Drywall Knife And Multi-Tool Assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

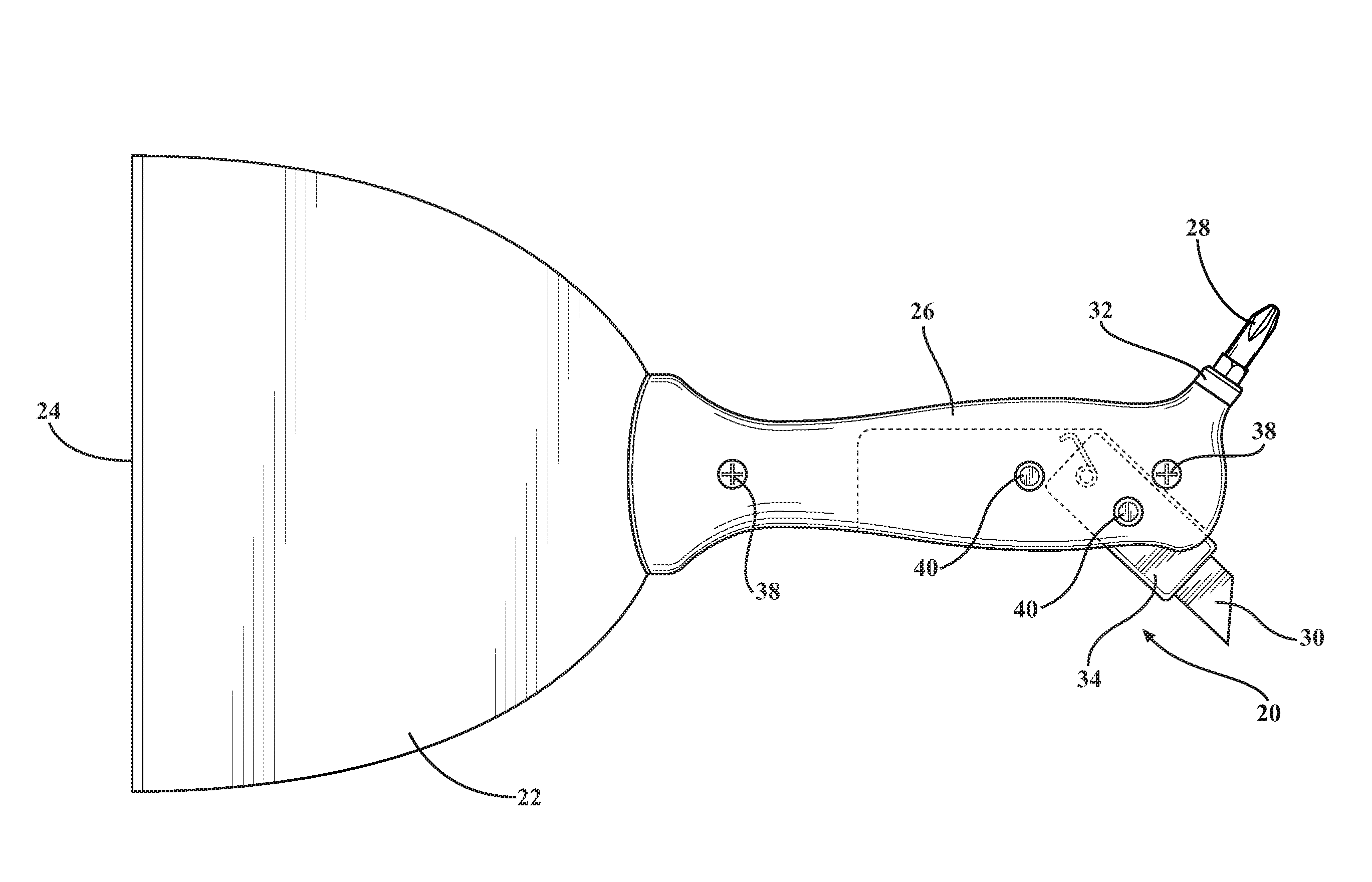

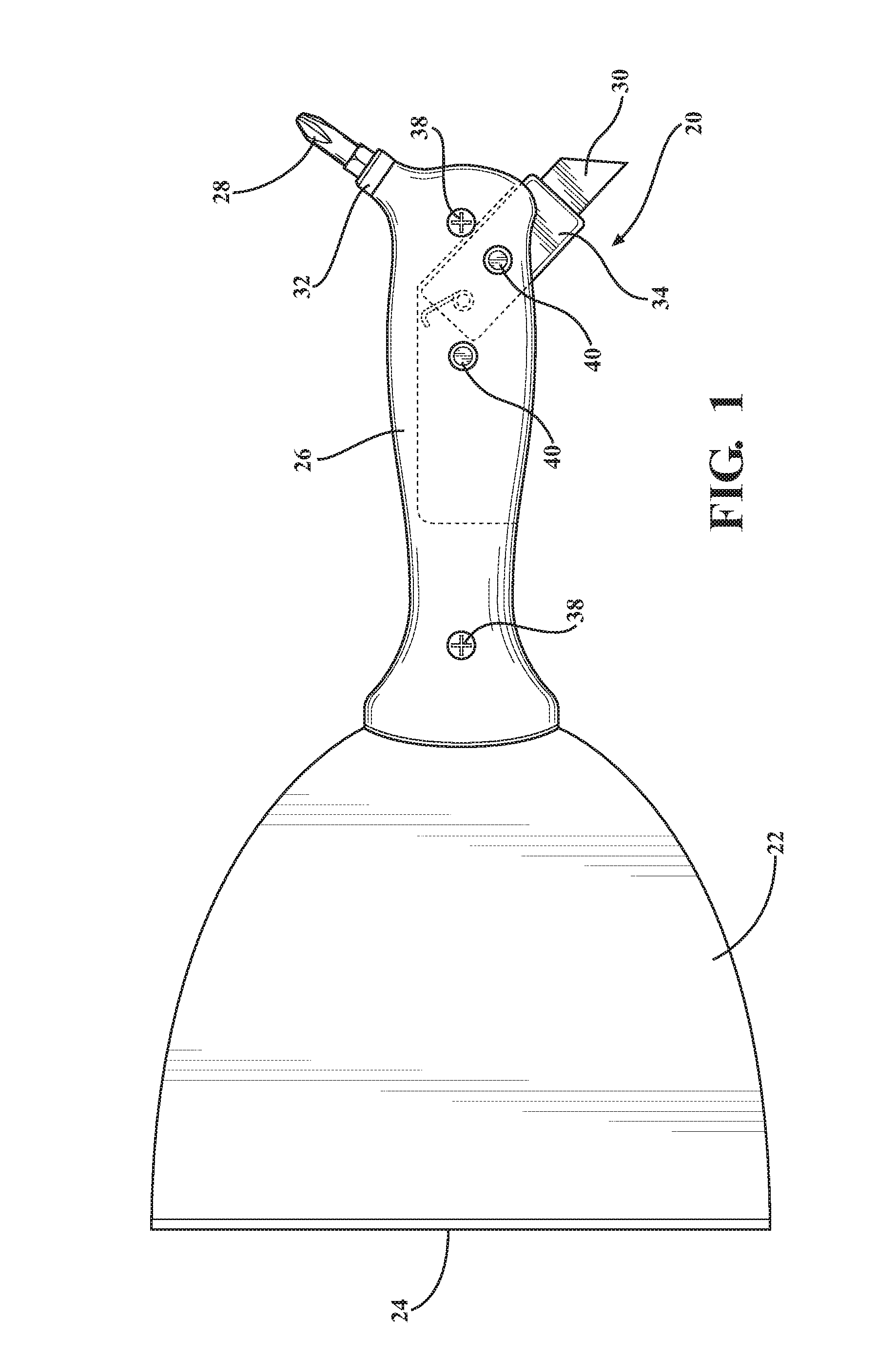

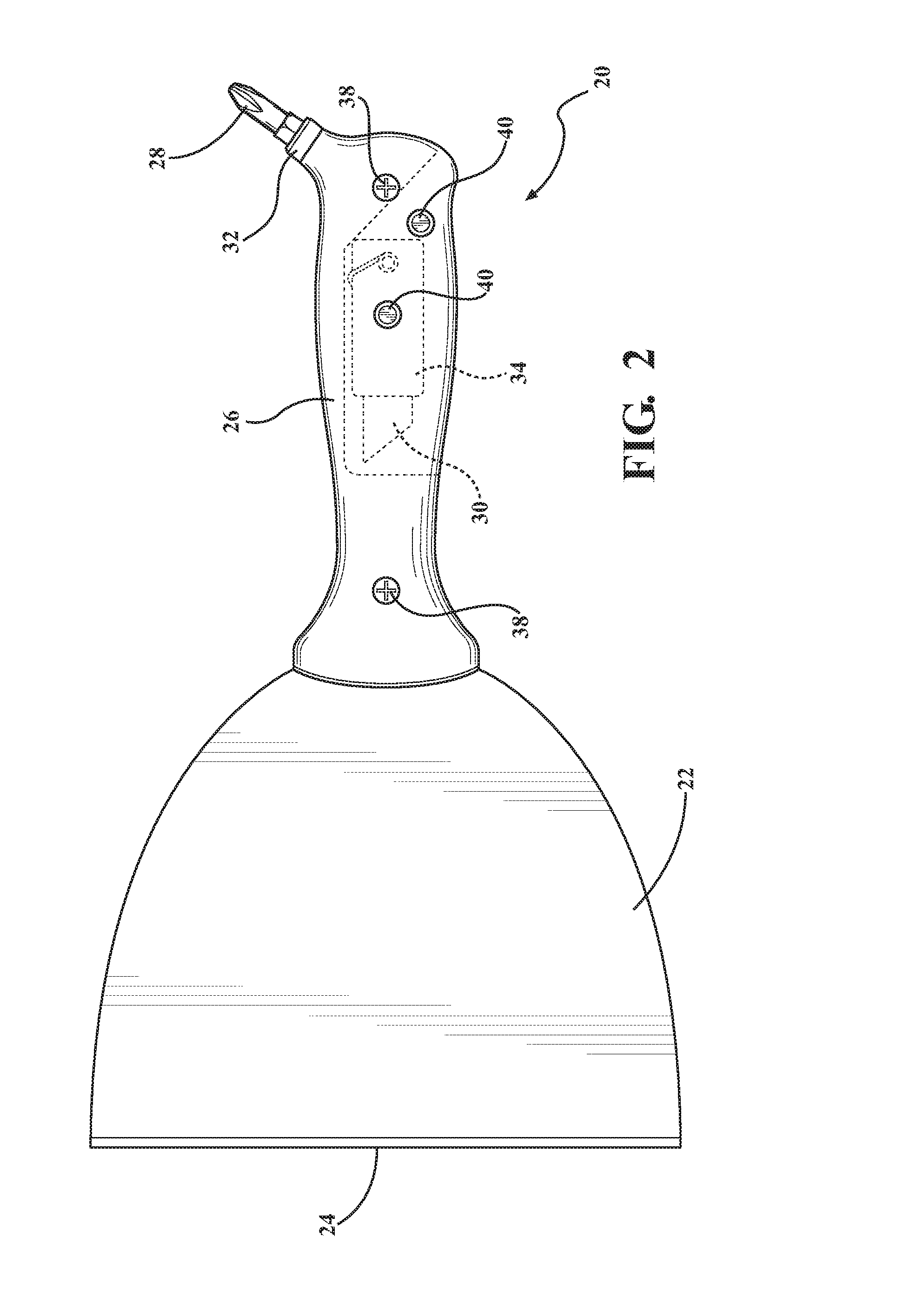

[0029]Referring to FIG. 1, wherein like numerals indicate corresponding parts throughout the several views, an exemplary embodiment of an improved drywall working multi-tool assembly 20 is generally shown in FIG. 1. As shown, the exemplary drywall working multi-tool assembly 20 includes a generally planar putty blade 22 with a flat edge 24 and a handle 26 which is joined with the putty blade 22 opposite of the flat edge 24. The putty blade 22 is preferably made of metal (such as, for example, stainless steel) or a hard plastic, and the flat edge 24 is adapted for evenly spreading a drywall joint compound onto a joint between adjacent drywall panels. The handle 26 extends from the putty blade 22 to a distal end. The handle 26 may be made of any suitable material including, for example, rubber, nylon, plastic or metal.

[0030]At the distal end of the handle 26, the exemplary drywall knife assembly 20 includes a Phillips head screwdriver bit 28 and a utility knife blade 30. As such, the mul

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap