Quaternary ammonium salt concrete anti-mud agent, and preparation method and application thereof

A technology for concrete and quaternary ammonium salt, applied in the field of concrete, can solve the problems of complex production process, decreased concrete strength and high risk, and achieves the effects of stable application performance, simple production process and good adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

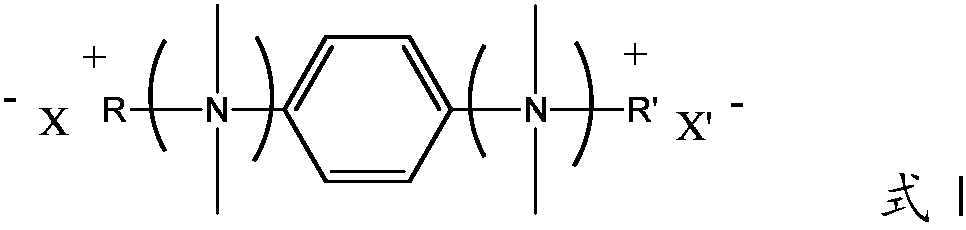

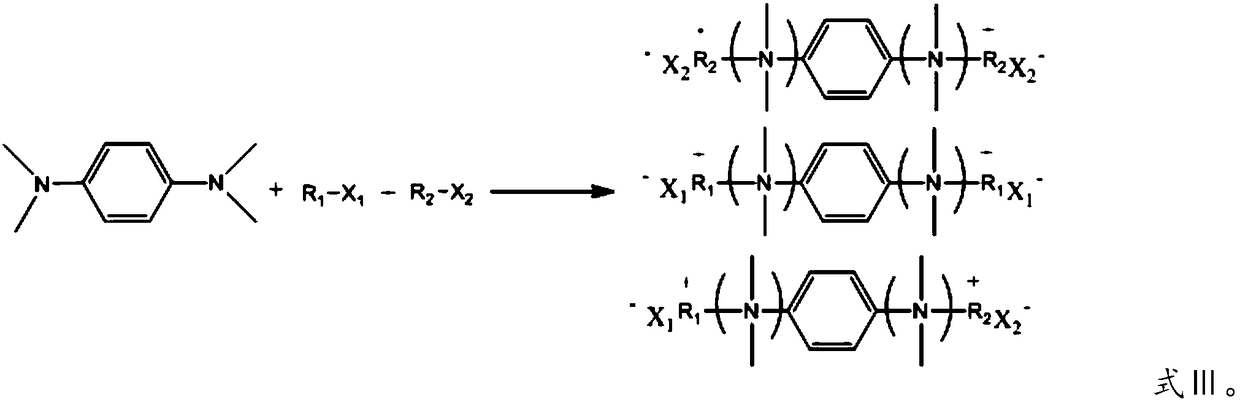

Method used

Image

Examples

Embodiment 1

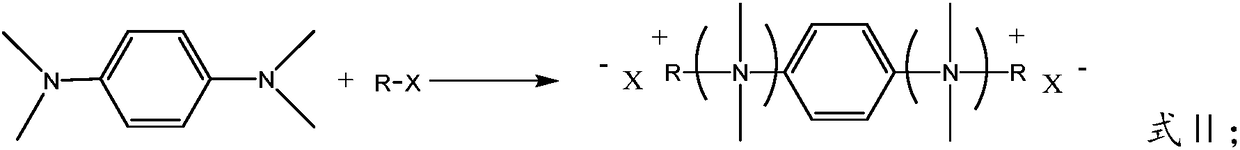

[0032] The preparation process of the present embodiment quaternary ammonium salt concrete anti-mud agent is as follows:

[0033] Under an inert gas nitrogen atmosphere, 1 part of substance N, N, N, N-tetramethyl-p-diphenylamine and 2 parts of substance halogenated hydrocarbon 1-bromopentane were dissolved in acetonitrile, an inert organic solvent, so that N, Keep the mass concentration of N, N, N-tetramethyl-p-diphenylamine and 1-chloropentane at 40%, control the temperature at about 50°C, condense and reflux for 3 hours, then distill off the solvent acetonitrile under reduced pressure, add deionized water to dissolve Make its solid content 40%, to obtain the concrete anti-mud agent A1. The chemical reaction process is as follows:

[0034]

Embodiment 2

[0036] Under an inert gas nitrogen atmosphere, dissolve 1 part of substance N, N, N, N-tetramethyl-p-diphenylamine and 2 parts of substance halogenated hydrocarbon 2-chloroethanol in acetonitrile, an inert organic solvent, to make N, N , N, N-tetramethyl-p-diphenylamine and 1-chloropentane mass concentration were kept at 40%, the temperature was controlled at about 40°C, condensed and refluxed for 3h, and the solvent acetonitrile was removed by distillation under reduced pressure, and deionized water was added to dissolve the Its solid content is 40%, and concrete anti-mud agent A2 is obtained. The chemical reaction process is as follows:

[0037]

Embodiment 3

[0039] Under an inert gas nitrogen atmosphere, 1 part of the substance N, N, N, N-tetramethyl-p-diphenylamine and 2 parts of the substance halogenated hydrocarbon methyl iodide and dissolved in the inert organic solvent ethanol, so that N, N, The mass concentration of N, N-tetramethyl-p-diphenylamine and 1-chloropentane is maintained at 40%, the temperature is controlled at about 30°C, condensed and refluxed for 5h, and the solvent ethanol is removed by distillation under reduced pressure, and deionized water is added to dissolve it. The solid content is 40%, and the concrete anti-mud agent A3 is obtained. The chemical reaction process is as follows:

[0040]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap