Apparatus for depositing a low work function material

a technology of low work function and apparatus, which is applied in the direction of vacuum evaporation coating, electric heating, coating, etc., can solve the problem that the activation procedure cannot be used for micro-meter-scale protrusions, and achieve the effect of low work function materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

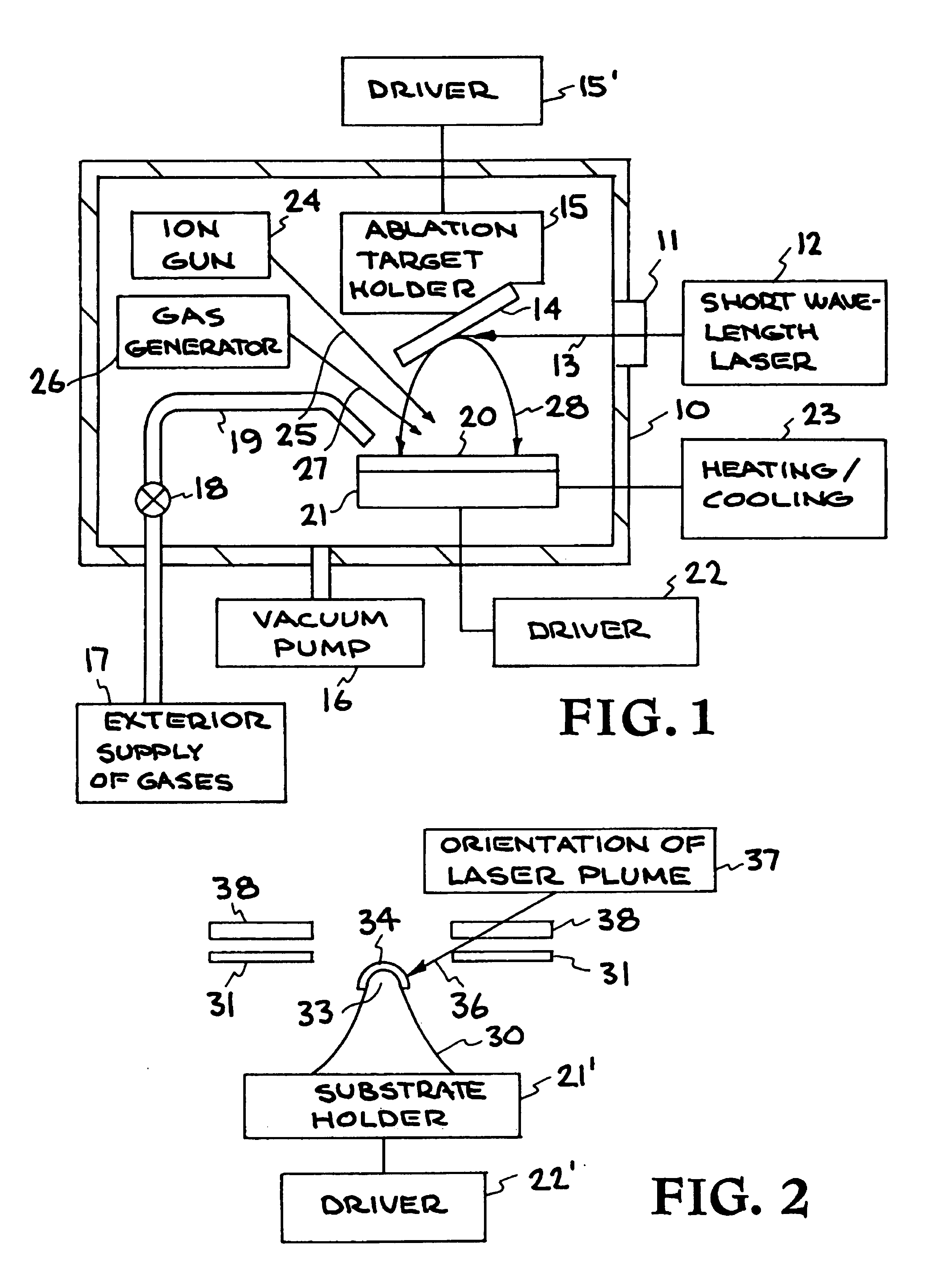

[0018]The present invention is directed to depositing low work function material on a surface by laser ablation using short-wavelength photons. The short-wavelength photons are at or below visible wavelength and thus are in the range of 200 to 550 nm. The elemental composition of the deposited low work function layer can be controlled by the composition of the laser ablated target and the gaseous environment in which the ablation process is performed. The invention is particularly applicable for use in fabricating devices using electron emission from sharp tips, such as in tunneling microscopy and flat panel display technology, wherein it is important that the tips: (1) have low work functions, (2) are smooth on a nanometer scale, and (3) are stable in varying gaseous environments and under high electric field conditions. Tests have established that each of these three (3) properties has been achieved by the process and apparatus of the present invention. Since laser ablation can be pe

PUM

| Property | Measurement | Unit |

|---|---|---|

| Time | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap