Wheel type conversion feeding and discharging device and numerically-controlled machine tool

A CNC machine tool and wheeled technology, applied in metal processing and other directions, can solve the problems of high labor cost, glass panel preventing position error, unfavorable flexible production, etc., so as to improve the efficiency of loading and unloading, save loading and unloading time, and save labor. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

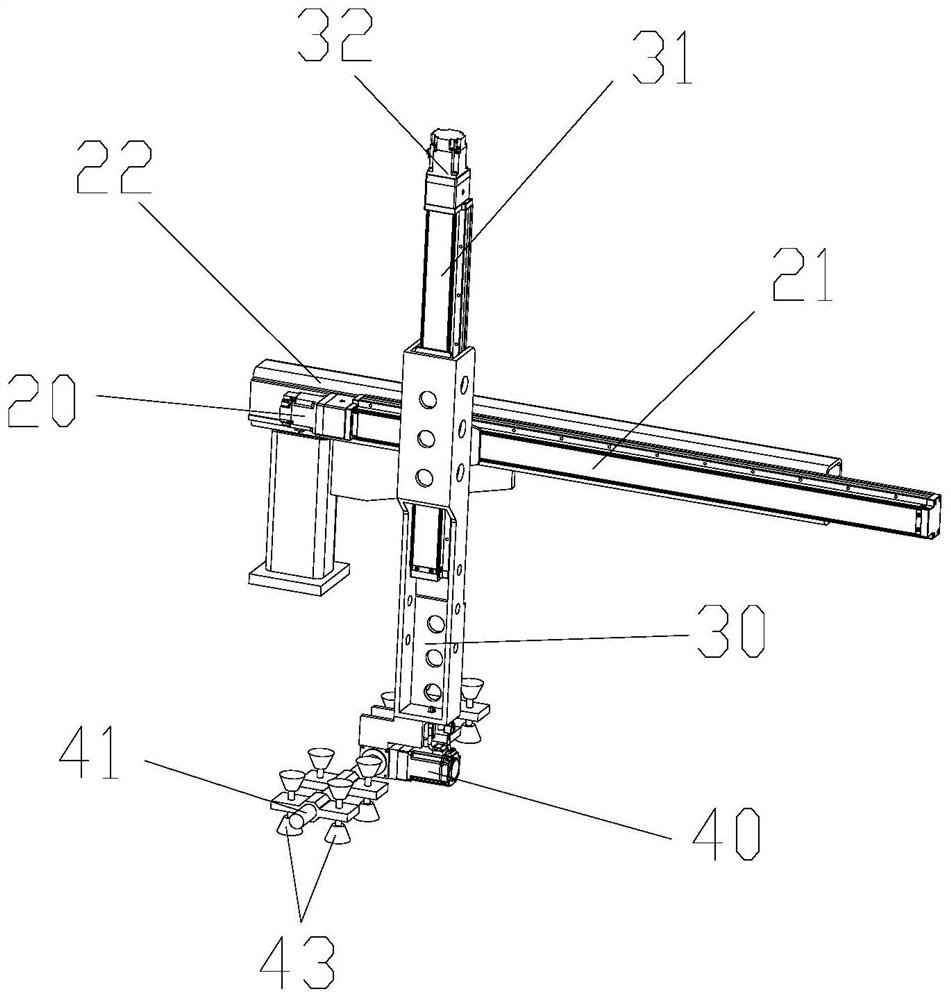

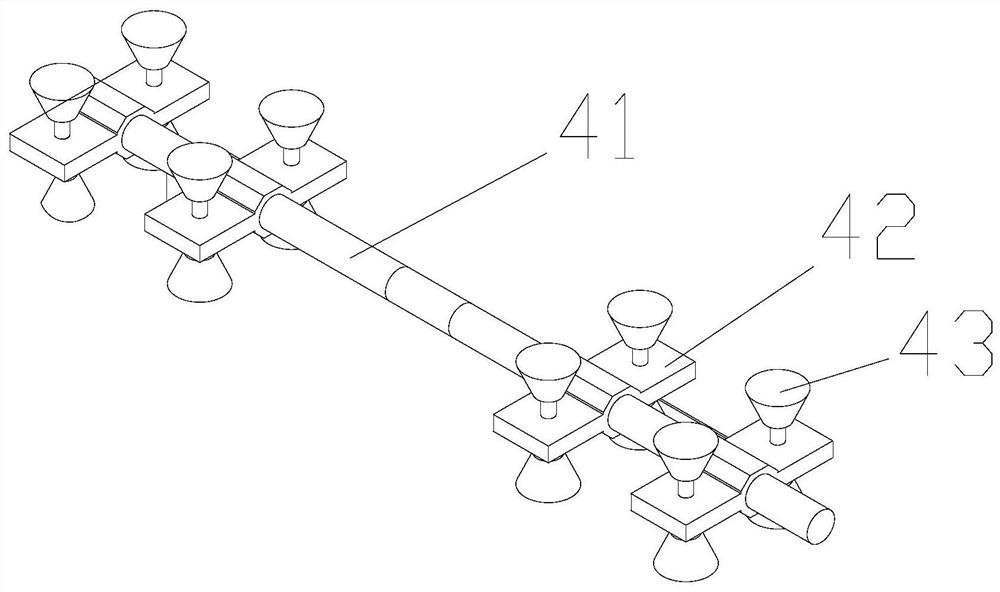

[0038] refer to Figure 1-3 , a wheel-type conversion loading and unloading device, including a crossbeam 12, a reclaiming device, the reclaiming device includes a first moving assembly, a second moving assembly, and a rotating mechanism; the first moving assembly is fixed on the crossbeam 12, and the second moving machine assembly Connected with the first moving assembly, the first moving assembly can be used to drive the second moving assembly to move horizontally; the second moving assembly is connected to the rotating mechanism, and the second moving assembly can drive the rotating mechanism to move vertically; the rotating mechanism includes a rotating Rod 41, material retrieving part 43, retrieving part 43 is fixed on the rotating rod 41, and rotating rod 41 can rotate relative to the second moving assembly; Rotating rod 41 comprises at least two retrieving surfaces, and retrieving part 43 is positioned at the retrieving surface , the pick-up member 43 can be used to pick a

Embodiment 2

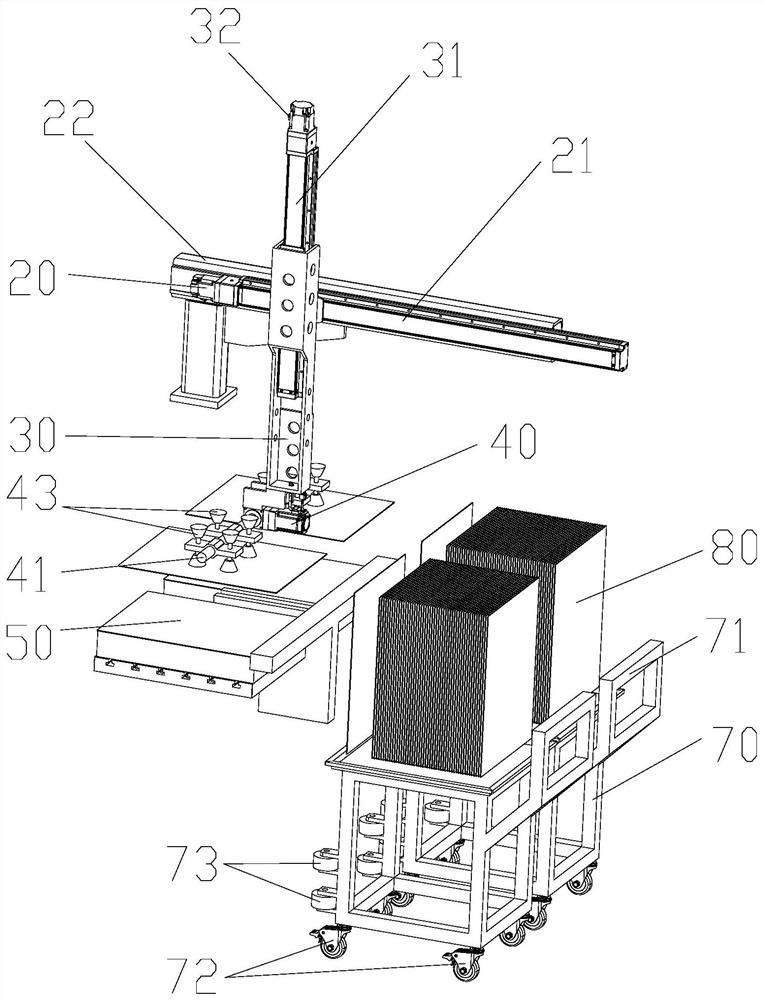

[0044] refer to Figure 1-9 , a kind of numerically controlled machine tool, comprises the wheel type conversion loading and unloading device in embodiment 1, also comprises workbench, processing device, crossbeam 12 is fixed on the workbench, and crossbeam 12 divides workbench into front workbench 10 and rear workbench 11. The wheel-type conversion loading and unloading device is located on one side of the rear workbench 11; the processing device is fixed on the beam 12, and the processing device is located on one side of the front workbench 10, and the processing device is used for processing the material 80.

[0045] Specifically, the workbench is a square structure, the beam 12 spans the workbench, the processing device includes a processing base 50, and the processing base 50 is movably arranged on the workbench through the third moving assembly, and the processing base 50 is used for positioning And fixed material 80. In a specific embodiment, the third moving assembly inc

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap