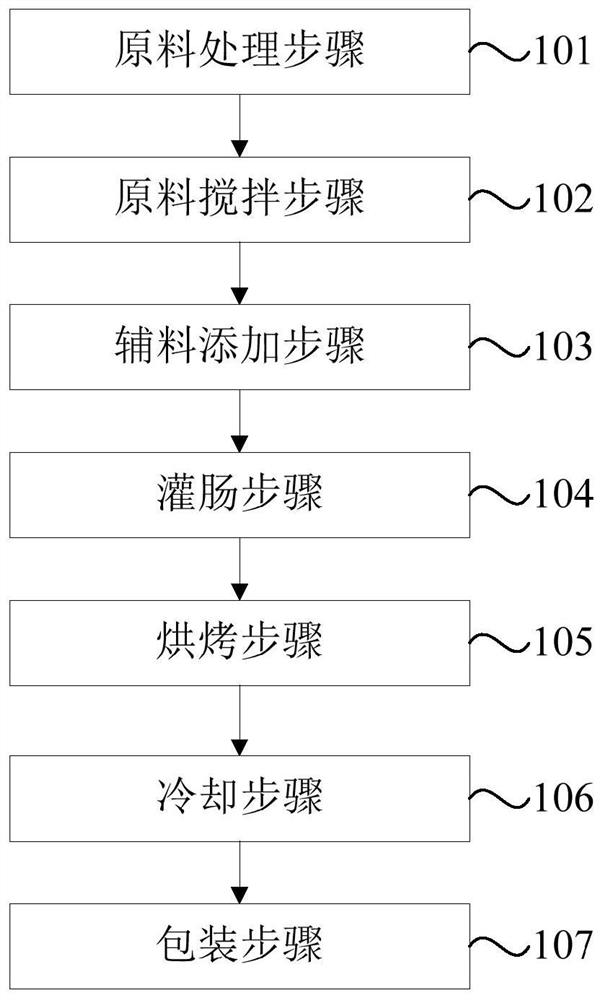

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

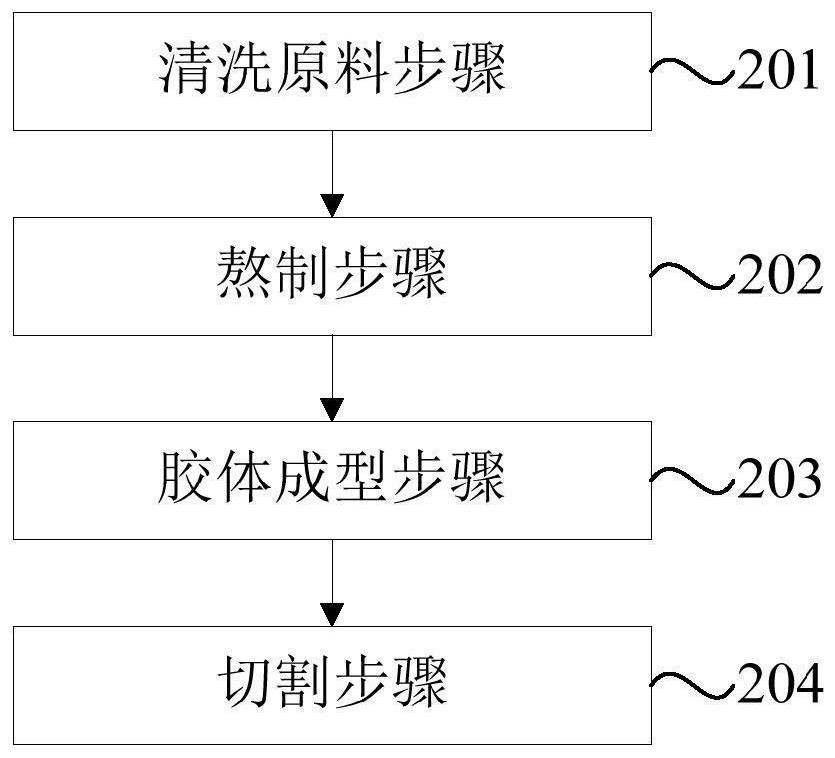

[0030] The invention provides a double-protein sausage, the double-protein sausage includes a casing and a casing, the casing is wrapped in the casing: the casing includes the following components in parts by mass: 30 parts by mass of lean pork to 40 parts, 30 to 50 parts of pork fat, 5 to 15 parts of silk protein, 4 to 8 parts of colloidal jelly, 2.5 to 3.5 parts of edible salt, 5 to 8 parts of white sugar, 0.2 to 0.3 parts of monosodium glutamate , 0.5 to 1 part of white wine and 0.005 to 0.006 part of Monascus Red, and the balance is water. Further, the intestines include the following components

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap