Electrochemical stripping solution formula for vacuum ion plating

A technology of deplating solution and ions, which is applied in the field of vacuum ion plating electrochemical deplating solution formula, and can solve problems such as stability defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

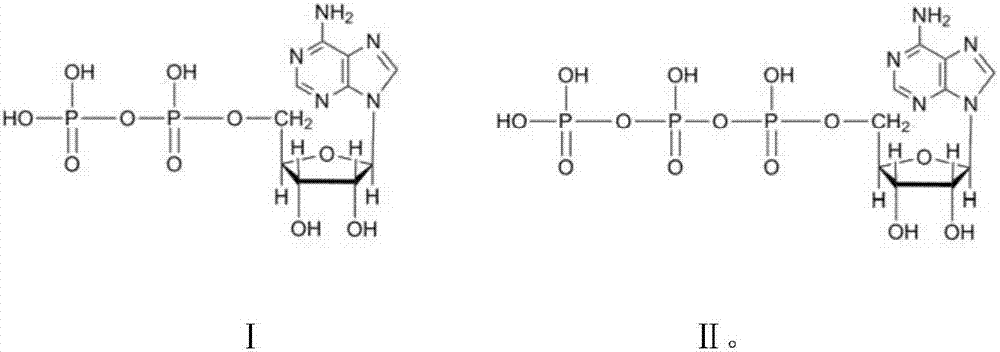

[0014] The vacuum ion plating electrochemical deplating solution formula is 1% adenosine diphosphate, 5% hydrochloric acid, 0.1% sodium silicate, 0.1% EDTA, 2% sodium chloride, 0.1% urotropine, 0.1% triethanolamine, the rest is water.

[0015] When using this formula for stripping, the surface coating of unqualified products will be removed in 30 seconds, and the samples after stripping the surface coating are analyzed by X-ray diffraction, and no coating elements are found, which proves that the film layer is completely stripped; Scanning electron microscope (SEM) tests were performed on the samples after surface coating, and it was found that the substrates were not corroded.

Embodiment 2

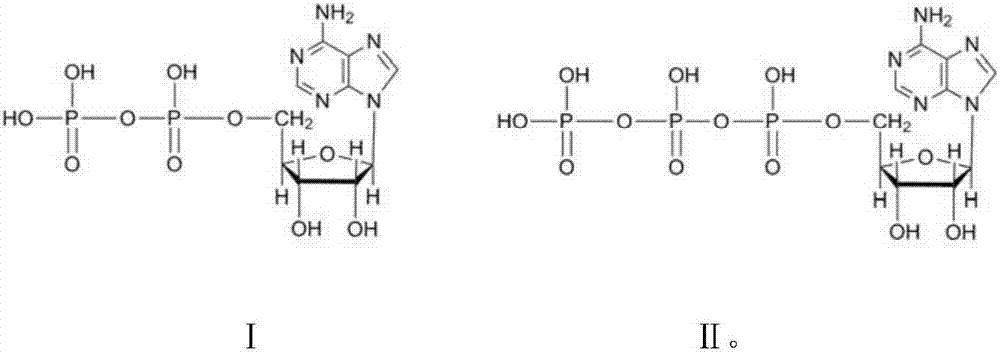

[0019] The vacuum ion plating electrochemical deplating solution formula is 5% adenosine triphosphate, 15% sulfuric acid, 1% sodium silicate, 5% EDTA, 20% sodium acetate, 3% urotropine, 1 % of triethanolamine, the rest is ethanol.

[0020] When using this formula for stripping, the surface coating of unqualified products will be removed in 30 seconds, and the samples after stripping the surface coating are analyzed by X-ray diffraction, and no coating elements are found, which proves that the film layer is completely stripped; Scanning electron microscope (SEM) tests were performed on the samples after surface coating, and it was found that the substrates were not corroded.

Embodiment 3

[0022] The vacuum ion plating electrochemical deplating solution formula is 2.5% adenosine diphosphate, 10% nitric acid, 0.5% sodium silicate, 3% EDTA, 10% sodium nitrate, 1.5% urotropine, 0.5 % of triethanolamine, and the rest is a mixed solvent of ethanol and water.

[0023] When using this formula for stripping, the surface coating of unqualified products will be removed in 30 seconds, and the samples after stripping the surface coating are analyzed by X-ray diffraction, and no coating elements are found, which proves that the film layer is completely stripped; Scanning electron microscope (SEM) tests were performed on the samples after surface coating, and it was found that the substrates were not corroded.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap