Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

16 results about "SODIUM DODECYL BENZENE SULFONATE" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sodium Dodecyl Benzene Sulphonate (SDBS, LAS) is a kind of efficient additive which can improve the quality of organic and inorganic chemical products that are easy to absorb moisture and agglomerate.

Optical element cleaning agent and cleaning method thereof

InactiveCN102102050AEasy to useEasy to cleanInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsUltrasonic assistedWater conductivity

The invention relates to an optical element cleaning agent and a cleaning method thereof. The cleaning agent comprises the following components: sodium hydroxide, sodium tripolyphosphate, sodium silicate, sodium dodecyl benzene sulfonate and emulsifiable penetrant. The cleaning method comprises: preparing a cleaning agent by mixing sodium hydroxide, sodium tripolyphosphate and emulsifiable penetrant according to a weight percentage ratio and dissolving the cleaning agent in water in a container to form cleaning agent aqueous solution I; preparing a cleaning agent by mixing the raw materials including sodium silicate, sodium dodecyl benzene sulfonate and emulsifiable penetrant, and dissolving the cleaning agent in water in a container to form a cleaning agent aqueous solution II; using the cleaning agent aqueous solution I and the cleaning agent aqueous solution II with assistance from ultrasonic waves and a pure water conductivity of greater than 8Mohm, wherein the concentration of the cleaning agent aqueous solution I and the concentration of the cleaning agent aqueous solution II are both 0.1 to 0.8 percent and the temperature of the aqueous solutions is 30 to 70 DEG C; and performing the steps of rinsing, dewatering, steaming and the like to accomplish cleaning. The cleaning method is convenient to use, low in cost and good in cleaning effect.

Owner:JIANGXI PHENIX OPTICS TECH CO LTD

Thin-film capacitor housing heat dissipation coating and preparation method thereof

A thin-film capacitor housing heat dissipation coating is prepared from, by mass, 35 parts of resol, 3 parts of gelatin, 5 parts of glycidyl methacrylate, 3 parts of sodium dodecyl benzene sulfonate, 3 parts of gloss oil, 5 parts of dimethyl dicarbonate, 3 parts of olive oil, 3 parts of colored glaze carbylic acid, 3 parts of olive oil, 3 parts of graphene, 5 parts of pigment, 50 parts of distilled water, 3 parts of benzoyl paeoniflorin, 3 parts of sodium hypochlorite, 5 parts of a modifying agent, 3 parts of calcium carbonate, 3 parts of glacial acetic acid, 3 parts of magic acid, 5 parts of polyester resin, 3 parts of potassium dihydrogen phosphate, 1 part of sodium phosphate, 3 parts of aluminum silicate, 3 parts of imidazole, 3 parts of cohesive soil, 3 parts of polyvinyl alcohol and 3 parts of sodium borohydride. The modifying agent is added in a traditional formula to perform modification processing, the coating coated on a capacitor housing can effectively guide capacitor inside temperature rising due to work to the housing and convert heat into infrared radiation waves, and the working voltage of a capacitor can be also in a stable state in addition to prolonging of the service life of the capacitor.

Owner:HUAIAN SHENGYU ELECTRONICS

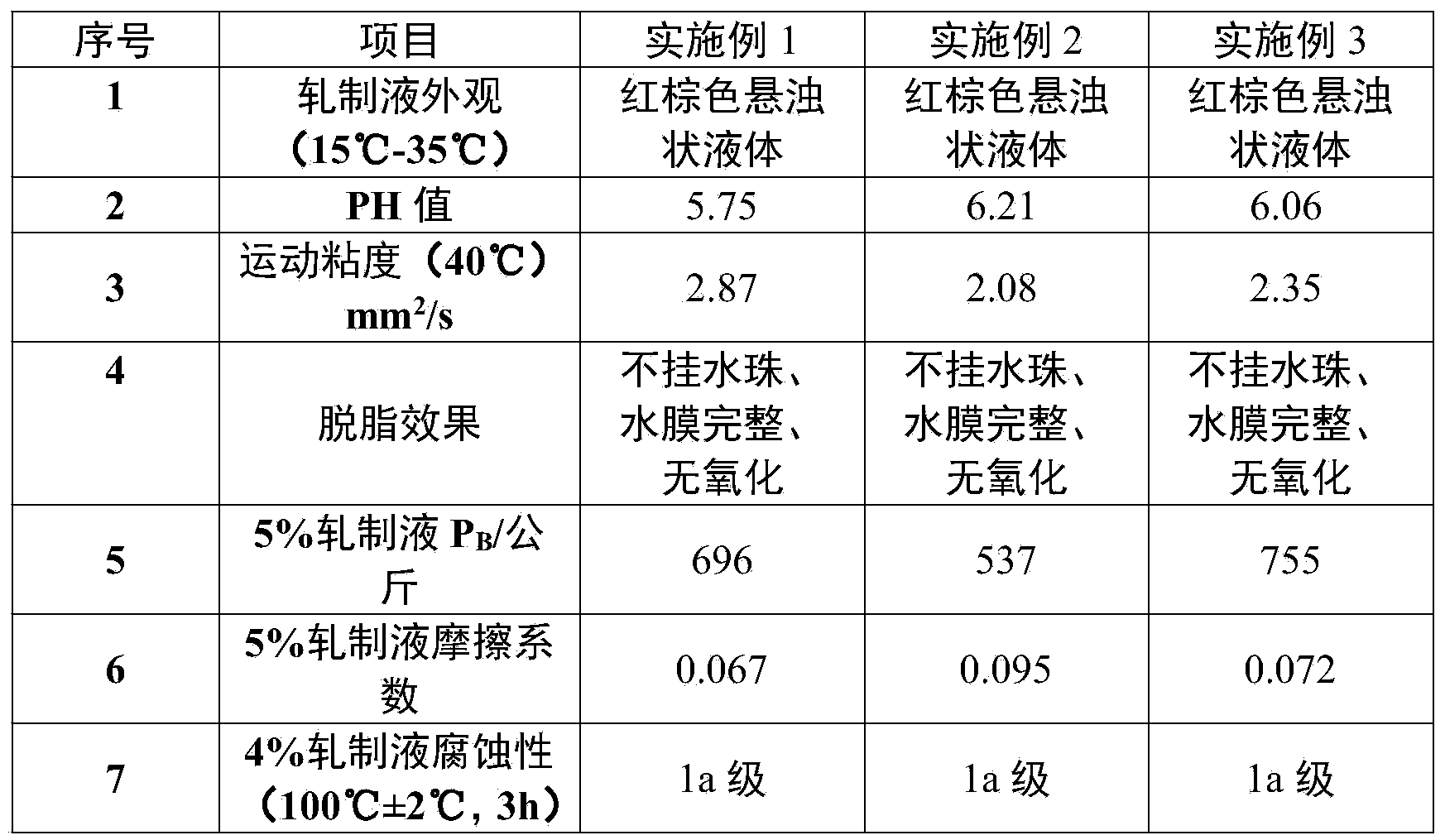

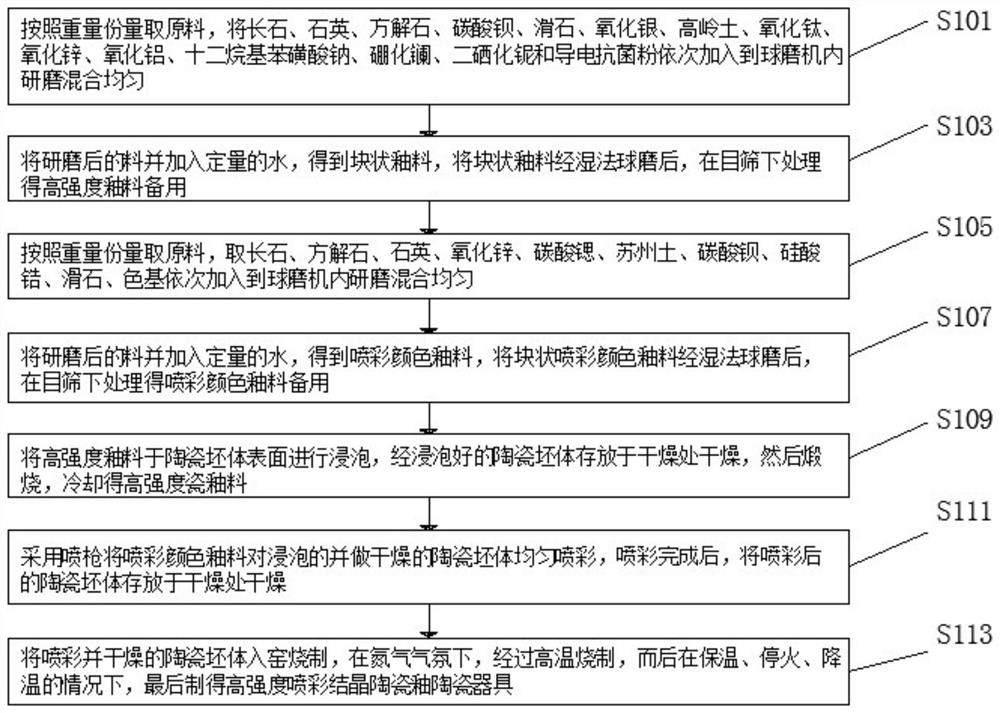

Functional rolling liquid of water-based nano Cu and preparation method of functional rolling liquid

Owner:UNIV OF SCI & TECH BEIJING

Preparation method of electrostatic spinning lithium ion battery negative electrode plate

InactiveCN108735976AIncrease transfer rateLower internal resistanceElectrode manufacturing processesSecondary cellsWater basedElectrical battery

The invention discloses a preparation method of an electrostatic spinning lithium ion battery negative electrode plate. The preparation method comprises the following steps of dissolving polyoxometallate salt into deionized water to form a polyoxometallate solution; adding graphite into the polyoxometallate solution, and adding a surfactant sodium dodecyl benzene sulfonate and a water-based adhesive La13<x> to form a spinning solution; putting the spinning solution into an electrostatic spinning instrument for spinning, and performing spinning of the spinning solution on a copper foil, whereinwire strips are dense and are uniformly adhered to the copper foil; and then drying the copper foil adhered with the wire strips to obtain the battery negative electrode plate. Compared with a traditional stirring and coating process, the preparation method adopting the electrostatic spinning process has the advantages that the process time is shortened, and the production efficiency is improved.

Owner:DONGFANG ELECTRIC CORP

Water-based wood protective agent and preparation method thereof

InactiveCN107914328AAvoid bloomingPrevent mildewWood treatment detailsWood impregnation detailsWater basedAlkylphenol

Owner:BEIJING FORESTRY UNIVERSITY

Stone-like paint and preparation method thereof

InactiveCN104830187AImprove water resistanceGuaranteed hardnessRosin coatingsStarch coatingsPolymer scienceMethacrylate methyl

Owner:CHONGQING PINSHENG PAINT

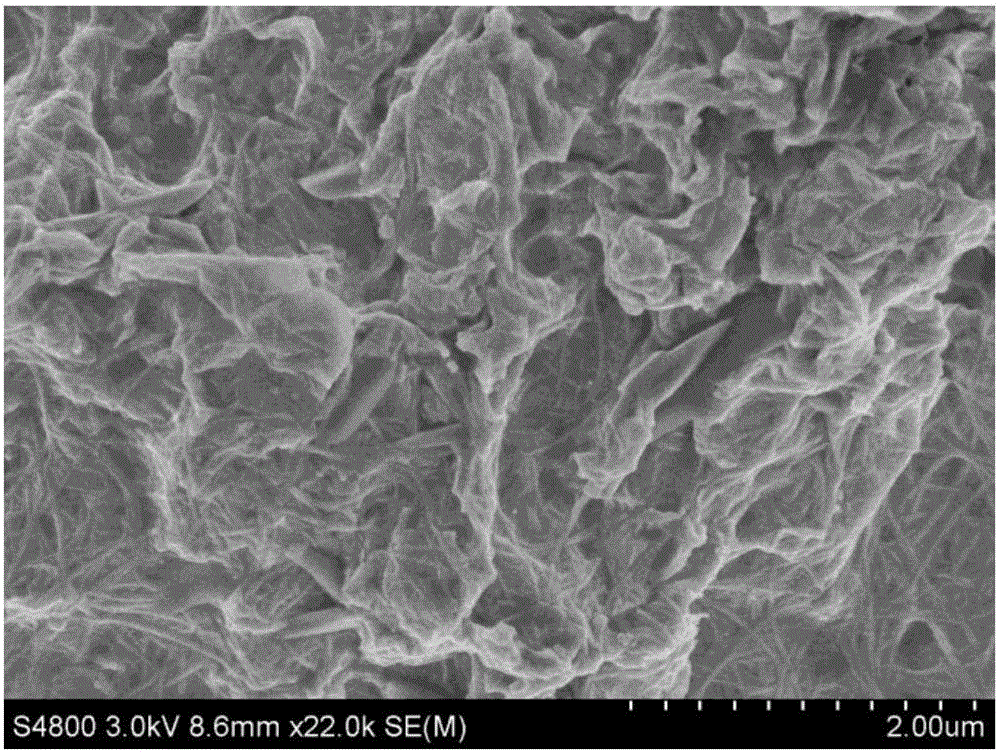

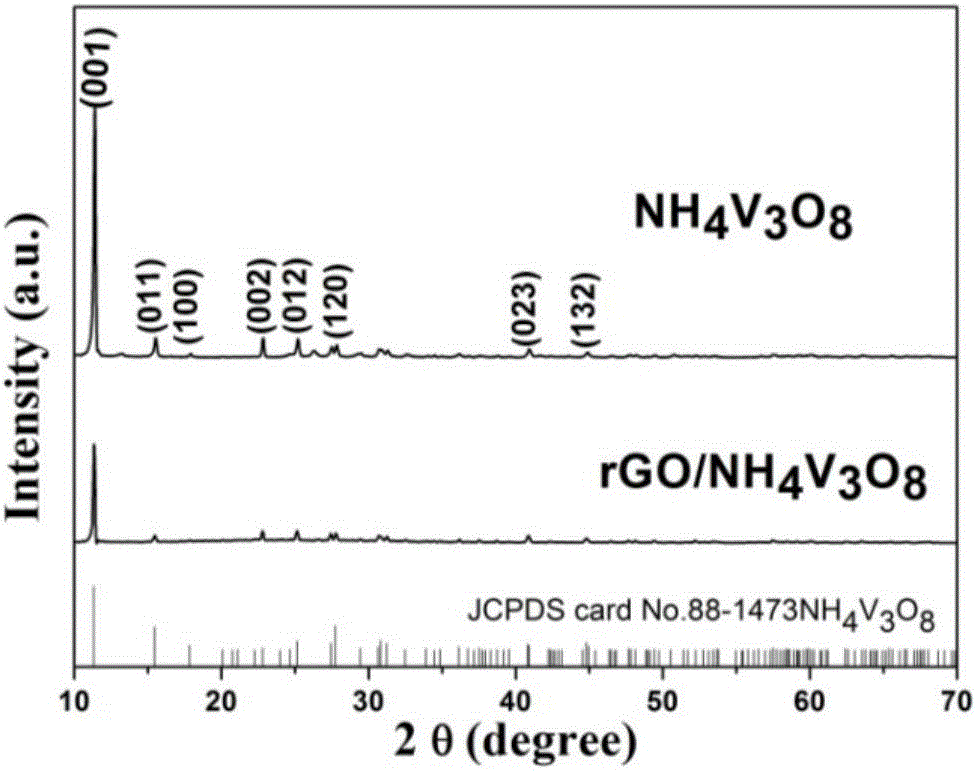

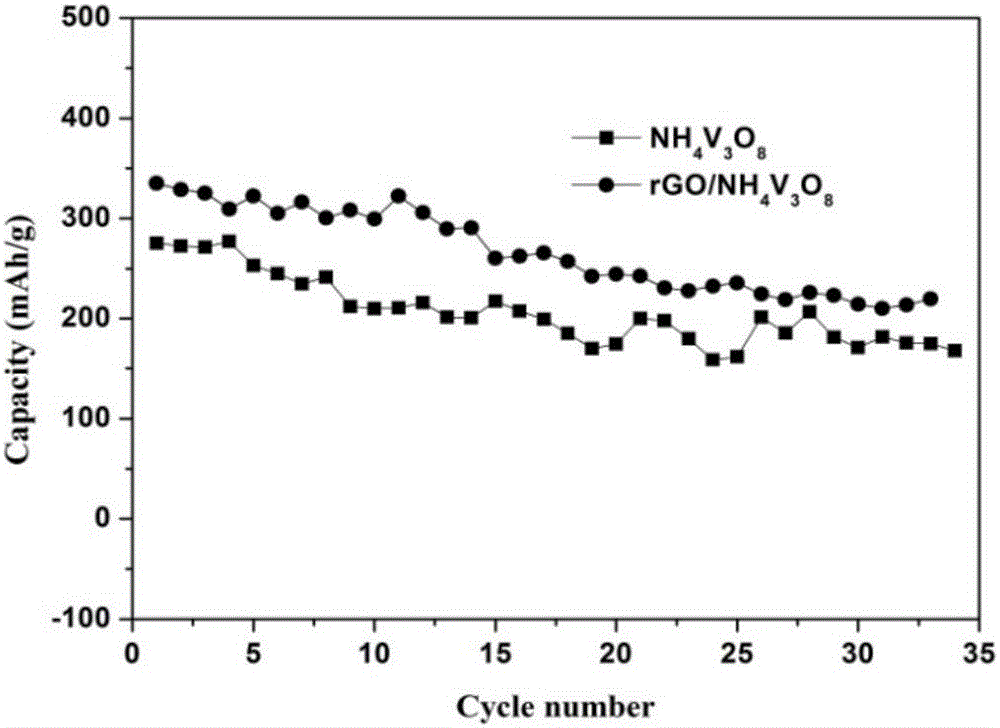

Graphene and ammonium vanadate composite material and preparation method thereof

InactiveCN106384817AImprove mobilityHigh charge and discharge capacityCell electrodesSecondary cellsGrapheneVanadate

Owner:SHAANXI UNIV OF SCI & TECH

Metal surface cleaning agent based on firmiana simplex bark extract and preparation method thereof

InactiveCN105543881ASulfadiazineSurface cleaning

Owner:铜陵铜官府文化创意股份公司

Polypyrrole carbon composite electrode material capable of strengthening conductivity through nickel oxide and acetylene black

InactiveCN106531461AHybrid capacitor electrodesHybrid/EDL manufacturePyrroleSODIUM DODECYL BENZENE SULFONATE

Owner:TONGLING CITY START ELECTRONICS MFG

Anticorrosion paint comprising a benzenesulfonic acid/calcium stearate composite stabilizing agent

InactiveCN106167660ASimple preparation processEasy to operateAnti-corrosive paintsEmulsionBenzenesulfonic acid

The invention relates to anticorrosion paint comprising a benzenesulfonic acid / calcium stearate composite stabilizing agent. The paint comprises 20-30% of sodium silicate, 45-60% of ultrafine zinc powder, 10-20% of silicone-acrylic emulsion, 3-5% of a titanate coupling agent, 3-4% of an aqueous MgCl2 solution, 2-3% of zinc stearate and 2-3% of sodium dodecyl benzene sulfonate. The prepared anticorrosion paint has excellent properties, such as good stability and no material grain settlement.

Owner:吴房文

Anti-rust lubricating aqueous copper drawing fluid and preparation method thereof

InactiveCN104293458AImprove anti-corrosion effectQuality assuranceLubricant compositionCopper wireLubrication

Owner:ANHUI TATSU PRECISION ALLOY

Weather-resistant modified solution and colored weather-resistant polyvinyl chloride resin as well as preparation methods thereof

Owner:XINJIANG ZHONGTAI CHEM CO LTD

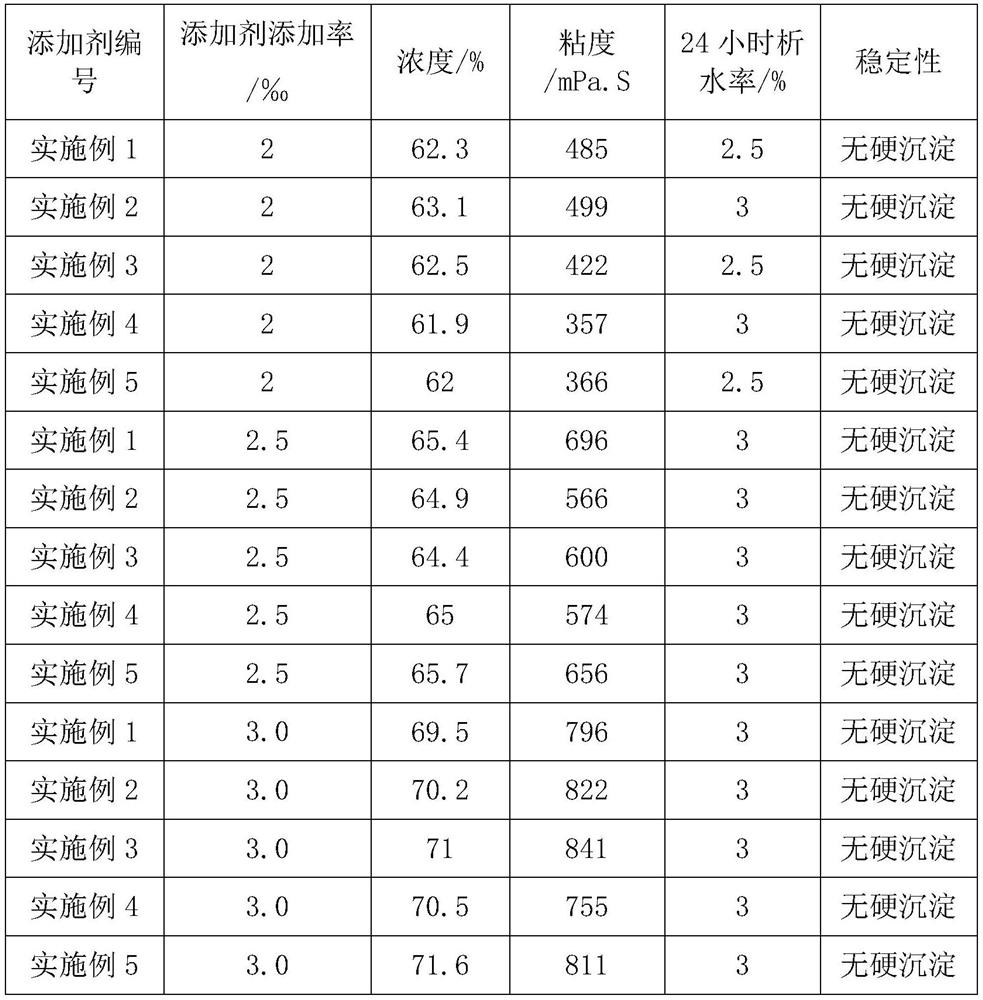

Method for producing high-sulfur petroleum coke slurry additive

PendingCN114540088AIncrease the concentration of char slurryEfficient use ofLiquid carbonaceous fuelsCelluloseSodium hydrogen sulphite

Owner:浙江石油化工有限公司

Preparation method of prefabricated concrete member

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap