Functional rolling liquid of water-based nano Cu and preparation method of functional rolling liquid

A functional liquid and nanotechnology, applied in the field of lubricants, can solve the problems of affecting process treatment, poor surface quality, high fuel consumption, etc., and achieve the effects of reducing pollution, good surface quality, and simple use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

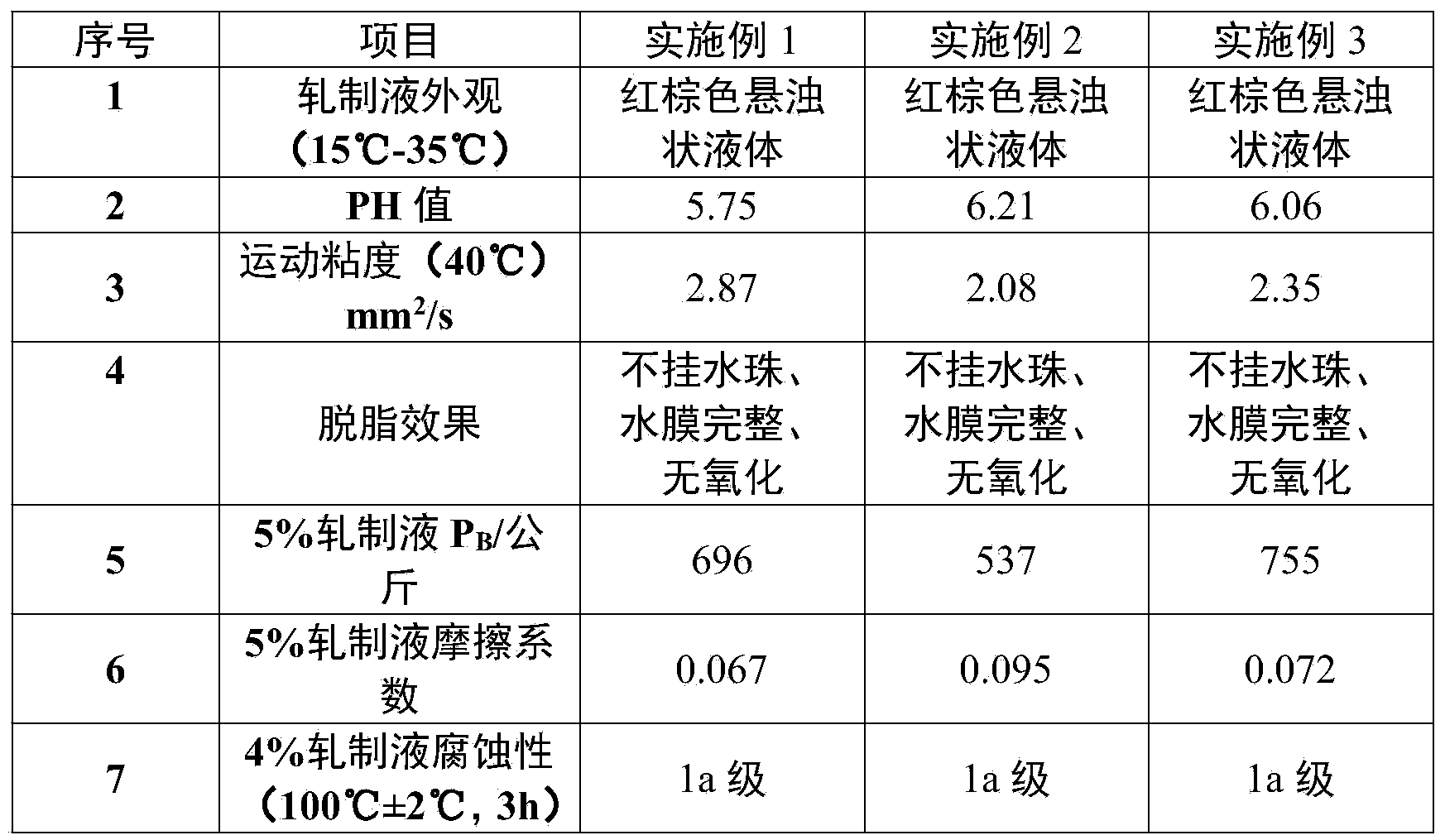

Embodiment 1

[0011] Embodiment 1 formula sees the following table:

[0012] serial number

[0013] According to the weight formula of each component in the above table, 72g deionized water, 2g sodium dodecylbenzenesulfonate, 3g toluene, 5g polyethylene glycol, 2g triethanolamine, 4g oleic acid, 10g aniline and 1g mercaptothiadiene Add azoles sequentially, put them in a reaction kettle with a rotating speed of 80-120 rpm for heating and stirring, when the temperature reaches 70-80°C, add 1g of nano-Cu, keep warm and continue stirring for 45-60 minutes, then stop heating and continue Stir to room temperature to obtain a reddish-brown turbid liquid, which is formulated into the required water-based rolling liquid. The rolling liquid of this formula is left at room temperature for about 240 hours to produce a small amount of precipitation, and the dispersion effect is better.

Embodiment 2

[0015] Embodiment 2 formula sees the following table:

[0016] serial number

[0017] According to the above formula, 74.8g deionized water, 12.0g sodium dodecylbenzenesulfonate, 2.0g toluene, 0.8g polyethylene glycol, 1.5g triethanolamine, 2.0g oleic acid, 2.6g aniline and 0.8g mercapto Add thiadiazole in sequence, put it in a reaction kettle with a rotation speed of 80-120 rpm for heating and stirring, when the temperature reaches 70-80°C, add 0.5g nano-Cu, keep warm and continue stirring for 30 minutes, then stop heating Continue stirring to room temperature to obtain a reddish-brown turbid liquid, which is then formulated into the required water-based rolling fluid. After standing for 96 hours, the formula rolling fluid clearly separated, and the nano-Cu completely precipitated after 7 days.

Embodiment 3

[0019] Embodiment 3 formula sees the following table:

[0020] serial number

component name

Weight (g)

1

Nano Cu (20-50nm)

1.0

2

toluene

3.0

3

Mercaptothiadiazole

2.0

4

Oleic acid

2.5

5

polyethylene glycol

1.5

6

Sodium dodecyl benzene sulfonate

9.0

7

aniline

1.0

8

Triethanolamine

2.0

9

Deionized water

78.0

[0021] According to the above formula, 78.0g deionized water, 9.0g sodium dodecylbenzenesulfonate, 3.0g toluene, 1.5g polyethylene glycol, 2g triethanolamine, 2.5g oleic acid, 1.0g aniline and 2.0g mercaptothiol Add oxadiazoles in turn, put them in a reaction kettle with a rotation speed of 80-120 rpm for heating and stirring, when the temperature reaches 70-80°C, add 1.0g of nano-Cu, keep warm and continue stirring for 30 minutes, then stop heating and continue Stir to room temperature to obtain a reddish-brown turb

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap