Static-pressure labyrinth gear box of planet ball mill

A planetary ball mill and labyrinth technology, applied in the direction of belts/chains/gears, mechanical equipment, engine components, etc., can solve the problems of shortening the service life of the whole machine, increasing maintenance costs, and inaccurate processing errors, so as to reduce consumption, The effect of simple structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings.

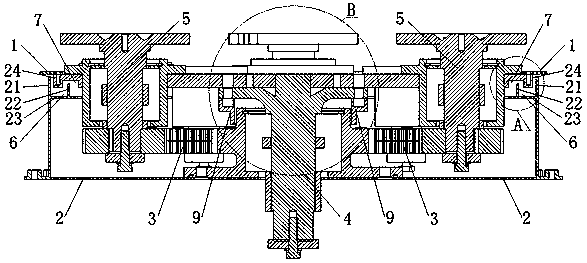

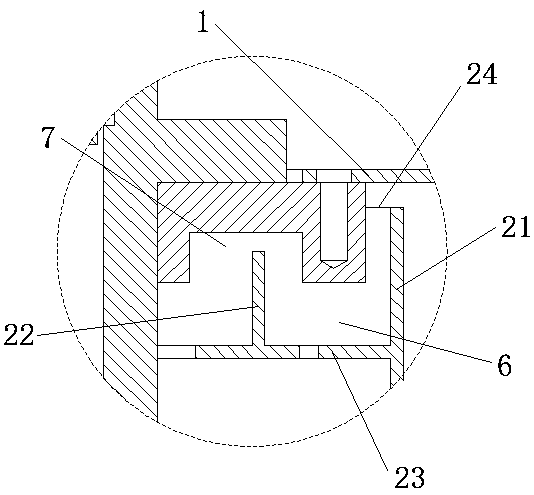

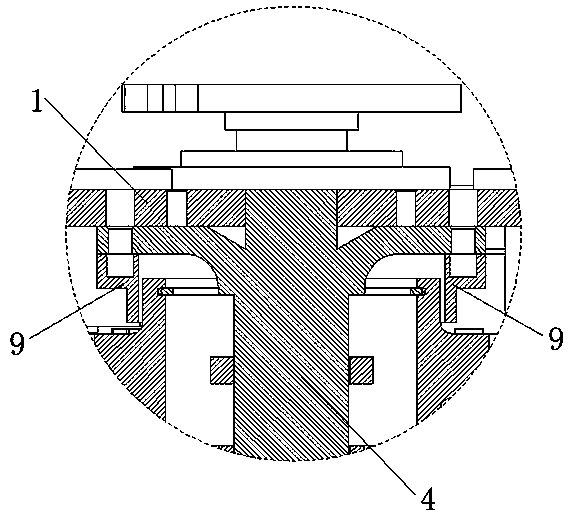

[0025] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, a planetary ball mill hydrostatic labyrinth gearbox includes an oil box cover 1, an oil box 2, a transmission gear 3, a main transmission shaft 4 and a mill shaft 5, and the main transmission shaft 4 passes through the oil box. At the center of the box 2, the grinding jar shaft 5 passes through the oil box cover 1 and is located around the main transmission shaft 4, and the main transmission shaft 4 and the grinding jar shaft 5 pass through the transmission gear 3 transmission connection, the oil box cover 1 is connected with the bearing seat of the main drive shaft 3 through screws, the side wall of the oil box 2 extends vertically upwards to form a first baffle 21, and the sid

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap