Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

14 results about "Process time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ultra-high temperature high pressure dyeing method for aramid fiber textile

InactiveCN101235598AHigh color fastnessBright colorPhysical treatmentDyeing processColour fastnessAtmospheric pressure

The invention discloses a method for dying kevlar fabrics under ultrahigh temperature and high pressure, which comprises: a preprocessing procedure under the ultrahigh temperature and the high pressure and a dying procedure under the ultrahigh temperature and the high pressure, wherein in the preprocessing procedure under the ultrahigh temperature and the high pressure, atmospheric pressure plasmas are used to process the kevlar fabrics for 1-5min, the processing temperature is 100-150DEG C, while in the dying procedure under the ultrahigh temperature and the high pressure, the temperature is 160DEG C-190DEG C, and the pressure intensity is 0.8-0.9MPa, wherein the plasma preprocessing procedure is an important procedure before the dying procedure under the ultrahigh temperature and the high pressure, since the processing for the plasma produces a plurality of active groups on the kevlar fabrics, which enables carriers to be better absorbed on the kevlar baric and thereby is beneficial for dying dye on the kevlar fabrics, simultaneously, the kevlar fabrics after dying under the ultrahigh temperature and the high pressure has high fastness, fresh color and soft hand feeling, and the washing color fastness and the abrasion color fastness of the kevlar fabrics are improved better.

Owner:ZHEJIANG SCI-TECH UNIV

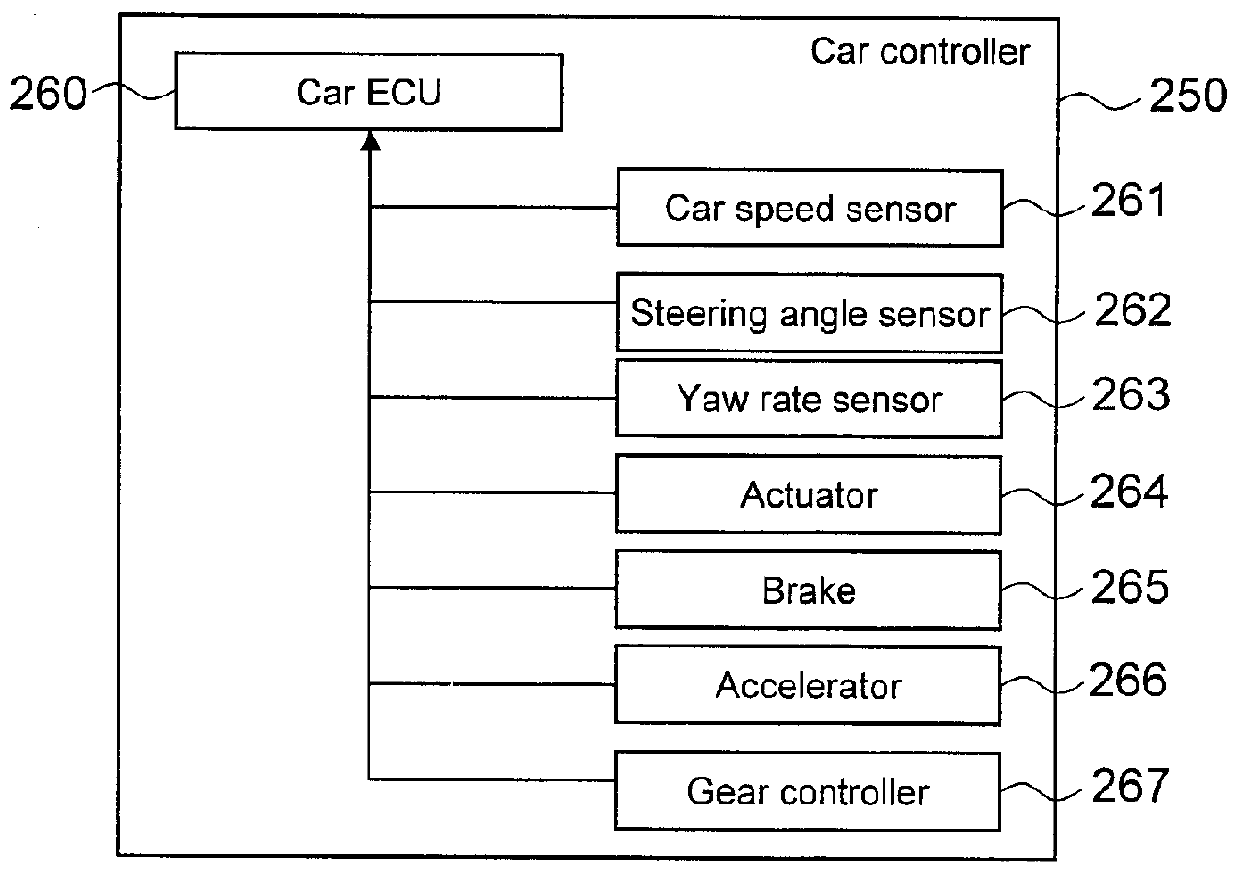

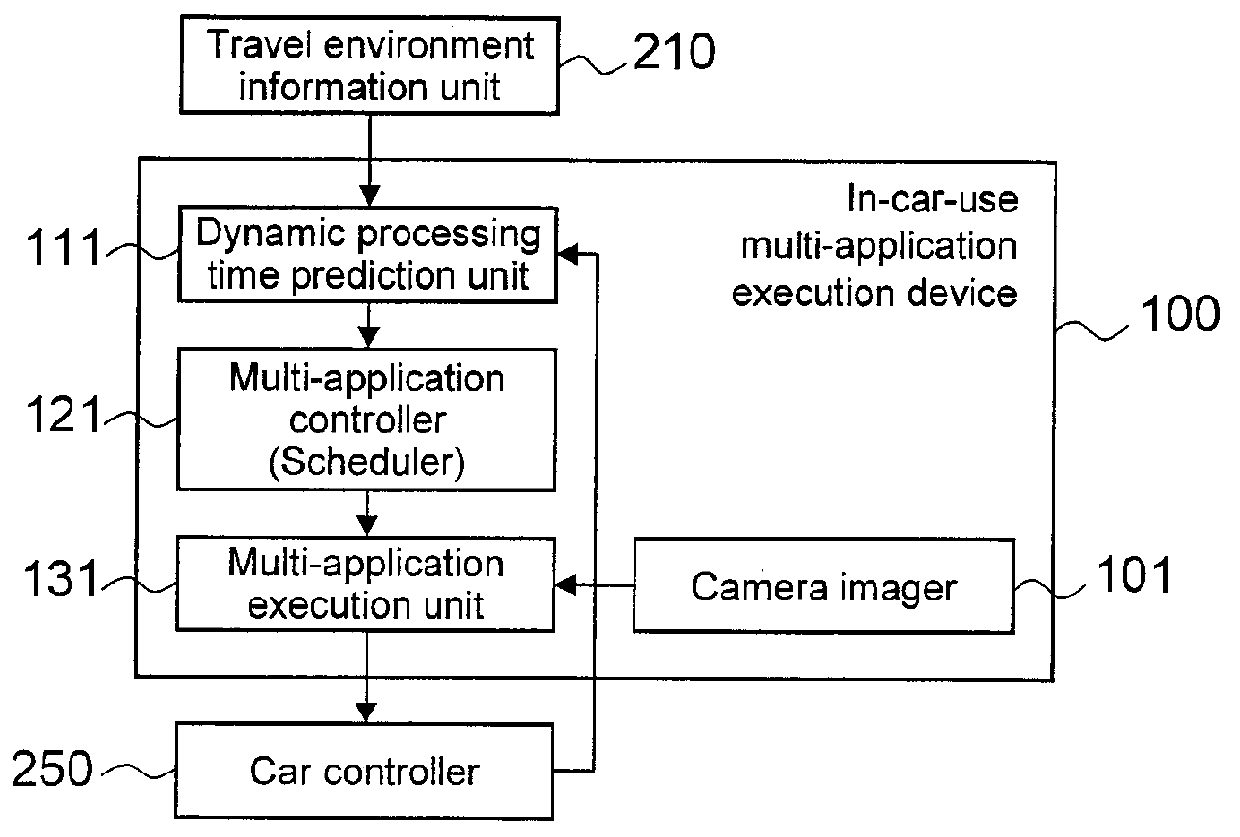

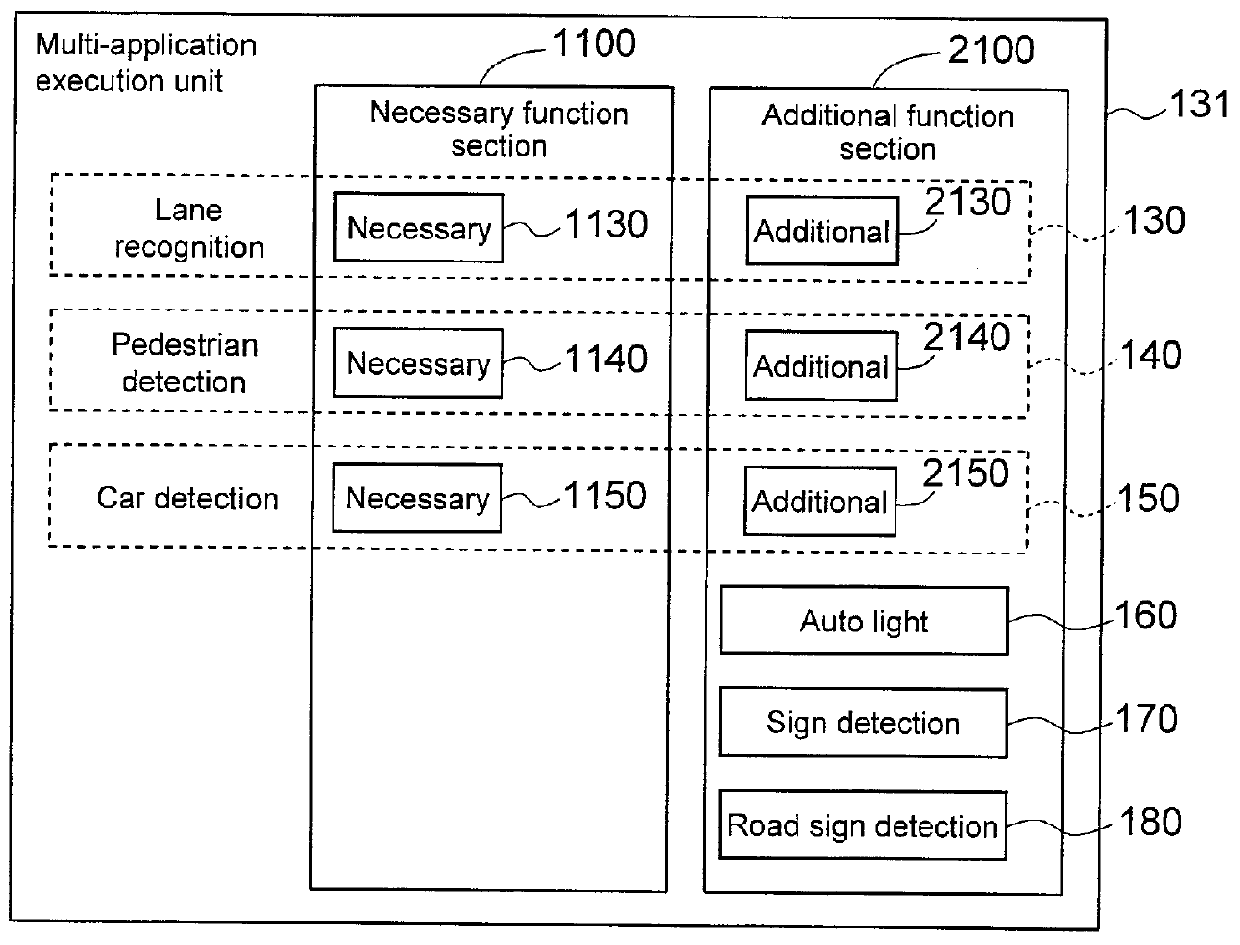

In-Car-Use Multi-Application Execution Device

ActiveUS20120216208A1Limited processing capabilitiesEnsure safetyProgram initiation/switchingRoad vehicles traffic controlApplication softwareOperating system

Owner:HITACHI ASTEMO LTD

Method for generating data in storage system having compression function

ActiveUS20140114936A1Improve performanceSuppressing unnecessary processingDigital data information retrievalDigital data processing detailsComputer engineeringProcess time

The present invention aims at improving the performance of a compression function in a storage system, and solves the prior art problem of having to decompress a whole compression unit even if a read request or a write request targets only a portion smaller than the compression unit, causing increase of overhead of decompression processing and elongation of processing time, and deteriorating performance The present invention prevents unnecessary decompression processing and reduces the overhead of processing by suppressing the range of decompression processing to a minimum portion according to the relationship between the read / write request range and the compression unit.

Owner:HITACHI LTD

Wireless communication system for determining the number of operation stages of interference canceller

InactiveUS20060120436A1Improve performanceReduce processing timeEcho effect reductionInterference cancellerTelecommunications link

An SIR measurement sections are provided for respective stages of an interference canceller section and SIR values of the respective stages of the interference canceller section is notified to a station of the other end of a communication link to allow the station to determine the number of operation stages of the interference canceller section. The determined number of operation stages is received from the station and the interference canceller section is operated by the determined number of operation stages. This reduces processing time and power consumption. Further, the reduction in processing time makes it possible to perform communication according to an adaptive transmission method in an error-free manner.

Owner:NEC CORP

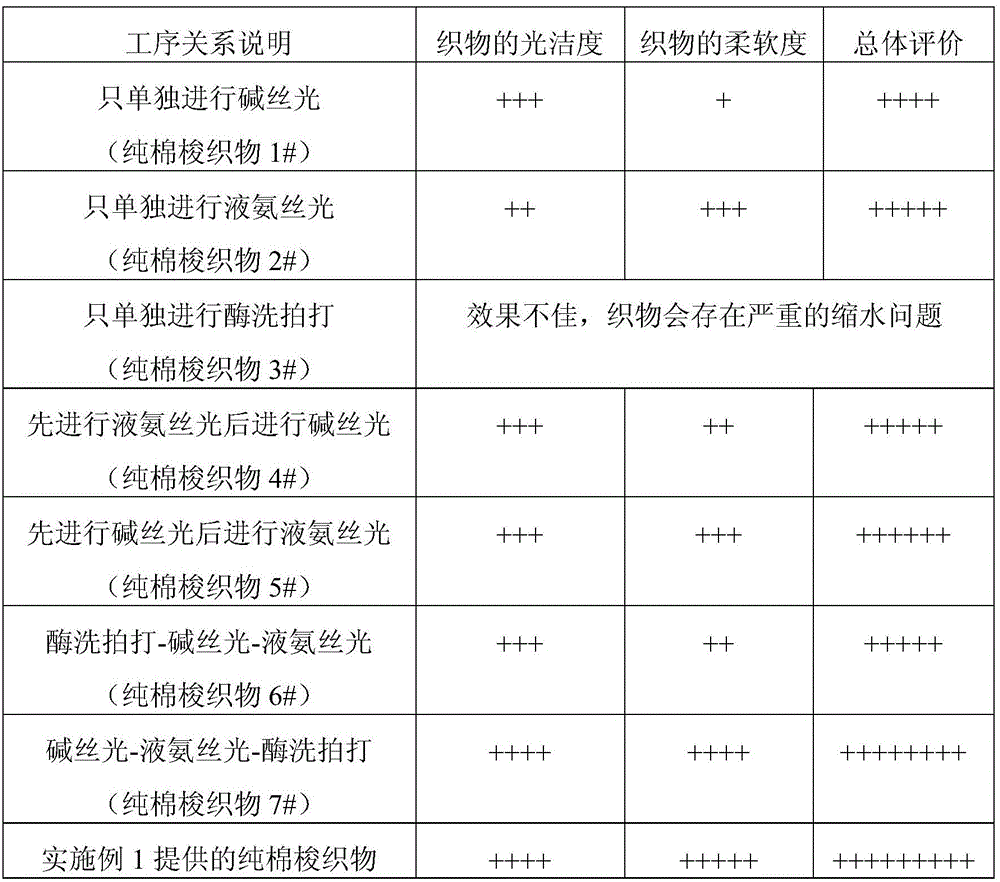

Elastic pure cotton woven fabric with smooth surface and soft handle and preparation method thereof

ActiveCN106012494AObvious bodyIncrease elasticityBiochemical treatment with enzymes/microorganismsGrip property fibresCellulaseProcess time

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

Sequencing boarding method through boarding passenger information correlation and real-time trajectory tracking

ActiveCN109636995AImprove boarding efficiencyImprove boarding speedChecking apparatusResourcesSimulationHabit

The invention discloses a sequencing boarding method through boarding passenger information correlation and real-time trajectory tracking. The method comprises the following steps of passenger checking-in, seat service area dividing and area identifier establishing, boarding passenger boarding, boarding passenger entering gallery bridge, boarding passenger queuing sequence information monitoring,boarding passenger sequentially arriving at cabin door, entering passenger cabin for placing luggage, seating and the like. The method has the advantages that modern information are fully utilized forfusing principle and technology, through the modes such as intra-cabin area division, boarding passenger identification, gallery bridge walking track monitoring, and free sequence and extraction, anyone boarding passengers can complete the process without stay in the channel, can directly and accurately reach the corresponding seat area, then confirm the seat, place the luggage and seat; so thatthe boarding efficiency can be remarkably improved, and the boarding process time can be shortened. On the premises that the personal habits of the passengers are honed and extra burdens are not increased, the time of finding the seat and arranging the luggage of the passenger in the cabin is shortened, and the boarding speed is greatly improved.

Owner:CIVIL AVIATION UNIV OF CHINA

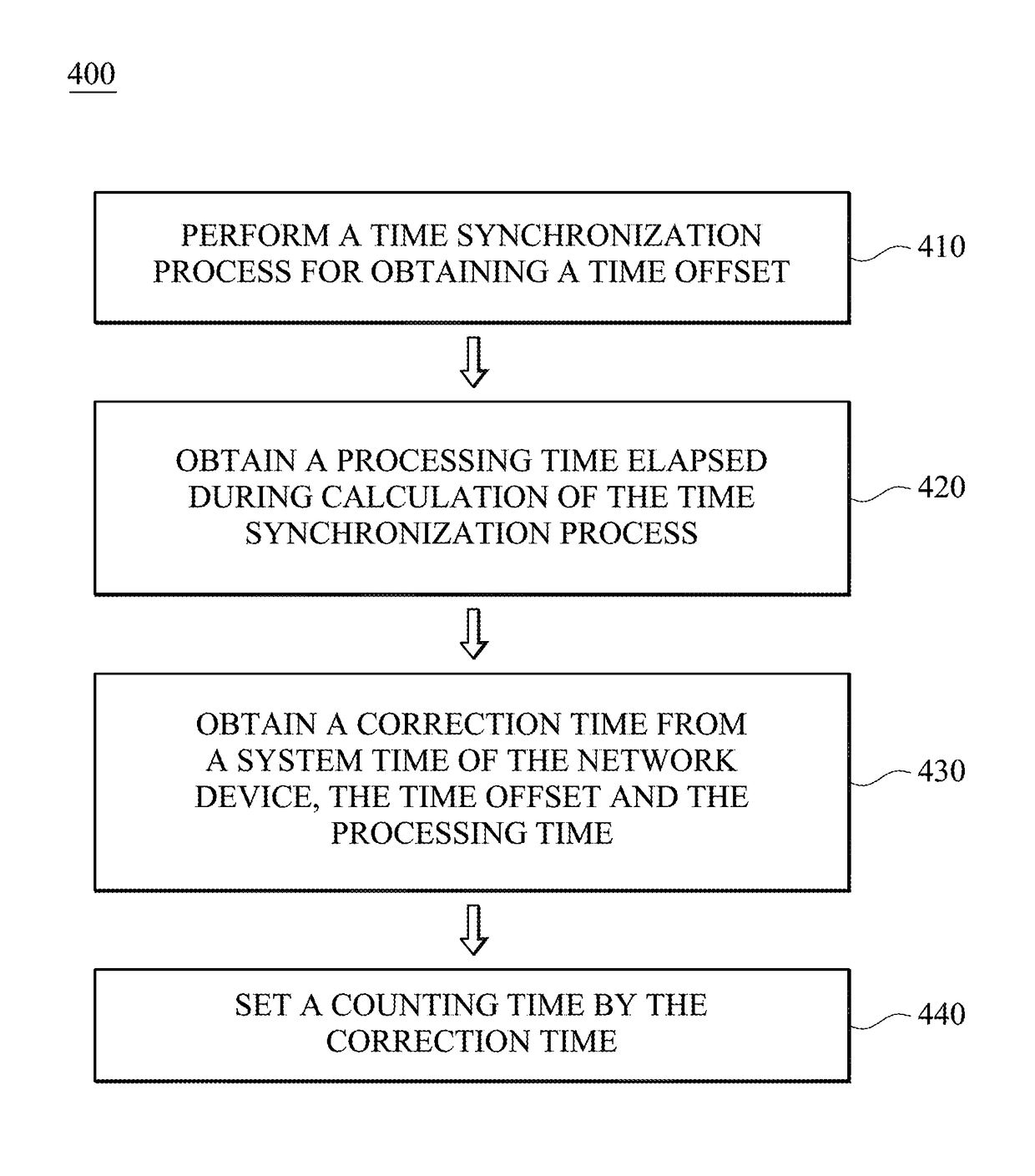

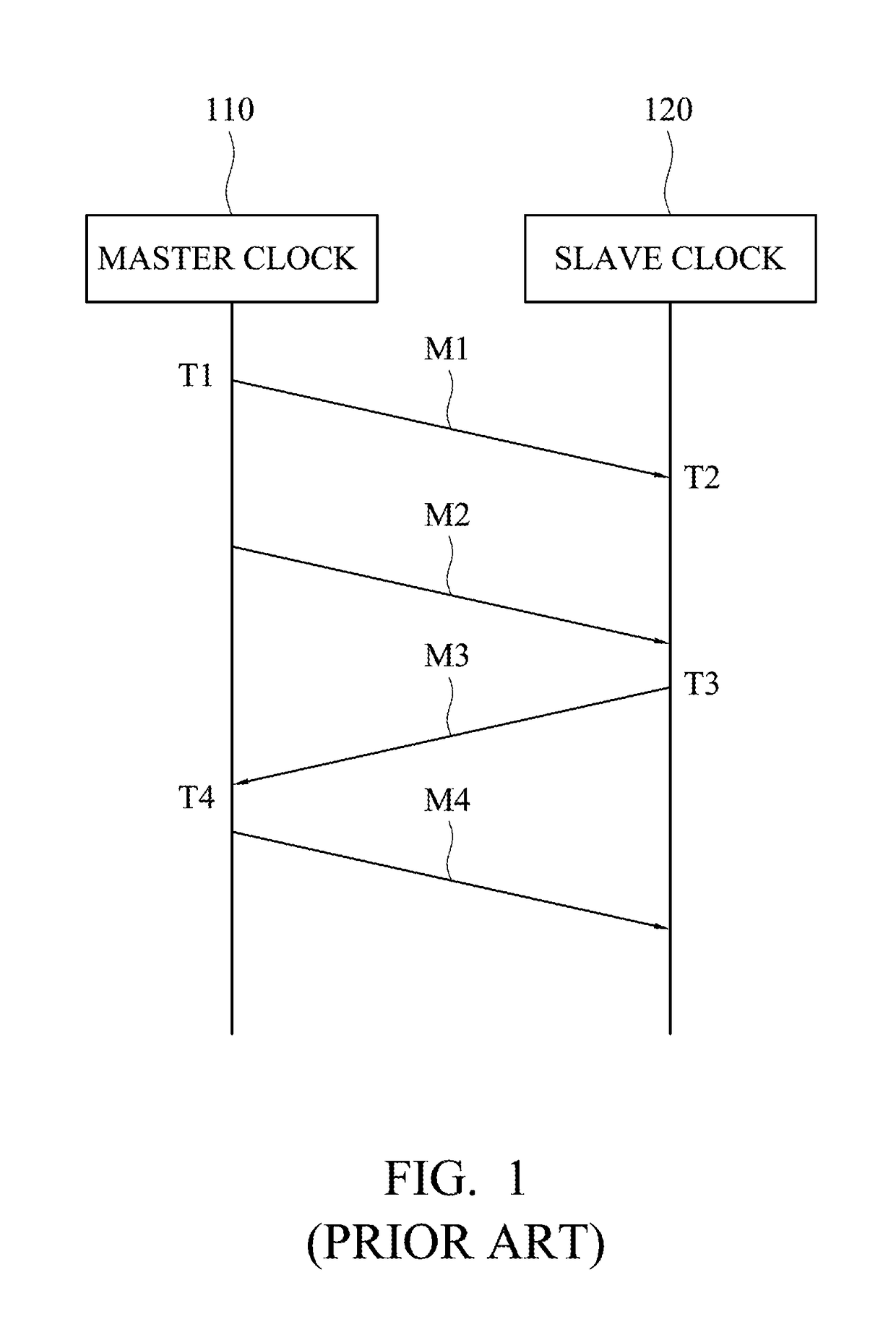

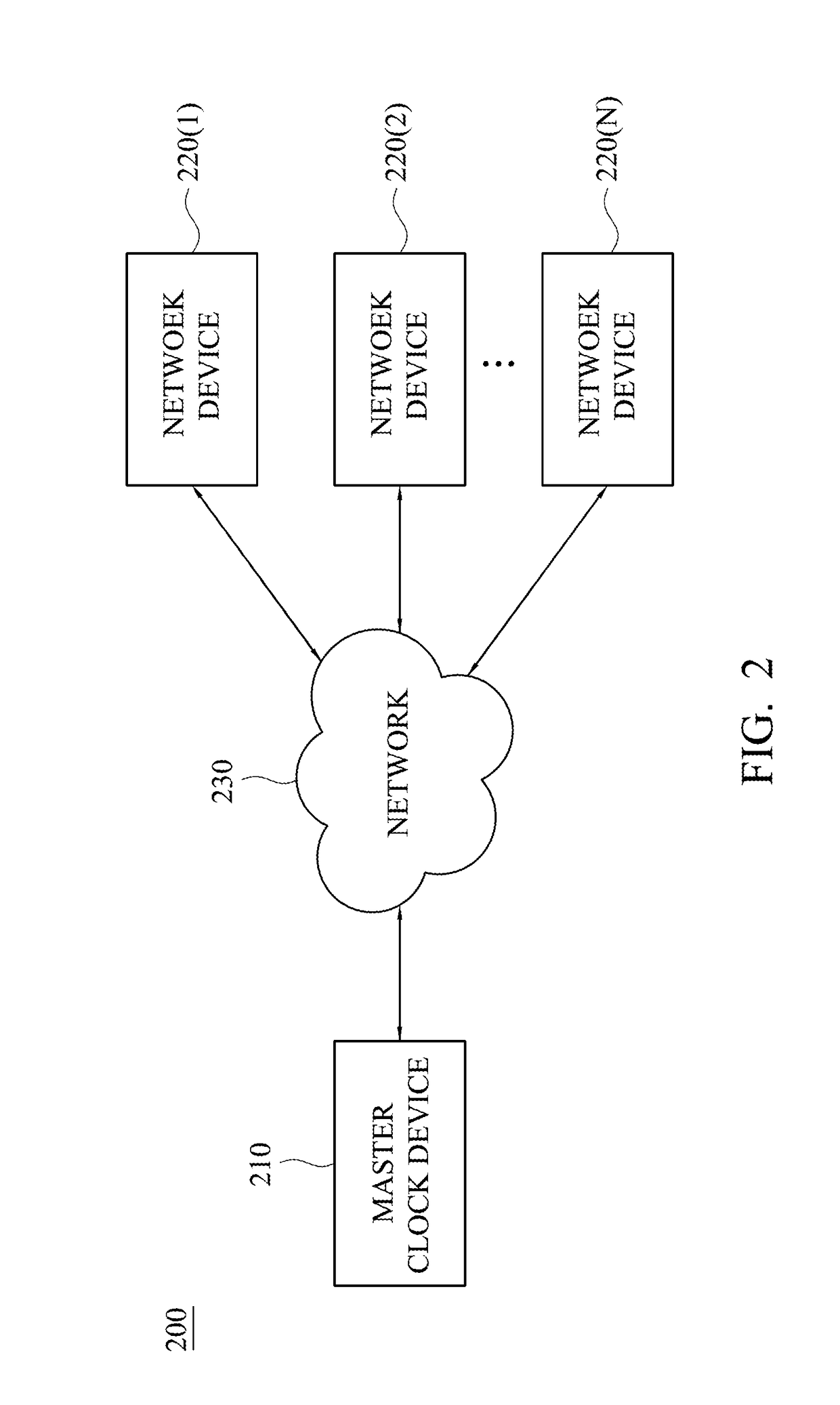

Time synchronization for network device

InactiveUS20170117980A1Accurate updateTime-division multiplexSynchronisation signal speed/phase controlCommunication unitControl communications

Owner:ACCTON TECHNOLOGY CORPORATION

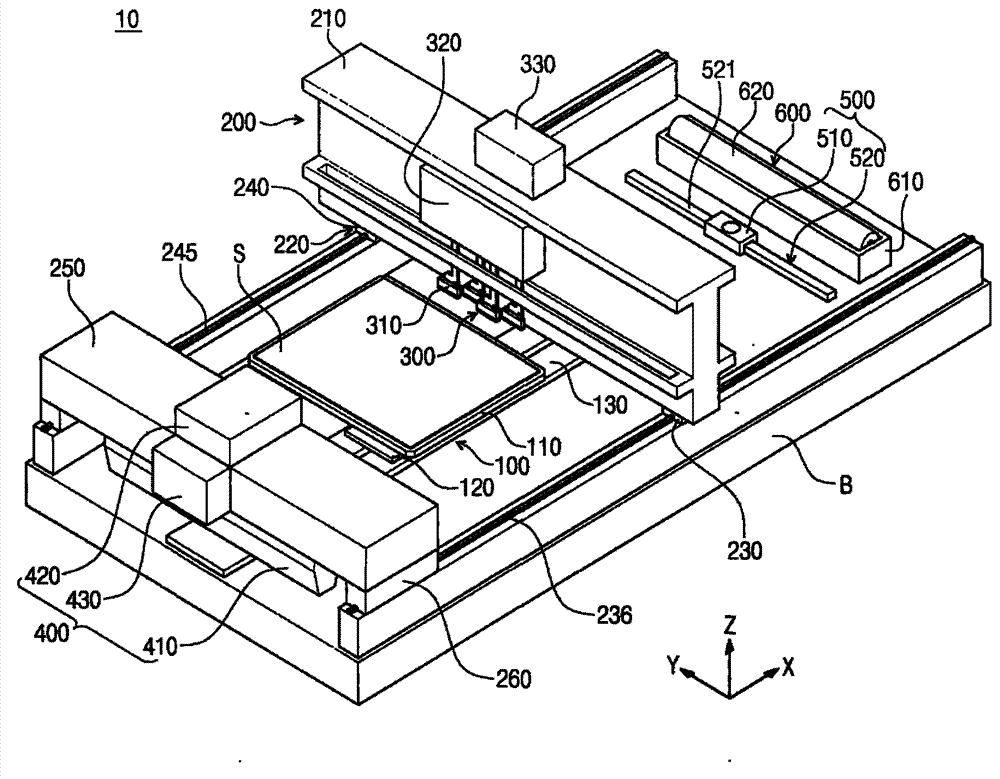

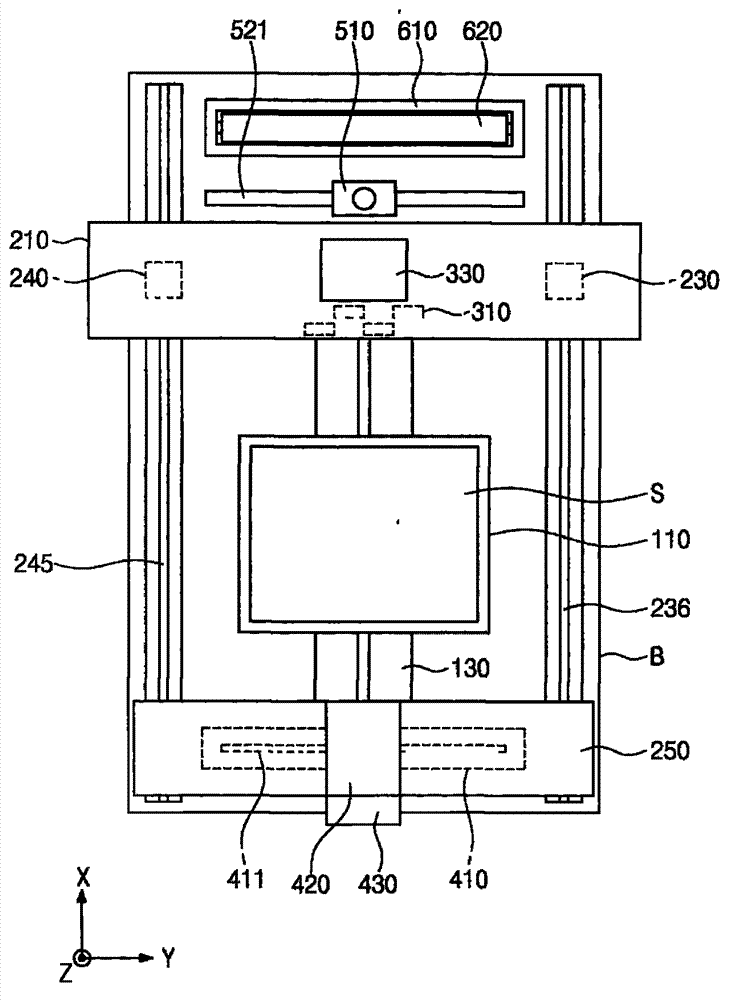

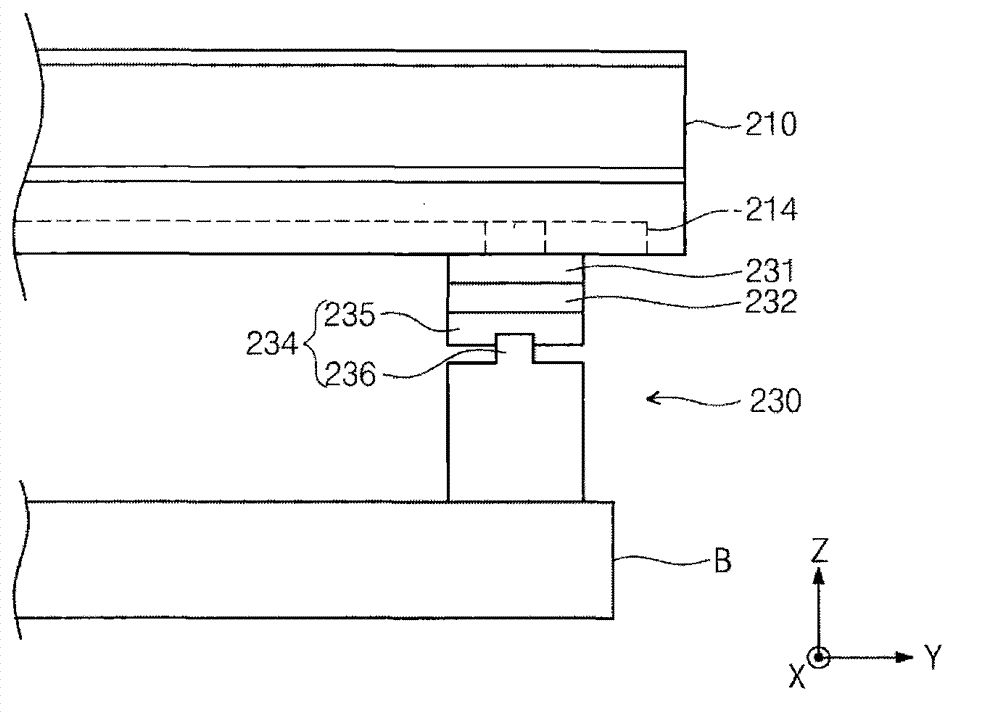

Apparatus and method for treating substrate

Owner:SEMES CO LTD

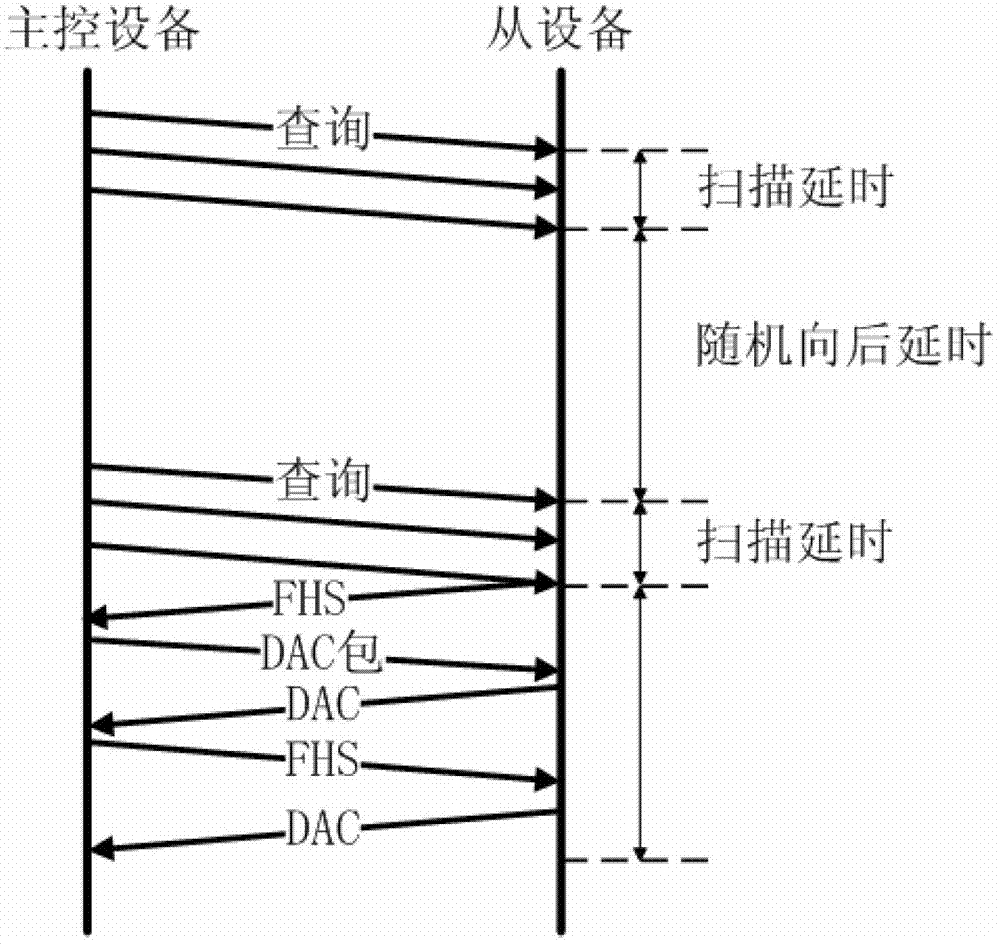

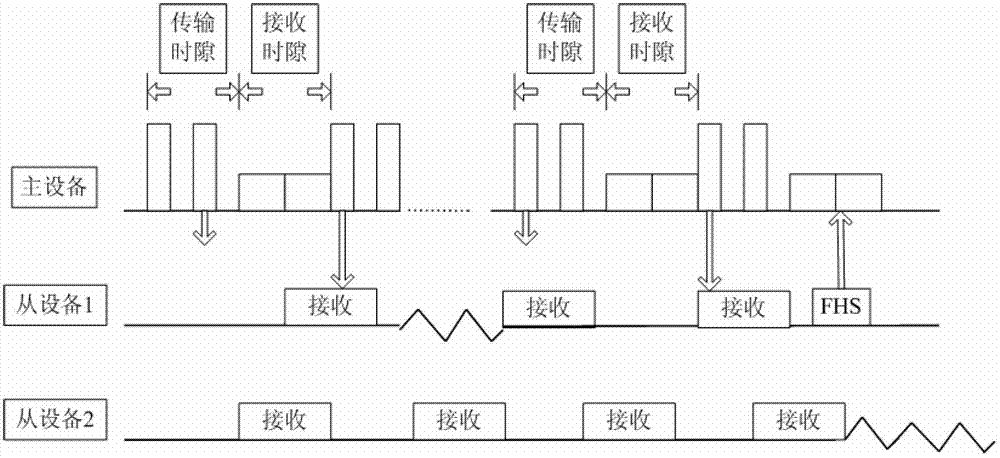

Discovery process time delay optimization method of bluetooth device

Owner:NANJING UNIV OF POSTS & TELECOMM

Preparation method of electrostatic spinning lithium ion battery negative electrode plate

InactiveCN108735976AIncrease transfer rateLower internal resistanceElectrode manufacturing processesSecondary cellsWater basedElectrical battery

The invention discloses a preparation method of an electrostatic spinning lithium ion battery negative electrode plate. The preparation method comprises the following steps of dissolving polyoxometallate salt into deionized water to form a polyoxometallate solution; adding graphite into the polyoxometallate solution, and adding a surfactant sodium dodecyl benzene sulfonate and a water-based adhesive La13<x> to form a spinning solution; putting the spinning solution into an electrostatic spinning instrument for spinning, and performing spinning of the spinning solution on a copper foil, whereinwire strips are dense and are uniformly adhered to the copper foil; and then drying the copper foil adhered with the wire strips to obtain the battery negative electrode plate. Compared with a traditional stirring and coating process, the preparation method adopting the electrostatic spinning process has the advantages that the process time is shortened, and the production efficiency is improved.

Owner:DONGFANG ELECTRIC CORP

PLC-based feather and down separation system

InactiveCN104611789AReduce usageSimple and fast operationAnimal fibre deburring machinesFibre separationAutomatic controlSeparation system

Owner:ANHUI LION GOOSE PROD

Heat treatment method for engine valve

PendingCN113981199AImprove mechanical propertiesEasy to processFurnace typesHeat treatment furnacesThermodynamicsProcess engineering

Owner:HUAI JI DENG YUE VALVE CO LTD

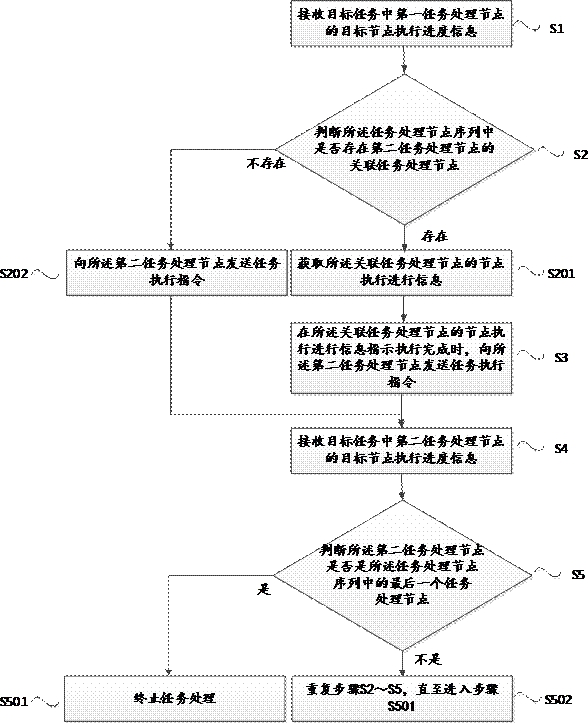

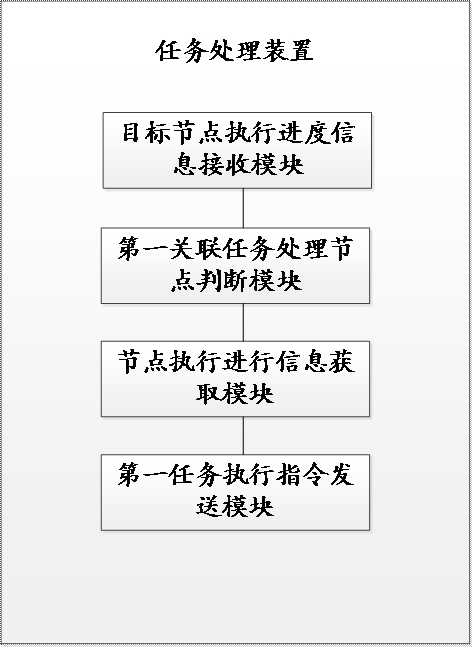

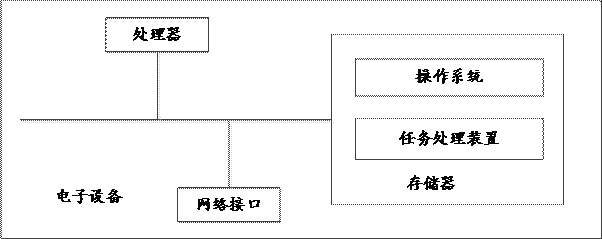

Task processing method and device, electronic equipment and readable storage medium

InactiveCN114020442AEasy to closeAvoid confusionProgram initiation/switchingComputer hardwareComputer architecture

Owner:连连宝(杭州)信息技术有限公司

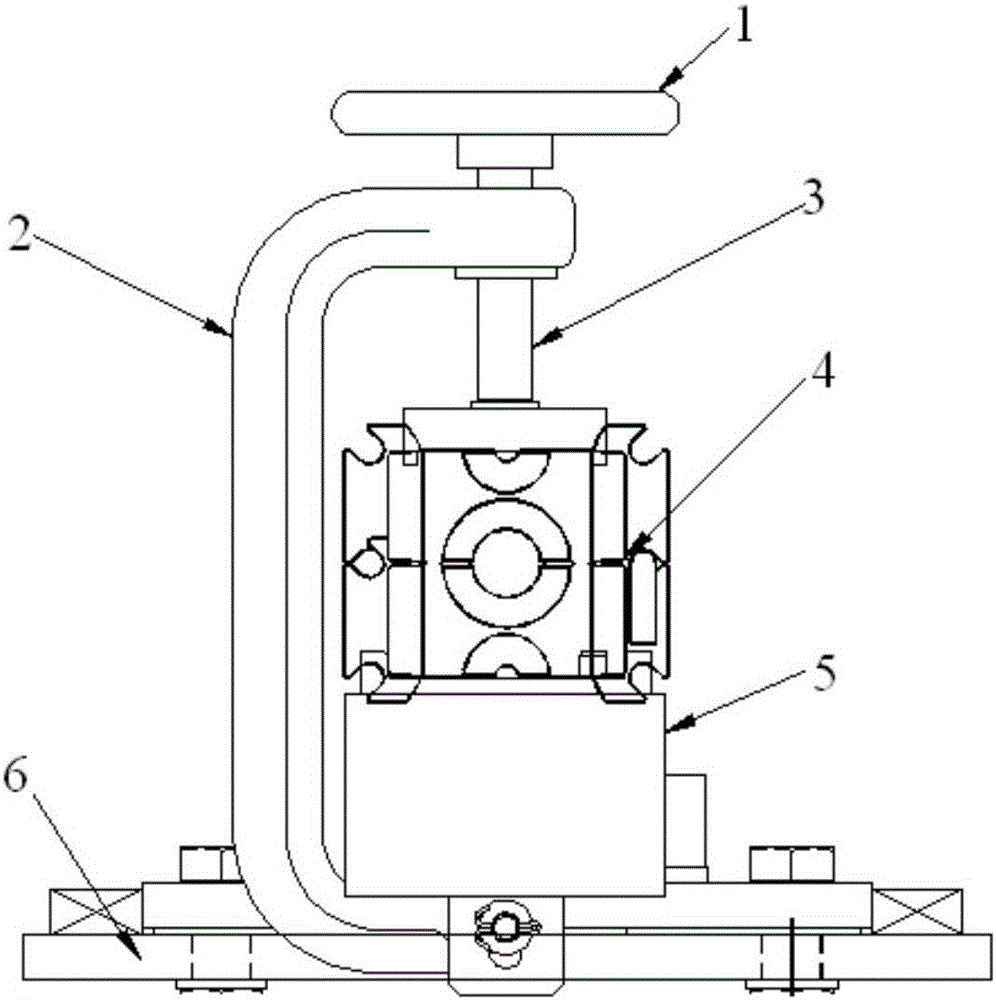

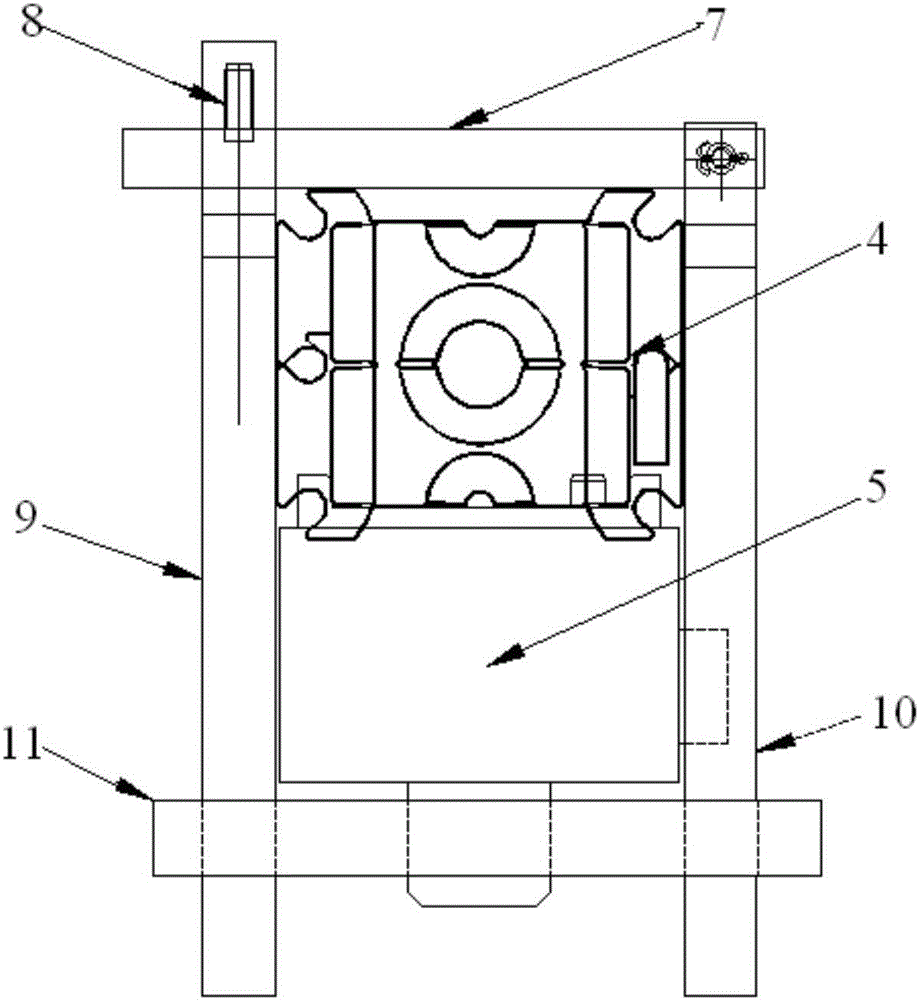

Fixing device for double-sided running groove of high-speed steel rolling production line

InactiveCN106180206APrevent looseningAvoid misalignmentRolling safety devicesMetal rolling arrangementsProduction lineManufacturing technology

Owner:WUHU XINXING DUCTILE IRON PIPES

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap