Full-automatic equipment and method for testing helium diffusion coefficient of reactor material

A diffusion coefficient and reactor technology, applied in the direction of analyzing materials, measuring devices, surface/boundary effects, etc., can solve the problems of high requirements, short test time, high precision, and achieve the effect of high speed, wide test range and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

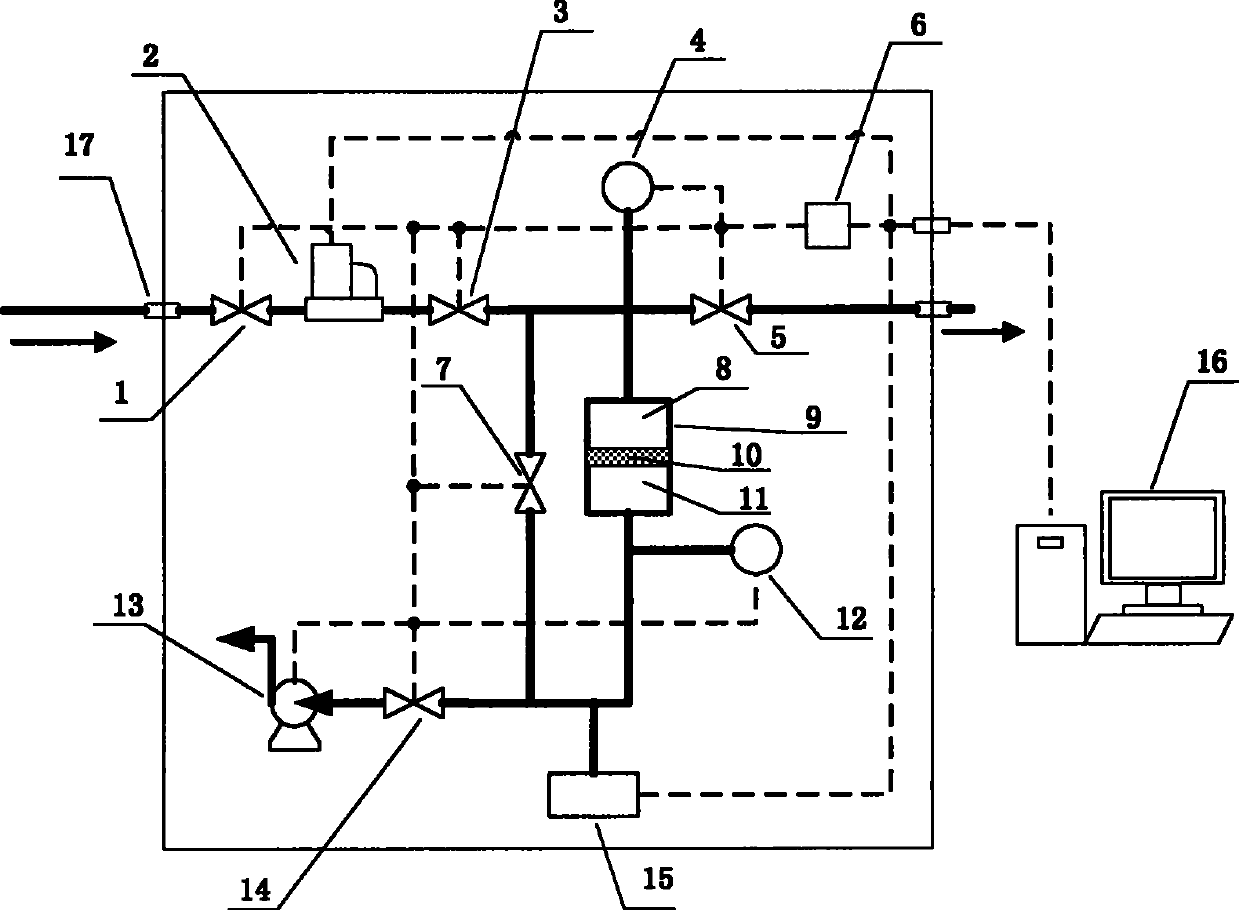

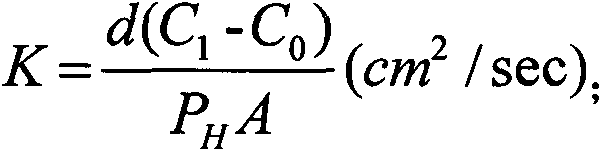

Embodiment 1

[0035] This embodiment provides a fully automatic device for measuring the helium diffusion coefficient of reactor materials, the device includes a gas source control valve 1, a mass flow controller 2, a flow control valve 3, a low vacuum side vacuum gauge 4, a gas release control Valve 5, data acquisition card 6, test cell control valve 7, sample test cell 9, sample to be tested 10, high vacuum side vacuum gauge 12, vacuum pump 13, vacuum pump control valve 14, helium leak detector 15, computer 16, helium Gas source 17, relay (not marked in the figure) and pipeline etc.

[0036] The helium gas source 17 is connected to the inlet of the mass flow controller 2 through a pipeline, and the gas source supply is controlled by the gas source control valve 1 .

[0037] The low vacuum side 8 of the sample test cell is connected to the outlet of the mass flow controller 2, the vacuum gauge 4 on the low vacuum side and the deflation control valve 5, and the outlet of the mass flow controll

Embodiment 2

[0054] The test device and test method of the present embodiment are the same as those in Example 1, except that the helium gas detector is selected as a mass spectrometer, and the selected area of the sample to be tested is 5 cm 2 , A graphite matrix sample with a thickness of 0.3 cm.

[0055] In this example, the graphite matrix sample is tested, and finally the diffusion coefficient is 9.96×10 -3 cm 2 / sec.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Area | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap