Leak-proof protection system

A protection system and anti-leakage technology, applied in the direction of polycrystalline material growth, crystal growth, single crystal growth, etc., can solve the problem of poor sealing of polycrystalline ingot furnace body, and achieve the effect of ensuring production quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The technical solution of the present invention will be described in detail below with reference to the accompanying drawings.

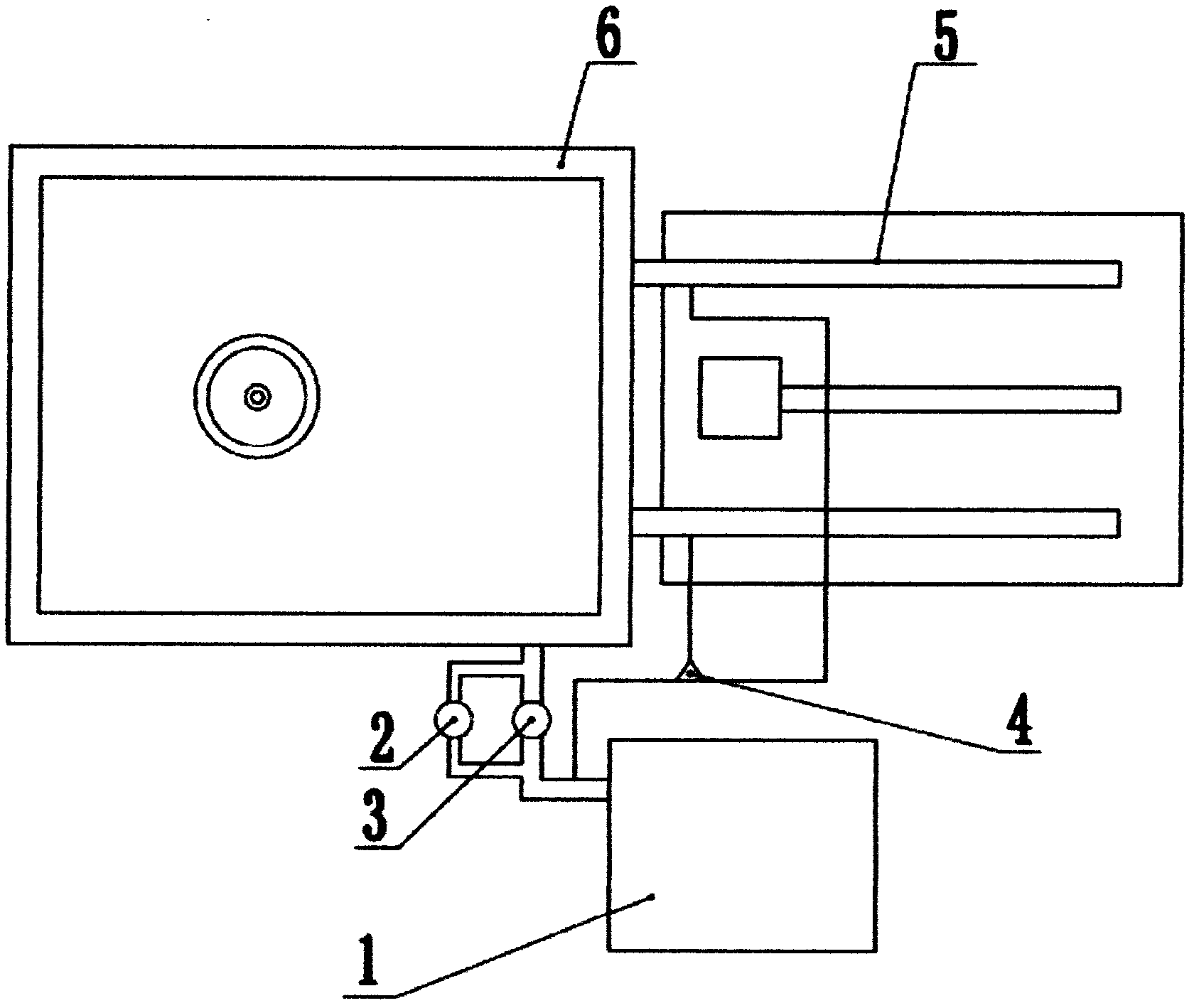

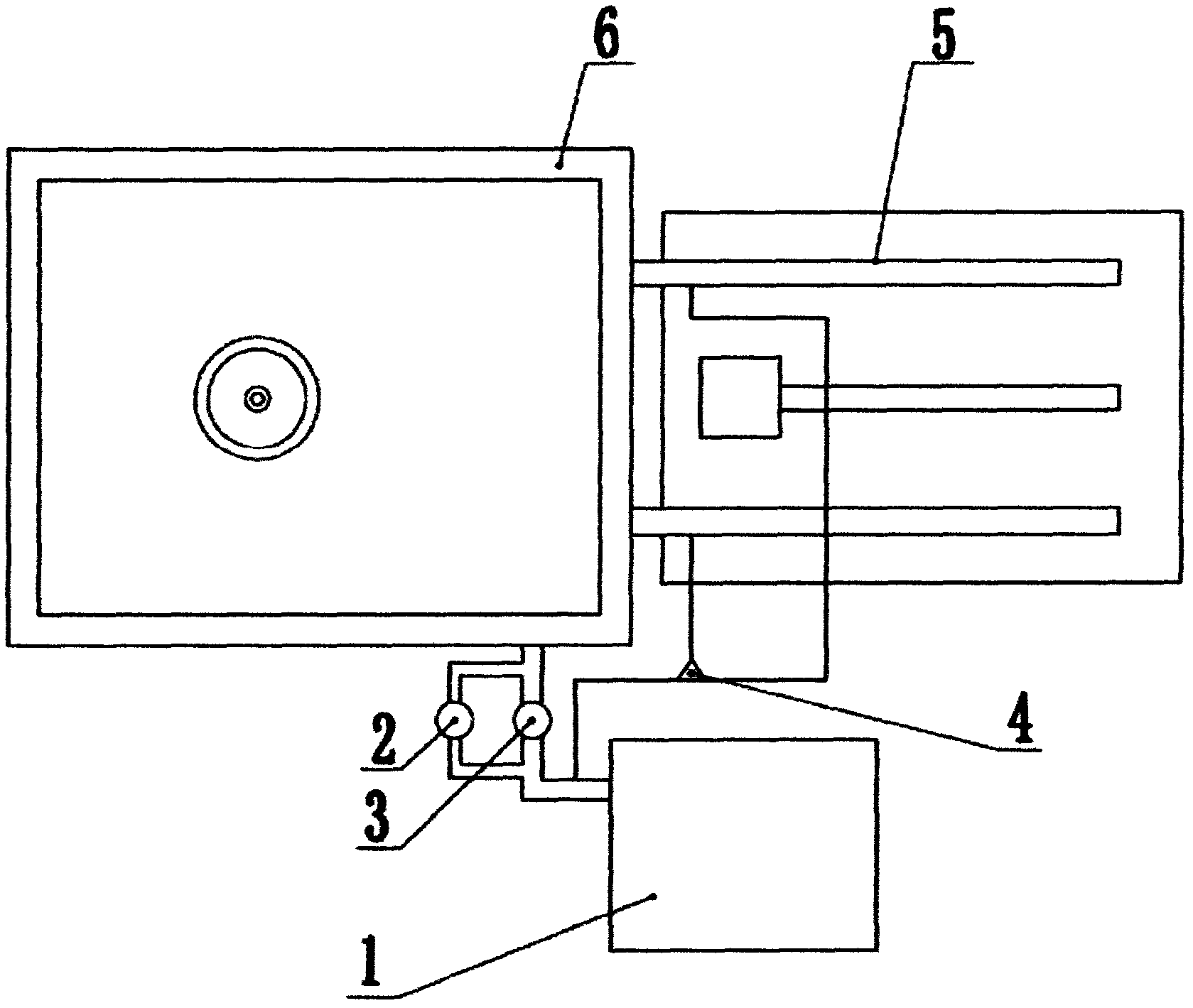

[0009] Such as figure 1 As shown, the anti-leakage protection system includes a vacuum pump 1. The vacuum pump 1 is connected to a polycrystalline furnace 6 through a bypass valve 2 and a pump main valve 3 respectively. One end of the pipeline branch 4 is connected to the vacuum pump 1, and the other end of the pipeline branch 4 They are connected to two sliding screws 5 respectively. The polycrystalline furnace 6 is also equipped with an insulating door panel, and a sealing ring is arranged between the insulating door panel and the sliding screw 5 to prevent air from entering the furnace body from between the insulating door panel and the sliding screw 5.

[0010] During the operation of the polycrystalline furnace 6, the vacuum pump 1 is in a normally open state, and the excess gas in the polycrystalline furnace 6 is pumped away through the pump ma

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap