Pneumatic numerical control threading machine

A threading machine and thread technology, applied in the field of pneumatic CNC threading machines, can solve the problems of poor adaptability and flexibility, damage and burnout, low practicability, etc., and achieve high stability and adaptability, convenient and flexible use, and improved flexibility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment

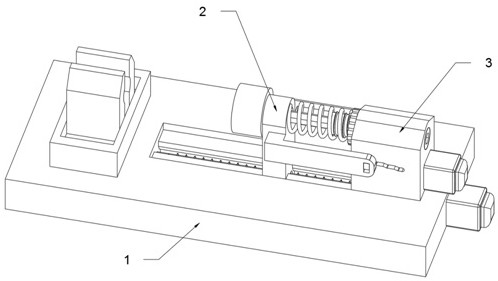

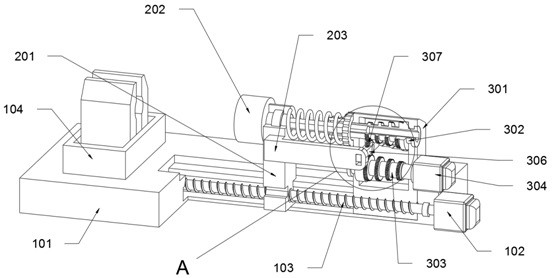

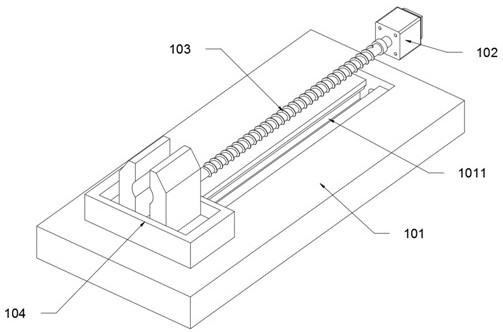

[0038] Example: Please refer to Figure 1 to Figure 9 :

[0039] The present invention proposes a pneumatic numerical control threading machine, including: a base assembly 1, the base assembly 1 includes a mounting base 101, a feed motor 102, a feed control rod 103 and a pneumatic clamp 104, and the pneumatic clamp 104 is fixedly installed on the mounting base 101 The side of the top, and the feed motor 102 is fixedly installed on the side of the installation base 101, the feed control rod 103 is rotatably connected to the inside of the installation base 101, and the feed control rod 103 is connected to the feed motor 102 in transmission; the processing assembly 2, The processing assembly 2 includes a support base 201, a threaded cutter head 202 and an adaptive control rod 203. The support base 201 is inserted into the inside of the installation base 101, and the threaded cutter head 202 is rotatably connected to the inside of the support base 201, and the adaptive control rod 20

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap