Tail ash recovering device for bag-type dust remover

A technology of bag dust collector and recovery device, which is applied in the direction of chemical instruments and methods, separation of dispersed particles, filtration of dispersed particles, etc., can solve problems such as insensitivity of action, reduction of dust removal effect, and insufficient consideration of details, etc., to achieve structure and work The principle is simple, the effect of adjusting the working running time and flexible working running time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

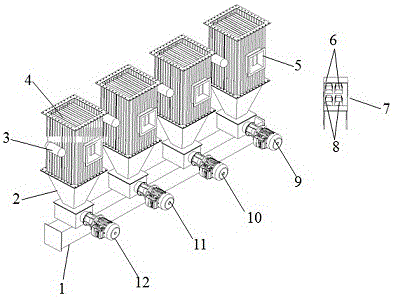

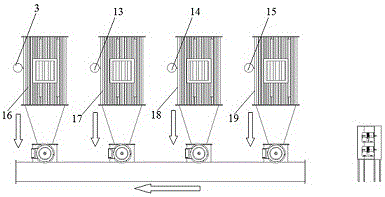

[0017] Compare below Figure 1 to Figure 2 To explain, due to the harsh working environment, the installation positions of the upper box 1 16, 2 17, 3 18, and 4 19 are relatively high. Before the device starts working, it is necessary to check the connection of each component, and at the same time ensure that the components are reliably connected. If necessary, observe whether the dust bag 4 is damaged or whether the thickness of the adhered dust exceeds the limit thickness, and then test run to check whether the pneumatic sequence of each part meets the design requirements, and the device has completed the preparatory work.

[0018] When the device is working, the gas with dust enters the upper box 16, the upper box 2 17, the upper box 3 18, and the upper box 4 19 from the ash-containing gas inlet 5, and the dust adheres when passing through the dust removal bag 4 On the dust-removing bag 4, dust continues to accumulate, and the dust-removing ability of the dust-removing bag 4 i

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap